Press release

Heraeus Infrared Helps Produce High Performance Thermal Insulation System for Pipelines

A custom-built, infrared system from Heraeus Noblelight has helped the Barrier Group, of Wallsend, to develop a high performance, thermal insulation system for submarine pipelines, which offers significant advantages over conventional systems. The high power infrared system is used to cure adhesive to ensure that a polypropylene material, which imparts impact resistance, corrosion protection and additional thermal insulation, can be efficiently applied to an innovative insulation shell around a conventional steel pipe. This results in reduced lay tension, together with significant improvements in pipe-laying productivity.The Barrier Group has established a well-earned global reputation for providing corrosion protection coatings for steelwork and pipelines in the oil and gas sector. It has now diversified into areas such as passive fire protection, metal spraying, powder coatings and subsea insulation. One result of this has been the development of the patented Bubbletherm system, where a conventional steel pipe is enclosed with epoxy syntactic insulation and the whole assembly is further insulated and protected with a wrapping of a proprietary polypropylene material.

Subsea pipelines are used to carry oil and oil/gas mixes from subsea wellheads to onshore refineries or offshore processing platforms. Oil discharges from wellheads at temperatures, typically, between 80ºC and 160ºC. To prevent wax and hydrate formation, which could restrict oil flow, it is important that the oil does not cool significantly in the ambient subsea temperatures. Consequently, pipe insulation is vital. Conventionally, this achieved by pipe-in-pipe manufacture, where the annular space between the inner and outer pipes is filled with lightweight insulation material. This kind of pipe is expensive to produce and because it uses two individual steel pipes, it is also heavy. As a result, a reel pipelaying vessel can only carry a restricted tonnage, which, in turn, restricts the length of pipe it can lay before returning to port for re-loading. With the new Bubbletherm pipe, which is cheaper to produce than competitive pipe, it is now possible to lay pipe with reduced reload cycles and with lower levels of tension. When the pipe is laid from a “S” lay vessel, it is possible to lay 20 km of pipe in 11 days compared with the 45 days of its pipe-in-pipe counterpart.

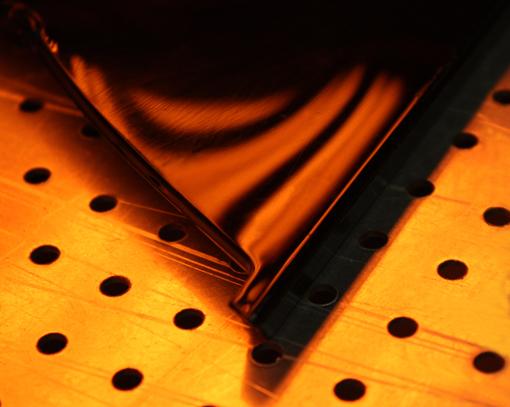

An important step in the manufacture of the new pipeline system is the application of the polypropylene protective wrap. This is carried out as a continuous process, where the wrap is overlapped to provide a three ply coating. The infrared system comprises five modules, with a total of 24, QRC short wave emitters delivering a total power of 50.4kW. The first module is used to provide rapid activation of the adhesive on the wrap, while the second module heats the top of the wrap to maintain flexibility. The third module provides additional heat before the wrap is brought into contact with the insulation and the final two modules apply heat to the insulation as it is rotated to ensure that hot adhesive is not applied to a cold surface. Precise temperature control is provided by optical pyrometers for modules 1, 3 and 5.

The QRC emitters used in this application provide high energy short wave radiation rapidly and responsively. They feature a new quartz reflective coating with a special nano-and micro-structure, which provides the reflector with very high diffusion characteristics to ensure the stability of process parameters, such as temperature and coating homogeneity. As Dave Robinson, adhesives consultant at Barrier, explains, “The high power and the response of the infrared emitters are vital to the curing process. The Heraeus units are capable of bringing the adhesive very rapidly to its working temperature and, just as importantly, they can switch off very quickly, so that there is no damage to the wrap material.”

Heraeus specialises in the production and application of high quality energy sources covering the electro-magnetic spectrum from ultraviolet to infrared. It has over 40 years experience in infrared technology and offers the expertise, products and systems to provide efficient and effective solutions to drying, heating and curing problems throughout industry.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology and market leaders in the production of speciality light sources. In 2008, Heraeus Noblelight had an annual turnover of 92.5 Million € and employed 735 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, sensors, dental and medical products, quartz glass, and specialty lighting sources. With product revenues approaching € 3 billion and precious metal trading revenues of € 13 billion, as well as over 13,000 employees in more than 110 companies worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Germany

Press: Dr. Marie-Luise Bopp

marie-luise.bopp@heraeus.com

www.heraeus-noblelight.com/infrared

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Heraeus Infrared Helps Produce High Performance Thermal Insulation System for Pipelines here

News-ID: 124332 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

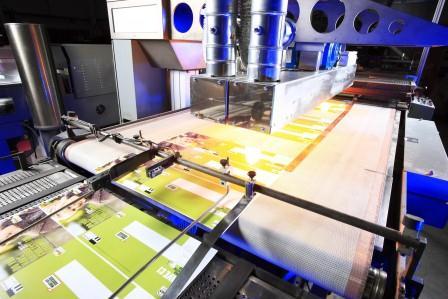

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…