Press release

Vacuum Test Center for Infrared Emitters

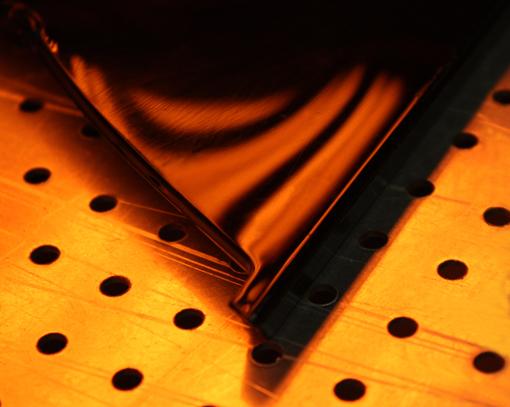

Increasingly, coating processes in photovoltaics, for semi-conductors and also for other products in glass or metal, require vacuum conditions or inert gases. Infrared emitters transfer energy without contact and are consequently ideal heat sources for vacuum processes. It is of great advantage if the infrared system is precisely matched to the vacuum application.Heraeus Noblelight has created a vacuum test chamber in its in-house Application Center in Kleinostheim. Since its foundation, the test centre has helped to allow infrared emitters to be matched precisely to product and process. In-house tests keep track, in a targeted manner, of the influences of vacuum conditions on infrared heat; they allow customers to investigate their materials and processes more precisely, so that they can design infrared systems of maximum efficiency.

In photovoltaics, for semi-conductors and even generally for glass- or metal-coatings, heating processes under vacuum conditions are being increasingly used. Plates, discs or work pieces are processed at very high temperatures and, during this, in many cases oxidation must be prevented.

Generally, infrared heating technology is used for the heating process, as infrared radiation transfers energy without contact and at high power.

“We have quickly established that the ambient atmosphere can influence the efficiency of the infrared radiation,” says Martin Klinecky, specialist for vacuum applications at Heraeus, “we carry out tests in conditions as near to those met in practice as possible, so that we can design infrared systems in the most optimum fashion.” When, for example, metals oxidize when they are heated in air, then often their surface character and color change and thus their capacity to absorb infrared radiation. Consequently, test results cannot be simply extrapolated to vacuum conditions.

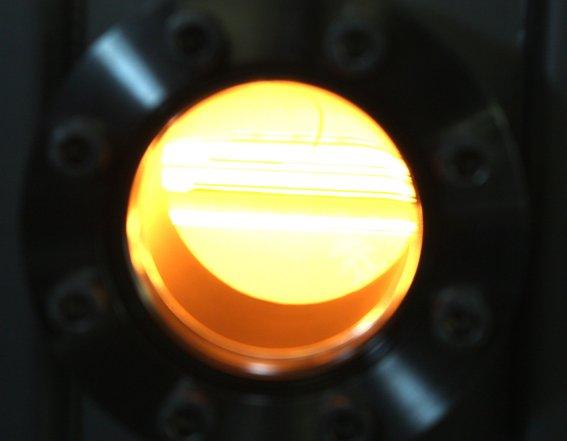

Because customers have asked increasingly for tests of infrared radiation under vacuum, Heraeus have set up a vacuum chamber with infrared heating technology in their in-house Application Centre, where pressures of 1000 mbar up to 10-6 mbar can be generated according to customer requirements. For these tests, short wave infrared emitters or medium wave Carbon Infrared (CIR) emitters can be used. These heat the materials either directly in the chamber or via a quartz glass sheathing tube. When a sheathing tube is used, it is possible to replace the emitter simply from outside. The tests are recorded by computer with the aid of temperature sensors and are evaluated in collaboration with the customer.

Sometimes with striking results: “Some metals heat up under vacuum twice as quickly as in normal atmospheres, with others there is practically no difference,” says Martin Klinecky, “this very much depends on the conditions of the heating process!”

One example is that of aluminum components which are heated at 1000 mbar and then, in comparison, at 10-4 mbar with short wave infrared emitters. In normal atmospheres, 150ºC is reached in 4 minutes; under vacuum, the same temperature is achieved after 2 minutes.

The color and the type of the material and the color and the thickness of the coating, as well as the required temperature and drying time all affect the design of the heating process. Even with innovative coatings and new materials, tests are very much worthwhile to ensure that systems are designed and built in the most energy-efficient ways possible.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology and market leaders in the production of specialty light sources. In 2009, Heraeus Noblelight had an annual turnover of 71.6 Million € and employed 707 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, sensors, biomaterials and medical products, dental products, quartz glass, and specialty light sources. With product revenues of € 2.6 billion and precious metal trading revenues of € 13.6 billion, as well as more than 12,300 employees in over 110 subsidiaries worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Press: Dr. Marie-Luise Bopp

marie-luise.bopp@heraeus.com

www.heraeus-noblelight.com/infrared

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vacuum Test Center for Infrared Emitters here

News-ID: 139309 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

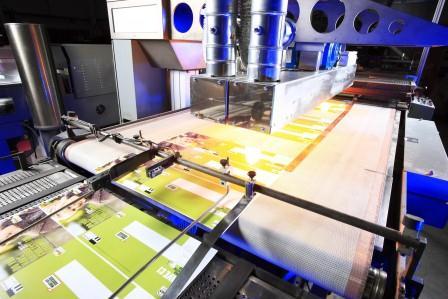

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

More Releases for Infrared

Infrared Heat Lamp Market Set for Dynamic Boom as Key Players Philips, Sunlight, …

The qualitative latest Research report (2025-2032) on the Infrared Heat Lamp Market by Coherent Market Insights Provides a deep dive into key market trends, drivers, challenges, and the competitive landscape. As part of our Black Friday Limited-Time Discount, this premium research report is now available at up to 60% off, offering an exceptional opportunity for businesses, analysts, and stakeholders to access high-value insights at a significantly reduced cost. It analyzes…

Healix Infrared: Transforming Wellness with Advanced Infrared Sauna Solutions

In today's fast-paced world, finding effective ways to prioritize health and relaxation is more important than ever. Healix Infrared , a leader in home wellness solutions , is redefining the way people experience self-care with its cutting-edge infrared saunas . Designed to promote detoxification, pain relief, and stress reduction, Healix's products are a game-changer for health-conscious individuals and homeowners alike.

Harness the Power of Infrared Technology

Unlike traditional saunas, infrared saunas use…

Non-Dispersive Infrared Market: Infrared Insights - Market Analysis 2024

The non-dispersive infrared (ndir) market size has grown strongly in recent years. It will grow from $0.43 billion in 2023 to $0.47 billion in 2024 at a compound annual growth rate (CAGR) of 9.4%. The growth in the historic period can be attributed to miniaturization and cost reduction, environmental regulations, energy efficiency, industrial safety, healthcare applications.

The non-dispersive infrared (ndir) market size is expected to see strong…

infrared Thermometer Market

Market Overview:

The global infrared thermometer market reached US$ YY billion in 2022 and is anticipated to grow at a CAGR of YY% to reach US$ YY million by 2030.

Infrared thermometers, particularly IR forehead thermometers, have gained traction due to the COVID-19 pandemic, offering non-contact temperature screening and finding application in diverse settings beyond fever checking.

Market Dynamics:

Drivers: Rise in technological advancements, increased focus on industrial and emergency uses, and the introduction…

Infrared Collimators Market Analysis: Key Trends to Drive Business Success | Lig …

Global Infrared Collimators Market Overview:

Global Infrared Collimators Market Report 2022 comes with the extensive industry analysis by Introspective Market Research with development components, patterns, flows and sizes. The report also calculates present and past market values to forecast potential market management through the forecast period between 2022-2028.This research study of Infrared Collimators involved the extensive usage of both primary and secondary data sources. This includes the study of various parameters…

Infrared Imaging Industry

The global Near Infrared Imaging market is estimated to attain a valuation of US$ 785 Mn by the end of 2032, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 12.7% during the forecast period, 2022-2032.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders…