Press release

Analyzing the Impact of High-Efficiency And Stable Sludge Conveyor Systems on Modern Treatment Plant

As global industrialization accelerates and environmental regulations tighten, wastewater treatment plants face growing operational challenges, making efficient and reliable sludge handling essential. APEX MACHINERY & EQUIPMENT CO., LTD addresses this need with its High-Efficiency and Stable Sludge Conveyor Systems(https://www.apexecoequip.com/Sludge-Conveying-System-pl43535607.html), which play a critical role between sludge dehydration and final disposal. Integrating advanced screw transport technology, precision pumping, and hermetically sealed designs, these systems handle diverse materials such as municipal sludge, industrial oily sludge, and high-viscosity chemical residues. By preventing secondary pollution while reducing energy consumption and maintenance costs, APEX is setting new benchmarks for environmental compliance and operational excellence worldwide.The Global Environmental Protection Industry: Outlook and Technological Trends

The global environmental protection equipment industry is currently undergoing a strategic shift from traditional "waste disposal" to "resource recovery." Driven by international goals for carbon neutrality and peak carbon emissions, sludge treatment is no longer viewed as a simple volume reduction task but as a pivotal component of the circular economy and energy recovery. Market data indicates that global demand for high-performance environmental governance equipment is rising steadily, with modern treatment plants demanding smarter monitoring, lower failure rates, and superior energy efficiency ratios. This shift is particularly evident in the transition toward "Green Technology," where the focus is on reducing the environmental footprint of the treatment process itself.

Within this broader trend, sludge conveying technology is evolving toward modularity and intelligent automation. Traditional open-air transport methods are rapidly being replaced by fully enclosed, automated systems due to issues such as odor emission, material leakage, and large spatial requirements. Industry experts emphasize that the treatment plant of the future will prioritize process integration-achieving a seamless, collaborative chain from dewatering and conveying to drying and incineration or resource utilization. This integration requires conveying equipment to possess extreme stability, as any mechanical failure in the transport phase can lead to the paralysis of the entire processing line, causing significant economic and environmental risks.

Furthermore, energy conservation has become an essential industry requirement. Modern conveyor systems are now evaluated based on their ability to handle high-solid-content sludge with minimal power input. By optimizing transport routes and enhancing the power factor of drive systems, treatment plants can significantly cut operational expenditures. This aligns with the core tenets of green, low-carbon manufacturing worldwide, where every stage of the waste lifecycle is optimized for sustainability. The rise of "Zero-Waste" initiatives in major industrial hubs further accelerates the adoption of stable conveyor systems that can interface with advanced drying and incineration units.

Core Strengths of APEX Machinery & Equipment Co., Ltd.

In this transformative industry environment, APEX MACHINERY has emerged as a professional provider in the environmental protection machinery sector. Located in Zhuhai, China, the company's core competitive advantage stems from a persistent pursuit of "Green Technology" and a deep technical understanding of complex operating conditions. APEX operates a sophisticated manufacturing base and has established a high-standard quality control system encompassing research, development, design, and production of specialized equipment for waste treatment.

The sludge conveyor systems and related equipment provided by APEX have reached high industry standards in terms of corrosion resistance, wear resistance, and automated control. The company's product portfolio is comprehensive, featuring Sludge Drying Equipment, Sludge Conveying Systems, and complete Sewage Treatment Equipment. Compared to standard machinery, APEX systems demonstrate exceptional performance when handling sludge with high water content or high viscosity. Through precise torque control and specialized screw blade designs, the systems effectively prevent material clogging and "bridging," ensuring the continuity and stability of the conveying process. This reliability is particularly crucial for large-scale municipal or industrial plants that require 24-hour uninterrupted operation.

A key differentiator for APEX is its commitment to providing "Turn-key projects." This means the company handles the entire lifecycle of a project, from initial technical consultation and equipment selection to installation, commissioning, and long-term technical support. This holistic approach ensures that the High-Efficiency And Stable Sludge Conveyor Systems are perfectly integrated into the client's existing infrastructure, maximizing operational synergy and minimizing the risk of technical incompatibility.

Main Product Application Scenarios and Industry Impact

The application of APEX equipment spans multiple pillars of the global economy, reflecting the versatile nature of their technical solutions. In the thermal power sector, APEX's sludge drying and conveying systems play a vital role in energy recovery. By reducing the moisture content of the sludge and transporting it stably to incineration units, these systems facilitate the co-processing of sludge with coal. This not only solves the problem of waste disposal but also allows enterprises to convert waste into a viable energy source, significantly improving the plant's overall energy efficiency.

In the municipal sewage, metallurgical, and papermaking industries, where equipment faces heavy loads and high volumes of material, APEX machinery maintains long-term stable operation. For municipal treatment plants, the stability of the conveyor system is synonymous with public health and safety; any failure in transport could lead to backlogs in the treatment process. APEX's focus on automated control allows these plants to operate with minimal manual intervention, using intelligent sensors to monitor flow rates and system health in real-time.

Market Validation and Professional Commitment

The market influence of APEX is evidenced by its successful implementation of projects across diverse industrial sectors. By focusing on the specific needs of industries such as printing and dyeing, mining, and food processing, APEX has developed a reputation for reliability and innovation. The company's equipment is designed to meet the rigorous demands of modern industrial processes, where consistency is as important as capacity.

Clients choosing APEX solutions benefit from a reduction in total cost of ownership. While the initial investment in high-efficiency systems is a consideration, the long-term savings in energy, maintenance, and reduced downtime provide a clear economic advantage. Furthermore, by ensuring leak-proof and odor-free transport, APEX helps its partners maintain positive relationships with local communities and regulatory bodies, which is increasingly important in the modern ESG (Environmental, Social, and Governance) framework.

Conclusion

In summary, high-efficiency and stable sludge conveyor systems have become the core engine for industrial upgrading and green development in modern treatment plants. As global environmental standards continue to rise and the focus shifts toward resource recovery, the demand for equipment that is high-end, intelligent, and reliable will only increase. APEX MACHINERY & EQUIPMENT CO., LTD, with its professional expertise in environmental machinery, extensive application experience across chemical and power sectors, and its precise grasp of industry trends, is continuously pushing the boundaries of waste treatment technology.

By providing cleaner, more efficient, and more reliable solutions, APEX not only enhances the production efficiency of its clients but also contributes actively to the global cause of sustainable development. The company remains dedicated to its mission of technological innovation and environmental stewardship. Looking ahead, through the integration of innovative "Green Technology" and automated systems, APEX will continue to lead the industry toward a more low-carbon, efficient, and environmentally friendly future.

For more information regarding high-performance environmental equipment and sludge treatment solutions, please visit the official website: https://www.apexecoequip.com/index.html

APEX MACHINERY & EQUIPMENT CO., LTD

RM1203,12F,8 YINHUA ROAD,XIANGZHOU,ZHUHAI,CHINA

postmaster@apexmeco.com

APEX Company, founded in 2004 in Zhuhai, China, is a recognized leader in advanced environmental protection equipment. We specialize in high-quality sludge drying, conveying systems, and complex wastewater treatment solutions, earning a strong global reputation. Our international trade team excels in meeting market demands and navigating trade regulations, consistently delivering exceptional service and support.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Analyzing the Impact of High-Efficiency And Stable Sludge Conveyor Systems on Modern Treatment Plant here

News-ID: 4378421 • Views: …

More Releases from APEX MACHINERY & EQUIPMENT CO., LTD

APEX MACHINERY Introduces A Comprehensive Thermal Oxidation Of Wastewater Sludge …

APEX MACHINERY & EQUIPMENT CO., LTD, a premier global provider of environmental protection machinery, formally announces the launch of its latest technological milestone: the Comprehensive Thermal Oxidation Of Wastewater Sludge Solution(https://www.apexecoequip.com/). This integrated system is engineered to address the escalating challenges of industrial and municipal sludge management by utilizing advanced thermal processes to significantly reduce waste volume while neutralizing hazardous components. The solution incorporates high-efficiency waste drying systems and three-dimensional…

Key Features Of APEX MACHINERY's Global Leading Pesticide Wastewater Management …

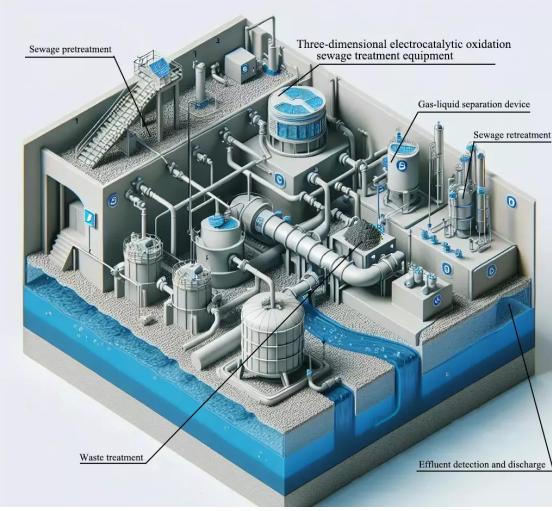

As the global chemical industry faces an era of unprecedented environmental accountability, APEX MACHINERY & EQUIPMENT CO., LTD (APEX) has officially unveiled the core technical advantages of its integrated treatment infrastructure. Central to this development is the Global Leading Pesticide Wastewater Management Factory(https://www.apexecoequip.com/) solution, a sophisticated engineering framework designed to neutralize the most persistent organic pollutants. By combining three-dimensional electrocatalytic oxidation with high-efficiency thermal drying and automated conveying, APEX provides…

How To Select China Standard-Compliant Pharmaceutical Wastewater Treatment Solut …

As global pharmaceutical manufacturers face increasingly strict environmental regulations, APEX (APEX MACHINERY & EQUIPMENT CO., LTD), a leader in environmental protection technology, provides essential guidance on integrating advanced purification systems. Selecting China Standard-Compliant Pharmaceutical Wastewater Treatment Solutions(https://www.apexecoequip.com/) is a strategic decision that directly affects regulatory compliance and long-term operational stability. APEX's solutions, including three-dimensional electrocatalytic oxidation systems and integrated sludge management equipment, are designed to treat high-concentration organic pollutants and…

Solving Material Handling Challenges with a Specialized China XG Series Sludge S …

At present, global industry is making significant strides toward effective waste management and resource recovery. As environmental regulations tighten and material handling requirements become more demanding, APEX MACHINERY & EQUIPMENT CO. LTD (APEX) has emerged as a leading China Best XG Series Sludge Flight Conveyor Supplier(https://www.apexecoequip.com/Professional-sludge-conveyor-pl41535607.html) to meet these complex operational needs. APEX is the go-to source for reliable XG Series Sludge Flight Conveyor solutions designed to transport various forms…

More Releases for Sludge

Sludge Dewaterers Market

Sludge dewaterers are machines used to remove water from sludge, which is a semi-solid material produced during wastewater treatment. This process significantly reduces the volume of sludge, making it easier and cheaper to transport and dispose of. The global market for sludge dewaterers has witnessed a significant uptick, driven by a convergence of factors ranging from stringent environmental regulations to the imperative for efficient wastewater management.

Governments worldwide are increasingly enacting…

ENV200Ultrasonic Sludge Density Meter | WESS GLOBAL

WESS GLOBAL's ultrasonic sludge density meter is used for measuring the density or concentration of sludge in a variety of industrial and environmental applications.

WESS Global technology is primarily concerned with measuring flow, level, and water quality in the environmental protection field, employing well-established ultrasonic, light, and microwave principles. They offer cutting-edge sludge measuring meters, including the Ultrasonic Sludge Blanket Level Meter (ENV120) and the Ultrasonic Sludge Density Meter (ENV200 Series).

WESS…

Ultrasonic Sludge Density Measuring Meter | WESS Global

WESS Global has been developing the measuring instruments since its establishment in 2004 and, since then, has upgraded the company's measuring instruments' state-of-the-art. WESS Global is now offering its services and products to more than 40 countries around the world in many industries such as steel mills, power plants, water and waste water treatment facilities, pulp and paper plants, etc. And it always appreciates all international and domestic customers and…

Sludge Treatment Chemicals Market Progression Status

Data Bridge Market Research analyses that the sludge treatment chemicals market will witness a CAGR of 5.18% for the forecast period of 2021-2028. Increase in the demand for sludge treatment chemicals by a wide range of end user verticals such as automotive, oil and gas, metal processing, food and beverage, pulp and paper, personal care and chemicals, electronics, paint and coatings, mining and others, growth in the demand and supply…

Sludge Port

Universal Sludge India Pvt. Ltd. offers Sludge and Slop Discharge at all Indian Lanka Bangladesh and UAE ports

To create a strong connection with 'Vessel to Up lifter', Universal Sludge India Pvt. Ltd. has taken a pledge that contributes a lot of a good deal to the country. Registered under Companies ACT 1956, this organization has proudly introduced them to be the only coordinating hub that provides easy as well as…

Alarming Rise in Sludge Being Produced from Industries to Bolster Deployment of …

The demand for sludge dewatering equipment is increasing at a significant rate across the world due to the alarming rise in the amount of sludge being produced. As a result of this, regulatory authorities and government bodies of several countries are focusing on reforming their regulations and guidelines on effective sludge disposal and treatment. Government bodies of countries in the Asia Pacific and the European Union are specially focusing on…