Press release

Montech: news and proven solutions at Motek 2009

At Motek 2009 in Stuttgart, Montech is introducing a new generation of shuttles and a heavy-load version, the new TB conveyor family, the Basic belt conveyors and the full range of automation components.The new-generation shuttles are specifically designed for large-scale intralogistic projects. The shuttles can travel up to 60 m/min and carry heavy weights, while so far speeds up to 30 m/min and loads up to 28 kg were possible.

The shuttle is equipped with a powerful processor like the previous models, with the additional option of wireless communication. “The transfer of large data volumes and direct communications to other systems are no longer a problem, and the RFID interface is even more efficient,” says Yves Dicke, Montrac Division Manager of Montech.

Shuttle for heavy loads

For loads up to 80 kg, a so-called heavy-weight shuttle has been developed and will be exhibited at Motek. The new shuttle has reinforced carriage and profiles and runs at controlled speed. For higher loads, Montech has created a trailer for the shuttle, while weights up to 50 kg can be carried directly on the shuttle. “Thanks to the monorail, also the version for heavy loads ensures maximum accuracy and efficient application,” adds Dicke.

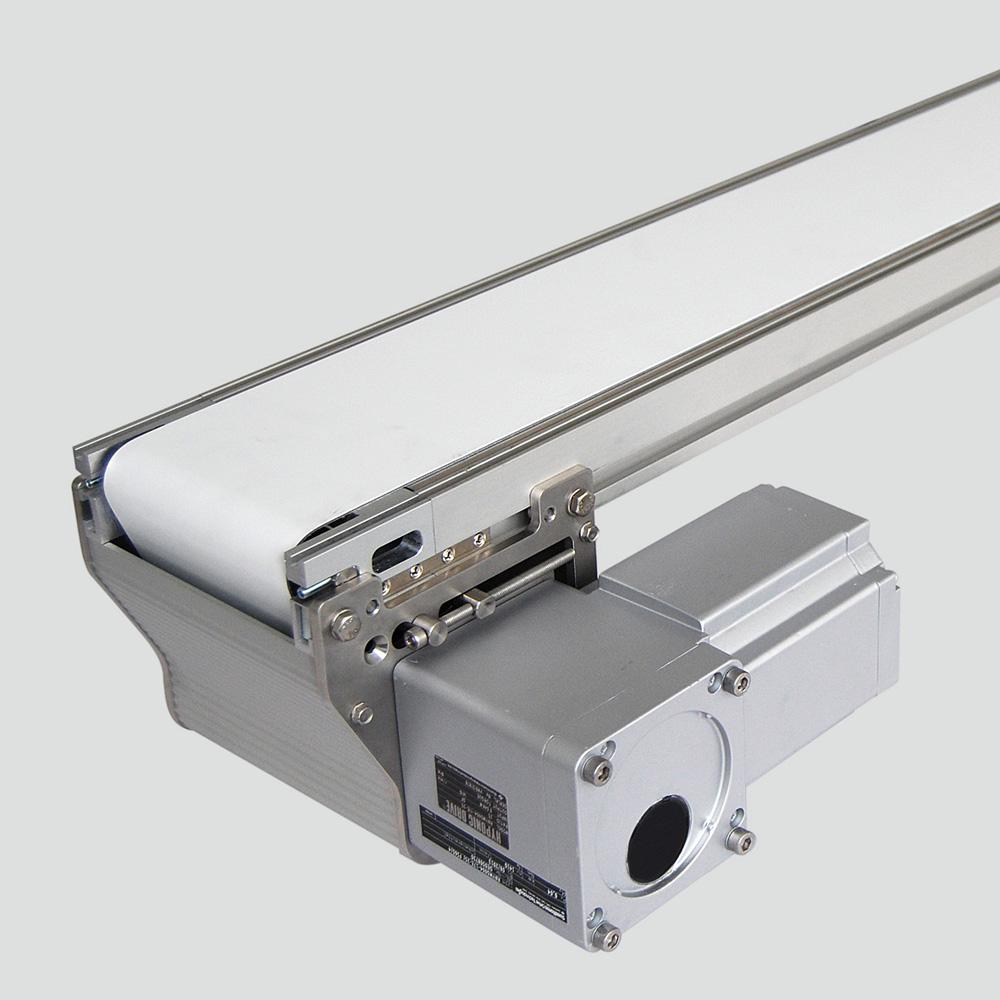

New belt conveyors, more stable and sturdy

In the TB belt conveyors, the covers of chains and pinions, so far made of plastic, have been replaced with a new aluminum cover. The drive rollers are protected by a rear cover that prevents the penetration of dirt and dust. “The new TB series of belt conveyors is more stable and sturdy”, says Gianluca Aloisi, Conveyors Division Manager, Montech. Also accessing the conveyors for maintenance operations is easier and more efficient, thanks to the reduction of locking screws and the use of quick closures. Another enhancement is the sliding sheet metal plate that can be simply pushed downwards. This avoids dirt and particles falling off the belt and reaching into the conveyor.

Six different frame widths

The TB belt conveyors are available with six frame widths, from 60 to 250 mm, and can be ordered with single or double belt. The drive unit can be installed horizontally or vertically, in any position along the entire free length of the frame. The 230/400V motor allows to reach belt speeds from 0.6 to 38.4 m/min. According to the application, the TB belt can carry weights above 100 kg.

Basic belt conveyor

Latest news from Montech includes the Basic model added to the range of belt conveyors. These new belts have limited functionality, for instance only four speeds can be set. The Basic conveyors are available with drives installed at the end or in the middle, and frame widths between 45 and 800 mm. “The Basic belts are like high-end cars without options like heated seats, navigator or sunroof,” says Aloisi. With this product, according to Aloisi, Montech delivers high-quality belt conveyors in the lower price range.

Automation components, high flexibility

Users can achieve high flexibility with the electrified automation components: grippers, rotary drives, universal compact slides and Servoline. In electric grippers, the gripping strength and speed can be adjusted independently. The electrically operated rotary drive DAE-60 can move into different positions (up to 31 programmable positions), traveling at different speeds between one position and another. All electrified handling components can be driven by the same regulation device. The preset settings of the regulation device provide for very easy and quick commissioning. In addition, the digital I/Os allow very easy control.

In the stand No. 1170 in Hall 1, over a 180-square-meter surface, Montech will exhibit the latest news, the full range of belt conveyors and most automation components.

Montech AG markets basic modular components that automate demanding production and logistics processes. In addition to conventional conveyor belts, automation components and the Quick-Set profile system, the range of products also includes the Montrac transport system. Montrac is an intelligent transport system for networking industrial production and logistics processes. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 (0)32 6815500

Fax: +41 (0)32 6821977

www.montech.com

E-Mail: info@montech.com

Presscontact:

Elke Manthei

Phone: +41 (0)32 6815542

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Montech: news and proven solutions at Motek 2009 here

News-ID: 90843 • Views: …

More Releases from Montech AG

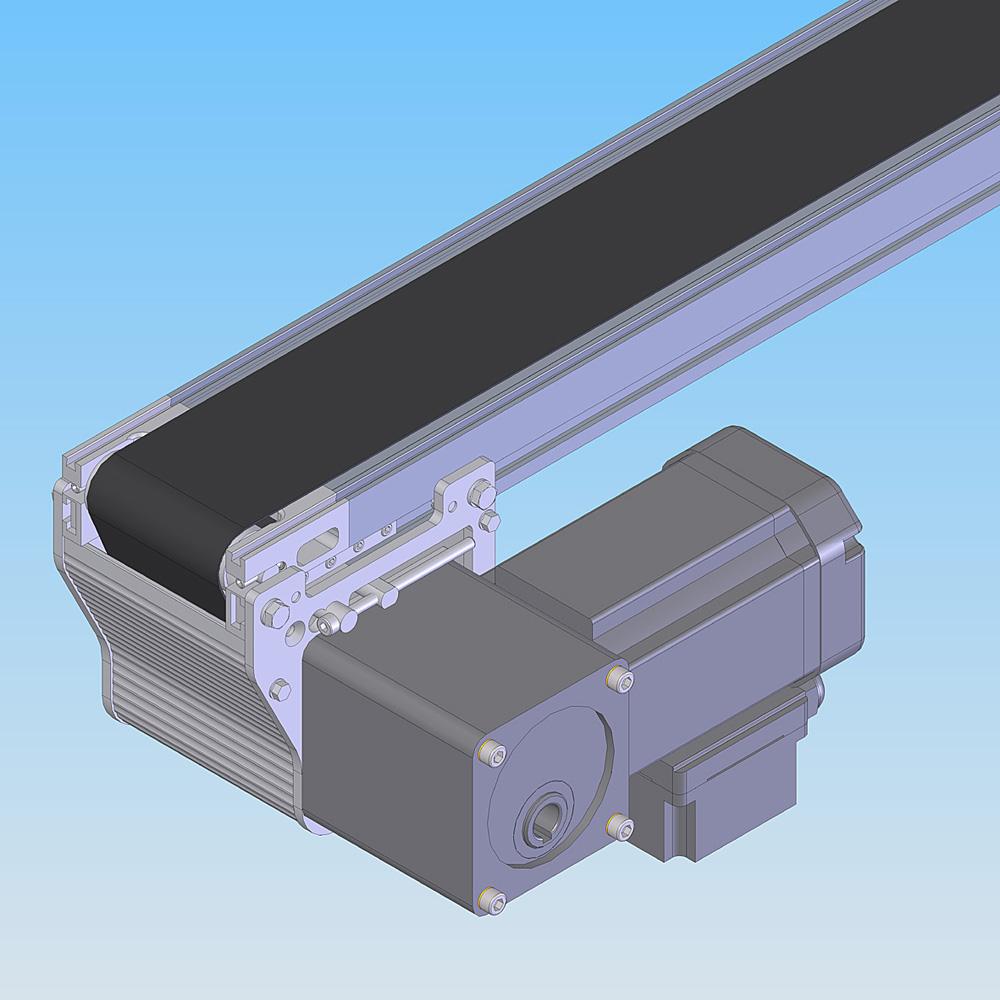

New conveyors from Montech: efficient and user-friendly

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

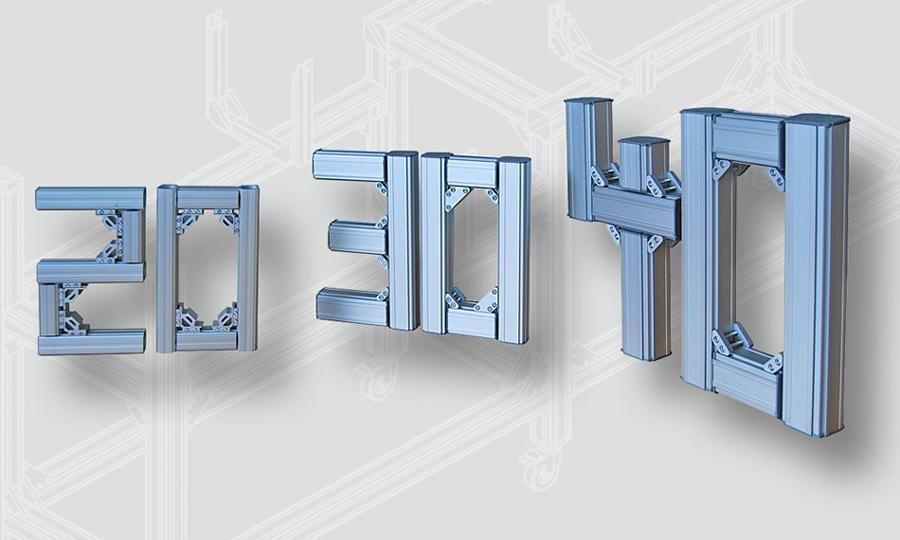

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech: new conveyors and LT40 transport system

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa,…

More Releases for Basic

Basic Makeup Tips and Skin Types

Cosmetics (also called makeup, make up, or make-up) are products used to make the human body look different. Often cosmetics are used to make someone more attractive to one person, or to a culture or sub-culture. In Western culture, women are the main users of cosmetics.

Skin types for Makeup

makeup for dry skin

The skin which remains dry in summer and monsoon season, it is natural for it to become drier in…

The Basic Information About Orlistat

According to statistics from the World Health Organization (WHO), nearly 2 billion people are overweight or obese worldwide. Every year, overweight or obesity causes 2.8 million deaths.

What 's Orlistat ?

Orlistat is a lipase inhibitor used in the treatment of obesity that works by inhibiting fat-metabolizing enzymes. It was originally approved by the FDA in 1999 as the prescription drug Exenical, was approved in 2007 as the over-the-counter…

Basic Notions about Motorcycle Luggage

Before going for the motorcycle trip, you have to know how to choose very well what accessories we will add to the motorcycle to maintain the weight balance. But it is also important to know what to buy and whatnot.

All in order

If your goal is to go on a long trip with your motorcycle, the first thing to consider is how you are going to distribute the weight. As for…

Basic Understanding Of Rhinoplasty

This surgery is performed under general or local anesthesia, but mostly done on an outpatient basis or sometimes 1 day night stay is required in the surgery centre. An incision is made inside the nose in such a way that it is visible during surgery to access the cartilage and bones that’s supports the nose. To get the desired look, either some tissue is added or some bones and cartilages…

Basic planning for a better project

MACS Software is a leading provider of warehouse management software in the UK. Every project it undertakes has challenges along the way … they are inevitable. But by planning well it is possible for warehouse operators to smooth the way towards a successful outcome. Here, Richard Miller, Implementation Director for MACS Software explains the importance of the basics.

Getting the brief right

A bad brief usually means a bad…

Basic PCT Formalities Course

The german Forum Institute for Management expandes continuously all over Europe. Its prosperous seminar \"Basic PCT Formalities Course\" ist now also arranged in Athens.

The purpose of this seminar is to inform the participants how to prepare an international application for filing under the PCT and subsequently monitor the consecutive procedural steps, time-limits and payment of fees in the PCT international phase up to and including entry into the national…