Press release

Compact camera reads barcodes and 2D codes

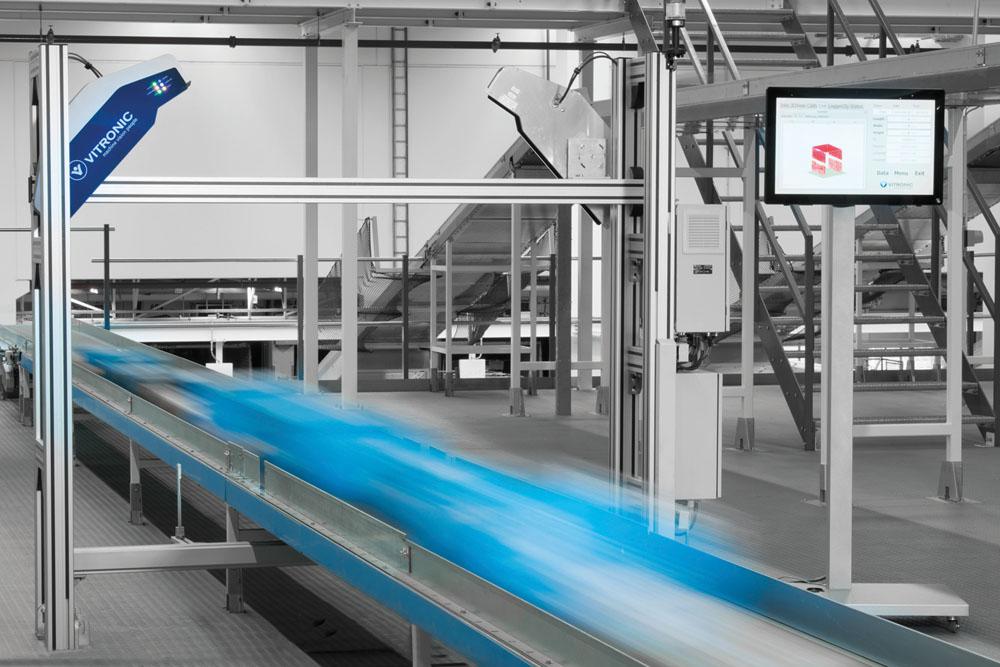

Handling and data acquisition in a single movementRecording barcodes as well as 2D codes and, at the same time, handling goods with both hands: the compact camera VICAMsnap! from VITRONIC makes it possible. VICAMsnap! is installed above the workstation and reads codes while the goods are continuously processed. Reading with the VICAMsnap! saves time, additional materials handling and increases the productivity of the employees.

No matter if the goods are being sorted, picked or stored: The compact camera VICAMsnap! reads barcodes fully automatically and provides images for archiving. The operator can move the goods below the camera even with high speeds. The reading field has a width of 30 cm, a depth of 30 cm and a height of 38 cm. This means, the operator has both hands free for handling the goods. The reading takes place continuously and fully automatically; manual triggering is no longer required.

Each second that can be saved with the VICAMsnap! for data acquisition increases the productivity of the employees. This, in turn, results in saving potentials with respect to reading stations and additional materials handling. Thus, the camera amortizes within a very short time.

The compact camera VICAMsnap! consists of a high-performance camera, white, long-term LED illumination, aiming device, loudspeaker, status display and an integrated decoder unit. This lightweight system can be easily and rapidly installed and put into operation by the user. The reading results are displayed and output via an interface. The operator can receive an optical or acoustic instruction (Pick-by-voice/Sort-by-voice). And finally, the image is output via an interface.

VITRONIC Machine Vision Ltd, a subsidiary of VITRONIC GmbH in Germany, is located in Louisville, KY. VITRONIC are interna-tional leaders in the packaging vision technology market. VI-TRONIC specializes in providing advanced technological solutions to a broad range of markets, such as logistics, traffic technology, and industrial automation. Its products incorporate the latest in machine vision equipment and software to resolve a wide range of issues. In a busy warehouse or post depot, maintaining control of what parcels are going in and out is essential, VIPAC is VITRONIC’s answer. It comprises a system that utilizes extensive image processing, to provide a state-of-the-art solution for multi-sided object identification. Offering a unrivaled read rate and much faster than conventional technologies, it makes parcel tracking easy.

Birgit Löschner

Phone +49 (0)611 – 7152 - 261

Birgit.loeschner@vitronic.com

www.vitronic.com

VITRONIC Dr.-Ing. Stein

Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

65189 Wiesbaden

Phone: +49 (0)611 – 7152 - 0

Fax: +49 (0)611 – 7152 - 133

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Compact camera reads barcodes and 2D codes here

News-ID: 168201 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

More Releases for VICAMsnap!

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

Follow-up order for carton-, flat sorting

VITRONIC supplies over 2,000 Auto-ID camera systems to parcel and post customer

VITRONIC Machine Vision LTD is proud to announce it has been awarded a multi-million dollar contract to automate the manual processing of flats and small parcels from a large parcel and post customer.

Under the terms of the contract, VITRONIC Machine Vision LTD, will provide over 2,000 VICAMsnap! camera units to be deployed in early 2014 for their facilities…

Action! The compact multi-code reader VICAMsnap! on video

Action! The compact multi-code reader VITRONIC VICAMsnap! on video

Camera systems for capturing items within the scope of material flow management, ware-housing and parcel/post services in both the retail trade and the production industry help reduce throughput times, accel-erate business processes and lower costs. The latest VITRONIC video demonstrates countless opportunities for using the VICAMsnap! multi-code reader and highlights the system’s advantages.

VICAMsnap! is a camera-based data capture solution that combines a…

VITRONIC at Smart Conference and Expo 2013 in Australia

For efficient sorting, order picking and storage of goods, customer and object related data needs to be captured and processed. VITRONIC will present its camera-based identification systems for Parcel Logistics and Warehouse & Distribution companies at Australia’s leading supply chain event Smart Conference and Expo in Sydney: VICAMsnap! speeds up capture processes, increases productivity of employees and reduces the logistics cost per item.

Advantages for efficiency, productivity and cost-savings

The compact…

VITRONIC supplies over 1,000 Auto-ID systems to parcel and post customer

VITRONIC Machine Vision Ltd. is proud to announce it has been awarded a multi-million dollar contract to automate the manual processing of flats and small parcels from a large parcel and post customer.

Under the terms of the contract, VITRONIC Machine Vision Ltd. will provide over 1,000 VICAMsnap! camera units to be deployed in early 2013 for the customer’s facilities throughout the United States. The VITRONIC camera systems will provide scanning…

VITRONIC at ProMAT 2013

Camera systems speed up processes and reduce expenses for data capture of Parcel Logistics and Warehouse & Distribution

For efficient sorting, order picking and storing of goods, customer- and object-related data needs to be captured and processed. At the ProMAT tradeshow in Chicago, VITRONIC will be presenting state-of-the-art camera systems for Parcel Logistics and Warehouse & Distribution companies: VICAMsnap! and VICAMssi2 speed up capture processes, increase productivity of employees and reduce…