Press release

One element for all directions

With the new and versatile OTU (the Omni-directional Transfer Unit) from Avancon one determinates the transporting direction. Similar to the railway track, all goods are guided into different directions by moving in line of a natural curve or a crossing with OTU. These new key elements allow to build easily any size of crossings or diverters in conveyors systems with versatile OTU-bricks. But it is also possible to build crossover transport, sideways movements or even sorters.“Have you ever wondered as to how train changes track while running? The train switching is a fascinating event and many people enjoy watching part of train moving onto another railway line from the window. Most times the process is so smooth, that one even doesn't notice it. However, an experienced traveler can make out by the sound, that indeed the track is changed.

To make a train change its track, a special mechanical switch is made. As the name suggests, the switching rails can guide the train, either on straight path or on the diverging path which is established by a curved rail line.

It is very important that the switch is set up carefully. Most train derailments take place at the points when trains go from one track to another track.”

In a similar way goods have to be moved in distribution and logistics centers.

In modern internal conveyor and distribution systems, millions of cartons and boxes are moved daily worldwide, whether for postal and parcel services, online shops, logistic companies, pharmaceutical wholesales, in internal distribution or at airports.

The flow of goods is growing all over the world: between Asia and Europe and America as well as within the European Union. What is loaded somewhere and shipped in a container, has been previously been sorted, distributed, palletized and has to be de-palletized, sorted and distributed in the destination country again.

Of course everywhere in the internal logistics one need conveyors, which have to be equipped with switches, diverters and crossings and sorters in order to change the direction in order to transport goods to the different destination.

But how did this all work so far? –There have been many expensive constructions; for example, transfers which lift pneumatically, diverters that slide sideways, drive belts with built-in wheels, which are moved by an underlying belt, diverters, which are moved by means of pneumatics and their wheels are driven by a shaft mechanism and many other complicated systems. These pneumatic cylinders, pneumatic controls and pneumatic pipe installation and compressors become obsolete through this new invention. Also special shafts mounted below the transfer tables with twisted round belts, fall away.

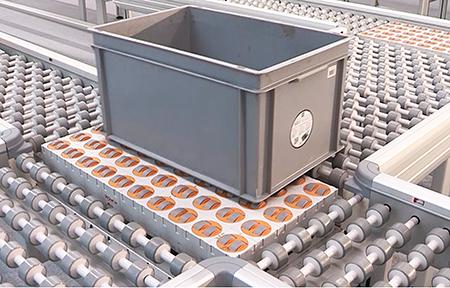

Because now there is something very simple from the Swiss Avancon. This so-called "OTU" Omni-directional Transfer Unit is an ideal component that moves goods in almost any direction and that you can use for all those purposes as infeeds, switches, diverters, crossing, transfers, sorters and so on. These OTUs can be universally combined to "OTU tables" in any length and width, adjusted respectively to the largest product to be conveyed as cardboard boxes or plastic boxes or anything else with flat bases.

The single element, which consists of several detailed parts made of valuable and strong Techno-Polymers, is 75 x 75 x 133 mm in size, is assembled together in dovetail similar forms and over-head confected with the belt and combined with a toothed rack. Where the toothed rack, which causes the movement of the rollers in any direction (nearly 360°). Fore instance in a diverter/switch the transporting rollers build a natural curve to transport the goods into the right or left direction. So the transport can be done very fast but smooth and uses less space.

The wheels have tires of PU (Polyurethane) and are powered via bevel gear system within each element. This cannot be seen from outside.

Particularly ingenious is the idea to drive and move everything electrically directly with the standard DC gear-motors of 48 V and 40 W. The whole construction can be build very small in height. Here one can save space and a lot of money!

Sure Avancon offers also a complete control system, based on the field bus AS-interface. This guarantees a smooth but very fast movement. It is also able to communicate with other bus- or higher IT- topology.

Such an "OTU table" can be easily installed in any conveyor construction because the individual assembled "OTU" elements are all pushed onto a substructure of aluminum profiles - no other attachments are necessary. So you can either screw the whole assembled table between or under the frame construction of each conveyor track.

This OTU-element is also available with a fixed direction, slightly to the right or slightly to the left, for the lateral move of different sizes of goods before a barcode reader. The whole thing is very easy to install. It will keep the distance near to the barcode reader and requires just a few of those OTU elements.

Furthermore, one can use this OTU-brick to build crossings, transfers, crosswise movements between two conveyor lines or even a U-turn for very small curves; but also sorter-lines are possible.

Instead of using expensive pneumatics and / or mechanical liftings, only some of these simple elements are needed for every application: "OTU". It’s easy to install – and much lower in cost.

Producers of conveyor systems can buy this versatile OTU element as individual parts for self-assembly or as the fully assembled OTU table including motors and control units to be mounted under or between any type of conveyor frame construction.

This OTU element was developed and worldwide patented by Dieter Specht, co-founder of the Interroll Group and is manufactured and sold worldwide by Avancon SA, Riazzino /Switzerland via Conveyor Manufacturers.

“There is nothing wrong with change, if it is in the right direction”

Winston Churchill

The young Swiss startup Avancon SA (www.avancon.com) has set itself the goal to revolutionize the unit handling systems in distribution and logistics centers. They offer now a new modern and very innovative conveying system. This will be distributed worldwide by manufacturers of conveyor systems and logistic system integrators. The system has been developed by Dieter Specht, the founder of the Interroll Group.

Avancon SA

via Campagna 27

6595 Riazzino TI

Switzerland

phone 0041 91 2221010

e-mail: media@avancon.com

www.avancon.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release One element for all directions here

News-ID: 965887 • Views: …

More Releases from Avancon SA

Conveyor systems in Logistics, exceptional clean and sleek.

Avancon SA in Switzerland has built together with its License Partner and System Integrator Hyundai LS/Asetec in South Korea a modern and exceptional example of a typical Logistics and Distribution Cen-ter.

The final customer is the largest wholesale pharmaceutical and medical device distributor in South Korea, the Company Geo Young. They serve more than 250 multi-national and domestic pharmaceutical and medical device companies, distributing to more than 11,000 pharmacies, hospi-tals, and…

Exceptional idea for sorting and distributing small packages

In China are many postal distribution centers. Most of them have a lot of small packages to handle and to sort, because the internet business is exploding in China. Here the Chinese partner of Avancon developed a brilliant idea to solve this problem by installing a fast and easy sorter, which is equipped with the Avancon OTU-tables and sorts very fast all kind of small items and packs.

"There are some…

Avancon builds the Samsung Distribution Center for small units

Together with the South Korean system integrator Asetec Co.Kr, a specialist for electronic control systems, "Pick-to-Light" and communication with higher-level BUS / IT systems, Avancon built the Samsung shipping center for small units-like the new Galaxy Note 10 -and simultaneously for larger boxes and for other products. The requirements for this sorting and distribution system were among others: a very short delivery time, the system had to fit into a…

New concept for an absolutely safe conveyor technology

This modern conveyor system is produced and marketed by Avancon SA, Switzerland and was developed by Dieter Specht, the co-founder of the Interroll Group. Through a special experience he has changed his mind from being a roller producer to a developer of a very clever and outstanding designed System, which is foremost focused on the safety- aspects.

The American Administration for Occupation, Safety and Health (OSHA) reported 25 serious accidents…

More Releases for OTU

Anti-Retropulsion Devices Market Size Report 2032 by DelveInsight Exploring Mark …

DelveInsight's Anti-Retropulsion Devices Market Insights Report 2032 provides the current and forecast market analysis, individual leading Anti-Retropulsion Devices Companies market shares, challenges, Anti-Retropulsion Devices Market Drivers, barriers, trends, and key market Anti-Retropulsion Devices companies in the market.

To read more about the latest highlights related to the Anti-Retropulsion Devices Market, get a snapshot of the key highlights entailed in the Market Report @ https://www.delveinsight.com/sample-request/anti-retropulsion-devices-market?utm_source=openpr&utm_medium=pressrelease&utm_campaign=ypr

Key Takeaways from the Anti-Retropulsion Devices…

Disposable Endoscopes Market Projected to Reach USD 13.58 Billion by 2034, Growi …

Disposable Endoscopes-Market Insights, Size Revenue, Outlook, Overview, and Analysis. The disposable endoscopes market was estimated to be worth USD 2.83 billion in 2024 and is predicted to expand to USD 13.58 billion by 2034, with a CAGR of 17.00% from 2025 to 2034.

𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐜𝐨𝐩𝐞:

This comprehensive study provides an accurate overview of the worldwide disposable endoscopes market. Comprehensive analyses of sales volume, price, revenue, market share, and important companies are included.…

Disposable Endoscopes Market Size, Top Companies, Share, Growth And Forecast 203 …

The most recent research study titled "Global Disposable Endoscopes Market Outlook and Forecast 2023-2030" has been unveiled by Allied Market Research. This study encompasses a comprehensive analysis of market risk factors, highlights opportunities, and offers crucial support for strategic and tactical decision-making from 2023 to 2030. The study divides the market into key regions that are driving its growth. The report delivers insights on market research and development, factors fueling…

Disposable Endoscopes Market Landscape: Current Dynamics, Key Players, and Futur …

The most recent research study titled "Global Disposable Endoscopes Market Outlook and Forecast 2023-2030" has been unveiled by Allied Market Research. This study encompasses a comprehensive analysis of market risk factors, highlights opportunities, and offers crucial support for strategic and tactical decision-making from 2023 to 2030. The study divides the market into key regions that are driving its growth. The report delivers insights on market research and development, factors fueling…

Single Use Cystoscope Market Reviews 2021 - 2031 | Ambu A/S, Boston Scientific C …

Single Use Cystoscope Market: Introduction

According to the report, the global single use cystoscope market was valued at US$ 95 Mn in 2020 and is projected to expand at a CAGR of 4.5% from 2021 to 2031. Cystoscope is a thin tube-like device used in the imaging of urethral organs such as bladder, prostate, and the urinary tract. Most often, cancers in these regions are diagnosed with the help of cystoscopy, which enables viewing the organ on a screen and helps in…

One Time Use (OTU) Surgical Device Market Is Expected To Witness Faster Growth T …

Acumen Research and Consulting has announced the addition of the "One Time Use (OTU) Surgical Device Market” report to their offering.

The One Time Use (OTU) Surgical Device Market Report 2018 is an in depth study analyzing the current state of the One Time Use (OTU) Surgical Device Market. It provides brief overview of the market focusing on definitions, market segmentation, end-use applications and industry chain analysis. The study on One…