Press release

Crystal clear liquid silicone from Momentive Performance Materials

Crystal clear liquid silicone from Momentive Performance Materials enables top reproduction accuracy for camera-based driver assistance systems

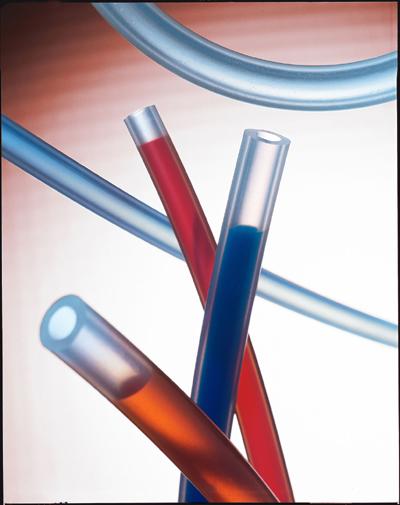

LEVERKUSEN, GERMANY — AUGUST 25, 2008 - High transparency Liquid Silicone Rubber (LSR) from Momentive Performance Materials for use in camera-based driver assistance systems from KOSTAL. KOSTAL, the technology specialist for automotive electronics and mechatronics, introduces a compact front view camera which attaches to the windscreen. Its special construction combines functional and technical design advantages. The material used to couple the camera directly to the windscreen was developed by LSR specialist Momentive Performance Materials.

Vehicle safety and comfort are central to modern automotive design

In view of the increasing volume of traffic on the roads, the combination of established security systems and innovative environmental sensors forms a forward-looking basis with which to safely deal with complex traffic situations.

Rain and light sensors are characteristic features of modern vehicles today. They increase comfort, reduce the workload of the driver and therefore make a significant contribution to improving active vehicle safety. Predictive driver assistance systems require a detailed analysis of the traffic situation using camera and video-based environment recognition. The corresponding optics must record the events in the environment of the vehicle reliably and true to life.

This requires robust, high-performance optical materials, which retain their characteristic transparent properties in the wavelength range of the light at the time, even in the event of extreme temperature fluctuations, differing levels of humidity and over a long lifespan.

The new driver assistance camera by KOSTAL with integrated rain and light sensors

KOSTAL GmbH & Co. KG and Momentive Performance Materials GmbH worked together to develop a new, highly-transparent liquid silicone rubber (LSR) for an innovative sensor module which integrates rain and light sensors as well as a camera and takes up minimal space.

The camera is attached directly to the windscreen to achieve maximum robustness against typical sources of interference such as dirt and light reflection. The highly transparent silicone cushion creates a blister-free transition between the optical sensors and the windscreen, adapts perfectly to different surfaces and thus also reduces scattered light and reproduction inaccuracies.

Highly transparent liquid silicone with the lowest hardness

Momentive Performance Materials meet this challenge with their completely new LSR material which will be launched as part of the new optically highly transparent LSR 7000 series as LSR 7005. The low hardness of the material (just 5 Shore A) allows a form-fitting, tolerance-compensating connection of the sensors to the windscreen, regardless of the windscreen radius, and low mounting forces. In addition, the new LSR does not adhere to the glass, even at high temperatures and after longer periods of time. This means the complete module can be used again when the windscreen is replaced. The excellent transmission values of 95% over a broad wavelength and temperature range and a refractive index comparable with glass ensure maximum light transmission and a clear, detailed visualization of the environment. Processing features are, the short cycle times for which LSR is renowned, a fully automated injection moulding process enabling the production of sophisticated geometries and complex multi-component parts.

Momentive will be showcasing the LSR 7005 at the Fakuma 2008 trade fair, Friedrichshafen, Germany from 14-18 October 2008 (http://www.fakuma-messe.de/en/fakuma, hall B2, booth B22107), along with other innovations in silicone elastomers, RTVs and hardcoats.

To find out more about Momentive’s transparent LSR products, please call: European customer service: 00 800 4321 1000, e-mail:cs-eur.silicones@momentive.com or visit our website www.momentive.com.

PR-Contact Europe, Middle East, Africa & India

Robert Scheib

robert.scheib@momentive.com

+49 214 304 0532

PR-Contact Americas/Canada

Nancy Pitts

nancy.pitts@momentive.com

+1 203 761 1938

PR-Contact Asia/Pacific (Japan, Korea, South East Asia, Australia)

Yoshiko Matsuda

Yoshiko.Matsuda@momentive.com

+03 5544 3092

PR-Contact Asia/Pacific (Greater China)

Joyce Sun

Joyce.Sun@momentive.com

+86 21 3860 4706

PR-Agency Europe, Middle East, Africa & India

EMG, Brigitta de Vries

bdevries@emg.nl

+31 164 317 020

PR-Agency Asia/Pacific (Japan, Korea, South East Asia, Australia)

Tokyo PR, Mitsuyoshi Sugino

sugino@tokyopr.co.jp

+03 3273 2731

PR-Agency Asia/Pacific (Greater China)

Fortune China Public Relations Ltd., Ren Yi

Yi.ren@fortunechina.com.cn

+86 21 6289 5658 – 22

About Momentive Performance Materials

Momentive Performance Materials Inc. is a premier specialty materials company, providing high-technology materials solutions to the silicones, quartz and ceramics markets. The company, as a global leader with worldwide operations, has a robust product portfolio, an enduring tradition of service excellence, and industry-leading research and development capabilities. Momentive Performance Materials Inc. is controlled by an affiliate of Apollo Management, L.P. Additional information is available at www.momentive.com.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Crystal clear liquid silicone from Momentive Performance Materials here

News-ID: 51835 • Views: …

More Releases from Momentive Performance Materials GmbH

GE RapidStrength* Silicone Sealant’s Productivity, Quality & Protective Glazin …

Enormous Increase in Sales of Close for GE RapidStrength Silicone Sealants. Momentive demonstrates product advantages on this years Glasstec Show in Düsseldorf Germany from 21st – 25th of October

LEVERKUSEN, GERMANY — OCTOBER 16, 2008 - The industry’s demand for the popular GE RapidStrength window bedding silicone sealant continues to grow at a rapid pace, as evidenced by an enormous increase in sales of close for Momentive Performance Materials. A cold-applied,…

Momentive’s New SPUR+* Prepolymers Offer High Tensile Strength for Next-Genera …

One-Part Formulations for Developers of Industrial Adhesives Open Door to High Performance Alternatives to Mechanical Fasteners

LEVERKUSEN, GERMANY — OCTOBER 9, 2008 - Momentive Performance Materials will introduce two breakthrough prepolymers for industrial adhesives formulations at the Adhesive and Sealants Council’s 2008 Fall Convention & Expo in Baltimore, Maryland, October 12th to 14th, 2008. SPUR+ 3100HM prepolymer and SPUR+ 3200HM prepolymer will join Momentive’s highly successful SPUR+ family of silylated polyurethane…

Momentive Performance Materials Inc. Announces Purchase of Certain Assets of Osr …

LEVERKUSEN, GERMANY - OCTOBER 7, 2008 - Momentive Performance Materials Inc. (the “Company”) today announced that its wholly-owned subsidiary, Momentive Performance Materials Quartz, Inc., has acquired certain assets of the semiconductor and lighting quartz products business of Osram Sylvania Products Inc. (“OSPI”), including manufacturing equipment, inventory, intellectual property and customer lists. OSPI is a wholly-owned subsidiary of OSRAM Sylvania Inc. Terms of the transaction were not disclosed.

“This acquisition is…

Momentive Performance Materials Announces Completion of its New Addisil* HCE fam …

LEVERKUSEN, GERMANY - OCTOBER 10, 2008 - Momentive Performance Materials, a leading manufacturer of custom heat-cured elastomers, liquid silicone rubber (LSR) and RTV adhesives, today announced the completion of its new Addisil* elastomers family of addition heat-curable elastomers (HCEs). The new elastomers feature next-generation properties that offer regulatory compliance, high clarity, enhanced mechanical performance and superior productivity.

Products are now available in 40, 50, 60, 70 and 80 Shore A,…

More Releases for LSR

LSR Injection Molding Machine Market Size, Trends, Growth: Global Forecast 2025- …

The global market for LSR Injection Molding Machine was estimated to be worth US$ 284 million in 2024 and is forecast to a readjusted size of US$ 532 million by 2031 with a CAGR of 9.4% during the forecast period 2025-2031.

Global Leading Market Research Publisher QYResearch announces the release of its latest report "LSR Injection Molding Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

Construction Aggregate Market Is Booming Worldwide : Wharehine, Hanlon Concrete, …

Latest Study on Industrial Growth of Construction Aggregate Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Construction Aggregate market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments…

Liquid Silicone Rubber (LSR) Market: Competitive Analysis and Global Outlook 202 …

The new report published by Stratview Research, titled Liquid Silicone Rubber (LSR) Market, is Segmented by Molding Technology Type (Liquid Injection Molding System), by Grade Type (Industrial Grade, Medical Grade, and Food Grade), by Application Type (Automotive, Medical, Electrical & Electronics, Consumer Goods, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

COVID-19 Impact & Recovery:

The report suggests that the Liquid Silicone Rubber (LSR) Market…

Liquid Silicone Rubber (LSR) Market Report 2018: Segmentation by Product (Indust …

Global Liquid Silicone Rubber (LSR) market research report provides company profile for ShinEtsu, KCC Corporation, Laur Silicone, Tianci Materials, Guangdong Polysil, Shenzhen SQUARE Silicone, BlueStar Xinghuo, Wynca, Dow Corning, Wacker Chemicals, Momentive and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR…

Global Liquid Silicone Rubber (LSR) Market Outlook 2016-2021

Liquid Silicone Rubber, with its low compression set, fast cure cycles, great stability and ability to resist extreme temperatures of heat and cold makes it ideally suitable for the production of parts where high quality is a must. Unlike most thermoplastic elastomers (TPRs and TPEs), LSR remains flexible and elastic down to -70o F and retains its properties up to 450o F. In addition to these qualities, the wide range…