Press release

Concentration measurement made easy - Inline process analysis in liquids

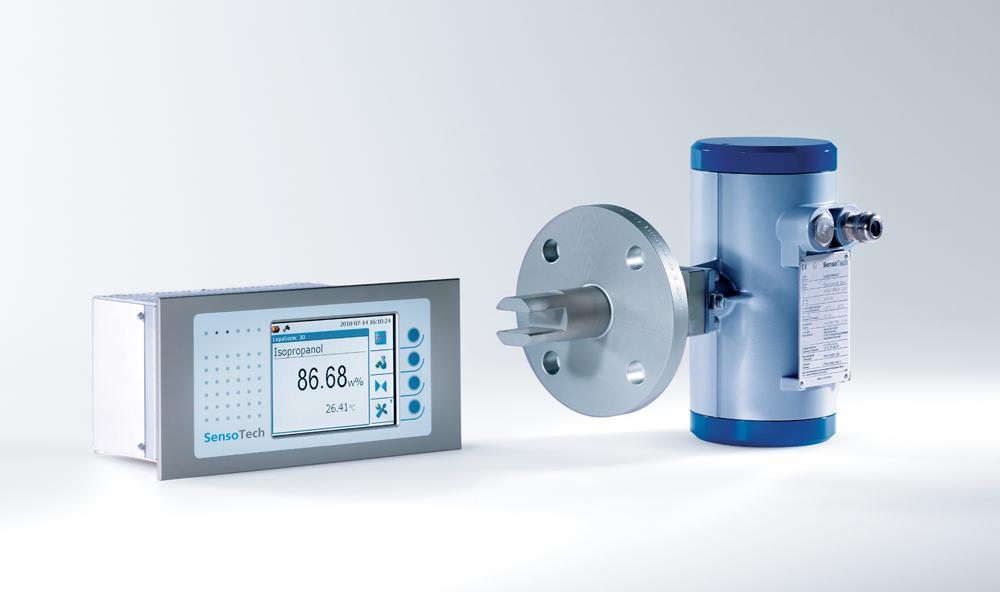

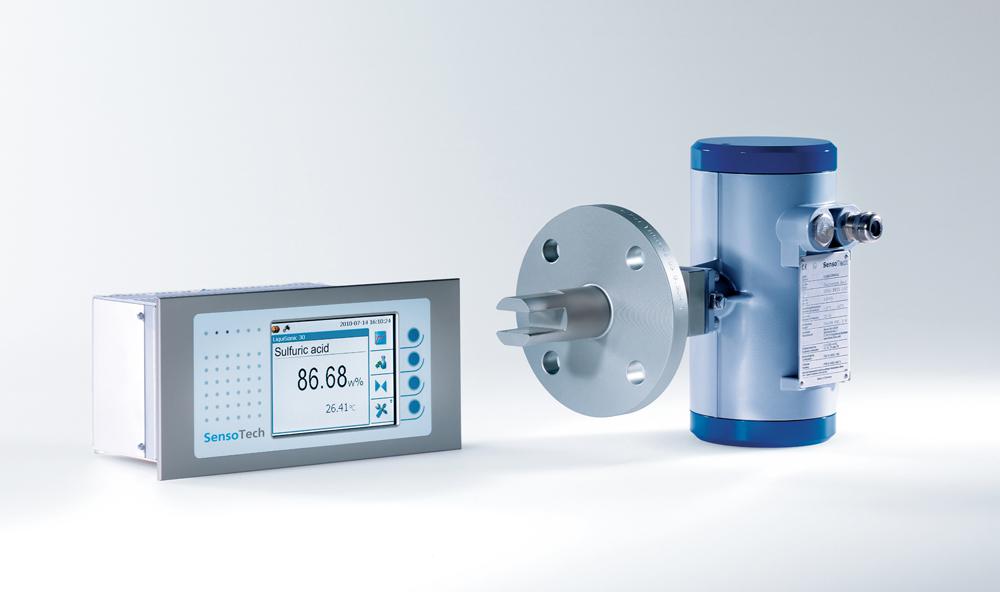

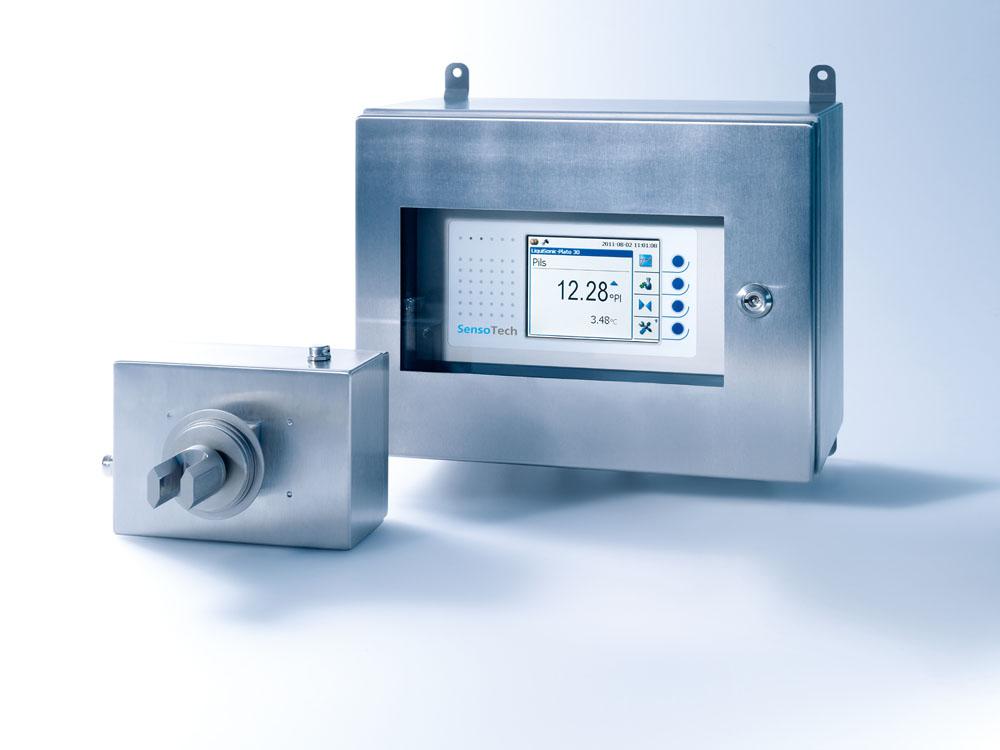

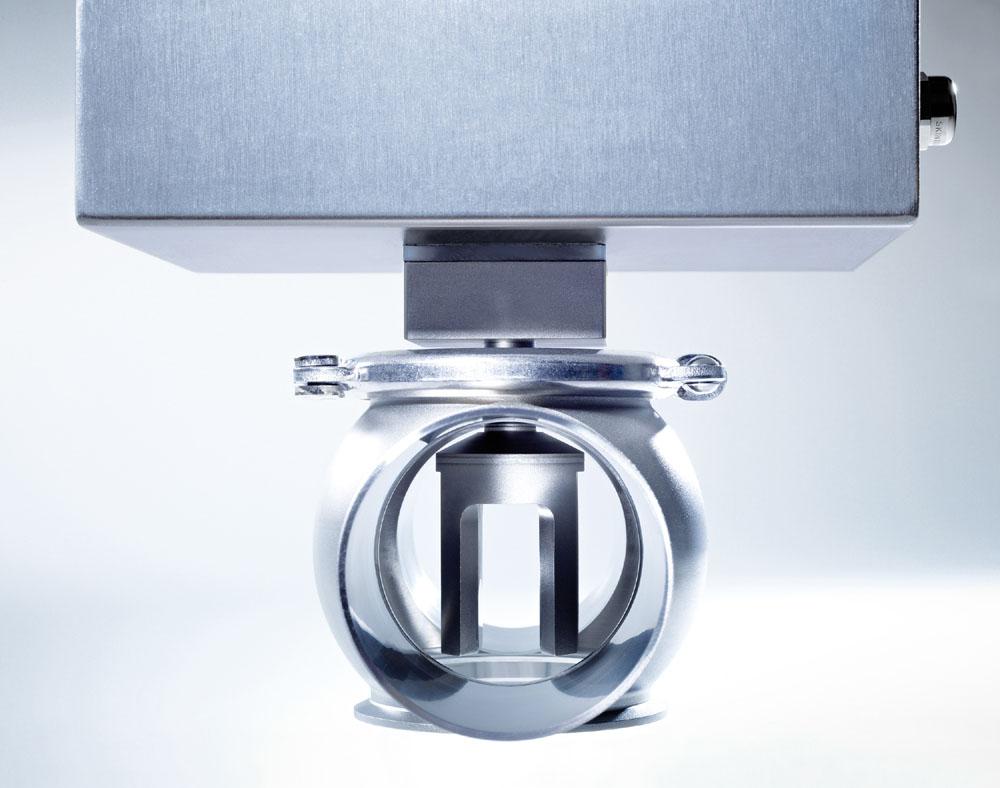

In numerous industrial manufacturing processes, the inline measurement of concentrations is required to monitor the product quality and to produce efficiently in terms of resources. Sonic velocity is recommended as a measuring method, because it provides highly precise and actual measuring values within seconds. Furthermore, the measuring systems can be installed without a bypass and are used in almost all chemical substances.The LiquiSonic® measuring system produced by SensoTech is based on the above mentioned method and has proved to be reliable for over 20 years in numerous industrial and laboratory applications. Whether installed directly in the pipeline or in a vessel, the measuring system measures reliably the concentrations of process liquids. The system is the most suited, not only due to its robust and maintenance-free construction and its easy handling, but also for use in specific processes with different materials and designs. Thus, there are lots of possibilities, for example, corrosion resistant sensor coatings, installation lengths up to 3 m or diverse process fittings like DIN, Varivent, Clamp or ANSI. These sensors are also available with an ATEX and IECEx approval for using them in hazardous areas. Beside the sensors, the controller is also included in the system. This controller manages and visualizes the measuring data transferred over common interfaces to control systems.

The measuring system is used in the chemical and pharmaceutical industry, the beverage production, steel and automobile industry and many further industries. The focus is particularly on process and quality safety, increased yield as well as savings in energy and raw material.

In the chemistry and pharmacy, the concentration of acids, alkali, solutions, emulsions or suspensions is monitored. The concentration measurement also detects exactly the phase transitions.

However, in neutralization and gas scrubbers, processes in the range of maximum absorption can be controlled.

In polymerizations and crystallizations, the precise analysis of the concentration determines the degree of polymerizations or different crystal parameters, such as saturation degree or crystal content.

Especially the chemical and pharmaceutical industry requires sensors that have high measuring accuracies and can be used at high temperatures or in chemically aggressive liquids. The LiquiSonic® sensors meet these requirements with a measuring accuracy of typically ± 0,05 wt%, operating temperatures of up to 200°C and coatings made of Halar, PFA or Hastelloy. For the pharmaceutical industry, SensoTech also offers electro-polished sensors.

In the beverage industry, for example, the measurement of the sugar, whey or must content is very important. In breweries, however, the main focus is the content of extract, original gravity and alcohol. For filter or filling processes, exact phase detection is also very essential. The highly precise LiquiSonic® sensors completely made of stainless steel 1.4571 meet the measuring and hygienic requirements of the beverage industry. Up to four sensors can be connected to one controller in case of large filling lines what causes comparatively low investment costs.

The steel industry requires a perfect surface treatment to get proper products of high quality at the end of the process chain. Therefore, pickling and chrome baths, cold rolling mills as well as acid regeneration and galvanizing plants are equipped with the LiquiSonic® measuring technology. The concentration measurement is used in different process steps for monitoring acid and rolling oil emulsion as well as for analyzing electrolytes within the steel strip or roller chrome plating. The LiquiSonic® sensors are very suitable for extreme process conditions in steel and rolling mills.

In the automobile industry, however, the measurement of oil in cooling agent or the determination of the concentration from cooling agents in refrigeration cycles is being performed. Monitoring sulfuric acid in car batteries or analyzing polyurethane for producing synthetic material contributes to ensure safe and efficient processes. Also in this case, SensoTech is offering sensors that meet specific process requirements.

And in many other industries, the LiquiSonic® measuring system is able to optimize process engineering procedures. For example, the concentration of cooking and black liquor is monitored in the pulp and paper production, the coffee extract or starch concentration in the food industry and the quality of cleaning and rolling oil baths in the Mechanical Engineering.

Since over 20 years SensoTech GmbH has been engaged in the development, manu-facturing and sales of inline analysis systems for process liquids. With worldwide in-stalled, highly precise and innovative measuring systems for monitoring of concentra-tions, compositions and changes of chemicals as well as properties directly in the process, SensoTech has significantly contributed to the enhancement of the state of the art. In addition to the measurement of concentration and density, the phase inter-face detection as well as the monitoring of chemical reactions like polymerization and crystallization are typical applications. SensoTech inline analyzers set standards in the technological and qualitative valence, user friendliness and reproducibility of process values. Special calculation methods and sophisticated sensor technologies enable reliable and precise measuring results even under the most difficult process conditions.

The knowledge and the experiences of the highly motivated and committed SensoTech staff are the result of many different applications supported by well-known customers from the chemical and pharmaceutical industry, food technology, semiconductor technology, automobile and steel industry as well as many other industries. In addition, these experiences also open up unimagined solution possibilities for new measuring challenges.

SensoTech GmbH

Steinfeldstr. 1

D-39179 Magdeburg-Barleben

Germany

Tel.: +49 39203 514100

info@sensotech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Concentration measurement made easy - Inline process analysis in liquids here

News-ID: 218719 • Views: …

More Releases from SensoTech GmbH

Measuring sulfuric acid and oleum strength using sonic velocity meters

Monitoring the sulfuric acid and oleum strength (wt%) inline, directly in the process, enhances safety and efficiency of production plants. The measuring results are available online and in real time. Due to the physical properties of sulfuric acid and oleum, the most suitable measuring method for determining the acid strength is sonic velocity measurement. The LiquiSonic® analyzer by SensoTech precisely measures with only one single sensor the sulfuric acid and…

Process analytical technology for concentration measurement, phase separation an …

In industrial processes, inline analytical technology is used to monitor critical parameters and to control processes for quality assurance, production efficiency and safety. This increases process reliability, reduces costs of raw material and energy, and eliminates failed productions.

With the LiquiSonic® analytical technology of SensoTech, parameters such as the concentration in process liquids can be monitored. The analyzer is used in almost any liquids of the chemical and pharmaceutical industry,…

Inline analysis of beverage ingredients: Plato, Brix, alcohol, extract, whey, dr …

The several processes of beverage production can be significantly optimized by using inline analytical measuring technology. For example, to improve evaporations, phase separations, blendings or fillings, the concentrations in beer and wine, mixed and soft drinks, juices and liquid dairy products can be monitored.

In the fruit juice and soft drink production usually the Brix content will be analyzed, whereas in dairies the whey or dry matter content is important.…

Inline analysis of ingredients in beverages and liquid food

In order to realize an excellent quality at low costs and short lead times, production processes should be monitored in the food industry in terms of preventive quality management. In the production of beverages and liquid food, for example, the correct concentration of ingredients matters. If the concentration is not kept, a false taste of the product and an inefficient use of resources will follow. As a solution SensoTech…

More Releases for Sonic

Global Crosshole Sonic Logging Service Market Size by Application, Type, and Geo …

USA, New Jersey- According to Market Research Intellect, the global Crosshole Sonic Logging Service market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

Growing infrastructure development and the requirement for high-precision foundation testing in building projects are driving the market for crosshole sonic logging (CSL) services.…

SONIC GLOW PICK REVIEWS 2024;IS SONIC GLOW PICK LEGIT OR JUST A HYPE?

The Sonic Glow Pick Has rapidly gained popularity among consumers looking for an effective solution to at-home oral care. In a world where dental hygiene is essential, but costly dentist visits can be a barrier, this innovative device provides a convenient alternative for removing plaque and tartar from your teeth without the discomfort of traditional methods. By combining advanced ultrasonic technology with user-friendly design, the Sonic Glow Pick offers professional-level…

360 SONIC TOOTHBRUSH REVIEW 2023: IS 360 SONIC TOOTHBRUSH ANY GOOD?

The 360 Sonic Toothbrush represents a groundbreaking advancement in oral hygiene technology, redefining the way we approach daily dental care. This innovative toothbrush is designed to provide an efficient and effortless tooth-cleaning experience, promising a level of convenience and effectiveness that traditional toothbrushes can hardly match.

In the realm of dental care, where the pursuit of healthy gums and a radiant smile is paramount, the 360 Sonic Toothbrush emerges as a…

SONIC GLOW BRUSH REVIEW 2023: IS SONIC GLOW BRUSH LEGIT OR JUST A HYPE?

The Sonic Glow Brush is a cutting-edge dental hygiene innovation that is revolutionizing the way we care for our teeth. Designed to provide an effective and efficient brushing experience, this sonic toothbrush combines advanced technology with user-friendly features to ensure optimal oral health for users of all ages.

At its core, the Sonic Glow Brush is not just a toothbrush; it's a comprehensive dental care solution. With its sleek design and…

Sonic Glow Brush Reviews: Does Sonic Glow ToothBrush Work Or A Hoax In The USA? …

Sonic Glow Brush Reviews: Does Sonic Glow ToothBrush Work Or A Hoax In The USA? (United States Reviews) - Sonic Glow Amazon Reviews - Sonic Glow Brush Amazon Reviews

For centuries, toothbrushes have pretty much stayed the same throughout the United States. But, even with all those years of brushing, dental problems still stick around. Things like brushing too hard, not enough, or not often, plus forgetting to floss or…

Sonic Studio Shows Latest at RMAF

Company’s Partners Will Demo & Preview New High End Audio Gear

Denver – October 2, 2009 — Once again, high end audio enthusiasts will gather in Denver, Colorado for this fall’s 6th annual Rocky Mountain Audio Fest. Sonic Studio, LLC will be exhibiting there in conjunction with several channel partners, including Audio Salon, Balanced Power Technologies LLC, Locus Design, SimpliFi Audio, Wavelength Audio Ltd. and others. OEM partner Weiss Engineering Ltd.…