Press release

Infrared heaters save space and time in powder coating

Powder coating on flat metal parts is cured quicker and on less floorspace than with a gas-fired oven.

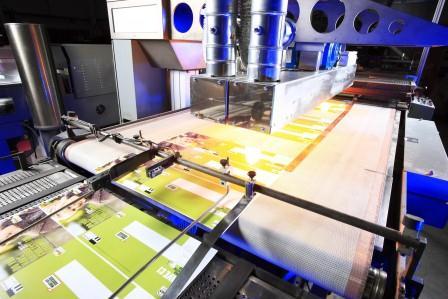

Saving space was a key argument when a manufacturer of metal plates for technical consumer products in China compared gas-fired and electrical infrared technology for its new plant in Fujian province. As the market for these powder-coated products is very competitive and downward cost pressure is huge, the floorspace has to be used in the best possible way. After testing electrical infrared emitters in the Heraeus test center in Shanghai, the company was impressed by the speed of curing which made a much more compact design of the line possible. Compared to a convection oven, the line speed could be increased by more than 50%. The coating line contains two infrared sections: drying of the uncoated parts before coating and curing the powder at approx. 200OC after coating. Both process steps use medium-wave infrared modules which were built and equipped with emitters by Heraeus Noblelight. They can be controlled in different zones to save power when smaller parts are running through the curing oven. The power of the infrared heaters can also be easily adjusted to the different colors of coating, dark coating requiring less energy than light coating.

Further benefits of infrared technology became obvious when the line started operation. The quality of the coated products improved further because the powder is cured faster, without time to flow down the plates. “We have not had a single complaint since the new line started operation” says the Engineering and Maintenance Manger of the company. The company was further able to take advantage of lower off-peak electricity rates, keeping the energy bill at a comparable level as for a gas-fired oven. Absolute energy consumption is even lower for electrical infrared because the heat can be better targeted, which reduces the heat load in the production building and is in line with China’s policy of efficient and clean energy usage.

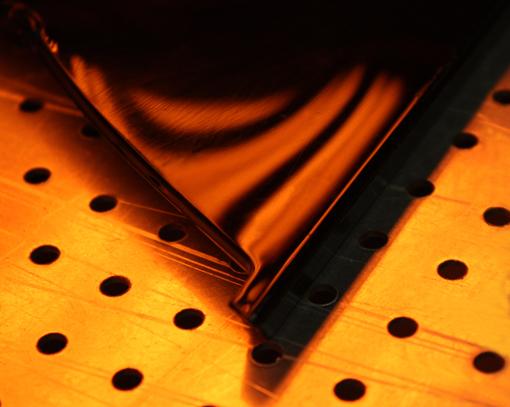

Electrical infrared emitters transfer heat without the need for a contact medium, where electromagnetic waves generate heat in the material to be heated. Infrared radiation is absorbed very well by powder, so that the powder mass heats up very quickly. Powder is gelled significantly faster than in a convection oven, and the transmitted power is higher than for gas-fired infrared ovens. Fast melting improves the surface quality and increases the throughput speed. In most cases, ovens are significantly shorter or the product speed is higher.

Infrared radiation offers many more advantages for power coating applications. Speed and space-saving have been demonstrated in the case study above. For flat parts like the metal plates mentioned above, it heats the surface evenly. But also round parts can be cured by rotating the part in front of the infrared heaters.

In comparison with hot air ovens, the powder is not disturbed or blown about. With no air movement, dust inclusions are also eliminated, so that quality is improved.

Compared to gas-fired infrared heaters, electrical infrared eliminates potentially dangerous gas supply in the factory. Electrical infrared systems also can be easily integrated in existing drying lines. This helps when upgrading existing hot air ovens in order to speed up production.

However, knowledge and experience is needed when designing an infrared system. There are many different types of infrared emitters, from short-wave and halogen heaters to medium-wave heaters. Each one has specific advantages that depend on the specific application of the customer. For example, using the wrong emitter for powder coating can easily lead to over-cooking the coating instead of curing it properly.

This is why Heraeus Noblelight operates test centers in five countries around the world, including the one in Shanghai. Here, customers can conduct experiments with their own materials together with the Heraeus experts. Thus, the customer can be sure that he selects the best-suited emitter for his application.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology- and market-leaders in the production of specialist light sources. In 2006, Heraeus Noblelight had an annual turnover of 88 Million € and employed 651 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company in the business segments of precious metals, sensors, dental and medical products, quartz glass and specialty lighting sources. With revenues of more than EUR 12 billion and more than 11,000 employees in over 100 companies, Heraeus has stood out for more than 155 years as one of the world’s leading companies involved in precious metals and materials technology.

Heraeus Noblelight

Reinhard-Heraeus-Ring 7

63801 Kleinostheim

Press: Marie-Luise Bopp

phone +49 6181 35 8547

marie-luise.bopp@heraeus.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Infrared heaters save space and time in powder coating here

News-ID: 22212 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

More Releases for Powder

Polyolefin Powder Market, By Type (Polyethylene Powder, Polypropylene Powder),Tr …

Data Bridge Market Research analyses the polyolefin powder market will exhibit a CAGR of 6.00% for the forecast period of 2022-2029 and is expected to reach the USD 11.79 billion by 2029.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-polyolefin-powder-market

Polyolefin is a polymer made from the simple monomer olefin, and its powder is made up of crystalline polyolefin made from olefins. Paper coating, ink and paint formulation, and injection moulding are just a few of the applications…

Nano Ceramic Powder Market: Information by Type (Oxide Powder, Carbide Powder, B …

Nano Ceramic powder is nanoparticles which are inorganic solids made up of oxides, ceramics, carbonates, and carbides. The Nano-Ceramic powder has a growing market as they are very useful due to its very small size.

Nano Ceramic powder is strong and the strength of these powder is similar to steel. They exhibit strength at high temperatures. They are more resistant to chemical situations than other metals. There is some ceramic powder…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Global Egg Powder Market Status, Industry Player (Egg Powder, Egg Yolk Powder, E …

An up-to-date research report has been disclosed by Market Research Hub highlighting the title “Global Egg Powder Market Increasing Consumption of Whole Egg Powder to be Observed in the Coming Years” which provides an outlook for current market value as well as the expected growth of Egg Powder during 2018-2025. The report studies the casing heads market worldwide, especially in North America, China, Europe, Southeast Asia, Japan and India, with…