Press release

Motek 2011: Custom transport and handling solutions with a modular concept

At Motek 2011 in Stuttgart, the Swiss company Montech is exhibiting its modular range of belt conveyors and automation components

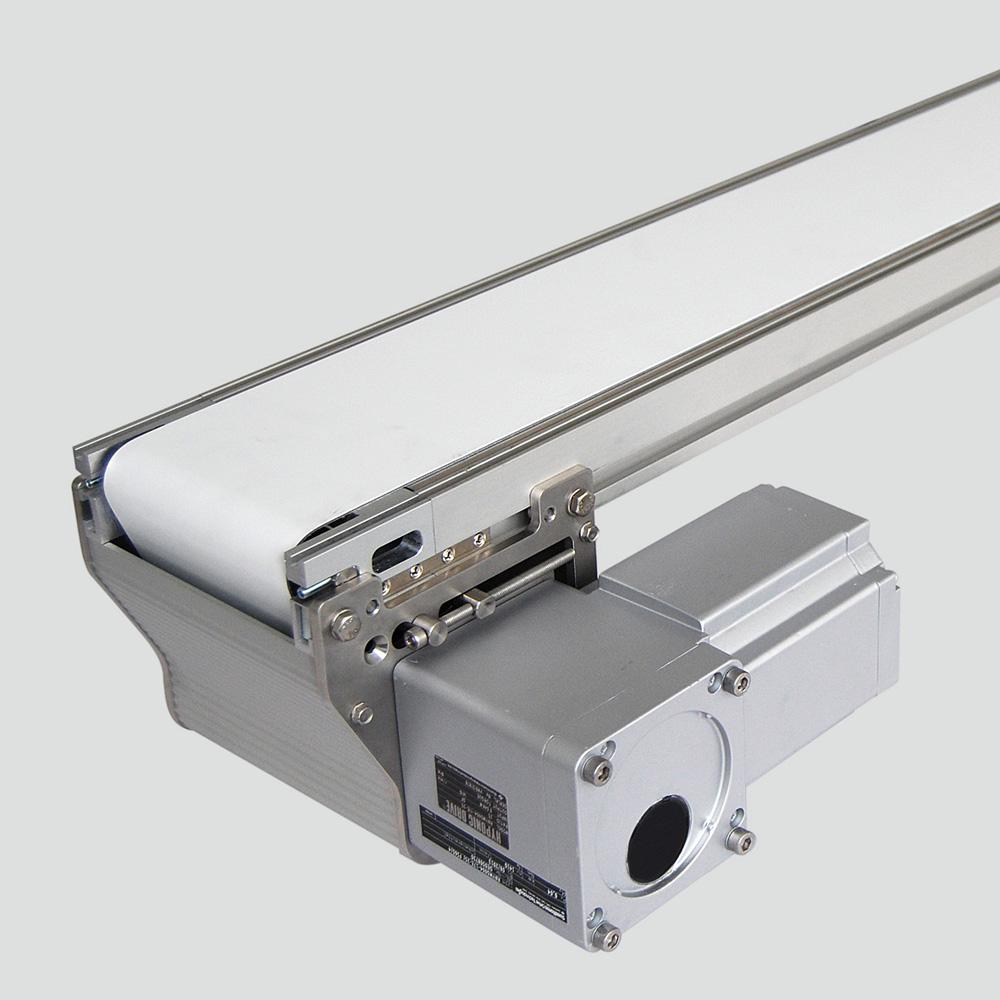

The Montech belt conveyors are based on a modular concept with ready-to-use components. Thanks to their modularity, the conveyors can be assembled in variable configurations, extended or shortened with a simple and cost-effective approach. “Thanks to their modularity, the conveyors can be adapted to the specific requirements of each customer and incorporated into complex plants or machinery,” says Gianluca Aloisi, Director Sales.

The Montech belt conveyors are particularly suitable for installations on production machinery in different industries and, for instance, find application in automated assembling systems, machine tools, production plants, automatic lathes and packaging equipment.

Vacuum conveyor: unproductive return track eliminated

The Vacuum conveyor allows to convey lightweight and flat packages at high speed. Compared to conventional belts, this conveyor offers a more dynamic acceleration and braking curve, combined with higher transport speed up to 5 meters per second.

Aloisi: “Conventional handling solutions require an unproductive return track. Montech’s Vacuum conveyor has no return and therefore helps increase productivity in the factory." Compared to other systems, this solution offers higher cost efficiency and is characterized by a modular construction.

Multitrack conveyor

To carry parts up to 120 kg, Montech will show a multitrack conveyor with belts or toothed belts at Motek 2011. The conveyor is available with three different drives with spur gear motor. According to the selected drive, there are different options for acceleration, delay, belt speed and positioning. The smooth and delicate handling of parts is guaranteed by accurate acceleration and braking curves.

ISO 5 Class conveyor for cleanrooms

The cleanroom conveyor with ISO 5 certification from the Fraunhofer Institute opens up new applications in unattended rooms. The conveyor can run at five different speeds and, optionally, it is available in single- and dual-belt versions. The cleanroom conveyor is available with drives installed at the end or in the middle, and frame widths between 45 and 250 mm; they can carry loads up to 40 kg.

Flexible automation components

At Motek, Montech will also showcase the range of modular high-precision components for assembly automation. Great flexibility is guaranteed by the availability of pneumatic and electric components: grippers, rotary drives, compact universal slides, linear units, portal slides, lifting units and Servoline.

Montech AG markets basic modular components for the automation of demanding transport, assembly and production processes. In addition to conventional conveyor belts, the product range includes automation components and the Quick-Set profile system. A specialist in standard and customized transport and conveyor systems, Montech offers an ideal combination of customer-specific solutions with a high degree of standardization. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Tel.: +41 (0)32 6815500

Fax: +41 (0)32 6821977

E-Mail: info@montech.com

www.montech.com

Presscontact:

Elke Manthei

Phone: +41 (0)32 6815542

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Motek 2011: Custom transport and handling solutions with a modular concept here

News-ID: 189642 • Views: …

More Releases from Montech AG

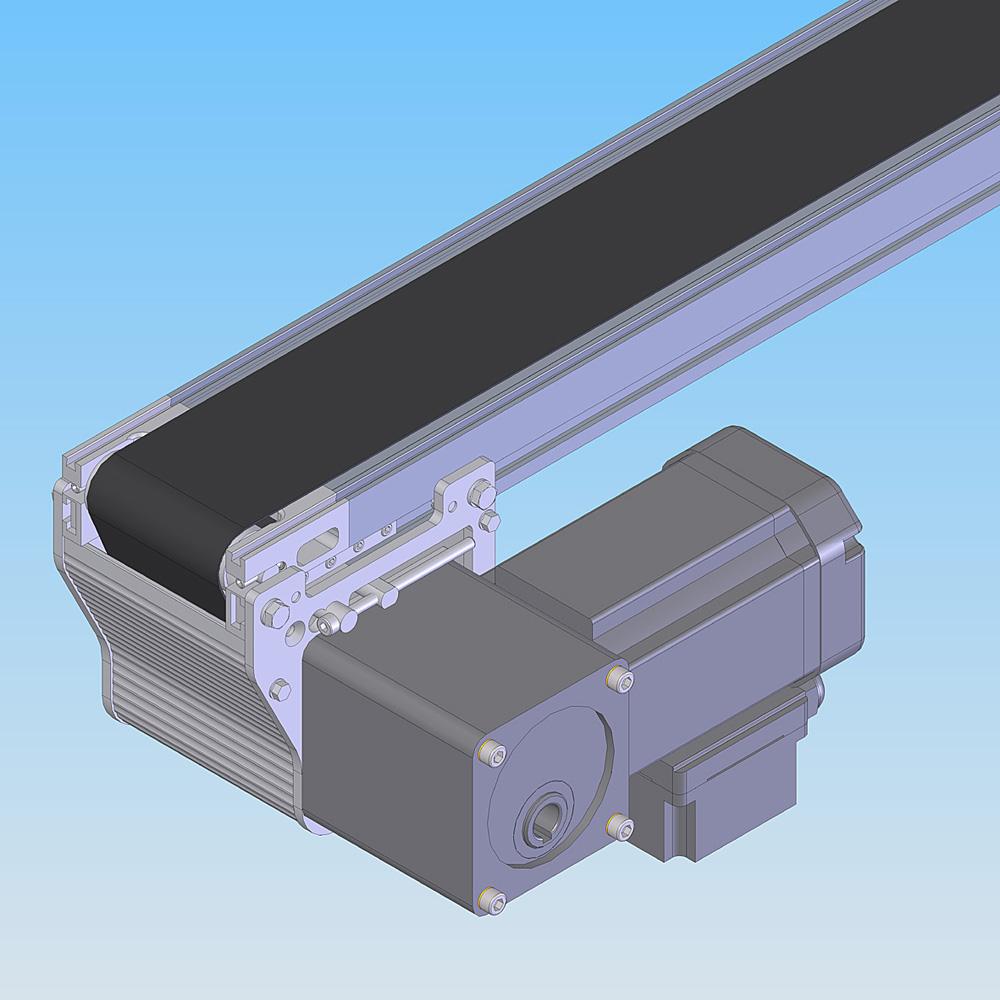

New conveyors from Montech: efficient and user-friendly

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

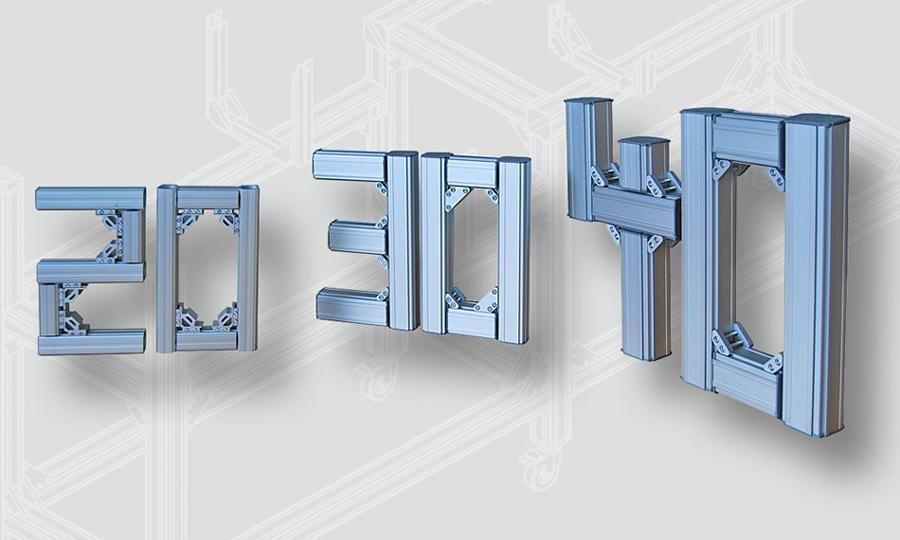

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech: new conveyors and LT40 transport system

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa,…

More Releases for Motek

Global Gait Rehabilitation System Market 2020 Growth Factors - Zebris Medical, P …

Global Gait Rehabilitation System Market 2020 by Manufacturers, Type and Application, Forecast to 2025 aims to define, describe, and analyse the market share, market competition landscape, SWOT analysis, and development plans in the next few years. The report studies and analyses market size (value & volume) by company, key regions/countries, products and application, history data from 2015 to 2019, and forecast to 2025. The report explains the structure of the…

Global Virtual Rehabilitation and Telerehabilitation Systems Market 2017 - Gestu …

The 'Global Virtual Rehabilitation and Telerehabilitation Systems Industry, 2017-2022 Market Research Report' is the detailed comprehensive analysis of the current state of the global Virtual Rehabilitation and Telerehabilitation Systems industry with a focus on the Chinese market. The report provides deep knowledge of historical information, forecasts, company profiles, technologies, market drivers, market trends and related parameters within the Virtual Rehabilitation and Telerehabilitation Systems Industry. The report includes accurate and sharp…

High-speed screwing system from Engmatec at the Motek

Radolfzell, Germany, 02.09.2014

At this year’s Motek trade fair to be held from 6-9 October 2014 in Stuttgart, Mitsubishi Electric together with Engmatec GmbH will be presenting a high-speed screwing station for inline operation as part of an assembly line. Within the system, a Mitsubishi Electric dual-arm SCARA robot from the RP series performs the handling and tightening of the screws using a vacuum suction unit. The compact system can handle…

Motek 2010: Montech presents a wide range of transport and handling solutions

At Motek, the visitors of Montech’s stand 1170 in hall 1 will find a peculiar and special application of the Montrac system: sitting on their bar stools, the guests will be able to order their favorite drink via touch panel, and have it served to their place by Montrac. This application shows the efficiency and suitability of Montrac for the smooth transport of items and the direct control of destination…

Motek 2009: Montech presented solutions for the future

At Motek 2009 in Stuttgart, Montech introduced the latest innovations for the Montrac transport system, belt conveyors and automation components. At the Montech stand, visitors showed great interest for the heavy-load shuttle, the new generation of shuttles and the new Basic belt conveyor. “High attendance at the stand and the tangible interest of visitors prove that Montech feels the pulse of the market and provides future-ready solutions,” said Alessandro Sibilia,…

Montech: news and proven solutions at Motek 2009

At Motek 2009 in Stuttgart, Montech is introducing a new generation of shuttles and a heavy-load version, the new TB conveyor family, the Basic belt conveyors and the full range of automation components.

The new-generation shuttles are specifically designed for large-scale intralogistic projects. The shuttles can travel up to 60 m/min and carry heavy weights, while so far speeds up to 30 m/min and loads up to 28 kg were possible.…