Press release

Plant Optimisation Saves Energy

Can the coating dry more quickly? Is it possible to reduce the rejection rate? Does the plant use too much energy? Many companies ask themselves questions like these. Energy and material costs are important considerations for industrial companies who wish to maintain or improve their competitiveness. At the same time, the optimisation of existing plant can often be the more sensible and cost-effective option over installing new plant. A newly established consulting team at Heraeus Noblelight now offers support through individual consultancy, practical planning and prompt implementation of measures to achieve optimisation of plant, equipment and processes.A drying oven is often the bottleneck in a production line. In order to increase production output, a convection oven can, for example, be extended – but this is not possible in every factory. It is more efficient to replace the hot air with infrared heating or to use a combination of the two technologies, which can generally lead to savings in space and energy. However, the best way is to examine the complete system. “Recently, we have carried out detailed investigations of their system technology for one of our customers using Time-Distance diagrams,” explains Joerg Woell from the new consulting division at Heraeus Noblelight. “In doing so, we could see immediately that a conversion of the drying process would make sense.” This showed that by using fast-acting carbon infrared emitters, with electronic linking to the conveyor system, there is an optimisation of the operating life and significant energy saving. Precise calculations showed that following the conversion only 460 kW of power was required compared with the previous 880 kW.

To carry out such calculations, the new Heraeus division also used modern numerical methods such as Ray Tracing and Computational Fluid Dynamic, in addition to the usual tests in the Application Centre and the information contained in the data banks built up over years.

Identifying and Implementing Optimisation Opportunities.

The new consulting team provides consultancy and advice, planning and implementation of economical energy efficiency measures. In accordance with VDI 3922, Heraeus investigates production plants for potential improvements, using a practical approach which is independent of equipment manufacturers. Tests have been carried out for many years to analyse heating processes in our in-house Application Centre and on site. Experimental data in our databases, built up over decades, has also been useful for first assessments. Now we have added modern numerical techniques. Ray Tracing and Computational Fluid Dynamics are very valuable methods, for example, for optimising the homogeneity of heating on surfaces or minimising edge zone losses.

The use of modern infrared technology together with defined process optimisation increases the degree of utilisation of the production plant. It is important to understand the heating process precisely so that infrared heat can be used “on demand”. For example, if emitters are switched on only when a product to be heated actually requires heat, then energy is saved, operating life is optimised and efficiency is increased significantly.

“In the aforementioned case, we could not only achieve 60% energy savings but also a reduction in rework rate,” enthused Joerg Woell. The measures established are evaluated in terms of economic viability to illustrate the possible energy-saving and production opportunities.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology and market leaders in the production of specialty light sources. In 2009, Heraeus Noblelight had an annual turnover of 71.6 Million € and employed 707 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, sensors, biomaterials and medical products, dental products, quartz glass, and specialty light sources. With product revenues of € 2.6 billion and precious metal trading revenues of € 13.6 billion, as well as more than 12,300 employees in over 110 subsidiaries worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Germany

Press: Dr. Marie-Luise Bopp

marie-luise.bopp@heraeus.com

www.heraeus-noblelight.com/infrared

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Plant Optimisation Saves Energy here

News-ID: 151622 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

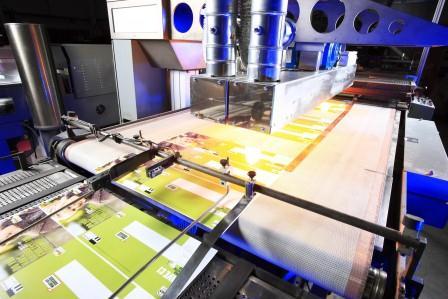

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

More Releases for Optimisation

Assortment and Space Optimisation Market Size & Share | 2034

According to the report by Expert Market Research (EMR), the global assortment and space optimisation (ASO) market attained a value of nearly USD 1.88 billion in 2024. Aided by the growing demand for data-driven retail planning and the increasing importance of enhancing customer experience, the market is projected to grow at a CAGR of 12.50% between 2025 and 2034 to reach a value of around USD 6.10 billion by 2034.

Assortment…

Radiation Dose Optimisation Software Market Size Analysis by Application, Type, …

USA, New Jersey- According to Market Research Intellect, the global Radiation Dose Optimisation Software market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The market for radiation dose optimization software is expanding significantly as a result of growing worries about radiation exposure in medical imaging. Healthcare…

Managing Capacity and Demand: Strategies for Optimisation

Effective capacity and demand management is crucial for any organisation aiming to optimise resources and ensure seamless operations. Aligning capacity with demand not only helps in meeting current business needs but also ensures preparedness for future requirements. Utilising techniques such as Capacity on Demand (COD) allows companies to make capacity available as needed, which can be particularly useful in dynamic environments.

Incorporating a structured approach to align capacity with demand can…

Marketing Mix Optimisation Market segmentation by 2026

Marketing mix optimisation or marketing mix modeling is a method that is used for the statistical analysis of the various advertising and marketing efforts done on a products performance in the market. The key elements of marketing mix modeling are product, promotion, distribution and the pricing, each of these elements are analyzed closely before finalizing the suitable model for marketing a particular product. The marketing mix modeling allows quantifying the…

Spiro Control Ltd unveil new factory optimisation device

Spiro Control Ltd is pleased to introduce Spiro: the factory optimisation device that continuously monitors and analyses factory sensor data, performs closed loop control, and operates as an edge gateway delivering real-time data to business intelligence and operational excellence software in the cloud.

The solution is appropriate for a range of applications in industrial manufacturing and is designed to easily connect to any control system. High performance edge processing, a…

New book dedicated to search engine optimisation

A new book helping individuals train themselves to become search engine optimisation (SEO) experts has been released.

"Search Engine Optimization with Richard John Jenkins," published by Iyada.com, gives essential tips to reaching the top of Google and Yahoo! rankings - from optimising keyword variations to purchasing placements.

The book promises to help the reader avoid "black hat" SEO practises frowned upon by search engines, as well as providing guides on setting up…