Press release

Montech: new conveyors and LT40 transport system

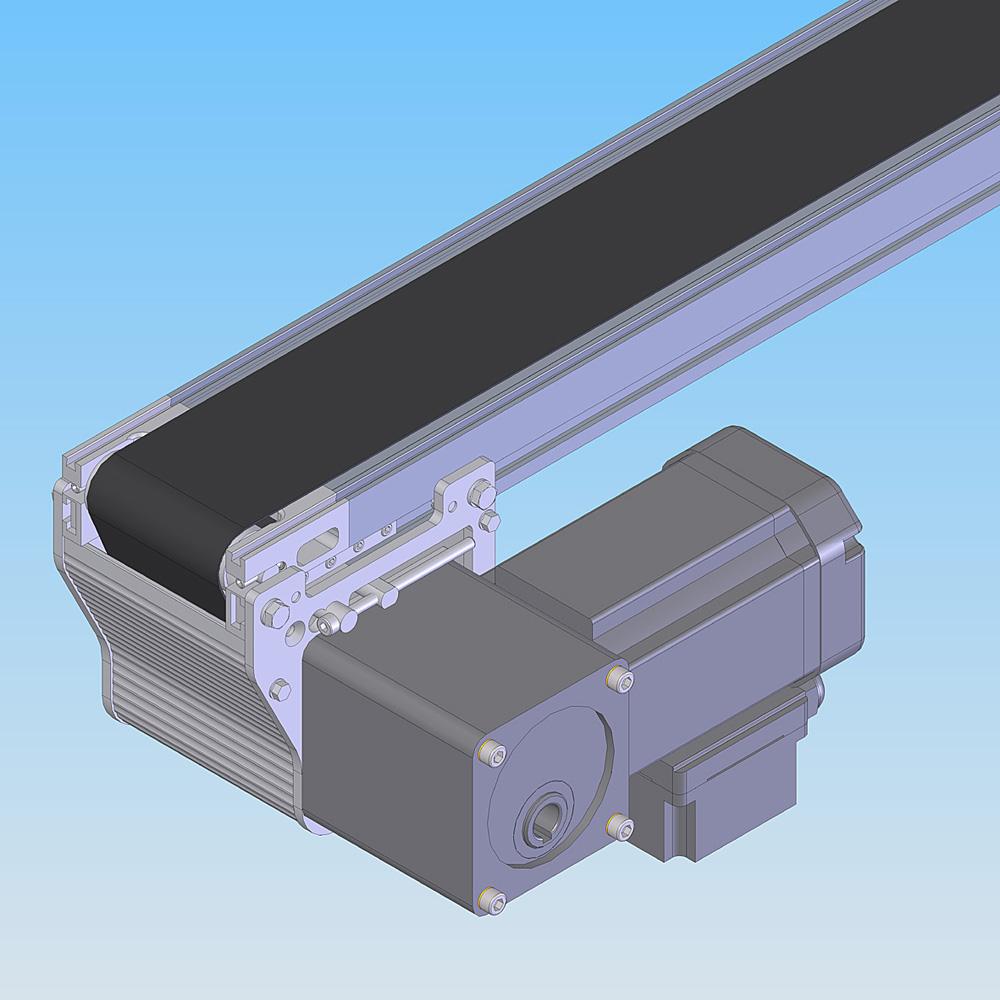

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa, without changing the belt. With the same chassis width, the belt has a wider useful surface; the belt can be easily replaced. The new conveyors offer several variations and combinations: 45 to 800 mm width, up to 10 meter length and several drive variants.

More user friendly and more efficient

“Compared to previous models, the new conveyors are more user-friendly through their flexibility and more efficient thanks to their drive,” said Gianluca Aloisi, Director Sales at Montech. In addition, they have an attractive pricing and Montech offers three-year warranty, excluding wear parts.

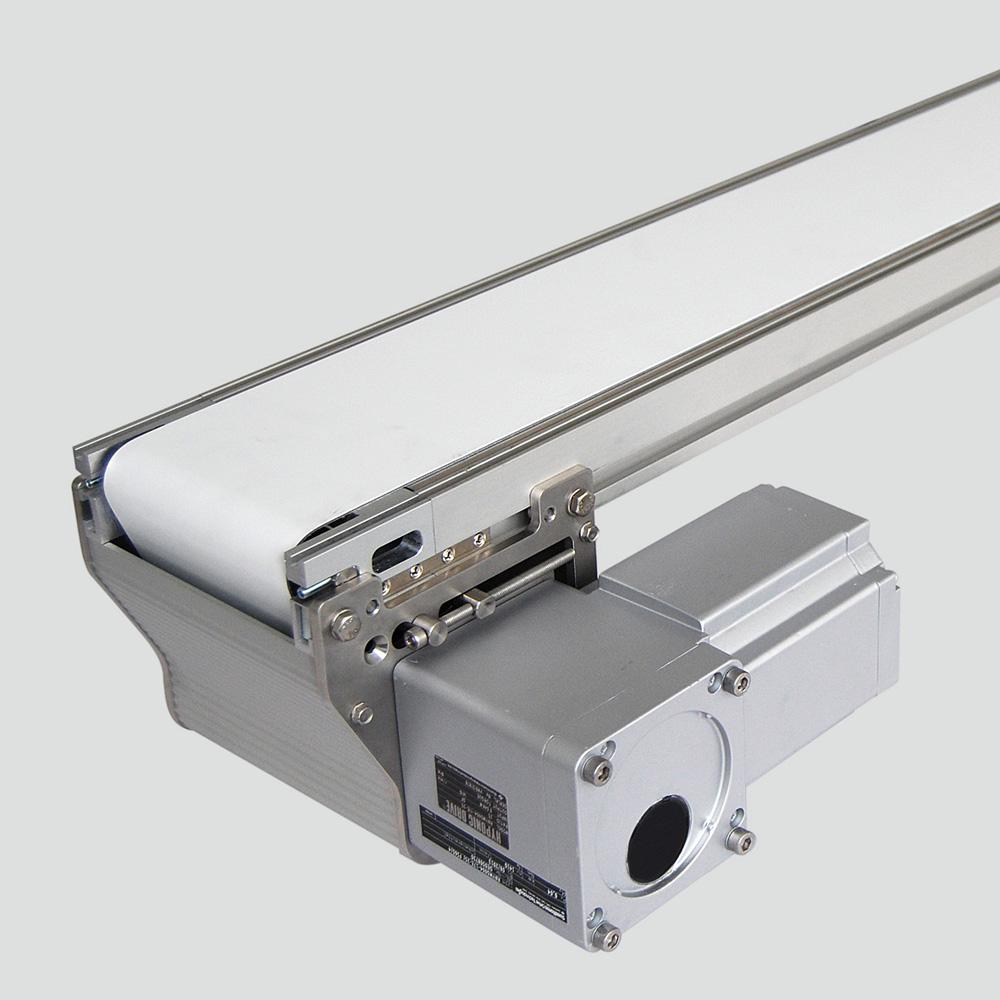

Transport system LT40

Montech is also exhibiting the transport system LT40 in a configuration including lifts, lateral transport, positioning and placing devices, lifting/turning unit. According to Aloisi, this will show the compact and easy concept for the transport of workpiece carriers with products.

LT40 is comprised of a double belt system, which carries individual workpiece holders at a speed up to 20 m/min. The workpiece holders have a load capacity of 16.8 kg and can be provided with RFID, so that they can be identified at any time.

The peculiarity of the transport system LT40 is the fully integrated and compact drive. The drive, with 60 mm diameter, is integrated in the shaft, with no protruding parts, and operates the LT40 conveyors almost noiselessly.

The drive is driven by a motor with stepless speed variation. The operator can adjust speed ramps and change the transport direction.

All components can be easily and quickly re-arranged thanks to the dovetail, normally without modifying the chassis.

Montech AG markets basic modular components for the automation of demanding transport, assembly and production processes. In addition to conventional conveyor belts, the product range includes automation components and the Quick-Set profile system. A specialist in standard and customized transport and conveyor systems, Montech offers an ideal combination of customer-specific solutions with a high degree of standardization. Founded in 1964, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 (0)32 6815500

Fax: +41 (0)32 6821977

E-Mail: info@montech.com

www.montech.com

Presscontact:

Montech AG

Elke Manthei

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 (0)32 6815542

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Montech: new conveyors and LT40 transport system here

News-ID: 270925 • Views: …

More Releases from Montech AG

New conveyors from Montech: efficient and user-friendly

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

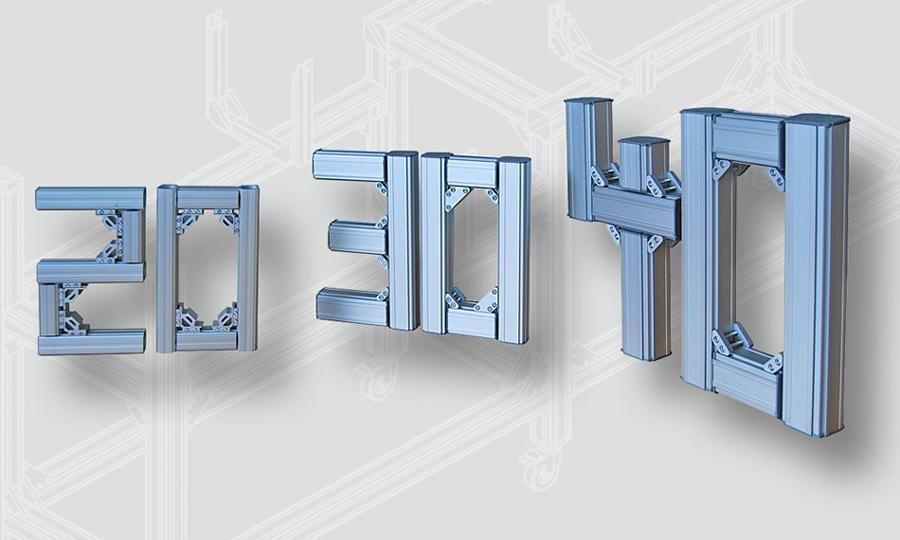

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

More Releases for LT40

Montech: New Transport System ready for sale

The transport system LT40 developed by Montech AG is ready for market launch. Its peculiar feature is the compact, fully integrated drive. The Swiss conveyor specialist offers three-year warranty on all components.

The peculiarity of the transport system LT40 is the fully integrated and compact drive. The drive, with 60 mm diameter, is integrated in the shaft, with no protruding parts, and operates the LT40 conveyors almost noiselessly.

The drive is driven…