Press release

Edible Oil Manufacturing Plant DPR 2026: Cost Structure, Production Process & ROI

The global food and beverage industry is experiencing transformative growth driven by rising health-conscious consumer preferences, the expanding food processing industry, and increasing demand in emerging economies. At the forefront of this essential food ingredients revolution stands edible oil-a versatile fat derivative valued for its critical role in cooking, frying, food preparation, and as an ingredient in packaged foods across food and beverage, restaurant and catering, health and wellness, and cosmetics and personal care industries. As urbanization accelerates, per capita income levels rise, and consumers increasingly shift toward healthier oil alternatives such as olive, cold-pressed, and avocado oils, establishing an edible oil manufacturing plant presents a strategically compelling business opportunity for food industry investors, agricultural processors, and consumer goods manufacturers seeking to capitalize on the expanding market for high-quality, nutritious, and sustainably sourced cooking oils with consistent flavor, reliable nutritional content, and regulatory compliance across multiple consumer and industrial segments.IMARC Group's report, "Edible Oil Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The edible oil manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/edible-oil-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The India edible oil market demonstrates steady growth trajectory, volumed at 25.33 Million Tons in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach 28.47 Million Tons by 2034, exhibiting a CAGR of 1.3% from 2026-2034. This sustained expansion is fueled by rising health-conscious consumer preferences, the expanding food processing industry, and increasing demand in emerging economies across household cooking, food manufacturing, and institutional catering segments.

Edible oil is fat derived from plants, animals, or synthetic sources, used primarily for cooking, frying, food preparation, and as an ingredient in processed foods. The most common types include vegetable oils such as soybean, sunflower, palm, and canola oils, as well as specialty oils like olive, avocado, and coconut oils. These oils provide essential fatty acids and are key to maintaining flavor, texture, and nutritional value in food products. They are produced through extraction processes like mechanical pressing or solvent extraction, followed by refining, which ensures the oil is purified, neutral in flavor, and safe for consumption. With growing health consciousness, oils like olive and avocado oil are increasingly favored for their health benefits, such as heart-healthy fats and antioxidants.

The edible oil market is driven by health trends, an increase in demand from the food processing industry, and changing consumer preferences. According to the National Institutes of Health, up to 70% of the diet in the U.S. consists of ultra-processed foods. Ultra-processed foods contain numerous artificial substances during food manufacturing. Hence, with consumers increasing awareness of the health risks related to unhealthy fats, consumers now opt for healthier oils like olive and avocado oil, offering healthy fats and antioxidants. The fast-growth food processing industry, mainly in developing economies, also fuels demand for edible oils used for cooking, frying, and ingredients for packaged foods. Additionally, the shift towards sustainable and eco-friendly practices is influencing the market, with an increasing focus on sustainable sourcing of oils, such as certified palm oil and non-GMO options.

Plant Capacity and Production Scale

The proposed edible oil manufacturing facility is designed with an annual production capacity ranging between 100,000-300,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from food and beverage industry applications to restaurant and catering, health and wellness, and cosmetics and personal care-ensuring steady demand and consistent revenue streams across multiple distribution channels serving the expanding natural food ingredients market.

Financial Viability and Profitability Analysis

The edible oil manufacturing business demonstrates profitability potential under normal operating conditions. The financial projections reveal margins supported by stable demand and value-added applications:

• Gross Profit Margins: 10-15%

• Net Profit Margins: 3-6%

These margins position edible oil manufacturing as a volume-driven venture with favorable return on investment (ROI) potential, supported by high demand for cooking oils from increasing urbanization and rising per capita income, growing health trends boosting consumption of better oils, cost efficiency and versatility across food industry, cosmetics, and biofuel applications, technological advancements improving extraction and refining processes, and consistent daily consumption patterns ensuring stable revenue generation.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for an edible oil manufacturing plant reflects extremely high raw material intensity:

• Raw Materials: 85-90% of total OpEx

• Utilities: 5-8% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, quality control, depreciation, and taxes

Oilseeds constitute the primary raw material cost driver at 85-90% of operating expenses, representing the highest intensity among food manufacturing sectors. Additional key inputs include hexane for solvent extraction, bleaching earth, caustic soda, and packaging materials. The cost structure requires careful management of oilseed price volatility through long-term procurement contracts, positioning edible oil manufacturing as a venture requiring strong agricultural supply chain management and efficient operational practices to maintain favorable margins across retail, food processing, restaurant, and institutional distribution channels.

Buy Now: https://www.imarcgroup.com/checkout?id=14982&method=2175

Capital Investment and Project Economics

Establishing an edible oil manufacturing plant requires comprehensive capital investment covering land acquisition, site preparation, civil works, machinery procurement, and working capital. Machinery costs account for the largest portion of total capital expenditure, with essential equipment including seed processing equipment, solvent extraction machines, refining equipment, and packaging machines. Operating costs in the first year cover raw materials, utilities, depreciation, taxes, packing, transportation, and repairs and maintenance. By the fifth year, total operational costs are expected to increase substantially due to factors such as inflation, market fluctuations, potential rises in the cost of key materials, supply chain disruptions, rising consumer demand, and shifts in the global economy.

The capital investment depends on plant capacity, technology selection, and location. This investment covers land acquisition, site preparation, and necessary infrastructure. Equipment costs represent a significant portion of capital expenditure. The scale of production and automation level will determine the total cost of machinery.

Raw material expenses, including oilseeds, hexane for solvent extraction, bleaching earth, caustic soda, and packaging, are a major part of operating costs. Long-term contracts with reliable suppliers help mitigate price volatility and ensure consistent material supply. Costs associated with land acquisition, construction, and utilities (electricity, water, steam) must be considered in the financial plan. Ongoing expenses for labor, maintenance, quality control, and environmental compliance must be accounted for.

Major Applications and End-Use Industries

Edible oil serves multiple critical applications across diverse sectors:

• Food and Beverage Industry: The food industry is the largest consumer of edible oils, using them for cooking, frying, and as an ingredient in packaged foods. Oils like palm, sunflower, and canola are essential for food preparation and processing due to their cost-effectiveness, versatility, and neutral flavor

• Health and Wellness: Oils high in healthy fats such as olive, avocado, and flaxseed oils are gaining consumer support, emphasized as healthy oils with a protective effect on the cardiovascular system

• Cosmetics and Personal Care: Edible oils are used in personal care products such as moisturizers, shampoos, and soaps. Oils like coconut oil, olive oil, and jojoba oil are known for their nourishing and hydrating properties, frequently found in natural or organic cosmetic formulations

• Restaurant and Catering: Large volumes of edible oils are used for frying, grilling, and food preparation, with soybean and sunflower oil favored for cost efficiency and suitability for high-temperature cooking

Why Invest in Edible Oil Manufacturing?

Several compelling factors make edible oil manufacturing an attractive investment opportunity:

• High Demand for Cooking Oils: As a major component of various cooking and processing processes in food products, edible oils' consumption is on the rise, especially considering factors like urbanization and substantial increases in per capita income levels as well as the consumption of food products

• Health Trends: Increasing focus on health and wellness by consumers is boosting the consumption of better oils such as olive oil, cold-pressed oils, and avocado oils, which are better alternatives to normal vegetable oils used by the population

• Cost Efficiency and Versatility: Edible oils have a wide range of usage, from the food industry and cosmetics to biofuels, ensuring diversified revenue streams across multiple end-use sectors

• Technological Advancements: Research and development in the processes of crude oil extraction and refining have resulted in the adoption of better and more cost-effective processes, thereby improving the efficiency of production

Manufacturing Process Overview

The edible oil manufacturing process involves several critical stages ensuring product purity and nutritional quality. The process begins with raw material sourcing and seed preparation where oilseeds are cleaned, dried, and conditioned. Oil extraction uses mechanical pressing or solvent extraction with hexane to separate oil from the seed material. Refining processes including degumming, neutralization, bleaching with bleaching earth, and deodorization remove impurities, free fatty acids, and unwanted flavors. Blending combines different oil types to achieve desired nutritional profiles or functional properties. Finally, packaging operations fill the refined oil into bottles, pouches, or bulk containers for distribution, with comprehensive quality control throughout ensuring consistent flavor, purity, nutritional content, and food safety compliance across all retail and industrial applications.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=14982&flag=C

Industry Leadership and Key Players

The global edible oil industry features several established multinational companies with extensive production capacities and diverse application portfolios. Leading manufacturers include ADM, Cargill Incorporated, Bunge Limited, Adani Wilmar Ltd, Aceites Borges Pont S.A., Apetit Kasviöljy Oy, and The Nisshin Oillio Group Ltd., all serving end-use sectors across food and beverage, restaurant and catering, health and wellness, and cosmetics and personal care. These industry leaders demonstrate the viability and scalability of edible oil manufacturing operations serving global markets with consistent quality, diverse product portfolios, and regulatory compliance.

Recent Developments and Market Dynamics

Recent industry developments highlight growing market momentum. In January 2026, Raj Oil Mills Limited launched a new edible palm oil product called "PALMRAJ," aimed at expanding its offerings in the domestic edible oil market and strengthening its product portfolio to meet consumer demand in India's cooking oil segment. In June 2025, following the Indian Government's move to reduce import tax rates on crude edible oils including halving the basic customs duty on crude palm, soybean, and edible sunflower oil, edible oil companies reduced prices on their goods in response to the government directive to convey the concession to consumers.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Edible Oil Manufacturing Plant DPR 2026: Cost Structure, Production Process & ROI here

News-ID: 4393782 • Views: …

More Releases from IMARC Group

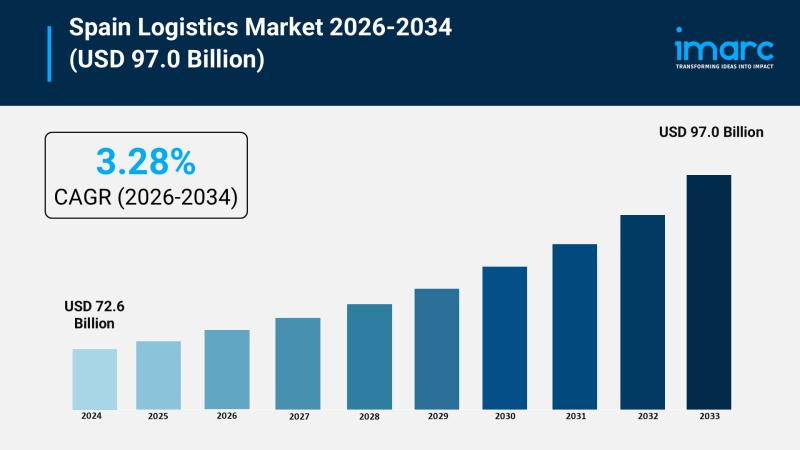

Spain Logistics Market Growth Forecast USD 72.6 Billion in 2025 to USD 97 Billio …

Market Overview

The Spain logistics market size reached USD 72.6 Billion in 2025 and is forecasted to grow to USD 97.0 Billion by 2034. The market is expected to expand at a CAGR of 3.28% during the forecast period 2026-2034. Driving factors include increasing e-commerce users, growing demand for warehousing, urban logistics, ongoing technological advancements, and rising focus on sustainability initiatives.

Study Assumption Years

• Base Year: 2025

• Historical Year/Period: 2020-2025

• Forecast Year/Period: 2026-2034

Spain Logistics Market…

Oral Rehydration Salt (ORS) Manufacturing Cost Analysis DPR 2026: CapEx/OpEx Ana …

The global oral rehydration salt (ORS) manufacturing industry is witnessing robust growth driven by the rapidly expanding healthcare sector and increasing demand for effective dehydration management solutions. At the heart of this expansion lies a critical essential medicine-oral rehydration salt. As healthcare systems transition toward preventive care and community-based treatment approaches, establishing an ORS manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and pharmaceutical investors seeking to capitalize…

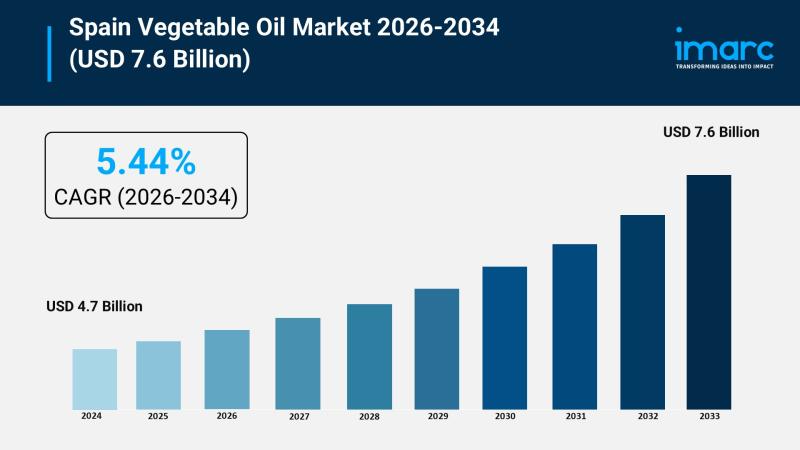

Spain Vegetable Oil Industry Growth Forecast USD 4.7 Billion in 2025 to USD 7.6 …

Market Overview

The Spain vegetable oil market size reached USD 4.7 Billion in 2025 and is expected to grow to USD 7.6 Billion by 2034, exhibiting a CAGR of 5.44% during the forecast period 2026-2034. The market growth is driven primarily by Spain's dominant production and cultural integration of olive oil, rising global demand for authentic oils, and increasing urban consumer preference for diverse, health-oriented oils. These factors collectively support the…

Fiber Optic Cable Manufacturing Plant DPR 2026: Investment Cost, Market Growth & …

The global telecommunications and digital infrastructure sector is experiencing transformative growth driven by the significant expansion of broadband infrastructure, rising investments in 5G networks, increasing deployment of data centers, and growing demand for high-speed communication across telecom, enterprise, and smart city projects. At the forefront of this digital connectivity revolution stands fiber optic cable-a critical communication medium valued for its ultra-high-speed data transfer, minimal signal loss, higher bandwidth, better security,…

More Releases for Oil

Hydraulic Oil Market,By Base Oil (Mineral Oil, Synthetic Oil, Semi-Synthetic Oil …

In recent years, the production capacity for hydraulic oil has increased significantly across the globe. Moreover, the Group II and III base oils are primarily gaining popularity for utilization in lubricant formulations for automatic transmission engines, heavy-duty trucks, and passenger automobiles. Therefore, these determinants are expected to for drive the development of the global hydraulic oil market in the anticipated period.

Global Hydraulic Oil Market was valued at USD 10.47 billion in 2021…

Cosmetic Oil Market Future Outlook 2023-2029, Industry Demand, Trends, Size, New …

This Cosmetic Oil Market research report is one of the best and wide-ranging, which provides market insights by considering numerous factors. Therefore, businesses can get important market insights cost-effectively with the help of the Cosmetic Oil Market research report. Such a persuasive report is the best to gain a competitive advantage in this quickly transforming marketplace. In addition, the report also provides market segmentation based on type and end-user. The…

Transformer Oil Market, Transformer Oil Market Size, Transformer Oil Market Shar …

The Transformer Oil Market research report consists of a detailed study of the market and the market dynamics that are related to the same. The in-depth data on the development of the market is presented in the Research report. Not only this but also the detailed data on the performance of the market for the forecast period are presented in the Transformer Oil Market research report. The performance analysis is…

Growing demand for corn oil as cooking oil is fuelling the Corn Oil Market

The research report "Corn Oil Market: by Product Type (High Oleic, Middle Oleic, Low Oleic), By Application (Biodiesel, Soap Making, Food Services, Pharmaceutical, Others) and Geography- Global/Region/Country Forecast to 2028." The global corn oil market size was valued at USD 4.2 Bn in the year 2021, growing at a CAGR rate of 7.2% during the evaluation time span 2022-2028.

Glance our 200 slides market research and competitive intelligence research report,…

Apricot Oil, Apricot Kernel Oil Supplier, Co2 Apricot Oil Manufacturer

The seed inside every apricot contains thin oil, which is extracted from the kernel of the seed after eating the delectable fruit. Apricot oil is also known as apricot kernel oil. This oil has been the interest of many experts for research purposes due to its infinite health benefits. It has been found that the oil could cure some serious health conditions (like cancer). Apricot oil has a profound nutty…

Global Sustainable Palm Oil Market analysis report- with Leading players, Applic …

Sustainable Palm Oil Market

The most widely used vegetable oil there is, palm oil is found in everything from snacks to household cleaners to cosmetics. Palm oil is used in many of the products on supermarket shelves, from margarine and chocolate to ice cream, soaps, cosmetics, and fuel for cars and power plants. The report presents a comprehensive overview, market shares, and growth opportunities of Sustainable Palm Oil market by product type,…