Press release

Capacitor Manufacturing Plant DPR 2026: Machinery Cost, Capex/Opex, ROI, and Raw Materials

A capacitor is a passive electronic component designed to store and release electrical energy in an electric field. It consists of two conductive plates separated by a dielectric material such as ceramic, polymer film, aluminium oxide, tantalum oxide, or electrolyte. Capacitors regulate voltage, smooth current fluctuations, filter noise, enable signal coupling and decoupling, and support energy buffering. Key properties include capacitance value, voltage rating, dielectric strength, equivalent series resistance (ESR), temperature stability, and lifespan.Depending on design and dielectric material, capacitors are manufactured as ceramic, electrolytic, film, tantalum, or supercapacitors, each optimized for specific electrical and environmental performance requirements. As a backbone component for electrification and system reliability, capacitors play an indispensable role across power electronics, automotive systems, consumer electronics, renewable energy, railways, and industrial equipment, making the capacitor manufacturing sector a highly promising investment opportunity.

IMARC Group's report, "Capacitor Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The capacitor manufacturing plant setup report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Market Overview and Growth Potential

The global capacitor market presents a compelling growth trajectory for investors and manufacturers. The global capacitor market size was valued at USD 26.70 Billion in 2025. According to IMARC Group estimates, the market is expected to reach USD 44.69 Billion by 2034, exhibiting a CAGR of 5.89% from 2026 to 2034.

The capacitor market is primarily driven by the expanding electronics industry, where capacitors are essential for circuit functionality and power stability. Growth in electric vehicles and charging infrastructure has increased demand for high-voltage and high-temperature capacitors used in inverters and power electronics. The global push toward renewable energy systems such as solar and wind has further strengthened demand for power capacitors in energy conversion and grid stabilization. Industrial automation and Industry 4.0 adoption also require reliable capacitors for motor drives, sensors, and control systems.

Additionally, ongoing advancements in dielectric materials and manufacturing technologies are enabling higher energy density, longer service life, and improved thermal performance, supporting broader adoption across advanced electronic applications.

Request for a Sample Report: https://www.imarcgroup.com/capacitor-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed manufacturing facility is designed with an annual production capacity ranging between 100 - 500 million units, enabling economies of scale while maintaining operational flexibility. The manufacturing process utilizes metallization, slitting, and winding as the primary processes. This production scale allows the plant to efficiently serve diverse end-use industries including electronics, telecommunications, automotive, industrial automation, and renewable energy. Applications span power conditioning circuits, filtering components, motor run systems, inverter modules, RFI suppression, and energy storage banks.

Financial Viability and Profitability Analysis

The project demonstrates healthy profitability potential under normal operating conditions. The financial projections have been developed based on realistic assumptions related to capital investment, operating costs, production capacity utilization, pricing trends, and demand outlook.

• Gross Profit: 35-40%

• Net Profit: 15-20%

These projections provide a comprehensive view of the project's financial viability, ROI, profitability, and long-term sustainability, making it an attractive investment prospect for stakeholders seeking stable returns in the electronics manufacturing sector.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8741&flag=C

Operating Cost Structure

The operating cost structure of a capacitor manufacturing plant is primarily driven by raw material consumption. The breakdown of operational expenditure is as follows:

• Raw Materials: 60-70% of OpEx

• Utilities: 10-15% of OpEx

Key raw materials include aluminum foil, dielectric films, and electrolytes. Securing reliable suppliers and negotiating long-term contracts are critical cost management strategies to stabilize pricing and mitigate supply chain risks. By the fifth year of operations, the total operational cost is expected to increase due to factors such as inflation, market fluctuations, and potential rises in material costs.

Capital Investment Requirements

Establishing a capacitor manufacturing plant requires significant capital investment across several categories. Machinery costs account for the largest portion of the total capital expenditure, while land and site development, including charges for land registration, boundary development, and related expenses form a substantial part of the overall investment.

Capital Expenditure Categories:

• Land and Site Development Costs

• Civil Works Costs

• Machinery Costs (largest CapEx component)

• Other Capital Costs

Essential Machinery and Equipment:

• Precision slitters and metalizers

• Capacitor winding/stacking machines

• Impregnation units

• Soldering/sealing systems

• Aging ovens

• Automated test and sorting stations

• Packaging lines

The site must offer easy access to key raw materials, proximity to target markets for minimized distribution costs, robust infrastructure including reliable transportation, utilities, and waste management systems, and compliance with local zoning laws and environmental regulations.

Buy Now: https: https://www.imarcgroup.com/checkout?id=8741&method=2175

Major Applications and Market Segments

Capacitors serve a broad spectrum of applications across multiple industries. The primary applications within the manufacturing process include electrode fabrication (metal foils, etched surfaces, and conductive layers), dielectric processing (dielectric films, oxide layer formation, and insulation materials), component assembly (lead wires, terminals, winding elements, and internal connections), and testing and packaging (electrical performance testing, encapsulation, and final packaging).

Key End-Use Industries:

• Electronics

• Telecommunications

• Automotive

• Industrial Automation

• Renewable Energy

Specific use cases include power conditioning circuits, filtering components, motor run systems, inverter modules, RFI suppression, and energy storage banks.

Why Invest in Capacitor Manufacturing?

Critical Component in Electrical and Electronic Systems: Capacitors are indispensable for energy storage, voltage regulation, power conditioning, filtering, and signal smoothing across power electronics, automotive systems, consumer electronics, renewable energy, railways, and industrial equipment - making them a backbone component for electrification and system reliability.

Moderate but Defensible Entry Barriers: While capital intensity is lower than semiconductor fabs, capacitor manufacturing demands precise material control (dielectrics, foils, electrolytes), tightly regulated processes, stringent quality standards, and long qualification cycles with OEMs - creating sustainable entry barriers that favor technically competent and quality-driven manufacturers.

Strong Alignment with Global Megatrends: Rapid growth in electric vehicles, renewable energy systems, data centers, consumer electronics, automation, and smart grids is driving sustained demand for high-performance capacitors. Electric car sales neared 14 million in 2023, 95% of which were in China, Europe, and the United States (IEA). Power electronics and EV-related capacitors are witnessing strong double-digit growth globally.

Policy and Infrastructure Tailwinds: Government-led investments in power transmission, renewable energy, rail electrification, EV charging infrastructure, and electronics manufacturing incentives (e.g., Make in India PLI schemes) are accelerating domestic demand for capacitors across multiple voltage and application segments.

Localization and Supply Chain Reliability Advantage: OEMs increasingly prefer localized capacitor suppliers to reduce lead times, mitigate geopolitical and logistics risks, manage raw material volatility, and ensure consistent supply - creating opportunities for regional manufacturers with strong process control and dependable sourcing strategies.

Industry Leadership

The global capacitor industry features several leading multinational manufacturers with extensive production capacities and diverse application portfolios.

• Murata Manufacturing

• TDK Corporation

• Nichicon Corporation

• Panasonic Industry

• Vishay Intertechnology

• KEMET

These manufacturers serve end-use sectors such as electronics, telecommunications, automotive, industrial automation, and renewable energy.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Capacitor Manufacturing Plant DPR 2026: Machinery Cost, Capex/Opex, ROI, and Raw Materials here

News-ID: 4378041 • Views: …

More Releases from IMARC Group

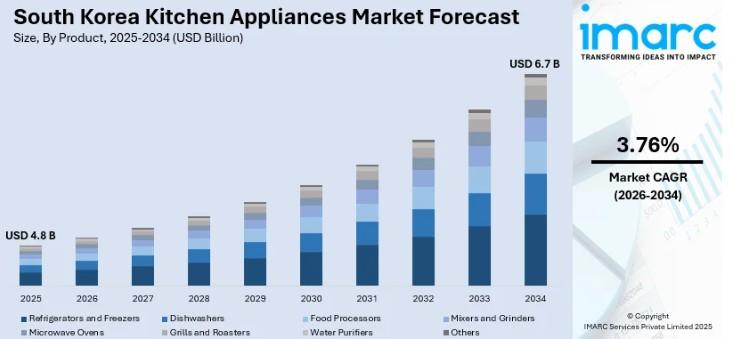

South Korea Kitchen Appliances Market Size, Industry Analysis, Growth Drivers & …

IMARC Group has recently released a new research study titled "South Korea Kitchen Appliances Market Size, Share, Trends and Forecast by Product, Distribution Channel, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

South Korea Kitchen Appliances Market Size Overview

The South Korea kitchen appliances market size was valued at USD 4.8 Billion…

PCB (Printed Circuit Board) Manufacturing Plant DPR 2026: Machinery Requirement, …

The PCB (Printed Circuit Board) industry stands at the heart of modern electronics supply chains, serving as the foundational substrate that interconnects and mechanically supports electronic components across diverse devices. According to the IMARC Group report, the global PCB market was valued at USD 75.51 Billion in 2025, with strong projections indicating continued expansion in the coming decade.

Printed circuit boards are essential in virtually every electronic system, enabling electrical connectivity…

Bamboo Pellets Manufacturing Plant (DPR) Report 2026: Unit Setup, CapEx/OpEx & P …

The global renewable energy landscape is undergoing a transformative shift driven by rising demand for clean energy sources, increasing environmental awareness, growing adoption of biomass fuels in power generation, and supportive government policies promoting sustainable energy solutions. At the forefront of this green energy revolution stands bamboo pellets-a versatile solid biofuel valued for its high calorific value, consistent combustion properties, and minimal environmental impact across industrial boilers, power plants, residential…

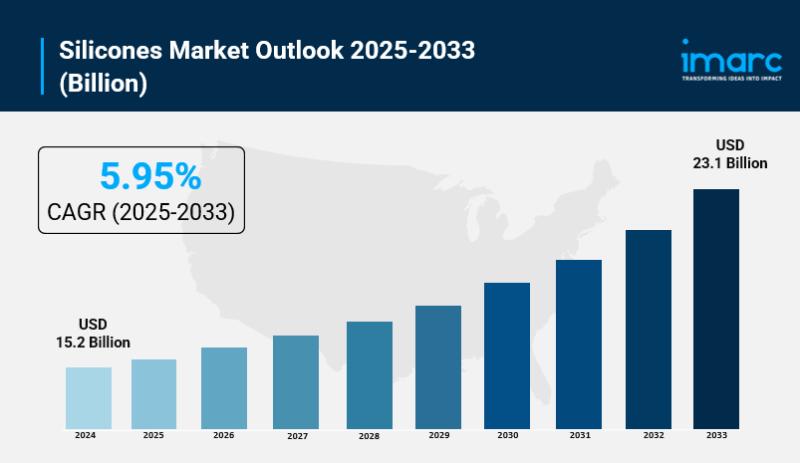

Silicones Market is Expected to Grow USD 23.1 Billion by 2033 | At CAGR 4.8%

IMARC Group, a leading market research company, has recently released a report titled "Silicones Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033." The study provides a detailed analysis of the industry, including the Silicones market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Silicones Market Overview

The global silicones market…

More Releases for Capacitor

Capacitor Motors Market Is Booming Worldwide| JB Capacitor, Lexur Capacitor, Sha …

Advance Market Analytics published a new research publication on "Capacitor Motors Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Capacitor Motors market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of…

HVDC Capacitor Market

Overview

The HVDC Capacitor Market, with a promising CAGR, employs capacitors for efficient high-voltage direct current power transmission. Government initiatives, demand for HVDC in power transmission, and North America's increasing adoption drive market dynamics.

Market Dynamics

Government initiatives for HVDC systems and escalating demand for HVDC capacitors propel market growth. However, challenges like high costs and low voltage impede progress, emphasizing the need for innovation in this dynamic market.

Download Sample:https://www.datamintelligence.com/download-sample/hvdc-capacitor-market

Rising Demand for HVDC…

Loudspeaker Capacitor Market Forecast, Trend Analysis, Competition Tracking And …

QY Research has recently published a new report, titled Global Loudspeaker Capacitor Market Report, History and Forecast 2017-2028, Breakdown Data by Manufacturers, Key Regions, Types and Application. The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Loudspeaker Capacitor market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment of their…

Global Columbium Electrolytic Capacitor Market, Global Columbium Electrolytic Ca …

The Columbium Electrolytic Capacitor market is expected to grow from USD X.X million in 2020 to USD X.X million by 2026, at a CAGR of X.X% during the forecast period. The Global Columbium Electrolytic Capacitor Market report is a comprehensive research that focuses on the overall consumption structure, development trends, sales models and sales of top countries in the global Columbium Electrolytic Capacitor market. The report focuses on well-known providers…

Pulse Discharge Capacitor Market Depth Survey By 2026 |Vishay Intertechnology, K …

Latest Report On Pulse Discharge Capacitor Market including Market Landscape, and Market size, Revenues by players, Revenues by regions, Average prices, Competitive landscape, market dynamics, and industry trends and developments during the forecast period.

The global Pulse Discharge Capacitor market is broadly analyzed in this report that sheds light on critical aspects such as the vendor landscape, competitive strategies, market dynamics, and regional analysis. The report helps readers to clearly…

Motor Capacitor Market by Top Players – Capacitor Industries, Seika, Tibcon, B …

The global market size of Motor Capacitor is $XX million in 2018 with XX CAGR from 2014 to 2018, and it is expected to reach $XX million by the end of 2024 with a CAGR of XX% from 2019 to 2024.

Global Motor Capacitor Market Report 2019 - Market Size, Share, Price, Trend and Forecast is a professional and in-depth study on the current state of the global Motor Capacitor industry.

Get…