Press release

APEX MACHINERY Introduces A Comprehensive Thermal Oxidation Of Wastewater Sludge Solution

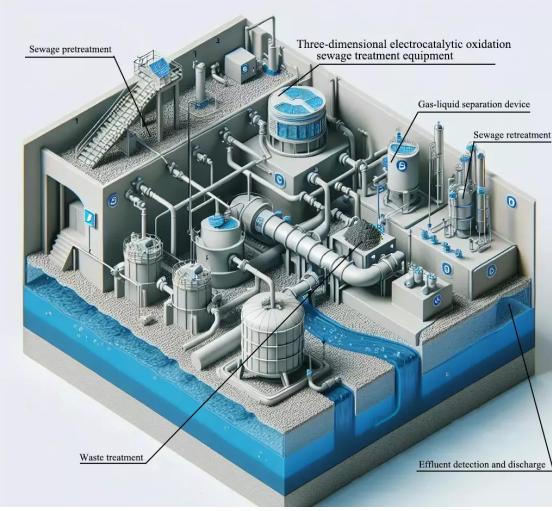

APEX MACHINERY & EQUIPMENT CO., LTD, a premier global provider of environmental protection machinery, formally announces the launch of its latest technological milestone: the Comprehensive Thermal Oxidation Of Wastewater Sludge Solution(https://www.apexecoequip.com/). This integrated system is engineered to address the escalating challenges of industrial and municipal sludge management by utilizing advanced thermal processes to significantly reduce waste volume while neutralizing hazardous components. The solution incorporates high-efficiency waste drying systems and three-dimensional electrocatalytic oxidation equipment, providing a robust framework for purifying complex wastewater and stabilizing sludge from diverse sources, including chemical, pharmaceutical, and municipal sectors. By integrating these technologies, the system ensures that contaminants are thoroughly oxidized, facilitating safer disposal and resource recovery in alignment with modern environmental mandates.I. Global Industry Landscape and Evolution of Sludge Treatment Trends

The global environmental landscape is currently undergoing a significant transformation, driven by stringent regulatory frameworks and a collective shift toward sustainable industrial practices. As urbanization and industrialization accelerate, the volume of wastewater sludge produced annually has reached unprecedented levels. Industry trends indicate a decisive move away from traditional landfilling and toward advanced thermal and chemical treatment methods. These modern approaches are increasingly favored because they offer a more permanent solution to the problem of "forever chemicals" and heavy metal stabilization within sludge. Thermal oxidation, in particular, has emerged as the gold standard for transforming hazardous residues into stable, manageable outputs.

In addition to volume reduction, the global market is prioritizing energy efficiency and carbon footprint reduction within the waste management sector. The integration of thermal oxidation and drying technologies allows for the recovery of thermal energy, which can be recirculated to power the treatment process itself. This circular economy model is becoming the industry standard, as companies seek to balance environmental compliance with operational cost-effectiveness. The push for "Green Manufacturing" has compelled enterprises across the chemical, textile, and power generation sectors to adopt sophisticated equipment that can guarantee zero-liquid discharge (ZLD) or meet the most rigorous discharge standards. Furthermore, the industry is witnessing a rising demand for decentralized treatment facilities that can handle high-salinity and toxic wastewater at the source, reducing the logistical risks and costs associated with transporting hazardous waste.

II. Corporate Manufacturing Strengths and Technical Innovation

APEX MACHINERY has positioned itself at the forefront of these industry shifts by leveraging over two decades of engineering expertise. Founded in 2004 in Zhuhai, the company has cultivated a reputation for technical innovation and rigorous quality control. A core advantage of the enterprise lies in its dual-factory production capability, which includes a 20,000-square-meter facility dedicated to bulk material handling and sludge treatment systems. This infrastructure enables the company to maintain a comprehensive quality management system, overseeing every stage of production from raw material procurement to final delivery.

The technical research and development team at APEX continuously drives product upgrades, ensuring that their machinery remains compliant with evolving international safety and environmental standards. The company's commitment to excellence is validated by numerous national honorary certificates and patent certifications. This intellectual property serves as the foundation for the organization's ability to offer high-durability solutions that withstand the corrosive and high-temperature environments typical of thermal oxidation processes. By maintaining control over the entire manufacturing lifecycle, APEX ensures that each system is optimized for long-term reliability in harsh industrial settings. Beyond production, APEX distinguishes itself through a "one-stop" service model, encompassing environmental assessment, equipment customization, and after-sales support, providing clients with a seamless path to environmental compliance.

III. Core Product Applications and Strategic Client Case Studies

The application scenarios for the company's primary product lines are extensive and cater to a wide range of industrial needs. The Comprehensive Thermal Oxidation Of Wastewater Sludge Solution is a multi-stage system designed for maximum efficiency:

Waste Drying and Volume Reduction: The Waste Drying System, featuring specialized Disc Dryers, is utilized for the treatment of municipal sludge and hazardous chemical residues. By removing water content efficiently using waste heat or steam, these systems reduce waste weight by up to 80%, significantly lowering transportation and disposal costs.

Precision Sludge Conveying: Complementing the drying phase, the Sludge Conveying System provides stable transport for high-viscosity materials. These systems are indispensable in thermal power plants and mining operations where consistent material flow is critical to plant safety and hygiene.

Advanced Liquid Oxidation: For complex liquid waste, the Three-Dimensional Electrocatalytic Oxidation equipment is applied to treat landfill leachate and high-salt wastewater from the pesticide and electroplating industries. This technology breaks down recalcitrant organic pollutants that traditional biological methods fail to address.

The efficacy of these solutions is evidenced by the company's extensive portfolio of successful client cases. APEX MACHINERY has collaborated with global leaders in the thermal power sector to implement waste drying facilities that enhance overall energy efficiency. In the chemical and pharmaceutical industries, the company's oxidation technologies have been instrumental in managing high-concentration organic wastewater, allowing facilities to maintain continuous production while adhering to local environmental codes. In the mining sector, heavy-duty conveying systems have proven their durability in demanding geographical environments. These partnerships are supported by a personalized customization service, where equipment is tailored to the specific chemical composition and volume requirements of the client's waste stream, ensuring optimal performance from the first day of operation.

IV. Conclusion: Advancing Toward a Sustainable Industrial Future

The introduction of the Comprehensive Thermal Oxidation Of Wastewater Sludge Solution marks a significant advancement in the field of environmental engineering. By addressing the critical need for efficient sludge volume reduction and the neutralization of hazardous pollutants, APEX MACHINERY provides a vital resource for industries striving to balance productivity with environmental responsibility. This solution not only meets current regulatory demands but also sets a new standard for efficiency and reliability in waste management.

As the global community moves toward a more sustainable future, the integration of such advanced thermal and chemical technologies will remain a cornerstone of industrial strategy. APEX MACHINERY remains committed to continuous improvement and innovation, ensuring that its technology evolves alongside the global needs for a cleaner and more efficient industrial ecosystem. Through technical innovation and manufacturing excellence, the company continues to empower its clients across the globe to achieve their environmental goals with confidence. The organization invites stakeholders and industry partners to explore how these comprehensive solutions can be integrated into their existing operations to achieve a new level of environmental and operational performance.

For more information regarding these solutions and to explore the full range of environmental protection equipment, please visit the official corporate website: https://www.apexecoequip.com/index.html

APEX MACHINERY & EQUIPMENT CO., LTD

RM1203,12F,8 YINHUA ROAD,XIANGZHOU,ZHUHAI,CHINA

postmaster@apexmeco.com

APEX Company, founded in 2004 in Zhuhai, China, is a recognized leader in advanced environmental protection equipment. We specialize in high-quality sludge drying, conveying systems, and complex wastewater treatment solutions, earning a strong global reputation. Our international trade team excels in meeting market demands and navigating trade regulations, consistently delivering exceptional service and support.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release APEX MACHINERY Introduces A Comprehensive Thermal Oxidation Of Wastewater Sludge Solution here

News-ID: 4378490 • Views: …

More Releases from APEX MACHINERY & EQUIPMENT CO., LTD

Key Features Of APEX MACHINERY's Global Leading Pesticide Wastewater Management …

As the global chemical industry faces an era of unprecedented environmental accountability, APEX MACHINERY & EQUIPMENT CO., LTD (APEX) has officially unveiled the core technical advantages of its integrated treatment infrastructure. Central to this development is the Global Leading Pesticide Wastewater Management Factory(https://www.apexecoequip.com/) solution, a sophisticated engineering framework designed to neutralize the most persistent organic pollutants. By combining three-dimensional electrocatalytic oxidation with high-efficiency thermal drying and automated conveying, APEX provides…

How To Select China Standard-Compliant Pharmaceutical Wastewater Treatment Solut …

As global pharmaceutical manufacturers face increasingly strict environmental regulations, APEX (APEX MACHINERY & EQUIPMENT CO., LTD), a leader in environmental protection technology, provides essential guidance on integrating advanced purification systems. Selecting China Standard-Compliant Pharmaceutical Wastewater Treatment Solutions(https://www.apexecoequip.com/) is a strategic decision that directly affects regulatory compliance and long-term operational stability. APEX's solutions, including three-dimensional electrocatalytic oxidation systems and integrated sludge management equipment, are designed to treat high-concentration organic pollutants and…

Solving Material Handling Challenges with a Specialized China XG Series Sludge S …

At present, global industry is making significant strides toward effective waste management and resource recovery. As environmental regulations tighten and material handling requirements become more demanding, APEX MACHINERY & EQUIPMENT CO. LTD (APEX) has emerged as a leading China Best XG Series Sludge Flight Conveyor Supplier(https://www.apexecoequip.com/Professional-sludge-conveyor-pl41535607.html) to meet these complex operational needs. APEX is the go-to source for reliable XG Series Sludge Flight Conveyor solutions designed to transport various forms…

Analyzing the Impact of High-Efficiency And Stable Sludge Conveyor Systems on Mo …

As global industrialization accelerates and environmental regulations tighten, wastewater treatment plants face growing operational challenges, making efficient and reliable sludge handling essential. APEX MACHINERY & EQUIPMENT CO., LTD addresses this need with its High-Efficiency and Stable Sludge Conveyor Systems(https://www.apexecoequip.com/Sludge-Conveying-System-pl43535607.html), which play a critical role between sludge dehydration and final disposal. Integrating advanced screw transport technology, precision pumping, and hermetically sealed designs, these systems handle diverse materials such as municipal sludge,…

More Releases for Oxidation

Global Advanced Oxidation Technologies Market Explore Outstanding Growth in Futu …

The report entitled, "Global Advanced Oxidation Technologies Market Report 2021" offers a large number of the latest and newest industry data that covers the overall market situation along with future lookout for the Advanced Oxidation Technologies market growth around the globe. The Advanced Oxidation Technologies Market research study includes significant data and also forecasts up to 2028 of the global market which makes the research report a helpful resource for…

Advanced Oxidation Technologies Market Size, Share 2021, Impressive Industry Gro …

The Advanced Oxidation Technologies Market is poised to take off in upcoming years hence showing a highly positive outlook through 2020-2028, according to a recently released report. Advanced Oxidation Technologies Market report covers industry chain analysis, latest market trends & dynamics along with cost profit analysis of major key players which focuses on expansion rate, prices, competition, size, prices, and value chain analysis of those leaders in the market.

The…

Advanced Oxidation Technology Market Growth, Analysis and Trends to 2025| Ast Cl …

The report on the global Advanced Oxidation Technology Market is comprehensively prepared with main focus on the competitive landscape, geographical growth, segmentation, and market dynamics, including drivers, restraints, and opportunities. It sheds light on key production, revenue, and consumption trends so that players could improve their sales and growth in the global Advanced Oxidation Technology market. It offers detailed analysis of the competition and leading companies of the global Advanced…

Global Advanced Oxidation Technologies Market 2019- 2025 || A-Zone Technologies, …

Synopsis of the Advanced Oxidation Technologies Market:

Latest Report on Advanced Oxidation Technologies Market deliberates the effect of various Factors influencing the market growth and drivers. Its further sheds light on market overview, key manufacturers, strategic adopted by them, size, latest trends and types, revenue, gross margin with regional analysis and forecast to 2025.

Overview of the Advanced Oxidation Technologies Market Report:

Advanced Oxidation Technologies Market report includes knowledge about the market overview…

Global Advanced Oxidation Technology Market Outlook 2019 - Ast Clean Water Techn …

The latest trending report Global Advanced Oxidation Technology Market 2018 by Manufacturers, Regions, Type and Application, Forecast to 2023 offered by Fior Markets is an informative study covering the market with detailed analysis. This is one of the most promising and extremely categorized sectors. The research report assesses historical, latest values, and current changes to forecast market way for upcoming years from 2018 to 2023. The report evaluates various aspects…

Global Advanced Oxidation Technologies Market Future Demand, Growth, Analysis By …

Researchmoz added Most up-to-date research on "Global Advanced Oxidation Technologies Market Future Demand, Growth, Analysis By Top Players - Advanced Oxidation, Advanced Oxidation Technology, Advanced Plasma Solutions (APS) and Anguil Environmental Systems" to its huge collection of research reports.

This report focuses on the global Advanced Oxidation Technologies status, future forecast, growth opportunity, key market and key players. The study objectives are to present the Advanced Oxidation Technologies development in United…