Press release

The Future of Operation & Maintenance

Media hype has led us to believe that technology would soon revolutionize maintenance. Dreams of flying robots, video game-like smart glasses, flashing digital twins, often hold the sad promise of getting rid of maintenance people altogether. The reality remains that the more automated, the more sophisticated the systems, the more demands are put on maintenance people and their skills. The problem is compounded when this glorious technology did not address actual needs.Predictive maintenance is often said to be the low hanging fruit of Industry 4.0. Yet to maintenance practitioners it is nothing new. Technology has improved, but the implementation challenges we met in the 1990s still exist today: a maintenance strategy that utilized predictive maintenance must be defined, relevant measurement points and corresponding actions established, people trained.

The idea to use 3D BIM models in operation has also emerged. We have all seen movies showing a technician using a tablet to view "behind the walls", almost knocking his head on the pipes, breaking half a dozen safety rules in the process of demonstrating this unnecessary usage of BIM. Luckily, this seldom passes the Proof-of-Concept stage. The company could not afford all the broken iPads.

The Covid-19 pandemic has seen many large companies slashing their innovation budgets, while paying lip service to the transformative nature of innovation in times of crisis. Yet, it has also accelerated certain trends. The use of smart glasses for remote support is perhaps the most striking example, paralleling the growth of video conferencing apps. In fact, this usage of "smart" glasses is often nothing more than portable, head-mounted, video conferencing…

Once at a conference, we were shown a fantastic 3D application combining all promises into one. Operators could navigate a hyper-realistic plant model, walk to the location of a meter, view the current meter value (capture from the SCADA), before walking to the next point. This was billed as a virtual meter-reading solution. Most people in the room were very impressed by this beautiful demo of how an otherwise perfectly functional engineer could waste his time walking around a 3D model (at approximately the same speed as in the real world) when a traditional SCADA could do a much better job, displaying in the control room all the meter values, or - here is the real improvement - only displaying abnormal readings on a simple plant or process layout. Whatever happened to common sense?

No amount of in-house and vendor-awarded innovation trophies can change the reality: this is not the future of Operation & Maintenance!

The main challenge of O&M is not its lack of efficiency, as technologists seem to believe. Instead, it is to address strategic needs, O&M risks, compliance. And doing so efficiently, of course. One of our strategic needs is also to enable workers with limited skills to deal with increasing sophisticated assets, in an increasingly complicated, regulated, risky world. Most of the tech touted by vendors and consultants ignores all that.

Standards such as ISO 55000 Asset Management, itself closely related to ISO 31000 Risk Management, offer a useful framework to address this need. I recommend its practical usage as guideline for the design and implementation of O&M technologies that make sense for your business. This naturally leads to redesigning most of the examples given above, as we have done at Siveco China with our clients all over Asia. As a result, the O&M technician takes the central place in the smart project. His role is promoted, his skills enhanced, his motivation increased.

- Real experience

Global automotive and industrial supplier Schaeffler has embedded Siveco China's Smart O&M technologies in its SmartLink condition monitoring solution, and vice-versa: SmartLink is also directly accessible from the bluebee® app "for the worker of tomorrow", enabling the engineers to drill down to specific measurements and vibration profile to support their analysis. All information can be seen in context: failure history, past diagnosis, next maintenance visit, trends for a better decision.

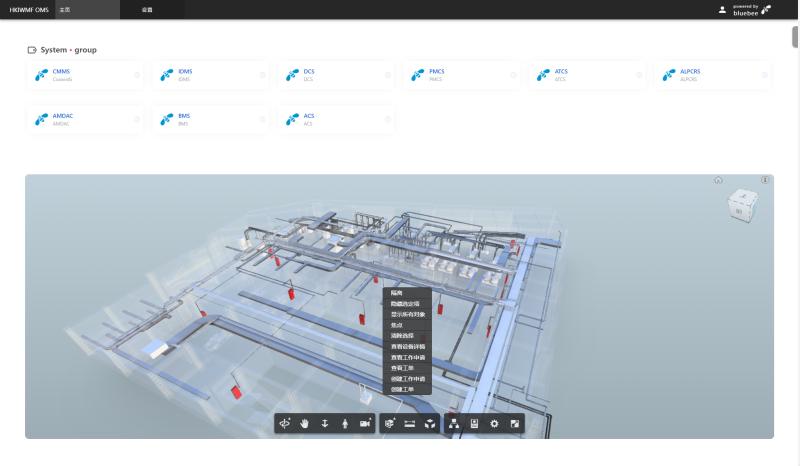

In the Sanwai Sewage Treatment Works project in Hong Kong, Siveco China ensured handover of technical data from construction to maintenance through the implementation of its BIM for Asset Management solution. Once the plant started operation, the O&M team uses the Siveco China suite for their daily work, which provides easy navigation into complex technical data, including when needed to the BIM model itself, for example to establish safety procedures or coordinate complex work with contractors. Altogether the system forms a true Lifecycle Digital Twin.

Hong Kong Airport Authority has taken the Smart Glass beyond glorified videoconferencing, to conduct the inspection of critical assets using the bluebee® mobile app plugin for smart glasses, with the objectives of providing a hands-free, convenient and safe wearable device for O&M technicians, while standardizing the technical inspection process. Technicians view step-by-step work instructions, interact with the app using voice commands and hand gestures, record their work as required.

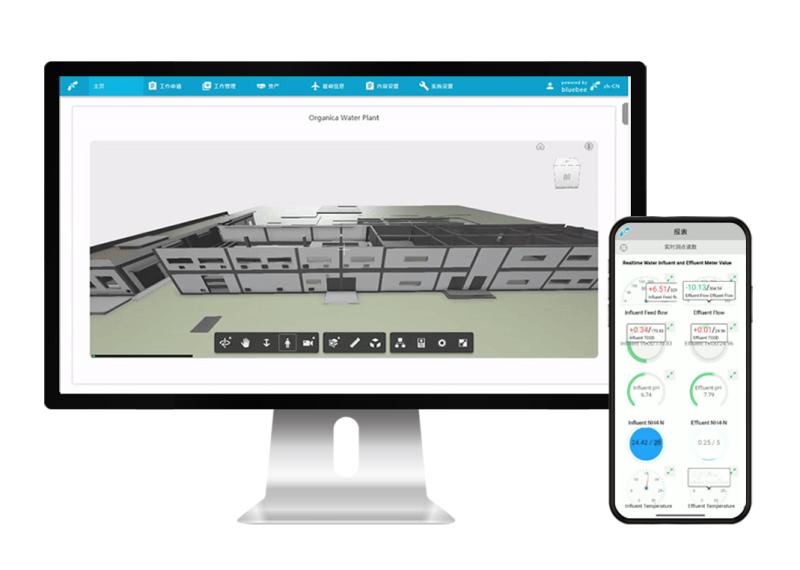

Organica, a provider of innovative wastewater treatment solutions, also supports O&M teams with highly practical, non-nonsense, Digital Twin solutions based on proven technology. The solution integrates the plant's 3D BIM model and real-time data from the SCADA, both designed by Organica, into Siveco China's Smart O&M platform. Relevant SCADA values are shown in the mobile, together with related maintenance instructions, for the technicians in the field.

Siveco China Head Office

Unit J, 20th floor, Zao Fong Universe Building

No.1800 Zhong Shan Road (W)

Shanghai 200235 - PR China

About Siveco China

Siveco China (www.sivecochina.com), founded in 2004, is a pioneer in the development of Smart Technologies for the Operation & Maintenance of infrastructures and industrial plants, with a focus on mobile solutions "for the worker of tomorrow".

Long before the terms "smart" and "4.0" were coined, Siveco has been helping clients optimize the lifecycle of their assets and ensure regulatory compliance using IT. Based on a long experience of "maintenance with Chinese characteristics", the company has designed a unique approach combining expert maintenance consulting and technological innovation. Smart O&M solutions developed in Siveco's R&D center in Shanghai cover Asset Management, Maintenance 4.0, Risk Prevention and HSE, utilizing Mobility, IoT, BIM, AR and AI technologies.

Siveco China has over 900 customer sites all over Greater China and on the Belt & Road, including ABB, Baosteel Metal, Beijing Environment, Capital Water, Carrefour China, CEPSA, CNEEC, CNOOC, COSCO, Fushun Mining, Engie, Everbright, GE, New World Development, Saint-Gobain, Shell, Suez NWS, Yingde Gases, Zhongshan Water etc. The company boasts a growing export business, working alongside Asian EPC companies and with international clients in Southeast Asia, the Middle-East and Africa.

Siveco China has won numerous awards, most recently the prestigious Brilliant 40 Years prize by the China Electric Power Equipment Management Association, Top Ten Enterprise for Asset Informatization Service by the and the China Association of Machinery Equipment Maintenance and Renovation (CAMER) and Best Industrial Software 2017 by Control Engineering China. Previous awards include CHaINA Supply Chain Excellence Award 2013 and Engineers' Choice Awards by Plant360 in three categories in 2015.

Siveco is ISO 9001-certified by Bureau Veritas for its entire scope of business. The company is headquartered in Shanghai, where it also operates its R&D center, and has offices in Hong Kong. Siveco China is a subsidiary of Siveco Group, a European pioneer in computerized maintenance management systems (CMMS).

Siveco China publishes the "Smart Operation & Maintenance - for the worker of tomorrow" newsletter dedicated to maintenance management, bilingual English and Chinese, available to subscribers and online.

Contact

Tel (China mainland): 4006 300 213

Tel (overseas): +86 21 64403226

E-mail : info@sivecochina.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Future of Operation & Maintenance here

News-ID: 2833927 • Views: …

More Releases from Siveco China

ESG & decarbonization in operations: the digital gap

(This article was previously published in the December 2022 issue of APUEA magazine.)

ESG (Environmental, Social, and Governance) is a framework that helps stakeholders understand how a company is managing risks and opportunities related to environmental, social, and governance criteria. Looking at ESG from a plant management's perspective: Environmental includes energy, water and waste. Social covers safety, first and foremost. Governance consists in complying with regulations and best practices, as well…

On the Belt & Road with clients and partners in Thailand

Thailand is a priority for Siveco China's development in Southeast Asia owing to the country's well-developed industry and growing infrastructure development. During October, our Managing Director visited local clients and partners.

Please enjoy our postcards from Thailand!

Several new partnerships and projects were also launched during this period - more on this later!

Siveco China is active all over Asia with projects not only in Thailand, but also in Brunei, India, Indonesia,…

Feedback on "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thail …

Siveco China organized a team of high-profile speakers at MIRA SUBCON EEC, Thailand's Leading Industrial Solutions Event, held on August 26 in Pattaya. The session was hosted by the Asia Pacific Urban Energy Association (APUEA). Under the theme "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thailand 4.0", the workshop aimed at sharing practical experience for the local market.

After an introduction by APUEA's Executive Director Peter Lundberg, the event…

More Releases for O&M

A Complete Guide of Hydropower O and M

Hydropower is one of the most researched and used renewable energy sources today. It is possible to generate enough clean energy to meet a significant portion of the world's ever-increasing energy demand by correctly utilizing the vast amounts of hydropower available around the planet. In the United States, it is still the most important source of renewable energy, and many other countries are stepping up their efforts to stay up…

Hydropower O and M Market Growth & Opportunities Till 2028

An exclusive Hydropower O and M Market research report has been fabricated through the in depth analysis of the market dynamics across five regions including North America, Europe, South America, Asia-Pacific, Middle East and Africa. The segmentation of the market by components, end users, and region was done based on the thorough market analysis and validation through extensive primary inputs from industry experts (key opinion leaders of companies, and stakeholders)…

Siveco China released its Digital Twin for O&M platform

On Earth Day 2022, Siveco China unveiled its Digital Twin for O&M solution, powered by bluebee® X. The new Digital Twin platform incorporates environmental compliance reporting from multiple data sources, in addition to the existing Asset Management and Risk Management functionalities.

Siveco China has since 2009 developed innovative yet practical digital solutions, designed by industrial people for industrial people, in line with the ISO 55000 Asset Management standard. The newly released…

Real Digital Twins for O&M in China & abroad

Siveco Group is known as a front-runner in digital innovations for maintenance since the mid-1980s. Unsurprisingly, the company was also among the first, perhaps the very first, to utilize BIM (Building Information Modeling) for maintenance purposes. Early research started by Siveco China in 2011 led to the development of standard products, part of the Coswin 8i and bluebee® suites, which have been deployed to many clients' sites all over the…

Capital Environment selects Smart O&M solution from Siveco

Capital Environment Holdings Limited (CEHL) has selected Siveco to provide its Smart O&M solution and related asset management consulting services to their Yangzhou hazardous waste project. The project aims at strengthening the management of operation and maintenance in line with world-class standards and Chinese market characteristics.

Capital Environment Holdings Limited (CEHL) is a public company whose shares are traded on the Hong Kong Stock Exchange. As a leading provider of…

Yingde Gases goes live with Siveco Smart O&M solution

On May 31, a ceremony was held with top managers of Yingde Gases to mark the official "Go Live" of Coswin 8i on the Changshu pilot site.

Yingde Gases Group (Yingde Gases), founded in 2001, is one of the leading companies engaged in on-site gas production and liquid supply. Main products include: industrial gases of oxygen, nitrogen, argon and hydrogen, which mainly provide products and services to enterprises of the iron…