Press release

User-friendly belt conveyor configurator

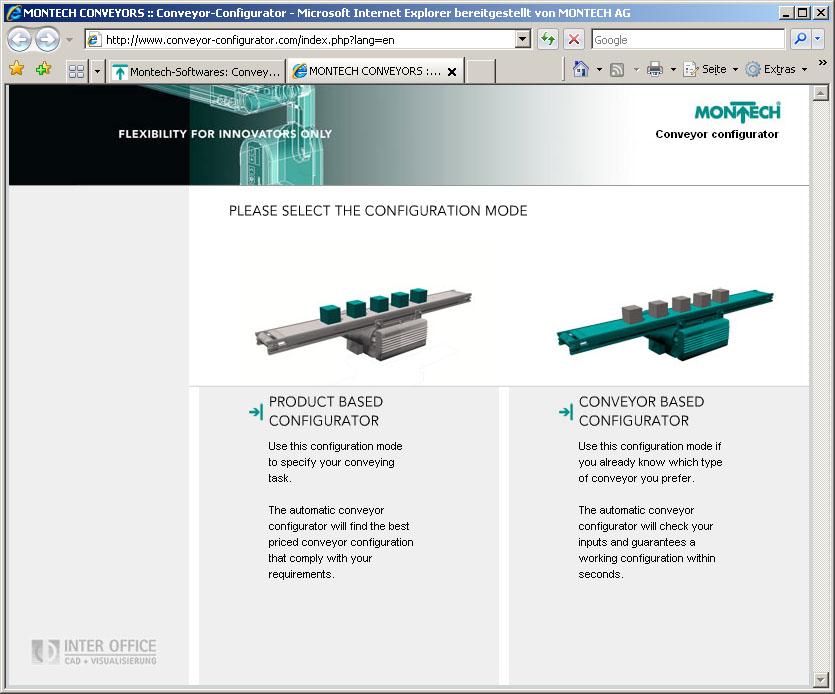

Montech’s conveyor configurator is now available in a product-oriented and a conveyor-oriented version.

In the product-oriented version, the configurator starts from user requirements and specifications to present a solution based on the best price. At this stage, the system guides the user to provide all necessary information to identify the transport solution. A plausibility check avoids that unsuitable or defective configurations are presented.

The users who have already identified the type of conveyor can use the conveyor-oriented version. “With the new belt conveyor configurator on www.montech.com, it is even easier and more intuitive to define the desired belt configuration,” says Gianluca Aloisi, Manager Conveyors Division.

The configurator (currently available in the second version) has been developed in collaboration with Inter Office GmbH in Dresden. “The simple and intuitive process that guides the user and the capacity to generate an order for a complex conveyor in just a couple of minutes will help Montech address a wider and wider spectrum of customers,” says René Kirchbach, General Manager of Inter Office.

Conveyors based on standard components

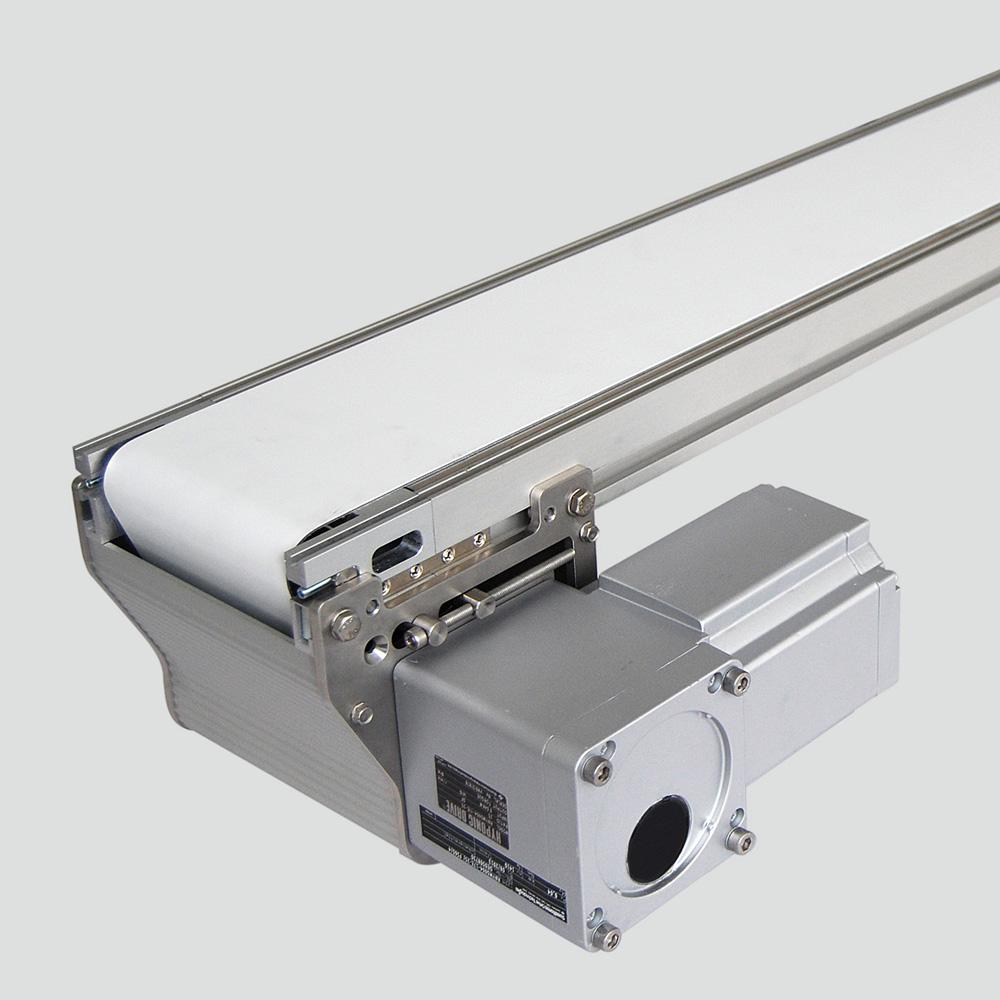

The belt conveyors in standard, Minidrive and Maxi versions are designed to carry parts to or from the various manufacturing stations or they are combined to form complete production lines. The conveyors have standard widths included between 45 and 800 mm and they can carry up to 125 kg weight, while their length can be selected freely up to 15 meters in one millimeter steps.

Traditional conveyors are based on a modular concept with ready-to-use standard components for specific functions. Thanks to their modularity, the conveyors can be assembled in variable configurations, extended or shortened with a simple and cost-effective approach. “With their modular construction, all belt conveyors by Montech are very suitable for customer-specific transport solutions,” underlines Aloisi.

Uninterrupted heavy-duty operation

All metal parts of Montech belts are made of nickel steel or stainless steel; the transmission rollers are normally made of stainless steel, while the driving rollers are provided with a special rubber cladding. The materials used are compatible with heavy-duty applications in continuous operation.

Montech AG markets basic modular components that automate demanding production and logistics processes. In addition to conventional conveyor belts, automation components and the Quick-Set profile system, the range of products also includes the Montrac transport system. Montrac is an intelligent transport system for networking industrial production and logistics processes. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Telefon: +41 32 681 55 00

Fax: +41 32 682 19 77

www.montech.com

E-Mail: info@montech.com

Press contact:

Elke Manthei

Telefon: +41 32 681 55 42

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release User-friendly belt conveyor configurator here

News-ID: 58732 • Views: …

More Releases from Montech AG

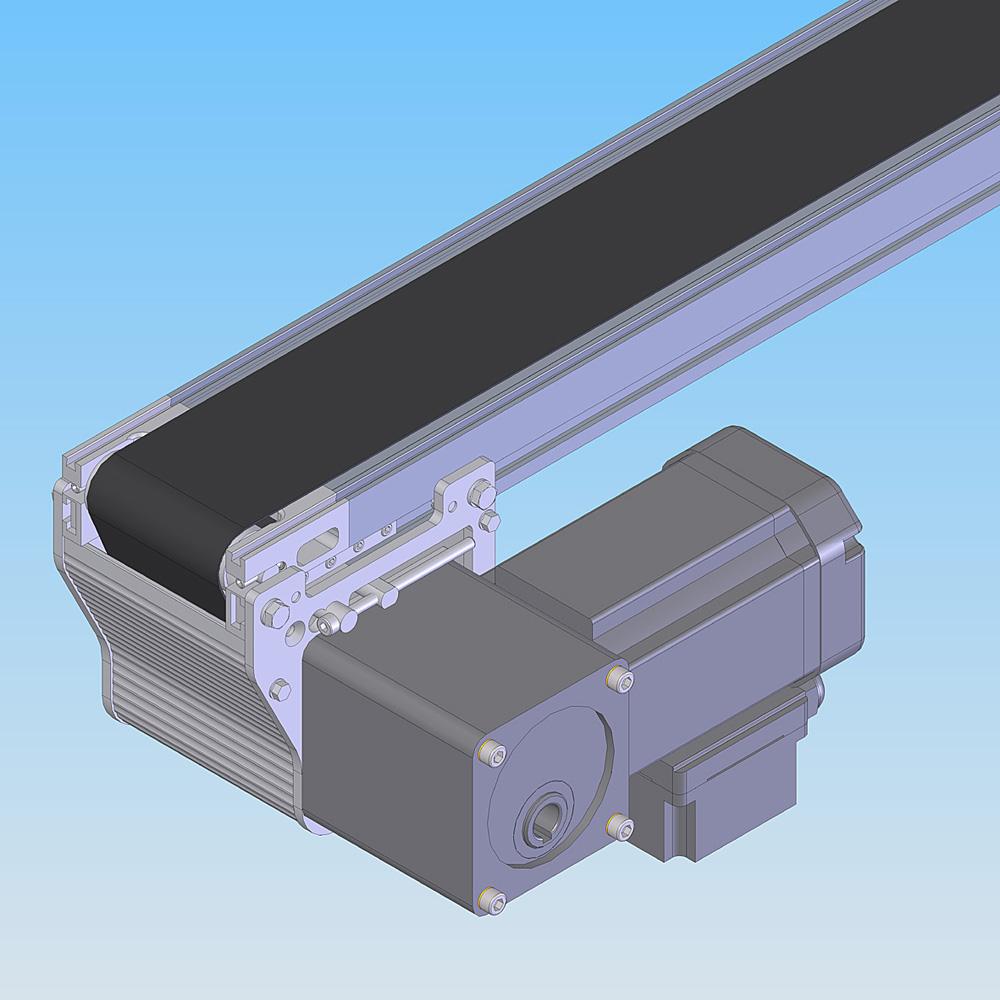

New conveyors from Montech: efficient and user-friendly

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

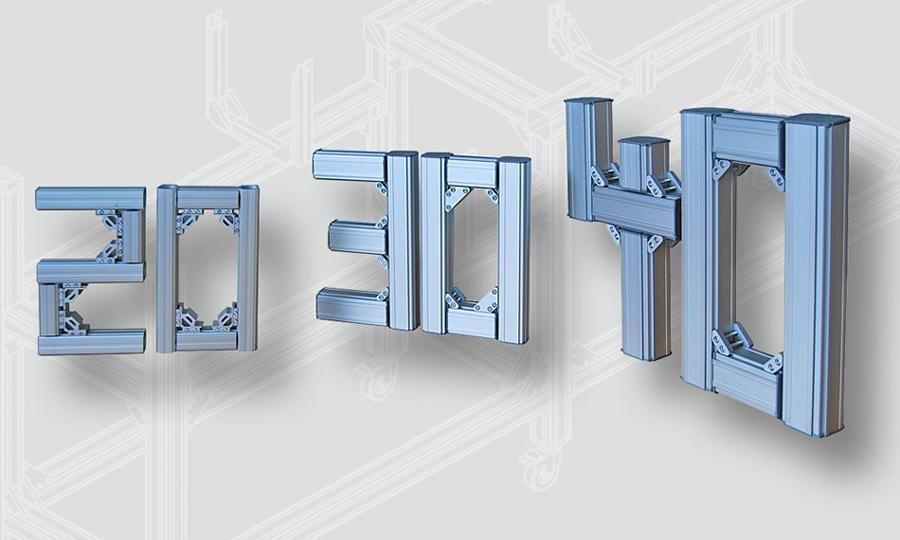

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech: new conveyors and LT40 transport system

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa,…

More Releases for Montech’s

Montech: Online Shop open around the clock

The products of Montech AG, Swiss conveyor specialist, can be ordered online quickly and directly.

The online offer of the specialist for automation of transport, assembly and production processes encompasses chassis, end sections and drive units, aluminum profiles and connectors, up to automation components such as grippers. “Our customers can find detailed information about Montech products on the web and submit orders around the clock,” says Gianluca Aloisi, Director Sales.

The Online…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech at LogiMAT: new transport system for intralogistic

(Derendingen, January 17, 2013) At LogiMAT 2013 in Stuttgart, Montech AG is introducing the new transport system LTplus as well as customized solutions for intralogistic based on standard conveyors.

The new transport system LTplus is comprised of a double belt, which carries individual workpiece holders at a speed up to 20 m/min. The latter have a load capacity of 16,8 kg and are provided with RFID, so that they can be…

Montech: New transport system saves time during start-up

At Motek 2012 in Stuttgart (Hall 1, Stand 1180), the Swiss specialist of transport systems is introducing a new developed transport system, that is wired and tested before delivery.

The new transport system consists of a double belt, which carries individual workpiece holders. They are equipped with RFID and can be identified at any time, thus enabling “chaotic” operation. The motor is integrated in the drive roller, with no protruding…

Vacuum conveyor for 4,000 wafers per hour

The Swiss conveyor specialist Montech AG has developed a new vacuum conveyor that can handle 4,000 wafers per hour.

The new vacuum conveyor, which can also be used as an overhead conveyor, carries several wafers simultaneously, running at speed up to 5 meters that allow handling 4,000 wafers per hour. Compared to other handling solutions, Montech’s Vacuum conveyor handles delicate wafers more smoothly and has a smaller footprint.

The system can…

At FachPack 2010, Montech’s solutions for sustainable production

At the special show dedicated to “Sustainable production and packing” during the FackPack exhibition in Nurnberg, the Swiss conveyor specialist Montech will present its range of modular belt conveyors at stand 4-227 in hall 4.

The Montech conveyors are based on a modular concept with ready-to-use standard components. Thanks to their modularity, the conveyors can be assembled in variable configurations, extended or shortened with a simple and cost-effective…