Press release

VITRONIC at ProMAT 2013

Camera systems speed up processes and reduce expenses for data capture of Parcel Logistics and Warehouse & DistributionFor efficient sorting, order picking and storing of goods, customer- and object-related data needs to be captured and processed. At the ProMAT tradeshow in Chicago, VITRONIC will be presenting state-of-the-art camera systems for Parcel Logistics and Warehouse & Distribution companies: VICAMsnap! and VICAMssi2 speed up capture processes, increase productivity of employees and reduce logistic expenses per item.

Advantages in efficiency, productivity and cost-saving

Both camera systems are most suitable for optimizing data capture processes in Parcel Logistics as well as Warehouse & Distribution, e.g. for handling of returns and inbound inspection, order picking, sorting and outbound inspection. As different code types on packages are read automatically, all capture processes are accelerated, cycle times are shortened and the logistic expenses per item are reduced.

Semi-automatic code reading with VICAMsnap!

VICAMsnap! matrix cameras are suitable for data capture during manual package handling, i.e. as part of incoming inspection. The camera is installed above the workstation. An operator manually moves the package through the large reading field. The codes and data are captured automatically and archived as images. This eliminates the need for additional, costly reading stations and conveyor technology.

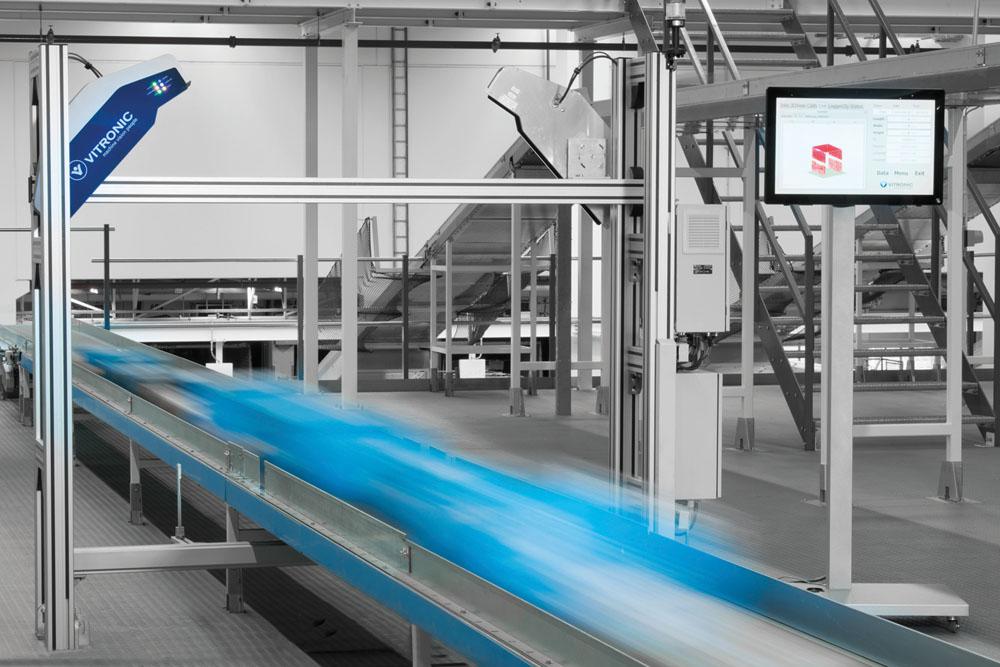

Automatic code reading with VICAMssi2

The VICAMssi2 auto-focus line-scan camera is the solution for automatic data capture. It provides highest read rates at fast conveyor speeds of up to 4,5 m/s. Besides barcodes and 2-D codes, plain text (OCR) is captured fully automatically. Furthermore, the camera reduces the energy consumption by 50% compared to cameras of other suppliers. VICAMssi2 is an in-house development of VITRONIC. The system is in the 7th generation of production and has been installed worldwide more than 5,000 times.

VITRONIC at ProMAT 2013

21 to 24 January 2013, McCormick Place, Chicago

Booth 4127

Since its foundation in 1984 in Wiesbaden, Germany, VITRONIC has stood for innovative machine vision systems for the manufacturing, traffic technology, and 3D scanning industries. VITRONIC’s highly qualified and motivated team of engineers develops high-end technical solutions for end users and OEM partners. With constant investment in research and development, VITRONIC is always a step ahead in the rapidly developing commercial and industrial imaging markets. Learn more at www.vitronic.com

VITRONIC Dr.-Ing. Stein

Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

D – 65189 Wiesbaden

Tel: +49 (0)611 – 7152 - 0

Fax: +49 (0)611 – 7152 - 133

Birgit Löschner

Tel: +49 (0)611 – 7152 - 261

birgit.loeschner@vitronic.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release VITRONIC at ProMAT 2013 here

News-ID: 246344 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

More Releases for VICAMssi2

VITRONIC at IMHX 2013

Optimized processes and greater efficiency with camera-based data capture and recognition of carton deformations at goods receipt

Wiesbaden, Germany, 24th January 2013 – VITRONIC will present its camera-based identification systems for use in distribution, contract and 3PL logistics at IMHX 2013 in Birmingham. With VICAM camera systems, packages are quickly and accurately identified at goods receipt, deformations on cartons are detected automatically, and the captured data is integrated seamlessly into ERP…

Automated parcel capture at UPS

VITRONIC Auto-ID systems increase the package sorting capacity of UPS at Cologne/Bonn Airport

Wiesbaden / Cologne-Bonn, 24th May 2012 – The machine vision experts VITRONIC are glad to announce a large order from UPS. At Cologne/Bonn Airport, 200 VICAMssi2 high-performance line scan cameras will capture parcels and envelopes for efficient sortation.

The background to this large order is the planned increase of the sortation capacity at this UPS site from 110.000 to…

VITRONIC at Post-Expo in Stuttgart 2011

Camera-based Auto-ID systems for highest read rates and more efficiency

Wiesbaden, 25th July 2011 – At Post-Expo in Stuttgart from 27th to 29th September 2011, VITRONIC will be presenting high-capacity camera-based systems for the identification of packages.

VITRONIC’s Auto-ID systems recognize, analyze and evaluate all relevant information from barcodes, 2-D codes and characters (OCR) - also many different code types in one image (multi-code reading). Furthermore, important additional information such as the…

Large Order from USPS: VITRONIC supplies 126 camera systems

VITRONIC Machine Vision Limited today announced that it was awarded a multimillion contract by The United States Postal Service ® (USPS) for 126 package sorter and overhead camera (PSOC) system kits for use in mail processing facilities.

Under terms of the agreement, VITRONIC will supply the USPS with 126 VICAMssi2 line-scan camera systems and mounting frames for use on a fleet of mail sorting equipment. This scanning solution will capture USPS…

Camera based identification technology speeds up intralogistics

The camera based identification system VIPAC provides even faster throughput of goods for intralogistical processes. Vitronic is introducing the latest generation of identification technology at CeMAT. For the first time this technology allows characters (optical character recognition - OCR) and barcodes to be read at speeds of up to 4.5 m/s. It also enables certified volumes to be measured over cross belt or tilt-tray sorters. That saves having a lot…

Identification in Logistics: New Line Scan Camera

The new VITRONIC camera generation, VICAMssi2, pushes the envelope of technology: it can be used at conveyor speeds of up to 4.5 m/s, it is smaller and lighter, easier to handle, install and service, and it requires less energy. The new VICAMssi2 is optimized for outstanding image quality at fastest conveyor speeds, resulting in highest barcode, 2-D code and OCR (optical character recognition) read rates. The camera unit consists of…