Press release

Process analytical technology for concentration measurement, phase separation and reaction monitoring

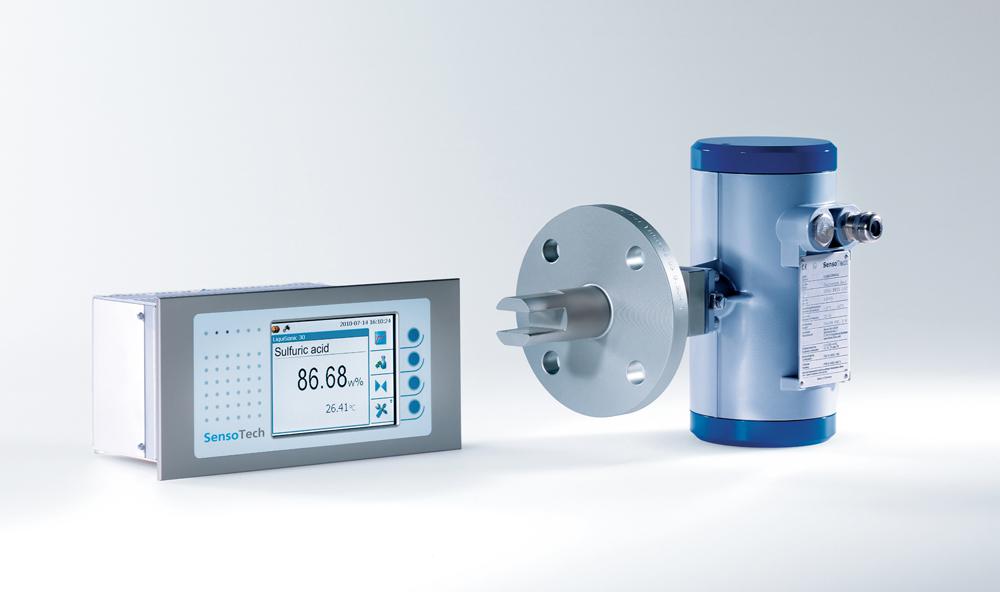

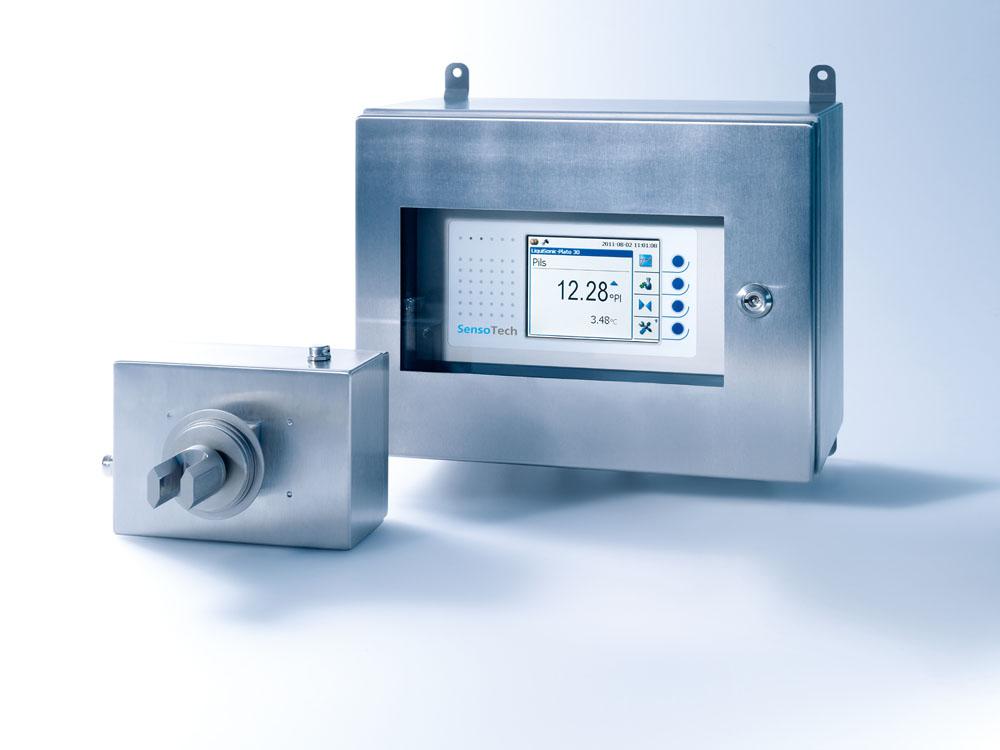

The LiquiSonic® inline analyzer of SensoTech measures concentrations in process liquids and provides the data online.

With the LiquiSonic® analytical technology of SensoTech, parameters such as the concentration in process liquids can be monitored. The analyzer is used in almost any liquids of the chemical and pharmaceutical industry, food production, semiconductor technology, metal production and many more industries. For example, in the chemical industry the LiquiSonic® sensors measure the concentration of sulfuric acid, ammonia, hydrofluoric acid and more chemicals. In the chlor-alkali electrolysis, the analyzer monitors sodium hydroxide, sodium chloride, hydrochloric acid and sulfuric acid. Also in gas scrubbers, phase separations, neutralizations, dissolvings or blendings, the LiquiSonic® sensors are integrated into the process. In addition, the analyzer monitors complex reactions such as crystallizations or polymerizations. In crystallizations, critical parameters include the saturation degree, the crystal content or the metastable range, whereas in polymerizations the analysis of the polymerization degree is important.

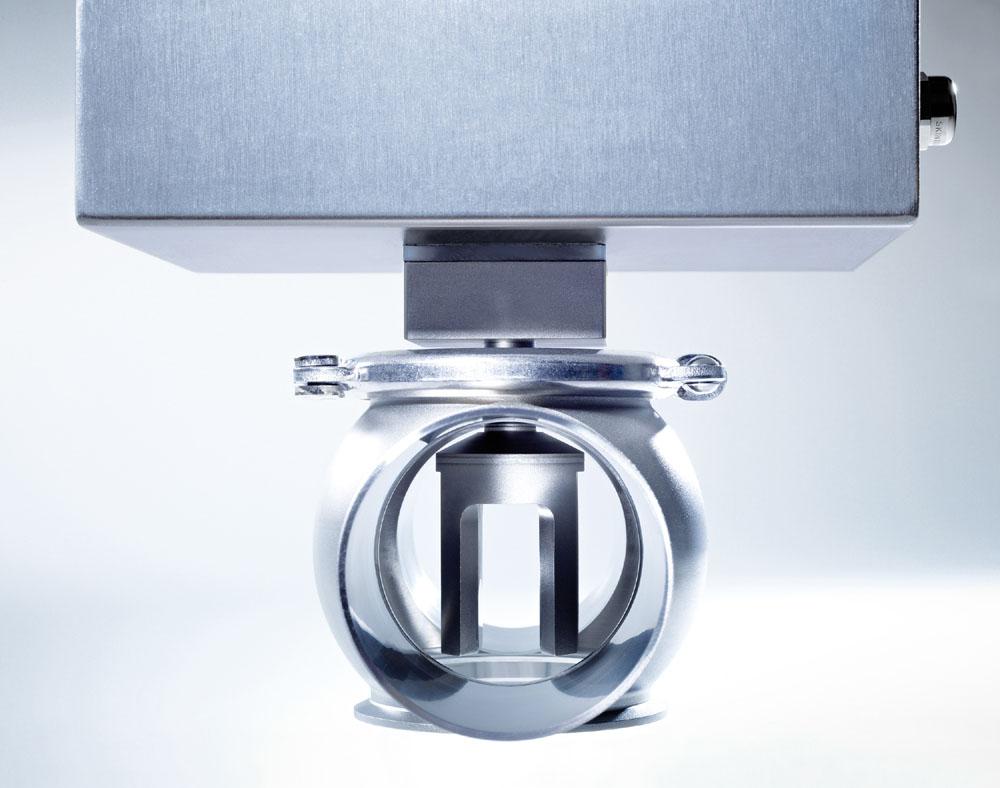

The LiquiSonic® technology is based on sonic velocity measurement that provides high-precision and stable measuring results being updated every second. Compared to other measuring methods, sonic velocity devices are extremely robust and maintenance-free, corrosion-resistant by using special materials, and integrable into the process without bypass. LiquiSonic® sensors, made in Germany, are installed directly into pipes of any size or into vessels. The measurment is continuously inline and the results are provided online. The LiquiSonic® controller displays and stores the results. The trend view shows the process status at any time. If the measuring result exceed or fall below thresholds, a signal will be sent immediately. For automated process control, the measuring results can be transferred to the process control system. Via a PC-interface, it is possible to read all data and to create reports and protocols.

For 25 years SensoTech has been focused on the development, manufacturing and sales of inline analysis systems for process liquids. With worldwide installed, highly precise and innovative measuring systems for monitoring of concentrations, compositions and changes of chemicals as well as properties directly in the process, SensoTech has significantly contributed to the enhancement of the state of the art. In addition to the measurement of concentration and density, the phase interface detection as well as the monitoring of chemical reactions like polymerization and crystallization are typical applications. SensoTech inline analyzers set standards in the technological and qualitative valence, user friendliness and reproducibility of process values. Special calculation methods and sophisticated sensor technologies enable reliable and precise measuring results even under the most difficult process conditions.

The knowledge and the experiences of the highly motivated and committed SensoTech staff are the result of many different applications supported by well-known customers from the chemical and pharmaceutical industry, food technology, semiconductor technology, automotive and metal industry as well as many other industries. In addition, these experiences also open up unimagined solution possibilities for new measuring challenges.

SensoTech GmbH

Ms. Rebecca Dettloff

Steinfeldstr. 1

D-39179 Magdeburg-Barleben

Germany

T +49 39203 514 100

F +49 39203 514 109

info@sensotech.com

www.sensotech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Process analytical technology for concentration measurement, phase separation and reaction monitoring here

News-ID: 311696 • Views: …

More Releases from SensoTech GmbH

Measuring sulfuric acid and oleum strength using sonic velocity meters

Monitoring the sulfuric acid and oleum strength (wt%) inline, directly in the process, enhances safety and efficiency of production plants. The measuring results are available online and in real time. Due to the physical properties of sulfuric acid and oleum, the most suitable measuring method for determining the acid strength is sonic velocity measurement. The LiquiSonic® analyzer by SensoTech precisely measures with only one single sensor the sulfuric acid and…

Inline analysis of beverage ingredients: Plato, Brix, alcohol, extract, whey, dr …

The several processes of beverage production can be significantly optimized by using inline analytical measuring technology. For example, to improve evaporations, phase separations, blendings or fillings, the concentrations in beer and wine, mixed and soft drinks, juices and liquid dairy products can be monitored.

In the fruit juice and soft drink production usually the Brix content will be analyzed, whereas in dairies the whey or dry matter content is important.…

Inline analysis of ingredients in beverages and liquid food

In order to realize an excellent quality at low costs and short lead times, production processes should be monitored in the food industry in terms of preventive quality management. In the production of beverages and liquid food, for example, the correct concentration of ingredients matters. If the concentration is not kept, a false taste of the product and an inefficient use of resources will follow. As a solution SensoTech…

More Releases for LiquiSonic®

Punch!® Software Releases Punch!CAD™ SharkCAD® & ViaCAD® 15

NOVATO, Calif., December 10, 2024 - Punch!® Software, a leading software developer of Home Design and CAD titles for over 25 years, today announced the release of new Windows and Mac versions of the SharkCAD® 15 and ViaCAD® 15 family of products.

This latest release encompasses a range of variants for the Windows and Macintosh platform: SharkCAD® Pro, SharkCAD®, ViaCAD® Pro, ViaCAD® 2D/3D, and ViaCAD® 2D.

Punch!CAD™ products continue to provide innovative…

Cherrywork® Accounts Payable Automation by Incture® Now Available on SAP® Sto …

Incture® today announced the availability of Cherrywork® Accounts Payable Automation for purchase on SAP® Store, the online marketplace for SAP and partner offerings. Cherrywork® Accounts Payable Automation is built on SAP Business Technology Platform (SAP BTP) to streamline end-to-end accounts payable operations, reduce accounting costs, and help increase cash flow for customers.

"Cherrywork Accounts Payable Automation is the hyperautomation solution to step up the source to pay process for our customers.…

Ultimate Chemicals® Featured in Manufacturing Marvels® on The Fox Business Net …

MOORE, OK., Oct. 8, 2021/ -- Ultimate Chemicals® Inc., an integrated manufacturer and supplier of chemicals and related services, is pleased to announce it will be showcased in a broadcast of Manufacturing Marvels® scheduled to air on October 14, 2021 at approximately 9:30-9:44 p.m. EST on The Fox Business Network® (FBN).

Ultimate Chemicals has created their products to help restore surfaces to their optimum surface capability. Non-destructive to the surfaces to…

Sunera Technologies, Inc Joins SAP® PartnerEdge® Delivering SAP® S/4HANA

Sunera Technologies, Inc Joins SAP® PartnerEdge® Delivering SAP® S/4HANA and Intelligent Enterprise to Manufacturing, Consumer Products, Higher education, and research, Industrial machinery and components, Life sciences and Automotive Industries

Chicago, IL, June 10, 2020 – Sunera Technologies, Inc announced that it had joined the SAP® PartnerEdge® program as a Re-sell & Services partner, through which it will resell SAP solutions to midsize organizations in North America. Through this engagement, SuneraTech…

GRAMMY® Performers Receiving AnthroSpa Logic® Announced

CHICAGO, IL- February, 2011- The Performers at the 53rd Annual GRAMMY® Awards, who will receive AnthroSpa Logic®, a luxury, 100% natural spa skin care and body care line inspired by the science of anthropology have been announced. The unique skin care line combines beauty secrets from around world and will be included in the in the Official VIP “Gift Bag” for the event, which takes place on Feb. 13,…

American Megatrends Announces AMIBIOS®8 & Aptio®4.x Support for the Intel® Xe …

ATLANTA, GEORGIA - American Megatrends (AMI) is pleased to announce that its AMIBIOS®8 & Aptio®4.x products feature support for the new Intel® Xeon® 5500 Platform.

The Intel® Xeon® 5500 platform combines the Intel® Xeon® Processor 5500 Series with the Intel® 5520 Chipset for embedded, storage, security and communications infrastructure applications in a wide range of form factors. There are four different processor options for this platform with seven year lifecycle support…