Press release

Efficient and fully automated intralogistics in the plastic industry

The Montrac transport system by the Swiss company Montech optimizes intralogistic operations for increased productivity. At Fakuma 2008, Montrac can be seen “live” in Hall A7, Booth 7106.When you need to increase productivity, the very first idea is to increase the number of machines. However, there is another option: automating and optimizing the material flow. “Often, a conventional conveyor cannot solve the intra-logistic requirements of a company. With Montrac, the products can be conveyed easily and quickly, with no queues”, says Alessandro Sibilia, CEO, Montech AG.

Transport system, belt conveyor and scale, all in one

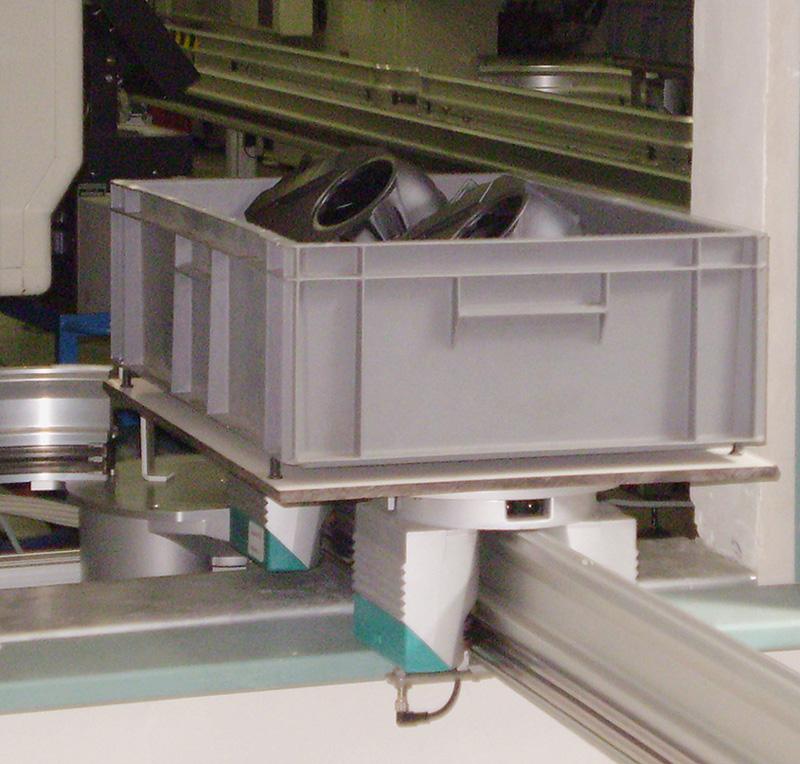

Specifically for the plastic industry, Montech has developed a Montrac module provided with a belt conveyor and integrated scale. Through an accumulation belt, that works independently of the machine and process cycle time, the finished parts leaving a machine (for instance, an injection press) are collected and fed into a container located on a shuttle of the Montrac system. Here, the integrated precision scale by Eilersen measures the content weight with an accuracy degree up to 1/10 grams.

The whole process is automated and the parts can be dosed in batches of any size and weight with no further manual operations. “With this solution, injection molding presses can be perfectly integrated with the logistic system,” Sibilia explains.

Universal shuttle system

With Montrac, Montech has developed a transport system with a modular concept for universal applications. The self-moving shuttles run along the maintenance-free monorail track with speeds up to 30 m/min. The electrically operated elements (switches and crossings) do not require pneumatic operation (compressed air). Electric power is supplied directly through the rails. Shuttles and rails communicate via infrared rays.

Easy installation

The Trac monorails and TracLink connection elements ensure quick and easy assembling: two tools are all it takes to install a Montrac line or to adapt it to new situations and requirements. “In this way, the layout flexibility is virtually unlimited,” Sibilia says.

Montrac Configurator

On the Website www.montech.com, all interested users can find an online configurator that allows to create their own Montrac line, testing different variants and options. With this online tool, it is quick and easy to adapt the monorail track to the customer’s operating needs and to available space in the installation place.

Montech AG markets basic modular components that automate demanding production and logistics processes. In addition to conventional conveyor belts, automation components and the Quick-Set profile system, the range of products also includes the Montrac transport system. Montrac is an intelligent transport system for networking industrial production and logistics processes. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 32 681 55 00

Fax: +41 32 682 19 77

www.montech.com

E-Mail: info@montech.com

Presscontact:

Elke Manthei

Phone: +41 32 681 55 42

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Efficient and fully automated intralogistics in the plastic industry here

News-ID: 56025 • Views: …

More Releases from Montech AG

New conveyors from Montech: efficient and user-friendly

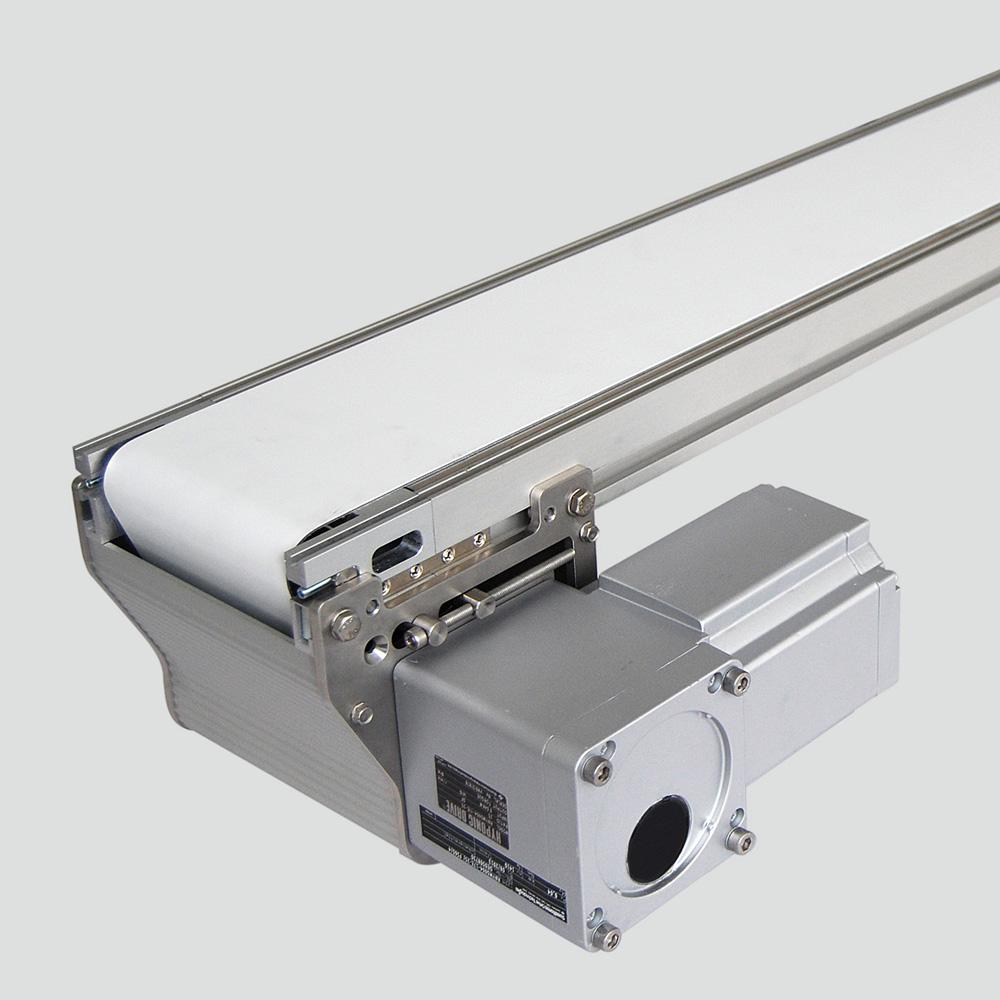

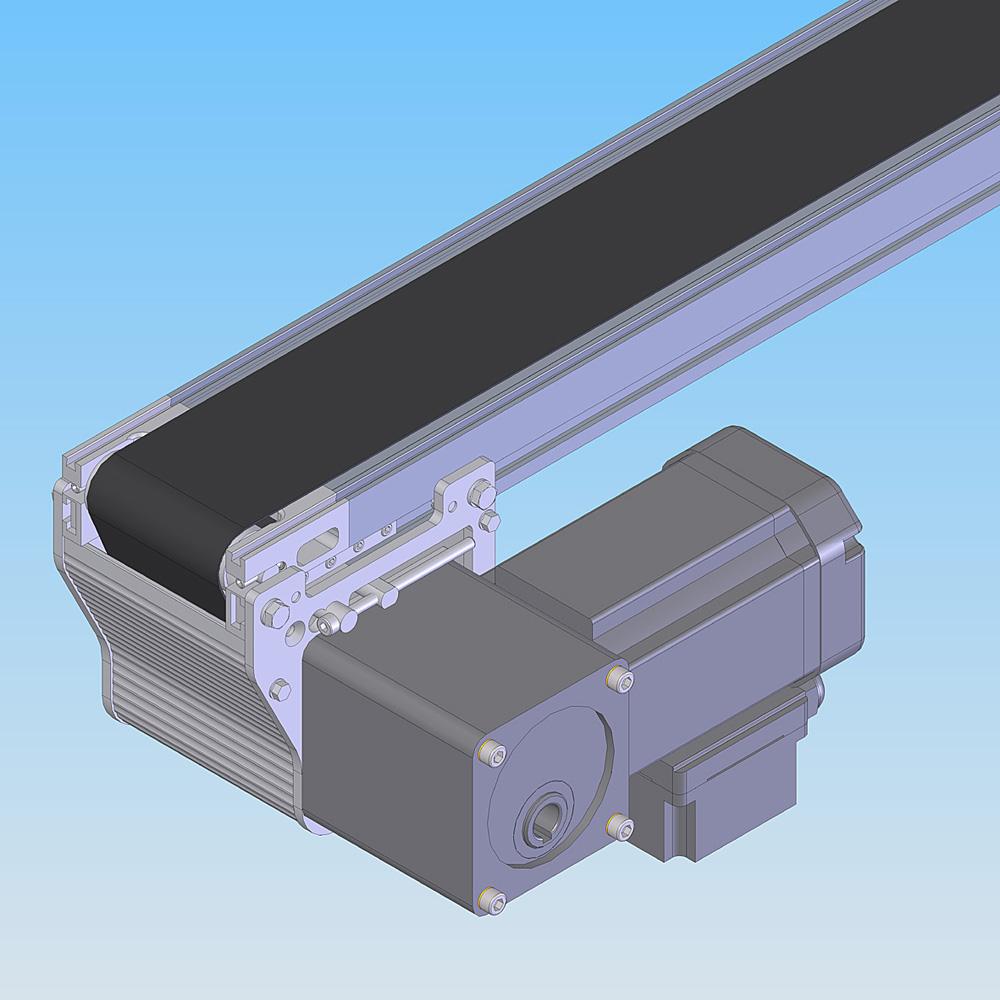

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

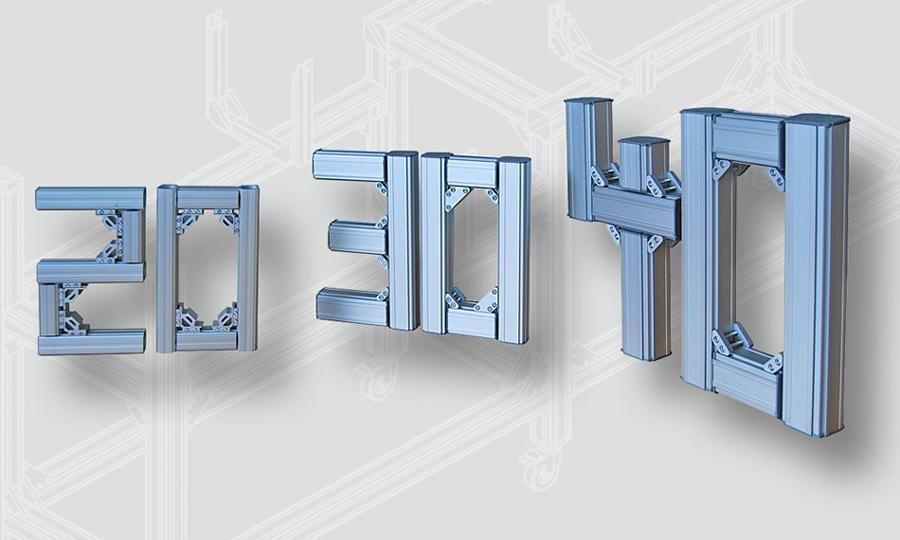

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech: new conveyors and LT40 transport system

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa,…

More Releases for Montrac

Montrac presents automated warehouse integration at LogiMAT 2011

The monorail transport system Montrac allows to create a link between warehouse and production, for instance. This application, interesting for companies across several industries, will be presented by the Swiss manufacturer at the upcoming LogiMAT in Stuttgart, Hall 3, Booth 171.

The self-moving shuttles, equipped with a belt for automatic loading and unloading, travel between the warehouse and production area according to the instructions of the central control system, running on…

Montech at LogiMAT 2010

The Swiss intralogistic specialist Montech AG is exhibiting at LogiMAT 2010, showing the Montrac transport system and its range of belt conveyors.

From 2 to 4 March 2010, at LogiMAT, Hall 1, Booth 407, Montech will show how many companies could optimize their intralogistic and increase efficiency by adopting the Montrac system. “The efficiency of operations in all company areas, especially intralogistics, is more and more critical,” said Gianluca Aloisi,…

Optimized intralogistics with Montrac

The Montrac transport system by the Swiss company Montech optimizes intralogistic operations and increases productivity.

“The issue of intralogistics is becoming more and more important,” says Yves Dicke, Manager Montrac of Montech. More and more companies are willing to deploy automated solutions to transfer small plastic parts produced by their injection molding presses. “Normally, the parts are transported manually or by means of fork-lift trucks to a buffer area,…

Matchbox cars ride with Montrac

Inaugurated on 27 June 2009, the new Road Transport Hall of the Swiss Museum of Transport in Lucerne is equipped with a Montrac system handling the presentation of 3000 Matchbox cars.

The idea to present the Matchbox cars with a Montrac system was conceived and developed by the museum in cooperation with Montech.

40 shuttle run along 36 meters of monorail track, carrying 3000 miniature models from all categories and times. The…

New set-up for Montrac in the Americas

FlexLink and Montech agree to a new distribution partnership for the Montrac monorail pallet system in North and South America.

The Montrac monorail pallet based conveying system is recognized for its high-tech production logistics applications in manufacturing, assembly, and test processes. It is used within the electronics, health care, and plastics industries in clean room applications up to class 10.

FlexLink and Montech have entered into a partnership to increase…

Automated connection to the warehouse with Montrac

At the intralogistic show LogiMAT 2009 in Stuttgart, Montech introduced a solution for the automated connection of the warehouse, based on the transport system Montrac. The solution is particularly interesting for companies looking for a way to link their warehouse with production or other facilities.

The self-moving shuttles, equipped with a belt for automatic loading and unloading, travel between the warehouse and production area according to the instructions of…