Press release

Vibration Welding Technology Market - Global Industry Growth, Trends and Forecast 2017 - 2025

Vibration Welding Technology Market: IntroductionVibration Welding was developed by Sonobond Ultrasonics, an American company in 1960. Vibration welding, also referred to as linear vibration welding, is a process where the surfaces that are to be joined with each other are rubbed against one another in an oscillatory mode under pressure. This causes very high friction between the surfaces which results in generation of tremendous heat between them. This heat causes the melting of the interfacial material and the molten film is allowed to cool down under pressure. This completes the vibration welding process. It is also called as linear friction welding. Weld frequency, weld pressure, vibratory motion and its amplitude and weld timing are the important parameters involved in the process. Generally, the machines operate at a pre-determined fixed weld frequencies (120 Hz and 240 Hz) with amplitude of vibration being 5mm and weld time of 10 seconds (which could vary, generally from 1 – 10 seconds). This technology is used in the automotive industry where it is used in welding of taillights, head lights and other assemblies; it is also used in the appliance industry and the aerospace industry.

Download PDF Brochure@ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=32819

Vibration Welding Technology Market: Growth Fuelling Aspects

Vibration welding can be used on almost all thermoplastic materials. As compared to ultrasonic welding, it can handle medium and large sized pieces (example: automobile bumpers). They can weld with higher moisture content than the ultrasonic welding. Surface contaminants do not affect the weld when done by vibration welding process. Moreover, the area which melts between the two pieces is not exposed to air which eliminates the occurrence of thermo-oxidative degeneration, this being a critical aspect. Other benefits impacting the growth of the vibration welding technology market are fast cycle time, ability to weld bigger parts, less power consumption, no fumes or harmful emissions, higher strength, easy automation is possible, capability to weld different and dissimilar materials, ideally used to weld PA materials, compatible with thermoplastics, welding of several parts per cycle is possible, low costs involved and low maintenance needed. Since no outside component is involved in the process, the weld interface is the same as the materials being involved in the process of vibration welding. This eliminates the chances of quality degradation. It also does not cause any degradation of material due to heat generated as the process is easier to control.

Vibration Welding Technology Market: Growth Challenges

Along with the plusses there are certain limitations that hinder the growth of the vibration welding technology market. The main limitation of the technology is that it can be used on material which are nearly flat. This technology is not applicable in case of low modulus thermoplastics (thermoplastic elastomers). Moreover, if the parameters such as weld time, pressure, amplitude and weld frequency are not controlled, this could result in uneven, irregular or poor quality welding. These are the challenges that lie in the growth path of the market.

Browse Report@ https://www.transparencymarketresearch.com/vibration-welding-technology-market.html?secure=NTIxNS41&type=PB

Vibration Welding Technology Market: Companies

The companies that deal with vibration welding technology are Emerson, Forward Technology (a Crest Group company), Dukane, Bonal Technologies Inc. and NTF Pvt. Ltd.

About Us:-

Transparency Market Research (TMR) is a next-generation provider of syndicated research, customized research, and consulting services. TMR’s global and regional market intelligence coverage includes industries such as pharmaceutical, chemicals and materials, technology and media, food and beverages, and consumer goods, among others. Each TMR research report provides clients with a 360-degree view of the market with statistical forecasts, competitive landscape, detailed segmentation, key trends, and strategic recommendations.

Contact Us:-

State Tower,

90 State Street,

Suite 700,

Albany NY - 12207

United States

Tel: +1-518-618-1030

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vibration Welding Technology Market - Global Industry Growth, Trends and Forecast 2017 - 2025 here

News-ID: 886794 • Views: …

More Releases from Transparency Market Research

Leisure Boat Market Size Forecast to USD 77.6 Billion by 2036 with Growing Deman …

Leisure Boat Market Outlook 2036

The global leisure boat market was valued at USD 54.1 Billion in 2025 and is projected to reach USD 77.6 Billion by 2036, expanding at a steady CAGR of 3.3% from 2026 to 2036. Market growth is driven by rising recreational boating activities, increasing disposable incomes, expanding marine tourism, and growing interest in water sports and luxury lifestyles.

👉 Get your sample market research report copy today@…

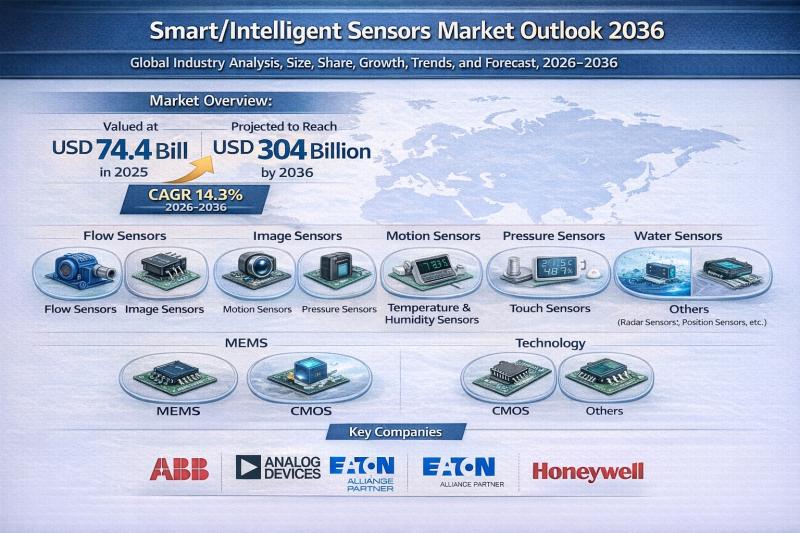

Smart/Intelligent Sensors Market to Reach USD 304 Billion by 2036, Expanding at …

The global smart/intelligent sensors market is witnessing robust expansion as connected ecosystems, automation technologies, and edge computing redefine digital infrastructure worldwide. Valued at USD 74.4 Billion in 2025, the market is projected to surge to USD 304 Billion by 2036, registering a strong CAGR of 14.3% from 2026 to 2036.

Smart or intelligent sensors go beyond conventional sensing capabilities by integrating embedded processing, data analytics, wireless connectivity, and decision-making intelligence directly…

Broadcast Switchers Market to be Worth USD 4.5 Bn by 2036 - By Production, Routi …

The global Broadcast Switchers Market is poised for sustained expansion over the next decade, driven by technological innovation and rising global demand for high-quality live content production. Valued at USD 2.3 Billion in 2025, the market is projected to grow to USD 4.5 Billion by 2036, expanding at a compound annual growth rate (CAGR) of 6.2% from 2026 to 2036.

Review critical insights and findings from our Report in this sample…

Global Tablet Coatings Market Outlook 2031: Projected to Surpass USD 1,543 Milli …

The global tablet coatings market was valued at US$ 824 Mn in 2021 and is projected to expand at a steady CAGR of 5.3% from 2022 to 2031, reaching more than US$ 1,543 Mn by 2031. This consistent growth trajectory reflects the rising consumption of coated pharmaceutical and nutraceutical tablets across developed and emerging markets.

Between 2017 and 2020, the market experienced moderate expansion driven by generics penetration and increasing oral…

More Releases for Vibration

Global Vibration Platform Market Size by Application, Type, and Geography: Forec …

According to Market Research Intellect, the global Vibration Platform market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The market for vibration platforms is expanding steadily due to rising interest in health, fitness, and rehabilitation technologies.…

Basic knowledge of motor vibration and the causes of large motor vibration

1. What are the calculation units of motor vibration value? How to understand these units?

The commonly used measurement units of motor vibration value are speed effective value (referred to as speed), vibration amplitude value (referred to as amplitude, divided into single amplitude and double amplitude) and vibration acceleration. The first one is used more.

"Speed effective value" can be simply understood as the distance moved by the vibrating material (which can…

Prominent Vibration Sensor Market Trend for 2025: Rising Technological Advanceme …

What industry-specific factors are fueling the growth of the vibration sensor market?

The expansion of the aviation sector is anticipated to fuel the vibration sensor market's growth. Vibration analysis in aircraft engines is utilized to check vibration levels and ensure the lack of cracks, functioning avionics, and overall engine performance. For example, Eurostat, a European intergovernmental statistical organization, reported in September 2024 that the air travel in the EU for 2022…

Rising Need for Noise & Vibration Reduction in Vehicles Driving Demand for Autom …

250 Pages of Research Study Published by Fact.MR, a Leading Market Research and Competitive Intelligence Provider Offers Riveting Insights into Key Factors Accelerating the Growth of the Global Automotive Vibration Absorber Market over the Assessment Period 2021-2031

The vibration control industry manufactures automotive vibration absorbers used in suspension components for reducing noise and vibration in automobiles, engines, powertrains, and other machine constructions. As suspension systems play vital role in maintaining safety and comfort…

Vibration Monitoring Equipment Market expects vibration measurement to rise as a …

The Vibration Monitoring Equipment Market deals with the development, manufacture and distribution of vibration measuring instruments. The process of monitoring and measuring the condition of a machine according to various parameters is called condition monitoring. One such parameter under condition monitoring is vibration measurement.

The vibration measuring instruments are utilized in major industries for the safety and proactive maintenance of the respective equipment. A vibration measurement instrument has the ability to…

Measuring Bearing Vibration Levels

Data Acquisition Systems for Fault Diagnosis & Condition Monitoring

The diagnosis of bearing damage in roller bearings is an integral part of servicing and maintenance tasks. Increasingly, technicians rely on condition monitoring systems (CMS) for machine diagnoses in plants and factories. Many CMS systems are based on vibration measurements. Two contrasting approaches exist: the diagnostic, qualitative approach (producing an envelope spectrum); and the quantitative approach (measuring vibration velocity).

Delphin Expert Vibro…