Press release

Swedish postal service uses VITRONIC technology: Offline videocoding shortens parcel delivery times

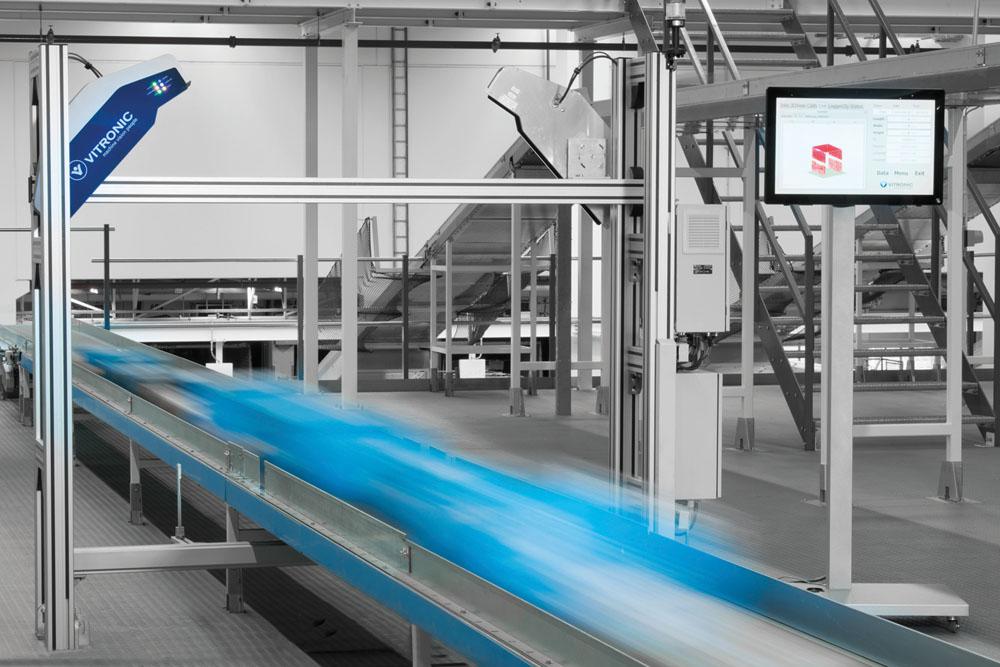

VITRONIC, a leading provider of optical identification systems for the enhancement of logistical processes, has been contracted with equipping the Swedish postal service with offline videocoding. At the sixth location, competitor systems will additionally be replaced with state of the art VITRONIC technology. This means that all of the distribution centers in the Swedish postal system are equipped with VIPAC systems which read barcodes fully automatically on three parcel sides.The Swedish postal system has contracted VITRONIC with equipping 59 work stations in six distribution centers with offline videocoding, meaning that the Swedish postal service can shorten parcel delivery times. To date, parcels are delivered to regional post offices from the six distribution centers. Here, employees take down the recipient addresses manually before prompting them to pick up their goods by sending them a postcard. Offline videocoding makes this procedure automatic: in future, in each of the six distribution centers, the complete address information of the recipient will be registered after sorting using photographic images. While the parcels are transported to local depots by truck, the Swedish postal service informs the end customer of the planned arrival of the parcel. This means that delivery is quicker and more efficient.

Together with videocoding, VIPAC achieves an identification rate of almost 100 per cent. Parcels which cannot be read by machine, or incompletely identified addresses, are transferred via a rapid network to videocoding work stations. An image is sent to an available work station, where trained personnel then supplement the information online or offline. Online videocoding means that the information is immediately entered in a defined space of time, and made ready for sorting and further processing. With offline videocoding, the personnel supplement this information downstream, which isn’t required for sorting, but for delivery. Information can also be transferred for videocoding to central processing points for several distribution centers.

About Vitronic:

Since 1984, Vitronic Dr.-Ing. Stein Bildverarbeitungssysteme GmbH in Wiesbaden, Germany, has produced industrial machine vision systems. Vitronic's solutions are all designed, developed, produced and marketed in-house. This approach enables Vitronic’s customers to obtain turn-key systems, including both hardware and software, from one source. Our customers in the fields of material flow, parcel logistics, warehousing and mail-order companies have a growing need to optimize their logistic processes. The basis for this is automated data collection relating to products, parcels, and customers. This also includes identifying addresses (OCR), bar codes, 2-D codes, and customer-specific codes as well as the online measurement of the volume and weight of a consignment. Using this information it is possible to effectively optimize internal sorting, storage, distribution and even revenue recovery processes.

For further information:

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

65189 Wiesbaden

Germany

Phone: +49-(0)611-7152-0

Fax: +49-(0)611-7152-133

Contact: Lucas Goebel

www.vitronic.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Swedish postal service uses VITRONIC technology: Offline videocoding shortens parcel delivery times here

News-ID: 20175 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

More Releases for VIPAC

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automated parcel capture at UPS

VITRONIC Auto-ID systems increase the package sorting capacity of UPS at Cologne/Bonn Airport

Wiesbaden / Cologne-Bonn, 24th May 2012 – The machine vision experts VITRONIC are glad to announce a large order from UPS. At Cologne/Bonn Airport, 200 VICAMssi2 high-performance line scan cameras will capture parcels and envelopes for efficient sortation.

The background to this large order is the planned increase of the sortation capacity at this UPS site from 110.000 to…

Review: VITRONIC at CeMAT exhibition 2011: Camera systems for data acquisition i …

Wiesbaden, 12th May 2011 – VITRONIC presented camera-based Auto-ID systems at this year’s CeMAT in Hannover from 2nd to 6th May. These camera systems outmatch conventional laser scanners regarding the acquisition of customer- and object based data of goods in intralogistics.

VIPAC systems for manual, semi-automatic and fully automatic data acquisition have been presented at the booth. These systems acquire data along the entire process chain in intralogistics, i.e. in incoming…

Vitronic Helps DHL Operate at Shutter Speed

Vitronic has supplied camera-based parcel recognition technology to DHL's distribution hubs in Madrid, Barcelona and Vitoria. It speeds up parcel sorting, ensures customers receive deliveries in a timely fashion and cuts costs. Vitronic's Spanish partner, Lyl Ingeneria, handled the project.

Part of the world's leading logistics group, Deutsche Post, DHL offers integrated services and tailored, customer-focused solutions for managing and transporting letters, goods and information. It operates all over the world…

Vitronic Helps Interlink Express Reduce CO² Emissions

Vitronic has supplied five VIPAC D2 volume-measuring units to Interlink Express. Used in the company’s Smethwick distribution centre, they allow operators to optimise valuable transport space in vehicles. This means Interlink Express can plan delivery routes efficiently, keeping costs and CO² emissions to a minimum.

Interlink Express is one of the UK’s leading parcel carriers. It offers a range of domestic and international services, and primarily serves the SME sector. Interlink…

How to reduce costs for manual no-read processing?

The processing of no-reads within intralogistics costs significant amounts of money. A large percentage of no-reads could be avoided. Around 95 % of all no-reads are generated because the codes are fundamentally unreadable. Invalid or low quality printed codes are only one example of unreadable objects. Courier-, Express- and Postal Service Providers want to change this. In order to optimize the operational costs, analyses should show who is delivering invalid…