Press release

Pipe bending: Cost-efficient bending of hose fittings

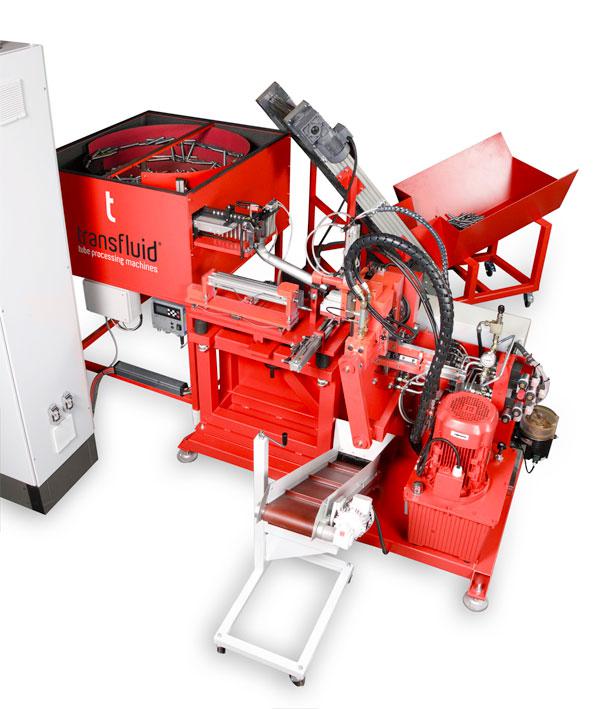

Tube bending maschines: transfluid offers two fast processing systems for different sizesSpecial solutions are required for special requirements – or just one efficient, customisable solution. For one-part hose fittings the german transfluid Maschinenbau GmbH has developed such a "twin" pipe bending solution and will equip its tube bending maschines systems with different modules depending on the application, varying mostly in the loading system. The challenges: Fittings are mostly mechanically processed, extremely short, relatively thick-walled and their sealing elements (sealing head or hose part) must not be damaged under any circumstances. "Cost-efficient processing options with our tube bending maschines are an aspect on which we place great emphasis. Large amounts of pieces are mostly manufactured for small sizes. And what counts here is the speed", says Gerd Nöker, the CEO of transfluid.

Pipe bending: Short cycles and bulk material hopper

The fittings bending machine for sizes up to 1 inch is fitted with a bulk material hopper with a capacity of 600 litres. The advantage: Fittings of any size can be loaded. A powerful drive is ensured by servo-electrical or hydraulic equipment. Bending can be therefore done in amazingly short cycles from 6 to 7 seconds including the entire handling. Special supporting elements ensure that the sealing cone and hose connections remain undamaged. Fittings starting with inner diameter of 8 mm are bent by the transfluid system always with an internal mandrel, so that bend ovalisation can be ruled out.

Further informations: http://www.tube-processing-machines.com/pipe-bending-machines.php

Tube bending maschine: Special handling of fittings with a diameter of up to 75 mm

Components with dimensions up to a diameter of 75 mm are transported by using a particularly robust loading system. As the weight of these fittings is so high, the loading system of the tube bending maschine prevents the components from uncontrolled falling down. The work pieces are therefore provided on a special pallet, taken from the handling system and supplied to the tube bending machine. These sizes are generally bent by the tube bending machines with an internal mandrel. A maximum ovalisation of 3 percent is given. Also for large component, special supporting adapters ensure that each piece is discharged in the optimum way in the process. Flanges or other sealing elements will stay safe from damage. Even for fittings of this size, the entire processing time of the tube bending maschine is maximum 25 seconds.

During EuroBLECH (23-27.10.2012, Hannover/Germany, hall 11 / booth E02) visitors can experience the solutions for tube processing from transfluid.

transfluid Maschinenbau GmbH – the solution for tubes

Since 1988 transfluid continually improved technologies in tube processing to meet customers’ demands, offering optimum, tailor-made solutions in machine and plant construction, that are used in the automobile, ship building and furniture industries as well as the construction of railings and conveyor technology. The Schmallenberg-based company has become a global brand with service offices in Europe and Asia.

transfluid’s product portfolio offers perfect solutions in five different machine categories, that meet all the requirements in tube processing. t bend includes semi- and fully-automatic tube bending machines as well as large-diameter tube bending machines.. t form represents high-quality axial, rolling and combined tube forming machines. Automation systems with sophisticated concepts for bending and forming technology belong to the t motion category. With t cut, transfluid offers tube cutting machines in different system variants und t clean is transfluid’s range of tube cleaning machines for guaranteed cleanliness of work pieces and pipes.

www.tube-processing-machines.com

transfluid®

Maschinenbau GmbH

Stefanie Flaeper

Hünegräben 20-22

57392 Schmallenberg

Germany

Tel.: +49 2972 97 15 - 0

Fax: +49 2972 97 15 - 11

info@transfluid.de

www.tube-processing-machines.com

Press contact:

Stefan Köhler

PR/Media

T. 02 71 . 77 00 16 - 16

F. 02 71 . 77 00 16 - 29

s.koehler@psv-marketing.de

www.psv-relations.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pipe bending: Cost-efficient bending of hose fittings here

News-ID: 225205 • Views: …

More Releases from transfluid Maschinenbau GmbH

10. Industry forum on the future of pipe processing

Pipe processing: Experts meet at the transfluid Innovation days for the tenth time

Progress thrives on the exchange of knowledge. This is also the conviction of transfluid Maschinenbau GmbH and it cannot be described more aptly than by the Albert Einstein quote above. With its Innovation days the company has been offering the pipe processing industry a platform for more than ten years already, with the objective of developing new perspectives…

transfluid Maschinenbau GmbH – the solution for tubes

When the hare arrives, the tortoise has already been there. The fastest way to the best results doesn't just rely on speed alone. The optimum tuning and interplay of different systems is where processes can really be made efficient. That's especially true when we're talking about powerful automation systems for pipe processing. transfluid Maschinenbau GmbH has developed specially tuned automation systems into efficient standards. They permit the accurate, rapid separation…

Efficient tube machining with Large-screen TV

Documents the manufacturing process by camera - fully electric system (t motion) from transfluid

Go to work in the morning and switch on the TV first thing: It sounds like a dream, but transfluid makes it the heart of an intelligent tube machining system (t motion) with its camera-controlled, fully electric manufacturing cell.

In fact, the large screen installed above the system does not broadcast the latest news into the…

The new standard for quick tube processing: tu go

tube bending and tube forming machines: transfluid wraps up new technology package for customers in a hurry

Providing tea "to go" is a standard service in fast-food outlets and the concept has now made a surprise leap into the world of advanced tube processing machines. The established standard at transfluid Maschinenbau GmbH with its customized solutions has become a characteristic drive to develop more and more advanced technologies. But because decisions…

More Releases for Special

Fujian Jinqiang Machinery Manufacture Co. Fasteners - Special Price for Special …

At Fujian Jinqiang Machinery Manufacture Co., Ltd., we believe that reliability shouldn't cost a fortune. For over 20 years, we have been dedicated to producing top-tier fasteners. Now, we are excited to launch a special promotion to make our partnership even more rewarding. For a special reason - to build strong, lasting relationships with our clients - we are offering special prices on key products.

Who We Are

Founded in 1998 and…

Houston Special Needs Trust Attorney Whitney L. Thompson Releases Article on Spe …

Houston special needs trust attorney [https://www.wthompsonlaw.com/houston-special-needs-trust-attorney/] Whitney L. Thompson of The Law Office of Whitney L. Thompson, PLLC sheds light on how special needs trusts work in Texas and why they are a critical planning tool for families with loved ones who have disabilities. The article explains the role of special needs trusts in preserving access to essential public benefits while ensuring that financial resources remain available for the individual's…

A Special Easter Message

A greedy friend

An angry mob

An appeasing ruler

A repentant thief

An obedient Son

A world in need

A tomb empty

When people think of Easter, the things listed above are probably not the first things that come to mind, but each element existed on the first Easter. They all played an essential role on a day in history that changed the world for eternity.

Thousands of years later, though the circumstance may be different, each…

Special Price for Bankers

Bandung, July 2023 - Exciting news for all bank employees in Indonesia! Building on the success of 2019, ASTON Pasteur is offering an incredibly attractive promotional room rate that you simply can't afford to miss. Whether you're planning a vacation or a business trip to the enchanting City of Flowers, Bandung, this offer is tailored just for you.

Enjoy an exclusive offer for bankers, priced at only Rp. 700,000 net per room…

A very special milestone

The 1.5 millionth awning has left the markilux factory

In 1972, markilux sold its first 500 ready-made awnings. Recently the company produced its 1.5 millionth awning. This special number exemplifies the strong transformation of the brand and its products over almost five decades.

A symbolic markilux awning recently set off on its journey to Hamburg. It is the 1.5 millionth to have left the factory. “The model was an MX-3, which embodies…

Special Purpose Machines

Special Purpose Machines (SPM) are those Machine which are not Available Off the Shelf. These are not Covered in Standard Manufacturing Programs. There Fore they have to be Designed & Tailor Made as Per the Customers Specific Requirements.

Whether it’s automobile, agriculture, auto bus and truck, construction, earth moving, forestry, machining, material handling, mining, molding, utility and power, or any other.

Standard Hydraulic & Automation Systems

…