Press release

Solving Material Handling Challenges with a Specialized China XG Series Sludge Scraping Conveyor Supplier

At present, global industry is making significant strides toward effective waste management and resource recovery. As environmental regulations tighten and material handling requirements become more demanding, APEX MACHINERY & EQUIPMENT CO. LTD (APEX) has emerged as a leading China Best XG Series Sludge Flight Conveyor Supplier(https://www.apexecoequip.com/Professional-sludge-conveyor-pl41535607.html) to meet these complex operational needs. APEX is the go-to source for reliable XG Series Sludge Flight Conveyor solutions designed to transport various forms of silt, industrial sludge and bulk materials securely. The XG series of conveyors, including the specialized XGS, XGC, and XGZ models, has been specially engineered to efficiently move viscous materials with high moisture content in demanding environments such as thermal power plants, construction sites, or mining facilities. These systems are distinguished by their exceptional wear resistance and customized flight mechanisms designed to address common industry problems related to material adhesion and accumulation, thus significantly decreasing unplanned downtime and increasing throughput at waste treatment facilities.Industrial Evolution and the Trajectory of Advanced Conveying Technology

Environmental protection machinery sector is currently experiencing an impressive transformation. Heavy industries globally are shifting away from fragmented waste disposal methods toward integrated systems that combine drying, conveying, and purification systems. This shift has been driven by rapid industrialization's ever-increasing amounts of waste produced, and by the imperative need to minimize environmental footprint in logistics operations onsite. Material handling no longer serves merely as an administrative function but has become a critical link for effective waste treatment lines. Without reliable conveying technology, even advanced drying and purification systems become bottlenecks in production cycles leading to increased operational costs and environmental hazards.

Current market trends indicate an increasing reliance on fully automated and hermetically sealed conveying systems, designed specifically to prevent secondary pollution such as leaks or odor emissions during transportation of toxic or sensitive sludges. Such designs are key in order to avoiding leakage of harmful emissions during sludge transport operations. In industries as diverse as metallurgy, chemical processing, and municipal wastewater management, the "one-stop" service model has become the industry standard. Organizations no longer look for individual components; instead they require integrated systems capable of handling materials from their initial point of generation through recycling or disposal. As global environmental assessment standards increase, facility managers increasingly value technical reliability of conveying equipment--in particular its ability to transport abrasive and high viscosity materials without frequent mechanical breakdown--as an indicator of facility's overall environmental sustainability. Industry trends indicate a shift towards heavier-duty customized flight that can withstand chemical sludges while remaining energy efficient and long-term structural integrity. Suppliers must offer more than machinery; rather they must possess strong engineering expertise in material science and fluid dynamics to manage specific rheological properties of industrial wastes.

Technical Superiority of the XG Series: XGS, XGC, and XGZ Models

The technical strength of the company's bulk handling portfolio is best demonstrated through the targeted engineering of the XG Series Sludge Flight Conveyors. The supplier has developed three distinct configurations based on official technical standards to ensure seamless material flow regardless of spatial constraints:

XGS Series Sludge Flight Conveyor: This model is the horizontal type of sludge flight conveyor. It is designed for the stable transportation of various types of silt and industrial sludge in a horizontal layout, providing an efficient solution for moving materials across large facility floors.

XGC Series Sludge Flight Conveyor: This model is the inclined type of sludge flight conveyor. It is engineered specifically to handle the transport of materials at an angle, making it suitable for feeding systems or moving sludge to elevated discharge points.

XGZ Series Sludge Flight Conveyor: This model is the Z-type sludge flight conveyor. It features a specialized configuration that allows for both horizontal and vertical movement in a combined path, offering high flexibility for complex industrial site layouts.

All three models-XGS, XGC, and XGZ-share a common foundation of high wear resistance and are capable of handling high-viscosity and high-moisture materials. By using specialized materials for the chains and flight, these systems provide a reliable service life even when transporting abrasive residues.

Corporate Infrastructure and Professional Manufacturing Standards

Established in 2004, the supplier has developed a reputation as a specialist in advanced environmental protection machinery. The company's growth is anchored in its strategic infrastructure, most notably the 20,000-square-meter manufacturing base dedicated to bulk material handling. This facility integrates advanced production machinery, CNC machining centers, and automated assembly lines, which enhance manufacturing precision and significantly shorten delivery cycles for international projects involving large-scale XG series installations.

The organization's competitive edge is rooted in its technical research and development department, which focuses on iterative innovation and product upgrades. This technical expertise is reinforced by a rigorous quality management system that monitors every production phase, from the procurement of raw materials to the final assembly. These standards have earned the company numerous national honorary certificates and multiple patent certificates, documenting its compliance with international safety protocols. The production of the XGS, XGC, and XGZ series follows strict industry standards to ensure that every unit delivered meets the high-stress requirements of the chemical and energy sectors.

Client Success and Global Service Integration

The company's market influence is further extended through its commitment to personalized, customized service. By delivering environmental protection machinery solutions that are specifically tailored to the client's site conditions, APEX ensures that unique operational challenges-such as high material corrosivity or extreme temperature fluctuations-are met with engineering precision. This service model is supported by a professional sales and international trade team capable of navigating diverse market requirements and global logistics.

Major customer cases frequently involve large-scale power plants and chemical complexes where the seamless integration of XGS, XGC, or XGZ conveyors has resulted in measurable improvements in efficiency. In addition to hardware manufacturing, the company provides a full lifecycle of support, including technical consultation, logistics delivery, and after-sales maintenance. Post-delivery support includes comprehensive customer training on equipment calibration and safety operating procedures, ensuring the long-term reliability and safety of the installation.

Conclusion

The demand for specialized material handling solutions continues to grow as industries prioritize efficiency and environmental compliance. APEX MACHINERY & EQUIPMENT CO., LTD has proven to be a reliable provider of high-quality environmental machinery, particularly through its specialized XG Series (XGS, XGC, XGZ) Sludge Flight Conveyors. By combining a dedicated scientific research team, a vast production base, and a "one-stop" service philosophy, the company effectively solves the most difficult material handling challenges faced by modern industry. As the sector evolves toward greater automation and integration, the company remains focused on delivering equipment that ensures operational stability while supporting global sustainability goals. Through constant innovation and a commitment to quality, the company continues to lead the way in providing the tools necessary for responsible and efficient industrial waste management.

For more information regarding the XG series and other industrial environmental solutions, please visit the official website: https://www.apexecoequip.com/index.html

APEX MACHINERY & EQUIPMENT CO., LTD

RM1203,12F,8 YINHUA ROAD,XIANGZHOU,ZHUHAI,CHINA

postmaster@apexmeco.com

APEX Company, founded in 2004 in Zhuhai, China, is a recognized leader in advanced environmental protection equipment. We specialize in high-quality sludge drying, conveying systems, and complex wastewater treatment solutions, earning a strong global reputation. Our international trade team excels in meeting market demands and navigating trade regulations, consistently delivering exceptional service and support.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Solving Material Handling Challenges with a Specialized China XG Series Sludge Scraping Conveyor Supplier here

News-ID: 4378436 • Views: …

More Releases from APEX MACHINERY & EQUIPMENT CO., LTD

APEX MACHINERY Introduces A Comprehensive Thermal Oxidation Of Wastewater Sludge …

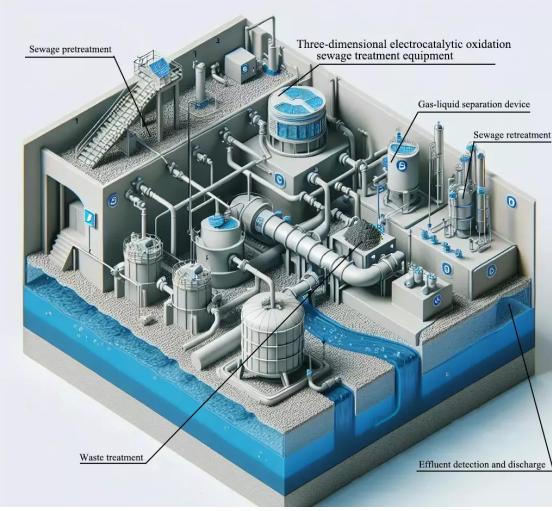

APEX MACHINERY & EQUIPMENT CO., LTD, a premier global provider of environmental protection machinery, formally announces the launch of its latest technological milestone: the Comprehensive Thermal Oxidation Of Wastewater Sludge Solution(https://www.apexecoequip.com/). This integrated system is engineered to address the escalating challenges of industrial and municipal sludge management by utilizing advanced thermal processes to significantly reduce waste volume while neutralizing hazardous components. The solution incorporates high-efficiency waste drying systems and three-dimensional…

Key Features Of APEX MACHINERY's Global Leading Pesticide Wastewater Management …

As the global chemical industry faces an era of unprecedented environmental accountability, APEX MACHINERY & EQUIPMENT CO., LTD (APEX) has officially unveiled the core technical advantages of its integrated treatment infrastructure. Central to this development is the Global Leading Pesticide Wastewater Management Factory(https://www.apexecoequip.com/) solution, a sophisticated engineering framework designed to neutralize the most persistent organic pollutants. By combining three-dimensional electrocatalytic oxidation with high-efficiency thermal drying and automated conveying, APEX provides…

How To Select China Standard-Compliant Pharmaceutical Wastewater Treatment Solut …

As global pharmaceutical manufacturers face increasingly strict environmental regulations, APEX (APEX MACHINERY & EQUIPMENT CO., LTD), a leader in environmental protection technology, provides essential guidance on integrating advanced purification systems. Selecting China Standard-Compliant Pharmaceutical Wastewater Treatment Solutions(https://www.apexecoequip.com/) is a strategic decision that directly affects regulatory compliance and long-term operational stability. APEX's solutions, including three-dimensional electrocatalytic oxidation systems and integrated sludge management equipment, are designed to treat high-concentration organic pollutants and…

Analyzing the Impact of High-Efficiency And Stable Sludge Conveyor Systems on Mo …

As global industrialization accelerates and environmental regulations tighten, wastewater treatment plants face growing operational challenges, making efficient and reliable sludge handling essential. APEX MACHINERY & EQUIPMENT CO., LTD addresses this need with its High-Efficiency and Stable Sludge Conveyor Systems(https://www.apexecoequip.com/Sludge-Conveying-System-pl43535607.html), which play a critical role between sludge dehydration and final disposal. Integrating advanced screw transport technology, precision pumping, and hermetically sealed designs, these systems handle diverse materials such as municipal sludge,…

More Releases for Series

NEW EXPLORER SERIES

Crafted from Legacy, Designed for Innovation! Where over a century of expertise meets the future of laboratory weighing

OHAUS Corporation, a global leader in the design and manufacturing of weighing products, has the pleasure to unveil the new EXPLORER Balance Series, a flagship evolution in laboratory weighing crafted from over 100 years of industry expertise and innovation.

This new flagship range combines a rich heritage of accuracy with cutting-edge technology tailored for…

NIYATI - Fiction Story Series

NIYATI - KARMBHUMI

PREMIUM COLLECTION

ISBN: 978-93-6128-001-6

COPYRIGHT OWNED BY: RAJESH MEENA & KRISHNA MEENA

A story that is similar to stories like 'Lord of the Rings' and 'Harry Potter', but in the Bhartiya context…

In the 'Niyati' series, the first episode, 'Karmbhumi', has been written in such a way that the reader, away from T.V. And mobile screen, is watching a movie on the screens of his imagination.

Along with the story, the author has…

Oscar Barby Releases New Children's Book Series - Oscar the Rabbits and Friends …

Introducing the Oscar the Rabbits and Friends Series: A Wonderful and Mischievous Journey of Fun and Friendship for Children

Oscar Barby, an imaginative storyteller, is thrilled to announce the release of his delightful new children's book series, Oscar the Rabbits and Friends Series. This enchanting collection of standalone stories promises to captivate the hearts of children and parents alike with its charming characters, humorous adventures, and valuable life lessons. Oscar Barby's…

Saelig Introduces Siglent SDS6000L Series Low Profile 2GHz/8-Ch Digital Oscillos …

Saelig Company, Inc. has introduced the Siglent SDS6000L Series Low Profile 2GHz/8-Ch Digital Oscilloscope Series, with 4 or 8 analog channels (expandable up to 512 channels) plus 16 digital channels (up to 1024 channels) in a space-saving chassis size that forms a standalone oscilloscope when connected to an external display and a mouse. There are 6 models in the series: SDS6208L (2GHz/8ch), SDS6204L (2GHz/4ch), SDS6108L (1GHz/8-ch), SDS6104L (1GHz/4-ch), SDS6058L (500MHz/8-ch),…

Gong Cha Maple Series vs. Gong Cha's Latest Bubble Tea Series - The Hot & Spicy …

New York, USA - Last month, (November) Gong Cha Bubble Tea shops launched a new tea series - The Maple Tea Series. The Maple Tea series is so delicious that it has become one of the most popular Gong Cha Boba tea series in their grand collection of tea series. In addition, it’s also now most certainly a favorite Bubble Tea series among Gong Cha Bubble Tea lovers.

Needless to…

2018 Cardan Shaft Market Study 2015-2025, by Segment (Small series, Medium serie …

Snapshot:

Cardan Shaft, also known as propeller shaft or drive shaft, is a mechanical component used for the transmission of torque and rotation. Cardan Shaft consists of universal joint, shaft yokes and intermediate support, etc. It acts as an intermediate between the driving and the driven shaft that are not aligned on the same axis transferring the running torque smoothly.

Cardan Shafts Market 2018 Industry research report is a meticulous investigation of…