Press release

Momentive Introduces Clear LSR Products

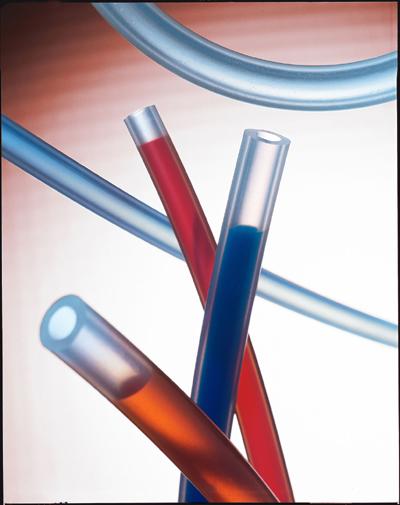

LEVERKUSEN, GERMANY — AUGUST 7, 2008 - Momentive Performance Materials today introduced the breakthrough LSR7000 series, a family of highly transparent liquid silicone rubbers (LSR). Combining typically 98 percent transparency with the unique processing and productivity advantages of an addition-cured, platinum-catalyzed LSR, the LSR7000 series is an excellent candidate to consider for outstanding optical characteristics and increased design flexibility. These features potentially enable customers to reduce manufacturing and assembly cycle times for complex parts."By offering high transparency, high elasticity and easy processing, the LSR7000 series may help designers and manufacturers to effectively address many of the toughest design challenges they face,” said Yang Nuo, Pacific electronics marketing manager, Momentive. “This material is an excellent example of our strategic focus: we combine our close customer collaboration with our leading research and development capabilities, resulting in quick response to complex industrial needs. We are excited about this technology, as it may provide a new elastomeric solution for a broad range of applications where higher transparency is desirable.”

The LSR 7000 family includes products ranging in 60 to 80 Shore A hardness. Recent innovation in optical systems, light-guide applications and mobile phones have increasingly seen liquid silicone rubbers replace materials such as transparent polycarbonate and polymethyl methacrylate (PMMA) in new applications, due to the unique processing and productivity advantages of LSR.

In China, Momentive has cooperated with Sunrex, a leading input device manufacturer, to apply the LSR7000 series to light guide film for commercial production. “By combining our proprietary technology with the super transparency of LSR7000, we have been able to successfully develop silicone light guide film for use in new mobile equipment,” said Liu Dianshan, director of the Sunrex facility in Suzhou. “We are now cooperating on a long-term basis with Momentive to develop new, flexible applications for smart 3D light guide film.”

Momentive will be showcasing the LSR7000 series at the Fakuma 2008 trade fair, http://www.fakuma-messe.de/en/fakuma, Friedrichshafen, Germany, October 14-18, 2008 (Hall B2, Nr. B22107), along with other innovations in silicone elastomers, RTVs and hardcoats.

To find out more about Momentive’s family of transparent LSRs, please call for contacting European customer service 00.800.4321.1000 or send us your request by mail to cs-eur.silicones@momentive.com or visit www.momentive.com.

Media Contact Europe, Middle East, Africa & India

Robert Scheib

robert.scheib@momentive.com

+49 214 304 0532

Media Contact Americas

Nancy Pitts

nancy.pitts@momentive.com

+1 203 761 1938

Agency Media Contact Europe, Middle East, Africa & India

Brigitta de Vries

bdevries@emg.nl

+31 164 317 020

About Momentive Performance Materials

Momentive Performance Materials Inc. is a premier specialty materials company, providing high-technology materials solutions to the silicones, quartz and ceramics markets. The company, as a global leader with worldwide operations, has a robust product portfolio, an enduring tradition of service excellence, and industry-leading research and development capabilities. Momentive Performance Materials Inc. is controlled by an affiliate of Apollo Management, L.P. Additional information is available at www.momentive.com.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Momentive Introduces Clear LSR Products here

News-ID: 50196 • Views: …

More Releases from Momentive Performance Materials GmbH

GE RapidStrength* Silicone Sealant’s Productivity, Quality & Protective Glazin …

Enormous Increase in Sales of Close for GE RapidStrength Silicone Sealants. Momentive demonstrates product advantages on this years Glasstec Show in Düsseldorf Germany from 21st – 25th of October

LEVERKUSEN, GERMANY — OCTOBER 16, 2008 - The industry’s demand for the popular GE RapidStrength window bedding silicone sealant continues to grow at a rapid pace, as evidenced by an enormous increase in sales of close for Momentive Performance Materials. A cold-applied,…

Momentive’s New SPUR+* Prepolymers Offer High Tensile Strength for Next-Genera …

One-Part Formulations for Developers of Industrial Adhesives Open Door to High Performance Alternatives to Mechanical Fasteners

LEVERKUSEN, GERMANY — OCTOBER 9, 2008 - Momentive Performance Materials will introduce two breakthrough prepolymers for industrial adhesives formulations at the Adhesive and Sealants Council’s 2008 Fall Convention & Expo in Baltimore, Maryland, October 12th to 14th, 2008. SPUR+ 3100HM prepolymer and SPUR+ 3200HM prepolymer will join Momentive’s highly successful SPUR+ family of silylated polyurethane…

Momentive Performance Materials Inc. Announces Purchase of Certain Assets of Osr …

LEVERKUSEN, GERMANY - OCTOBER 7, 2008 - Momentive Performance Materials Inc. (the “Company”) today announced that its wholly-owned subsidiary, Momentive Performance Materials Quartz, Inc., has acquired certain assets of the semiconductor and lighting quartz products business of Osram Sylvania Products Inc. (“OSPI”), including manufacturing equipment, inventory, intellectual property and customer lists. OSPI is a wholly-owned subsidiary of OSRAM Sylvania Inc. Terms of the transaction were not disclosed.

“This acquisition is…

Momentive Performance Materials Announces Completion of its New Addisil* HCE fam …

LEVERKUSEN, GERMANY - OCTOBER 10, 2008 - Momentive Performance Materials, a leading manufacturer of custom heat-cured elastomers, liquid silicone rubber (LSR) and RTV adhesives, today announced the completion of its new Addisil* elastomers family of addition heat-curable elastomers (HCEs). The new elastomers feature next-generation properties that offer regulatory compliance, high clarity, enhanced mechanical performance and superior productivity.

Products are now available in 40, 50, 60, 70 and 80 Shore A,…

More Releases for LSR

LSR Injection Molding Machine Market Size, Trends, Growth: Global Forecast 2025- …

The global market for LSR Injection Molding Machine was estimated to be worth US$ 284 million in 2024 and is forecast to a readjusted size of US$ 532 million by 2031 with a CAGR of 9.4% during the forecast period 2025-2031.

Global Leading Market Research Publisher QYResearch announces the release of its latest report "LSR Injection Molding Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

Construction Aggregate Market Is Booming Worldwide : Wharehine, Hanlon Concrete, …

Latest Study on Industrial Growth of Construction Aggregate Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Construction Aggregate market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments…

Liquid Silicone Rubber (LSR) Market: Competitive Analysis and Global Outlook 202 …

The new report published by Stratview Research, titled Liquid Silicone Rubber (LSR) Market, is Segmented by Molding Technology Type (Liquid Injection Molding System), by Grade Type (Industrial Grade, Medical Grade, and Food Grade), by Application Type (Automotive, Medical, Electrical & Electronics, Consumer Goods, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

COVID-19 Impact & Recovery:

The report suggests that the Liquid Silicone Rubber (LSR) Market…

Liquid Silicone Rubber (LSR) Market Report 2018: Segmentation by Product (Indust …

Global Liquid Silicone Rubber (LSR) market research report provides company profile for ShinEtsu, KCC Corporation, Laur Silicone, Tianci Materials, Guangdong Polysil, Shenzhen SQUARE Silicone, BlueStar Xinghuo, Wynca, Dow Corning, Wacker Chemicals, Momentive and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR…

Global Liquid Silicone Rubber (LSR) Market Outlook 2016-2021

Liquid Silicone Rubber, with its low compression set, fast cure cycles, great stability and ability to resist extreme temperatures of heat and cold makes it ideally suitable for the production of parts where high quality is a must. Unlike most thermoplastic elastomers (TPRs and TPEs), LSR remains flexible and elastic down to -70o F and retains its properties up to 450o F. In addition to these qualities, the wide range…