Press release

Coker Valve Monitoring in a Refinery

Measurement & Control Solution for ManufacturerCAS DataLoggers provided the measurement and control solution for a large manufacturer of valve systems used in many different industries. The company produces ball, needle, choke, control, gate, and other types of valve systems with many different diameters. One of its customers was a refinery using a custom 3-way switching valve in order to direct oil flow into different coking towers. However, the operation of the valve was periodically unreliable and caused costly shutdowns in the refining process. Therefore, a reliable coker valve monitoring solution capable of connecting to many different kinds of sensors was needed to monitor the correct operation of the valve with high accuracy and automatically analyze the data. This device would also need to be simple to configure and operate as well as include data analysis software and a modular design to accommodate possible expansion to add more input and output channels in the future.

Installation

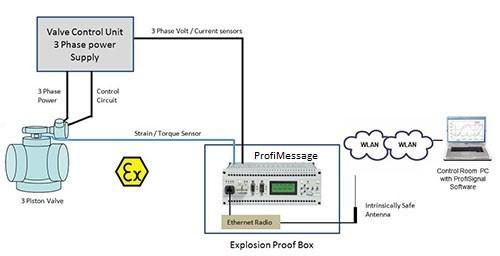

The manufacturer installed a Delphin ProfiMessage Data Acquisition & Control System close to the valve control unit in order to record all data describing the valve’s operation and movement. From the many available configurations, management selected a ProfiMessage data acquisition system with an 8 channel ADFT input module featuring synchronous fast sampled analog inputs. The DAQ system was placed into an explosion-proof enclosure in the hazardous zone; its compact design allowed it to fit neatly into the small available space inside the enclosure. Real-time communication to the control room was enabled by a wireless spread spectrum radio link connected to the Ethernet port of the system.

The ProfiMessage system measured the 3-phase motor current consumption and voltage. The installed sensors included a strain gauge for torque measurement, a motor voltage transducer, 2 control circuit voltage transducers, and 3 motor current probes. The strain sensor measured torque during the movement of the refinery valve. The inputs were configured for 1 kHz sample rate each, and the data acquisition system recorded on all 8 channels simultaneously onto on-board memory. Data transfer was accomplished through the wireless radio link.

The internal programmable logic channels of the ProfiMessage were configured in such a way so that the data storage was triggered at a specific threshold level of motor current consumption, ensuring that only relevant data during the valve movement was stored. These logic functions also allowed the user to configure the ProfiMessage device with event-based functions to alarm on specific conditions.

Usage for Coker Valve Monitoring

The Delphin ProfiMessage provided a modular and scalable system capable of highly accurate measurements with up to 24-bit resolution. The system measured all the data from each valve cycle only recording data when values were outside defined, normal operating levels. An event trigger automatically uploaded data from the system to a PC in the central control room via a wireless Ethernet network.

Data analysis and processing was facilitated using Delphin’s powerful ProfiSignal Software. Refinery management were specifically interested in the relationship between RMS motor current consumption and the torque profile during the valve movement, which gave a clear indication when the valve was performance was degrading and allowed them to schedule maintenance action before failures could occur.

Benefits

The manufacturer benefited in several key ways after installing the Delphin ProfiMessage system in its customer’s refinery. The ProfiMessage’s modular design offered the customer a wide range of I/O modules to select the best ones for this application, with different modules available for any number of channels and sensor types. Likewise, the system’s number of outputs could be easily expanded whenever needed. The ProfiMessage data acquisition system was highly accurate and reliable, and the customer was easily able to continually monitor the valve to check its performance and schedule maintenance before its operation could fail, preventing unscheduled interruptions in processing. Automatic downloads from the DataService Configurator software were uncomplicated to set up and streamlined the data acquisition process, leading to efficient data analysis and problem identification.

For more information on coker valve monitoring systems, Delphin systems, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or visit our website at www.DataLoggerInc.com.

Computer Aided Solutions, LLC. dba CAS DataLoggers is a distributor of data loggers, paperless recorders and data acquisition equipment.

We have the industry’s most complete selection of data logging equipment, with hundreds of different models from more than 18 manufacturers. With data loggers from 1 to 300 channels we can record temperature, humidity, force/strain, pressure, flow, voltage, current, resistance, vibration and other digital signals, in connection with serial (RS-232/RS-485), CAN/OBD or SDI-12 devices. We sell directly to end users and also work through a network of distributors and resellers throughout the United States, Canada, Central and South America.

CAS DataLoggers

8437 Mayfield Rd Unit 104

Chesterland, OH 44026

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Coker Valve Monitoring in a Refinery here

News-ID: 1146273 • Views: …

More Releases from CAS DataLoggers

New XH10 & XH11: Data Loggers Enhance Long-Distance Transport

CAS DataLoggers is pleased to announce the XHLogger series from Brainchild Electronics Co., Ltd. The new XH10 and XH11 temperature and humidity data loggers are designed specifically for environmental monitoring during cargo transportation. These reusable devices connect to a computer via USB and automatically generate a PDF report of the recorded data, or they can be used in conjunction with the Data Logger Viewer (DLV) software for in-depth data analysis.…

New MSR Data Loggers from MSR Electronics GmbH

CAS DataLoggers is pleased to announce that we have partnered with Swiss company MSR Electronics GmbH to bring the MSR family of universal data loggers to our customers. Designed to meet the highest standards of precision and reliability, the new MSR data loggers are compact with large memory to handle various measurement tasks such as measuring and recording shocks, vibration, temperature, humidity, pressure, or light.

Why Choose MSR Data Loggers?

The ability…

Ensuring Workplace Safety: Data Loggers for Compliance With California Regulatio …

In workplaces across California, ensuring the health and safety of employees is paramount. This commitment is not just a moral imperative, but a legal requirement under California Code of Regulations Section 3395, which mandates specific measures to ensure workplace safety by protecting workers from heat illness. Among these measures is the monitoring of environmental conditions such as temperature and relative humidity, critical factors that can significantly impact employee well-being.

Understanding California…

New AirGate 4G Cellular Router from Novus

NOVUS presents AirGate 4G, an industrial VPN router for cellular networks. Data sending is secure with this new device as it uses encryption protocols and firewall systems most commonly used in IT infrastructures, including automatic fallback for 4G, 3G, and 2G cellular networks. AirGate 4G is CE Mark certified and was developed for industrial environments. It can maintain its high availability performance even in extended operation situations, being equipment suitable…

More Releases for ProfiMessage

Safeguarding Production with Industrial Process Monitoring

Powerful Measurement Technology from Delphin

Delphin Technology and CAS Data Loggers present an industrial process monitoring application that provides substantial business benefit to your bottom line. Effective process monitoring is critical to avoiding downtime, ensuring product quality and alarm generation to avoid catastrophic loss. CAS DataLoggers will provide you with a Delphin data acquisition system to help protect your valuable business commodities by helping assess your requirements and finding the ideal…

Delphin Offers New ProfiMessage D Data Acquisition System

Measurement Data Acquisition, Monitoring & Automation

CAS Dataloggers is pleased to announce the new ProfiMessage D Modular Data Acquisition system from Delphin Technology. The ProfiMessage D is the latest in the extremely successful Message family of Delphin products targeted at Industry 4.0 applications. It is designed as a modular measurement, monitoring, and control system for use in industrial processes and test stands.

Features

For use as part of an upgrade for Industry 4.0…

Switch Testing for Performance Qualification and Compliance

German-Manufactured Systems for Test Measurement

Switches for medium-voltage networks (ranging from micro to power switches) first need to undergo repeated testing to comply with different types of standards. These demanding tests are performed according to switching points, bounces, and switch opening/closing delays.

For these test applications, Delphin Expert Key and Message devices provide users with all the necessary hardware, taking precise readings via their high-speed analog and digital inputs. Switch data…

Automation Solutions for Use in Testing Heating Units

Fast and Flexible Measurement Technology

The testing of heating units and systems is performed according to a wide range of demanding standards. To achieve this, automation of test procedures and results is required, but often involves lots of effort and is prone to error. While measurement data provides the basis for a product‘s technical specifications, the monitoring systems collecting it need to be capable of high-level precision.

However, the complex series of…

Precision Electrical Measurement Using Delphin

Fully-Automated Engine Test Stands

Motor Test stands are required during the automotive R&D phase for serial testing and also for endurance trials. Measurements taken during the developmental phase such as Temperature and Voltage are fully-automated whenever possible. Sensors check the electrical and mechanical properties of the test sample as well as temperature patterns and overload operation. Testing conditions can vary widely--from the tiniest of motors to large drives in the megawatt…

Delphin Technology Exhibiting at Hannover Messe 2016!

The World’s Leading Trade Fair for Industrial Technology on April 25-29

CHESTERLAND, OH—March 29, 2016

It’s almost April and one of the biggest industrial tradeshows in the world is about to get underway! If you happen to be in Germany this April, come visit Delphin Technology 25-29 April at Hannover Messe at Stand B51 in Hall 11. Delphin’s Frank Ringsdorf will be in attendance all week, showing visitors how Delphin data loggers…