Press release

Complete Die Springs from Lee Spring

Compression Die Springs from Lee Spring come at a significant cost saving over many competitive items – in the order of 1/3 to 1/2, while offering extended life and minimised in-service length loss by virtue of their shot peened finish and preset process in production. They fit the Lee Spring “complete spring” concept with closed and ground ends, plus easy identification by colour coding so they are ready for installation without additional specification.Die Springs are not solely used in dies, but find application in clutches, brakes, farm machinery and aircraft mechanisms. They are ideal for use as die springs or as heavy duty compression springs for any high stress, heavy load application. The standard catalogue range is available in five load ratings – from Medium (grey) through to Extra Heavy (orange).

Further information on Die Springs from Lee Spring can be found at www.leespring.com/int_learn_hefty.asp?, or follow them on twitter - https://twitter.com/leespringuk.

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

In addition, Lee Spring offer extensive custom design and manufacture services for one-off/prototypes or ongoing production requirements.

Lee Spring Ltd

Latimer Road

Wokingham

Berkshire

RG41 2WA

Tel: 0118 978 1800

email: sales@leespring.co.uk

www.leespring.co.uk

Press contact: Christopher Petts

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Complete Die Springs from Lee Spring here

News-ID: 938701 • Views: …

More Releases from Lee Spring Ltd

New website – New Online store – customers can now shop for Lee Spring parts …

Market leaders Lee Spring are delighted to provide their customers with the opportunity to buy online with full account management and basket purchasing facilities on their new easy to navigate website at www.leespring.co.uk – a fast ecommerce experience with highly efficient product search and CAD downloads.

Lee Spring offer over 25,000 stock spring designs on this site - ready to ship today with pricing and detailed specifications easy to view. These…

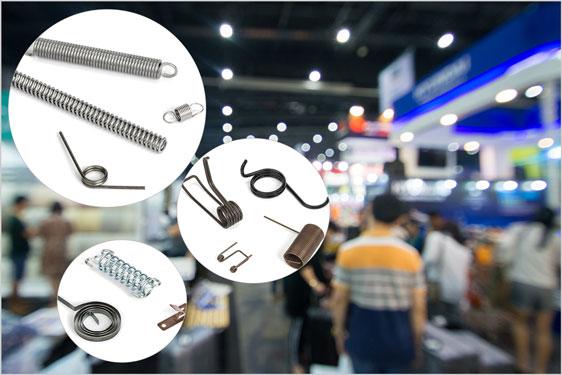

Lee Spring at Southern Manufacturing & Electronics Exhibition, Farnborough, 11-1 …

This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring. Lee Spring has recently expanded their UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products here in…

Exotic alloys - Lee Spring explain what they are and when to use them

Materials with high alloy content, known as super alloys or exotic alloys, offer enhanced performance properties including excellent strength and durability, and resistance to oxidation, corrosion and deforming at high temperatures or under extreme pressure. Because of these properties, super alloys make the best spring materials for demanding working conditions, which can be encountered across various industry sectors, including the Automotive, Marine and Aerospace sectors as well as oil and…

REDUX™ Wave Springs from Lee Spring – an enabling technology

Lee Spring REDUX™ wave springs offer a way of performing a spring function in minimal spaces – even perhaps where no other spring could work effectively. Typically, REDUX wave springs occupy just 30-50% of the compressed height space of the conventional round wire springs, yet they offer more deflection with the same load specifications. This not only helps to save space in the applications but also reduces the production costs,…

More Releases for Die

U.S. Die Casting Market Set for Dynamic Growth with Key Players Ryobi Die Castin …

Coherent Market Insights has released a report titled "U.S. Die Casting Market: Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2025-2032", which includes market percentage records and a thorough enterprise analysis. This report looks at the market's competition, geographic distribution, and growth potential. This comprehensive report encompasses industry performance, critical success factors, risk assessment, manufacturing prerequisites, project expenses, economic analysis, anticipated return on investment (ROI), and profit margins.

This comprehensive report…

Automotive Parts Die Casting Market Global outlook 2021 to 2026: Gibbs Die-casti …

The report presents an in-depth assessment of the Automotive Parts Die Casting Market including enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, operator case studies, opportunities, future roadmap, value chain, ecosystem player profiles and strategies. The report also presents SWOT Analysis and forecast for Automotive Parts Die Casting investments. The final report copy provides the impact analysis of novel COVID-19 pandemic on the Automotive Parts Die Casting market…

Automotive Parts Die Casting Market Global Outlook 2019-2025 | Leading Vendors- …

Up Market Research published a detailed report on “Automotive Parts Die Casting Market”. The report provides an in-depth overview of industry and competitive landscape, covering multiple market segments and elaborates market outlook and status to 2025.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/109602

The report contains 115 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Automotive Parts Die Casting…

Automotive Parts Die Casting Market 2019 Global Key Country Analysis: Alcast Com …

Automotive Parts Die Casting Market Research Report, by Production Process Type (Pressure, Vacuum, Squeeze and Semi-Solid), Raw Material Type (Aluminum, Zinc, Magnesium and Others), By Application Type, Vehicle Type, and by Regions - Forecast till 2023

The Key Players In Automotive Parts Die Casting Market Are:

Alcast Company (U.S.), Dynacast, LLC (U.S.), Endurance Technologies Limited (India), Gibbs Die Casting Corp (U.S.), and Rockman Industries (India). Ryobi Die Casting Inc. (U.S.), Kinetic Die…

Automotive Parts Aluminium & Magnesium Die Casting Market Report 2018: Segmentat …

Global Automotive Parts Aluminium & Magnesium Die Casting market research report provides company profile for Magic Precision Inc, Kinetic Die Casting Company, Texas Die Casting, Endurance Group, Sandhar technologies limited, Meridian Lightweight Technologies Inc, Sunbeam Auto Pvt. Ltd, Dynacast, Rockman Industries Ltd, Castwel Autoparts Pvt Ltd. and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market…

Global Automotive Parts Aluminium Die Casting Market Forecasat 2017 Texas Die Ca …

Automotive Parts Aluminium Die Casting Market

A market study ” Global Automotive Parts Aluminium Die Casting Market ” examines the performance of the Automotive Parts Aluminium Die Casting market 2017. It encloses an in-depth Research of the Automotive Parts Aluminium Die Casting market state and the competitive landscape globally. This report analyzes the potential of Automotive Parts Aluminium Die Casting market in the present and the future prospects from various angles…