Press release

Optimized wafer sorting using belt conveyors

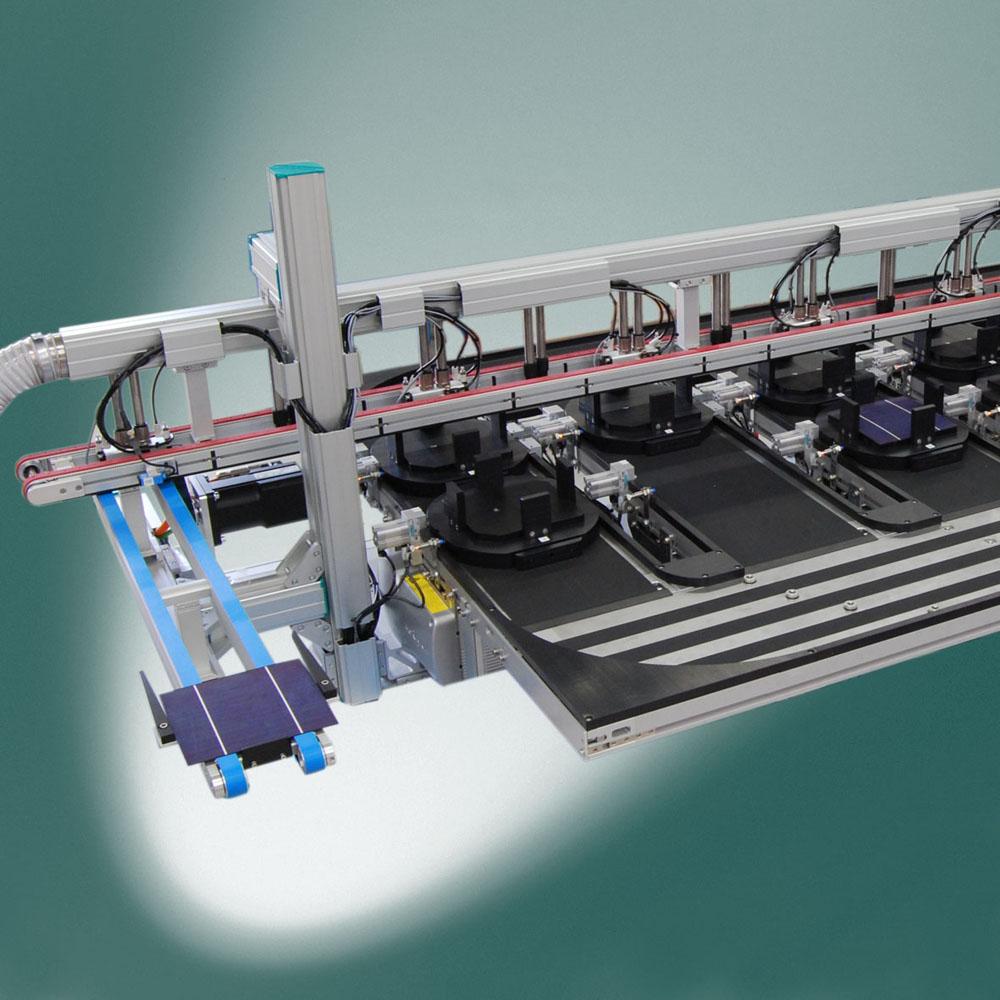

Using the modular belt conveyors by Montech, user can optimize wafer and cell sorting in the solar industry. A solar conveyor brings the wafers/cells, a vacuum conveyor transfers the wafers/cells to carriers or boxes after sorting, and finally, a closed-loop transfer system carries away the carriers or boxes. Montech exhibited this application for the first time at the European Photovolatic Solar Energy Conference and Exhibition 2011 in Hamburg, where it aroused the interest of many visitors.Unproductive return track eliminated

“It’s an endless working cycle, including picking, transport and placing operations, without unproductive return strokes, designed to optimize the sorting process,” explains Gianluca Aloisi, Sales Manager, Montech AG.

With the Vacuum conveyor running at 5 meters per second, the system can sort 4,000 wafers per hour, ensuring a significant productivity increase.

Dedicated handling of wafers and cells

Further benefits highlighted by Montech, compared to previous solutions with FlexPickers, include improved cost/performance ratio and softer wafer/cell handling. “As a specialist in this industry, Montech has shown we can develop and supply optimal solutions for the solar industry, offering innovative and creative systems based on standard components,” concludes Aloisi.

Montech AG markets basic modular components for the automation of demanding transport, assembly and production processes. In addition to conventional conveyor belts, the product range includes automation components and the Quick-Set profile system. A specialist in standard and customized transport and conveyor systems, Montech offers an ideal combination of customer-specific solutions with a high degree of standardization. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 (0)32 6815500

Fax: +41 (0)32 6821977

E-Mail: info@montech.com

www.montech.com

Presscontact:

Elke Manthei

Phone: +41 (0)32 6815542

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Optimized wafer sorting using belt conveyors here

News-ID: 194078 • Views: …

More Releases from Montech AG

New conveyors from Montech: efficient and user-friendly

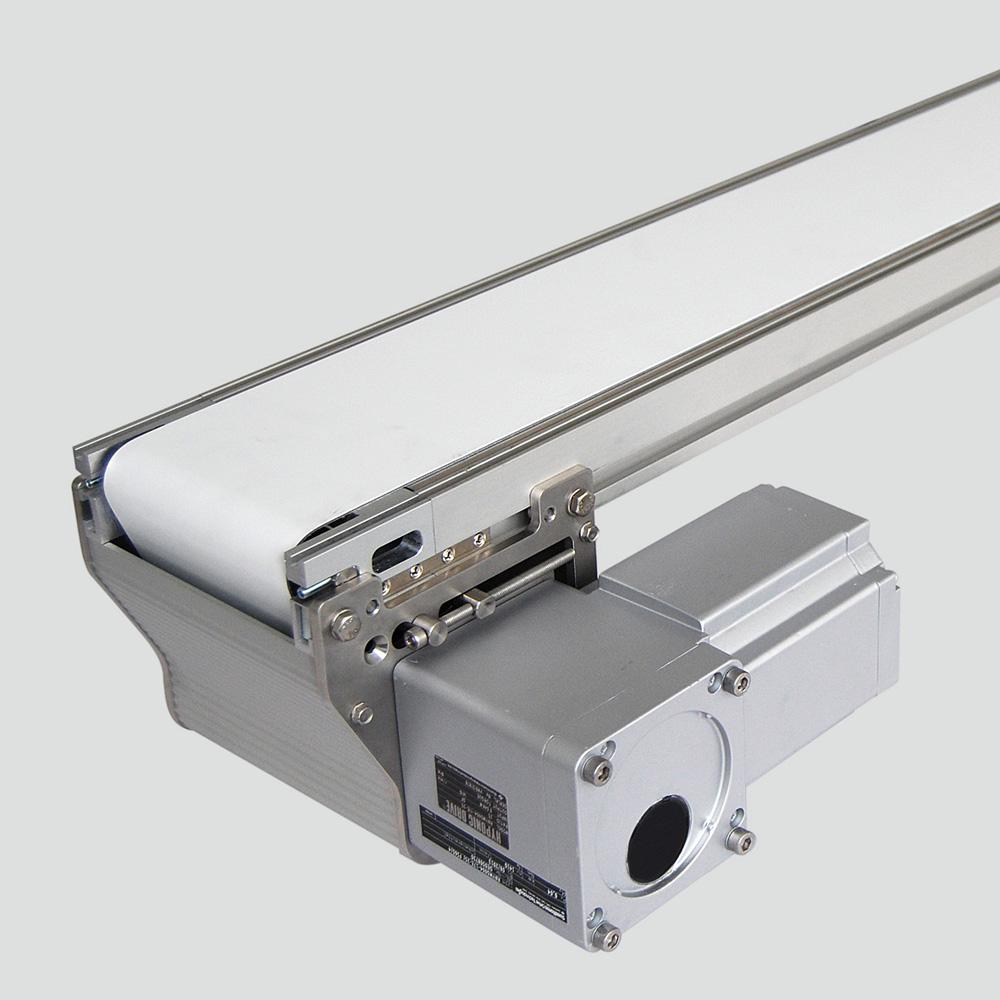

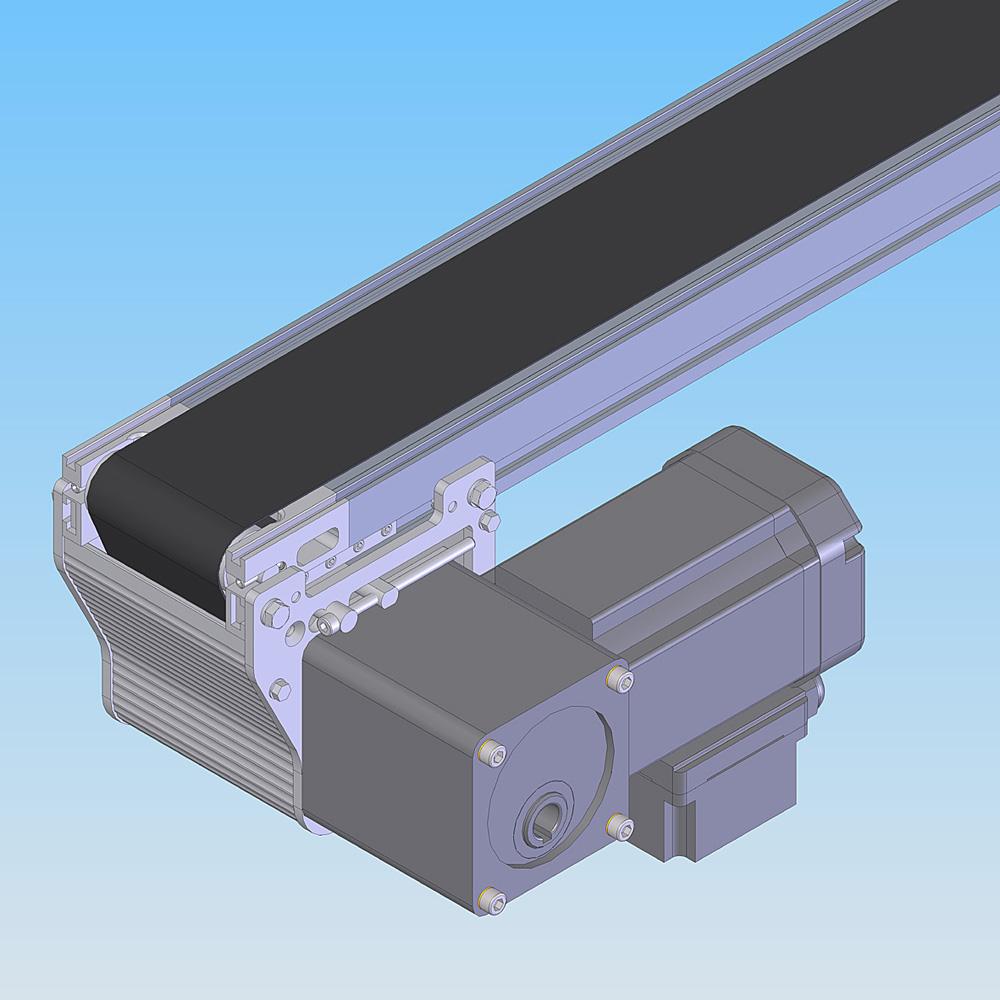

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

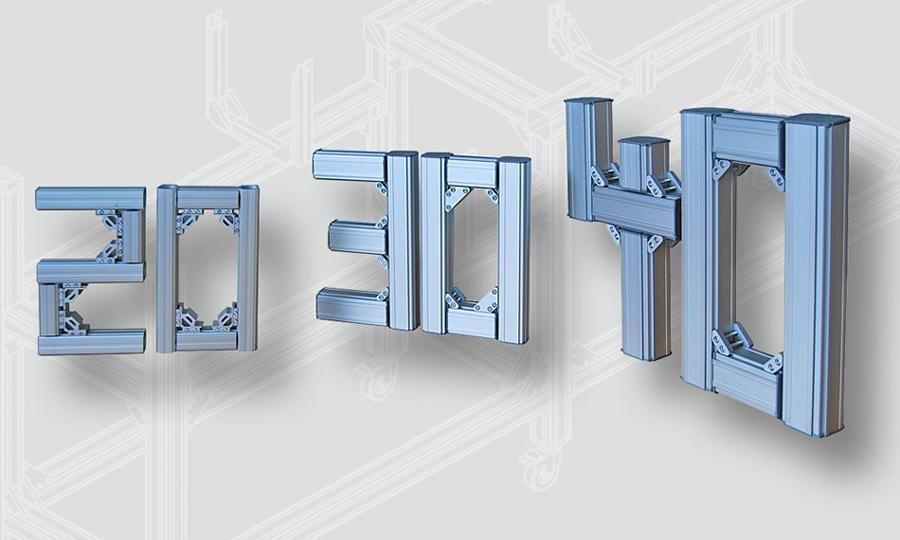

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech: new conveyors and LT40 transport system

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa,…

More Releases for Aloisi

Automatica 2012: Customized solutions from Montech

At Automatica in Munich, Montech AG (Booth 111 in Hall A2) is presenting customized solutions based on their portfolio of belt conveyors and automation components. Among several solutions, the Swiss manufacturer of transport systems is showing an application with a transfer system combined with a vacuum conveyor to carry and sort CDs: after sorting the vacuum conveyor transfers CDs, then a closed loop transfer system carries away the CD stack.

“It’s…

EU PVSEC 2011: New Solutions from Montech for photovoltaic industry

At the European Photovoltaic Solar Energy Exhibition (EU PVSEC) in Hamburg, Montech AG is displaying new solutions to sort and turn over wafers and cells.

Among other things, the Swiss company is presenting a new sorting system for wafers and cells, built with Montech's standard components. “It’s an endless working cycle, without unproductive return track, that optimizes the sorting process,” explains Gianluca Aloisi, Sales Manager, Montech AG.

Another innovation presented by the…

MEDTEC 2011: transport and handling solutions from Montech for the medical indus …

The Swiss belt conveyor specialist Montech AG is exhibiting at MEDTEC 2011 in Stuttgart, showing specific transport systems and handling components for the medical equipment sector.

At the Montech stand 6333 in Hall 6, visitors will find, among other things, the Vacuum conveyor, the cleanroom conveyor and specific handling components for the medical industry. “Our belts are manufactured with valuable materials that meet the sophisticated requirements of medical technology,” says Gianluca…

Automatica: Montech introduces new conveyor solutions

At Automatica 2010 in Munich, Montech is introducing a new multitrack conveyor. Other highlights include a special application of Montrac and the full range of belt conveyors, automation components and solar conveyors.

At Automatica and Intersolar, taking place concurrently in Munich, visitors at the Montech stand 318 in hall B1 will find consolidated solutions and the latest innovations for transport, handling and intralogistics from the Swiss company.

New: multitrack conveyor

To…

Montech at Photovoltaic Technology Show: new and proven conveyor and handling so …

At the Photovoltaic Technology Show 2010 in Stuttgart, the belt conveyor manufacturer Montech is introducing new and proven solutions to carry and handle wafers, cells, carriers and modules in the solar industry.

From 27 to 29 April 2010, the Photovoltaic Technology Show visitors will find the full range of Montech’s belt conveyors specifically designed for the solar industry, in Hall 4, Stand J22: solar conveyors, unloading conveyors, swiveling conveyors,…

Montech at LogiMAT 2010

The Swiss intralogistic specialist Montech AG is exhibiting at LogiMAT 2010, showing the Montrac transport system and its range of belt conveyors.

From 2 to 4 March 2010, at LogiMAT, Hall 1, Booth 407, Montech will show how many companies could optimize their intralogistic and increase efficiency by adopting the Montrac system. “The efficiency of operations in all company areas, especially intralogistics, is more and more critical,” said Gianluca Aloisi,…