Press release

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into a mold cavity. These components mix within a static mixer and are then injected into a heated mold under high pressure. The result is a durable, rubber-like product with excellent performance properties.

• How LSR Injection Molding Works

This process starts with two liquid silicone components stored in separate containers. These materials are pumped into a mixing chamber, combined, and then injected into a hot mold. As the mold heats the silicone, it cures and solidifies into the desired shape. Once cooled slightly, the finished part is removed from the mold automatically or manually.

• Key Advantages of LSR Molding

Liquid silicone rubber molding offers several benefits:

-- Thermal Stability: LSR components withstand extreme temperatures, making them ideal for high-heat environments.

-- Chemical Resistance: Silicone resists oils, acids, and other chemicals.

-- Biocompatibility: Medical-grade LSR is safe for use in healthcare applications.

-- Design Flexibility: It allows for complex geometries and thin walls without compromising strength.

-- High Volume Production: LSR molding supports rapid production cycles with minimal waste.

• Common Applications of Silicone Injection Molding

The versatility of LSR makes it suitable for a wide range of products:

-- Medical Devices: Catheters, respiratory masks, seals, and valves.

-- Automotive Parts: Gaskets, connectors, and sensor covers.

-- Consumer Goods: Baby bottle nipples, kitchenware, and wearable bands.

-- Electronics: Keypads, connectors, and insulation.

• Choosing the Right Silicone Grade for Molding

Selecting the appropriate silicone grade ensures optimal performance and regulatory compliance:

-- Medical Grade: Meets USP Class VI or ISO 10993 standards.

-- Food Grade: Compliant with FDA and LFGB regulations.

-- Industrial Grade: Designed for mechanical or chemical exposure.

Each grade has specific curing, tensile strength, and elongation characteristics tailored to its end use.

• Precision Tooling for LSR Molding

Successful LSR molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/) depends heavily on the mold design. Precision tooling is essential to manage the flow of silicone, vent trapped air, and maintain uniform heating. Key aspects include:

-- Cold Runners: Prevent premature curing before injection.

-- Hot Cavities: Ensure efficient curing once silicone enters the mold.

-- Venting Systems: Avoid air entrapment that could cause defects.

• Design Considerations for LSR Molded Parts

Product designers working with LSR must consider:

-- Undercuts: Avoid where possible or design for demolding.

-- Wall Thickness: Uniform thickness improves curing and strength.

-- Parting Lines: Should be strategically placed for cosmetic and functional quality.

-- Draft Angles: Necessary for easy part removal from the mold.

These factors impact cycle time, part quality, and mold life.

• Cost Factors in Liquid Silicone Rubber Molding

Although LSR molding has a higher initial tooling cost, its long-term benefits often outweigh the investment. Cost drivers include:

-- Tooling Complexity: Multi-cavity molds and complex designs increase cost.

-- Material Grade: Medical and food-grade silicones are more expensive.

-- Automation Level: Fully automated systems reduce labor but increase upfront setup costs.

-- Volume: Higher production runs decrease per-unit costs due to economies of scale.

• Environmental Benefits of LSR Molding

LSR molding is an environmentally responsible manufacturing process:

-- Low Waste: Precise injection reduces piece rates.

-- Recyclability: Some silicone parts can be ground and reused.

-- Energy Efficiency: Shorter cycle times and electric presses improve energy use.

-- Long Product Life: Durable LSR parts last longer, reducing replacement needs.

• Innovations in Silicone Molding Technology

Advances in LSR injection molding continue to push the boundaries of what's possible:

-- Micro Molding: Enables production of ultra-small, detailed components for medical and electronic devices.

-- Multi-Shot Molding: Combines LSR with other materials (e.g., thermoplastics) in a single mold cycle.

-- Smart Silicones: Embedded sensors and conductive elements for wearable and IoT applications.

These innovations drive efficiency, expand design options, and open new markets for silicone-based products.

• Why Choose Liquid Silicone Rubber Over Thermoplastics

While thermoplastics offer strength and rigidity, LSR provides superior elasticity, chemical resistance, and thermal performance. It's also:

-- Hypoallergenic: Ideal for sensitive skin applications.

-- UV and Ozone Resistant: Suitable for outdoor exposure.

-- Flexible Yet Strong: Maintains properties across a wide temperature range.

LSR is preferred for products requiring long-lasting flexibility and biocompatibility.

• Conclusion: Future of LSR Injection Molding

LSR molding continues to gain momentum as industries demand higher performance materials that are safe, versatile, and sustainable. With ongoing advancements in tooling, automation, and material science, the possibilities for silicone injection molding are expanding rapidly. From life-saving medical devices to next-generation wearable tech, LSR remains a key enabler of innovation.

Office 7602 182-184, High Street North, East Ham, London

Finixio Digital is a UK-based remote-first Marketing & SEO Agency helping clients worldwide. In only a few short years, we have grown to become a leading Marketing, SEO, and Content agency.

https://newsjotechgeek.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release LSR Molding: Understanding Silicone Rubber Injection Molding here

News-ID: 4090195 • Views: …

More Releases from Finixio Digital

Why millions still lack clean water & how donations can help

Despite decades of development efforts, access to safe drinking water remains out of reach for billions of people. International estimates show that more than two billion individuals still lack reliably managed water services. For many communities, daily life involves uncertainty about whether clean water will be available tomorrow.

Many people searching for ways to donate to water are surprised to learn how widespread the crisis continues to be. It is not…

Why Your Foreign Company Is Still Taxable in the US

There's a moment most US expats remember clearly. You register a company abroad. The paperwork goes through. A local accountant confirms everything is compliant. You pay tax in your new country. It feels settled.

Then, months later, usually while dealing with your US tax return, a different question lands:

Why is the IRS still involved?

It feels unfair at first. Even a little absurd. The company isn't in the US. The clients…

Filing U.S. Taxes Abroad: Tax Expert vs. Tax Preparation Firm

What Americans in the UK need to know before choosing how to file

For the growing number of Americans living in the United Kingdom, U.S. tax season comes with a familiar question: Should you hire a tax expert or use a tax preparation firm?

The answer is not the same for everyone. Your income type, visa status, length of stay and financial footprint in the UK all play a role in determining…

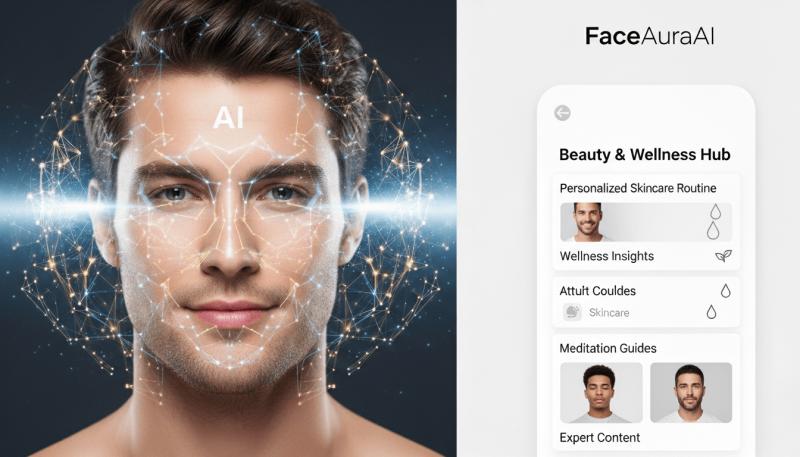

FaceAuraAI Launches a Beauty & Wellness Hub Powered by AI Face Analysis and Expe …

The platform combines free AI-powered face and body analysis tools with a growing library of expert-written guides covering skincare, hair care, natural oils, and holistic wellness.

Kolkata, India - February 18, 2026 - FaceAuraAI, an AI-powered beauty and wellness platform, today announced the expansion of its digital hub - bringing together a suite of free AI face and body analysis tools alongside an expert-curated content library covering skincare, hair care, natural…

More Releases for LSR

LSR Injection Molding Machine Market Size, Trends, Growth: Global Forecast 2025- …

The global market for LSR Injection Molding Machine was estimated to be worth US$ 284 million in 2024 and is forecast to a readjusted size of US$ 532 million by 2031 with a CAGR of 9.4% during the forecast period 2025-2031.

Global Leading Market Research Publisher QYResearch announces the release of its latest report "LSR Injection Molding Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based…

Construction Aggregate Market Is Booming Worldwide : Wharehine, Hanlon Concrete, …

Latest Study on Industrial Growth of Construction Aggregate Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Construction Aggregate market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments…

Liquid Silicone Rubber (LSR) Market: Competitive Analysis and Global Outlook 202 …

The new report published by Stratview Research, titled Liquid Silicone Rubber (LSR) Market, is Segmented by Molding Technology Type (Liquid Injection Molding System), by Grade Type (Industrial Grade, Medical Grade, and Food Grade), by Application Type (Automotive, Medical, Electrical & Electronics, Consumer Goods, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

COVID-19 Impact & Recovery:

The report suggests that the Liquid Silicone Rubber (LSR) Market…

Liquid Silicone Rubber (LSR) Market Report 2018: Segmentation by Product (Indust …

Global Liquid Silicone Rubber (LSR) market research report provides company profile for ShinEtsu, KCC Corporation, Laur Silicone, Tianci Materials, Guangdong Polysil, Shenzhen SQUARE Silicone, BlueStar Xinghuo, Wynca, Dow Corning, Wacker Chemicals, Momentive and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR…

Global Liquid Silicone Rubber (LSR) Market Outlook 2016-2021

Liquid Silicone Rubber, with its low compression set, fast cure cycles, great stability and ability to resist extreme temperatures of heat and cold makes it ideally suitable for the production of parts where high quality is a must. Unlike most thermoplastic elastomers (TPRs and TPEs), LSR remains flexible and elastic down to -70o F and retains its properties up to 450o F. In addition to these qualities, the wide range…

User Report - Praise for LSR Production Line

A customized production line for medical LSR applications by Scheugenpflug AG meets all client expectations

Liquid silicone rubber, or LSR, is an exceptionally versatile substance. Used in almost every technical area for products as diverse as protective coatings, electronics seals and plumbing washers, the medical industry has discovered the enormous potential of this material as well. It is used for producing heart catheters, baby cups and pacifiers, masks and contact lenses,…