Press release

Comprehensive Report on Process Pipe Coating Market by Future Market Insights 2017 - 2027

Pipe coating is a technique which utilizes protective materials to protect a pipe from corrosion and abrasion. Based on the requirement, the coating used can either be of a single or triple layer. Pipe coatings are important to protect a pipe from harmful environmental components, such as moisture, ultra violet rays, acid, carbon dioxide, hydrogen disulfide, etc. as these components are capable of directly meddling with performance, reliability, durability and flow of a pipe. Coatings on a pipe are applied both internally and externally. External corrosion frequently occurs in the form of oxide materialization when water comes in contact with air. Internal corrosion, on the other hand, frequently occurs due to the presence of active chemicals present in the liquid flowing through a pipe. These active chemicals react with the material of pipe, resulting in internal corrosion. The selection of a suitable coating depends on various factors, some of which are performance, economic concerns, regulatory consideration, chemical properties of the fluid, flammability and viscosity. Powder coating offers better durability and environmental benefits as it does not emit VOCs (Volatile Organic Compounds). The oil and gas industry is the leading end user of the global process pipe coating market as the pipes in this industry are subjected to significantly corrosive and harsh environmental conditions while oil extraction and transportation.Though there are various other corrosion prevention methods, such as current catholic protection and sacrificial anode, these methods are not very effective. Pipe coating is perceived to be the most consistent method for corrosion prevention, which can be a major contributor to market growth.

Request For Report Sample: https://www.futuremarketinsights.com/reports/sample/rep-gb-4962

Process Pipe Coating Market: Dynamics:

Drivers:

Robust growth of end use industries, such as oil and gas, is anticipated to be a prime force triggering the growth of process pipe coating market. Transportation of crucial liquids through pipelines requires proper maintenance of pipes to avoid losses. Governments around the world are putting strict regulations regarding VOCs, which creates the need for the development of new and eco-friendly products such as water-based coatings, which is anticipated to drive market’s growth. Focus of government across major regions to enhance sewage and potable water infrastructure is also anticipated to supplement market growth over the forecast period.

Restraints:

Increasing raw material cost, which further adds to the cost of manufacturing, may prove to be a major challenge for the global process pipe coating market over the forecast period.

Trends:

Preference for abrasion resistance overlay (ARO) is growing in the process pipe coatings market. ARO is designed to protect FBE (Fusion bonded epoxy) coated pipes during directional applications, such as thrust bore, river crossing and slick bore.

Process Pipe Coating Market: Segmentation

The global process pipe coating market can be segmented on the basis of form into:

Power coating

Water-based coating

Solvent-based coating

The global process pipe coating market can be segmented on the basis of product type into:

Thermoplastic polymer coating

Polypropylene

Teflon

Polyethylene

Polyurethane coating

Metallic coating

Electroplating

Galvanization

Cadmium plating

Fusion merged epoxy ash coating

Concrete coating

Asphalt coating

Coal tar enamel coating

The global process pipe coating market can be segmented on the basis of end users into:

Industrial

Mining

Chemical processing

Oil and gas industry

Agriculture

Residential

Commercial

Process Pipe Coating Market: Key Participants:

Some of the key players identified across the value chain of the global process pipe coating market include:

Shawcor Ltd.

The Bayou Companies

Arkema S.A.

Lyonde||Base||IndustriesHolding B.V.

L.B.Foster Ball Winch

BASF SE

AKZO Nobel N.V.

Covestro AG

The Dow Chemical Company

Wasco Energy Group of Companies

Celanese Corporation

Tenaris

Request For Report Table of Content (TOC): https://www.futuremarketinsights.com/toc/rep-gb-4962

Process Pipe Coating Market: Region-wise Outlook:

North America is anticipated to be the dominant region in the global process pipe coatings market owing to the increase in natural gas production from shale formation. Middle East and Africa (MEA), especially Saudi Arabia and Qatar, will closely follow North America and expected to be major markets for process pipe coating because of high production of petroleum and other liquids in the region. It is expected that Asia-Pacific will witness significant growth in the global process pipe coating market during the forecast period. China, Indonesia and India are anticipated to emerge as fast growing countries in the global process pipe coating market. In Europe, given the decreasing gas production in the Dutch field, the market in this region is anticipated to witness relatively lower growth over the forecast period.

ABOUT US:

Future Market Insights (FMI) is a leading market intelligence and consulting firm. We deliver syndicated research reports, custom research reports and consulting services, which are personalized in nature. FMI delivers a complete packaged solution, which combines current market intelligence, statistical anecdotes, technology inputs, valuable growth insights, an aerial view of the competitive framework, and future market trends.

CONTACT:

Future Market Insights

Abhishek Bhudoliya

616 Corporate Way, Suite 2-9018,

Valley Cottage, NY 10989,

United States

T: +1-347-918-3531

F: +1-845-579-5705

Email: sales@futuremarketinsights.com

Website: www.futuremarketinsights.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Comprehensive Report on Process Pipe Coating Market by Future Market Insights 2017 - 2027 here

News-ID: 819613 • Views: …

More Releases from Future Market Insights

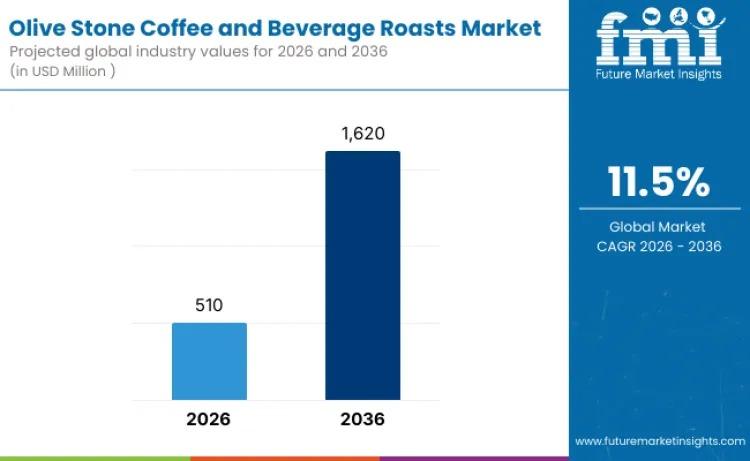

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

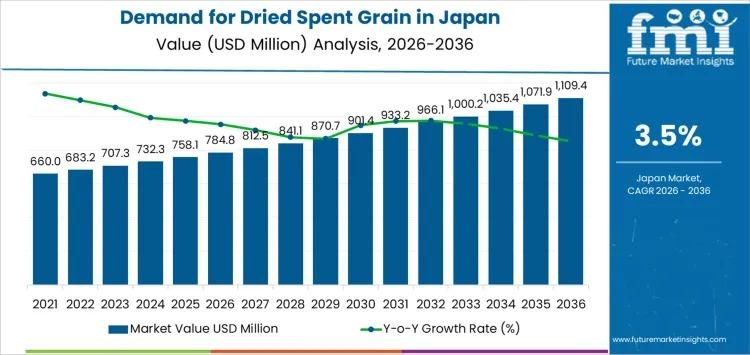

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

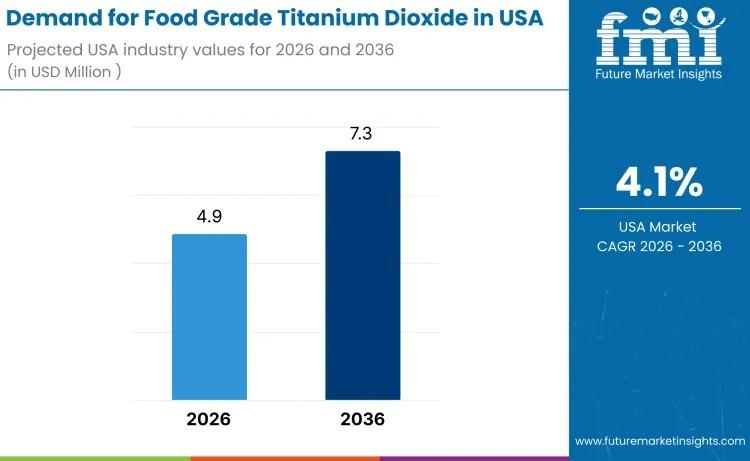

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

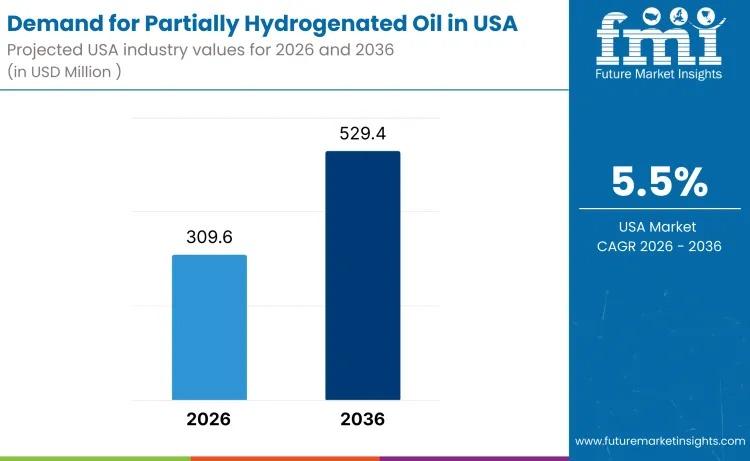

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Pipe

How to choose Seamless Pipe vs Welded Pipe vs Spiral Welded Pipe

Seamless pipe, welded pipe, and spiral welded pipe are the three most common types. They may appear similar in appearance, but the differences are profound in essence, with the core distinction indeed stemming from manufacturing processes.

Comparison Table

FEATURE DIMENSION

SEAMLESS STEEL PIPE

LONGITUDINALLY WELDED PIPE

SPIRAL WELDED PIPE

Manufacturing Process

Solid billet piercing and rolling, no weld seam.

Steel plate/sheet is curved and welded along a longitudinal straight seam.

Steel strip is coiled at a spiral angle, forming…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…