Press release

Exotic alloys - Lee Spring explain what they are and when to use them

Materials with high alloy content, known as super alloys or exotic alloys, offer enhanced performance properties including excellent strength and durability, and resistance to oxidation, corrosion and deforming at high temperatures or under extreme pressure. Because of these properties, super alloys make the best spring materials for demanding working conditions, which can be encountered across various industry sectors, including the Automotive, Marine and Aerospace sectors as well as oil and gas extraction, thermal processing, petrochemical processing and power generation.Super alloy springs can be used in a number of severe conditions including extreme high or low temperatures, great pressure and facing outdoor conditions, including extreme weather. Springs not made from super alloys, if used in these circumstances, are at risk of becoming deformed or damaged, as they will not be strong enough to withstand heavy impact or harsh conditions.

“The reliability of the finished product in its application hinges on the correct material selection to meet the specific application requirements” says Darren Eyre, Technical Specialist at Lee Spring. “Stainless steel, for example, is tough and corrosion resistant, but it does not offer the properties that are required in order to withstand extreme heat, so is likely to distort when exposed to high temperatures. It is essential to clearly understand the environment that the spring is likely to be used in.”

“Springs required to operate in harsh environments could mean anything from underwater, contending with corrosion from saltwater, or contact with ‘sour’ gas from drilling down under the sea bed, to 35,000 feet up in the air battling low temperatures and high wind speeds” says Barry Steele, Applications Engineer at global spring company, Lee Spring. “Offshore applications require equipment that is capable of ‘braving the elements’, and some manufacturing or furnace applications involve extreme high or low temperatures. Some applications will involve the equipment being subjected to highly corrosive substances.”

A good example is the nickel-cobalt alloy, MP35N which consists of nickel and cobalt and is ideally suited to marine and sub-sea applications due to its resistance to hydrogen sulphide, salt water and mineral acids, which can have a highly corrosive effect on most metals. Monel is a nickel based alloy that incorporates copper and iron. It is corrosion resistant and acid resistant, so is suitable for marine applications as well as applications involving acids and other highly corrosive substances.

Many and varied specific characteristics dependant on the actual alloy chosen, e.g. Ni Ti nickel-titanium springs exhibit super elasticity which can be useful in orthodontic applications.

Titanium alloy springs are widely used in off-road bicycles also F1, WRC rally and Touring/GT, in fact pretty much all levels of high-performance competition where weight and performance are critical.

Inconel alloys are available in different grades (600, X-750 and 718) and are suitable in valves, pumps or actuators, for applications that involve high pressure and high temperatures, for example in nuclear power stations or for drilling on offshore platforms. Nimonic and Hastelloy alloys are also corrosion resistant and are suitable for applications involving high pressure and high temperature.

Other nuanced alloy configurations are often used where more cost-conscious alternatives are desired without the absolute ultimate performance demand. It is essential to clearly understand the environment that the spring is likely to be used in and usually to consult the materials specialists at your spring manufacturer.”

Further information on Lee Spring products can be found on their website - www.leespring.co.uk or by following them on Twitter - https://twitter.com/leespringuk.

Lee Spring Ltd

Latimer Road

Wokingham

Berkshire

RG41 2WA

Tel: 0118 978 1800

email: sales@leespring.co.uk

www.leespring.co.uk

Press contact: Christopher Petts

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

In addition, Lee Spring offer extensive custom design and manufacture services for one-off/prototypes or ongoing production requirements.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Exotic alloys - Lee Spring explain what they are and when to use them here

News-ID: 1814769 • Views: …

More Releases from Lee Spring Ltd

New website – New Online store – customers can now shop for Lee Spring parts …

Market leaders Lee Spring are delighted to provide their customers with the opportunity to buy online with full account management and basket purchasing facilities on their new easy to navigate website at www.leespring.co.uk – a fast ecommerce experience with highly efficient product search and CAD downloads.

Lee Spring offer over 25,000 stock spring designs on this site - ready to ship today with pricing and detailed specifications easy to view. These…

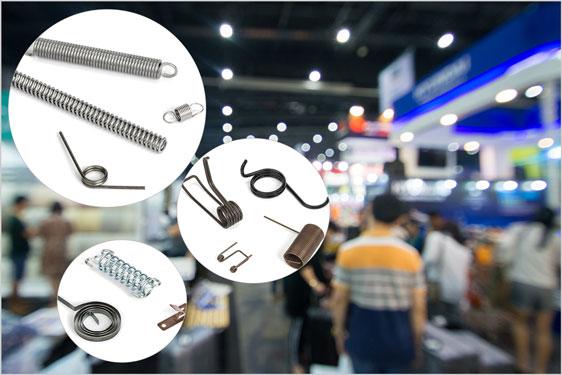

Lee Spring at Southern Manufacturing & Electronics Exhibition, Farnborough, 11-1 …

This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring. Lee Spring has recently expanded their UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products here in…

REDUX™ Wave Springs from Lee Spring – an enabling technology

Lee Spring REDUX™ wave springs offer a way of performing a spring function in minimal spaces – even perhaps where no other spring could work effectively. Typically, REDUX wave springs occupy just 30-50% of the compressed height space of the conventional round wire springs, yet they offer more deflection with the same load specifications. This not only helps to save space in the applications but also reduces the production costs,…

Lee Spring address extreme conditions of varying types

Lee Spring address the issues of extreme conditions through use of specialist materials and while low or high temperatures may take our minds toward expensive exotic alloys, extreme conditions vary to a wide extent such as being highly sensitive to magnetic, electrical or chemical conditions. To meet these conditions they also offer the ex-stock LeeP™ plastic spring range which provides non-magnetic, non-corrosive and chemically inert properties in a lightweight package…

More Releases for Springs

Coil Springs Market is Going to Boom | Acme Springs • Century Spring Corp • …

Latest Report, titled Coil Springs Market Trends, Share, Size, Growth, Opportunity and Forecast 2026-2033, by Coherent Market Insights offers a comprehensive analysis of the industry, which comprises insights on the market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

➤ The report features a comprehensive table of contents, figures, tables, and charts, as well as insightful analysis. The Coil Springs Market has been…

Springs Cleaning Celebrates Continued Success as the Top Commercial Cleaning Ser …

For thirty years, the commercial cleaning company has provided tailored cleaning and janitorial services for Colorado Springs businesses and institutions.

Image: https://www.globalnewslines.com/uploads/2025/01/0b75537b7e0776e9612ef0f10c487cc4.jpg

Springs Cleaning [https://www.springscleaning.net/] is celebrating its continued success as the number-one commercial cleaning company in Colorado Springs. This celebration marks the company's position as the commercial cleaning leader in 2025. In addition to maintaining leadership in Colorado Springs, this year also marks a milestone year for Springs Cleaning - 30…

Springs into Action: Automotive Spring Aftermarket Industry Springs Forward with …

The automotive spring aftermarket market plays a crucial role in enhancing vehicle performance and safety. Springs are essential components of a vehicle's suspension system, providing stability, comfort, and control. With a focus on quality, performance, and customization, the automotive spring aftermarket market offers a wide range of options to meet the diverse needs of vehicle owners, empowering them to optimize their driving experience and ensure safe journeys.

The aftermarket spring industry…

Nitrogen Gas Springs Market 2023-2029 by Leading Players DADCO, Barnes Group, Sp …

MarketsandResearch.biz recently introduced a new title on Global Nitrogen Gas Springs Market from its database. The report provides a study with an in-depth overview, describing the product/industry scope and elaborates market outlook and status (2023-2029). The report is curated after in-depth research and analysis by experts. The report provides comprehensive valuable insights on the global Nitrogen Gas Springs market development activities demonstrated by industry players, growth opportunities, and market sizing…

Telescopic Springs Guard

Global Info Research announces the release of the report "Global Telescopic Springs Guard Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets.…

Preference to Coil Springs over Air Springs Hampers the Air Springs Components M …

The Fact.MR report provides readers with the most important insights about potential opportunities, growth prospects, and recent developments in the air springs components market. Reliable and accurate qualitative and quantitative conclusions about the growth of the air springs components market are presented in the report. Air spring components have been witnessing robust sales as integral components of a vehicular system, underpinned by a burgeoning growth of the logistics & transportation sector,…