Press release

Bamboo Pellets Manufacturing Plant (DPR) Report 2026: Unit Setup, CapEx/OpEx & Profit Margin

The global renewable energy landscape is undergoing a transformative shift driven by rising demand for clean energy sources, increasing environmental awareness, growing adoption of biomass fuels in power generation, and supportive government policies promoting sustainable energy solutions. At the forefront of this green energy revolution stands bamboo pellets-a versatile solid biofuel valued for its high calorific value, consistent combustion properties, and minimal environmental impact across industrial boilers, power plants, residential heating systems, and commercial energy facilities. As industries and consumers increasingly seek carbon-neutral, renewable alternatives to coal and fossil fuels, establishing a bamboo pellets manufacturing plant presents a strategically compelling business opportunity for energy sector investors, biomass fuel manufacturers, and renewable energy developers seeking to capitalize on the expanding market for sustainable heating and power generation solutions with reliable performance, efficient energy output, and environmental compliance across multiple industrial and residential segments.IMARC Group's report, "Bamboo Pellets Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The bamboo pellets manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/bamboo-pellets-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global bamboo pellets market demonstrates robust growth trajectory, valued at USD 1.53 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 3.50 Billion by 2034, exhibiting a strong CAGR of 9.6% from 2026-2034. This sustained expansion is fueled by rising demand for renewable energy sources, increasing use of biomass fuels in power generation, growing awareness around carbon-neutral heating solutions, and supportive government policies promoting sustainable fuels across industrial and residential sectors.

Bamboo pellets are solid biofuels made by compressing processed bamboo biomass into dense, cylindrical forms. They deliver high calorific value, low moisture content, and minimal ash compared with many conventional biomass fuels. As a result, bamboo pellets are widely used as substitutes for coal, firewood, and other fossil fuels across industrial boilers, power plants, residential heating systems, and commercial energy facilities. Their consistent size and density support stable combustion, efficient heat output, and compatibility with automated feeding and storage systems, while also simplifying transport and handling. Bamboo's rapid growth, high yield, and ability to regenerate without replanting make it a sustainable feedstock. Consequently, bamboo pellets are regarded as a renewable, low-emission, and environmentally responsible energy solution for modern energy demands across industries worldwide today.

The bamboo pellet market is slowly gaining momentum due to rapid development of renewable energy sources. According to the Energy Statistics India 2025 by the Ministry of Statistics and Program Implementation (MoSPI), the capacity of grid-connected renewable power has grown by 14.77%, from 125,160 MW on March 31, 2023, to 143,645 MW on March 31, 2024. Rajasthan is at the forefront with 26,693 MW, while Gujarat is at the second position with 25,472 MW, and both states' power generation is majorly due to wind and solar sources. Along with this, stricter emission rules and higher coal and natural gas prices are pushing the market. Moreover, many countries' governments and energy providers are moving towards biomass co-firing and pellet-based heating systems as part of climate and decarbonization objectives. The increasing international biomass market, technology and processing advancement in pellet production, and the presence of long-term power purchase contracts are other factors contributing to market demand.

Plant Capacity and Production Scale

The proposed bamboo pellets manufacturing facility is designed with an annual production capacity ranging between 20,000-50,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from renewable energy sector applications to biomass power generation plants, industrial heating systems, and residential and commercial heating applications-ensuring steady demand and consistent revenue streams across multiple distribution channels serving the expanding sustainable energy market.

Financial Viability and Profitability Analysis

The bamboo pellets manufacturing business demonstrates strong profitability potential under normal operating conditions. The financial projections reveal healthy margins supported by stable demand and value-added applications:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 10-15%

These margins position bamboo pellets manufacturing as an attractive venture with favorable return on investment (ROI) potential, supported by growing demand for renewable energy, consistent quality control allowing precise combustion characteristics, expanding biomass power generation sector, export opportunities to international markets, and scalable cost-efficient production with moderate capital investment requirements.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a bamboo pellets manufacturing plant reflects balanced resource allocation:

• Raw Materials: 50-60% of total OpEx

• Utilities: 25-30% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, quality control, depreciation, and taxes

Bamboo waste constitutes the primary raw material cost driver at 50-60% of operating expenses, representing moderate to high intensity compared to other biomass sectors. The balanced cost structure combined with premium pricing for certified renewable energy sources creates favorable profit margins, positioning bamboo pellets manufacturing as an attractive venture with significant value captured through consistent quality, standardization benefits, and growing market demand across power generation, industrial heating, and residential energy applications.

Buy Now: https://www.imarcgroup.com/checkout?id=9403&method=2175

Capital Investment and Project Economics

Establishing a bamboo pellets manufacturing plant requires comprehensive capital investment covering land acquisition, site preparation, civil works, machinery procurement, and working capital. Machinery costs account for the largest portion of total capital expenditure, with essential equipment including bamboo chippers, dryers, hammer mills, pellet mills, coolers, screening systems, conveyors, and packing units. Operating costs in the first year cover raw materials, utilities, depreciation, taxes, packing, transportation, and repairs and maintenance. By the fifth year, total operational costs are expected to increase substantially due to inflation, market fluctuations, supply chain dynamics, and rising demand driving material cost escalation.

The capital investment depends on plant capacity, technology selection, and location. This investment covers land acquisition, site preparation, and necessary infrastructure. Raw material expenses, particularly bamboo waste, represent a major part of operating costs. Long-term contracts with reliable suppliers help mitigate price volatility and ensure consistent material supply. Costs associated with land acquisition, construction, and utilities (electricity, water, steam) must be considered in the financial plan. Ongoing expenses for labor, maintenance, quality control, and environmental compliance must be accounted for. A detailed financial analysis, including income projections, expenditures, and break-even points, must be conducted to secure funding and formulate a clear financial strategy.

Major Applications and End-Use Industries

Bamboo pellets serve multiple critical applications across diverse industries:

• Biomass Power Plants: Bamboo pellets are used as a stable fuel source offering consistent combustion and reduced emissions

• Industrial Boilers and Furnaces: Pellets provide reliable thermal output with lower ash residue

• Residential and Commercial Heating: Used in pellet stoves and heating systems for clean energy use

• District Heating Systems: Supports centralized heating networks with renewable fuel input

Why Invest in Bamboo Pellets Manufacturing?

Several compelling factors make bamboo pellets manufacturing an attractive investment opportunity:

• Rising Demand for Renewable Energy: Bamboo pellets align with global efforts to reduce dependence on fossil fuels and lower carbon emissions across industrial and residential sectors

• Abundant and Fast-Growing Feedstock: Bamboo grows rapidly and can be harvested sustainably, ensuring reliable raw material supply without the need for replanting

• Supportive Policy Environment: Incentives, biomass mandates, and renewable energy targets are encouraging biomass fuel adoption at government and institutional levels

• Export Potential: Strong demand from Europe, East Asia, and North America for certified biomass pellets creates international market opportunities

• Efficient Storage and Transport: High density and uniform size reduce logistics costs compared to raw biomass materials

• Carbon-Neutral Energy Solution: Bamboo pellets offer a low-emission alternative to coal and fossil fuels, supporting climate change mitigation goals

• Scalable Production Model: Manufacturing processes require moderate capital investment and allow scalable operations with efficient material handling

Manufacturing Process Overview

The bamboo pellets manufacturing process involves several critical stages ensuring product quality and consistency. The process begins with bamboo harvesting and preprocessing, followed by drying to reduce moisture content to optimal levels. Size reduction through chipping and grinding creates uniform particle sizes. Pelletization compresses the processed bamboo biomass into dense cylindrical pellets. Cooling stabilizes the pellets and enhances their structural integrity. Screening removes oversized or undersized particles to ensure uniform product quality. Finally, packaging operations prepare the pellets for distribution, with comprehensive quality inspection throughout ensuring consistent combustion performance and regulatory compliance.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=9403&flag=C

Industry Leadership and Key Players

The global bamboo pellets industry features several established companies with extensive production capacities and diverse application portfolios. Leading manufacturers include Pacific BioEnergy Corporation, Ecostan India Pvt. Ltd., Zhengzhou Leabon Machinery Equipment Co., Ltd., Shanghai Yuke Industrial Co., Ltd., Yulong Machine Co., Ltd. (Shandong Yulong Machinery Co., Ltd.), Jinan Taichang Transmission Machinery Co., Ltd., Henan Richi Machinery Co., Ltd., and Anyang GEMCO Energy Machinery Co., Ltd., all serving end-use sectors across renewable energy, biomass power generation plants, industrial heating systems, and residential and commercial heating applications. These industry leaders demonstrate the viability and scalability of bamboo pellets manufacturing operations serving global markets.

Recent Developments and Market Dynamics

Recent industry developments highlight growing market momentum. In November 2025, at the Agrovision 2025 event, the state of Maharashtra promoted bamboo as a significant green economy driver and emphasized its application in the production of ethanol, biomass energy, and industrial pellets. The state-supported scientific agroforestry, artisan clusters, and favorable policies envision an integrated value chain for the versatile use of bamboo as pellets, biofuels, construction materials, and rural livelihoods. In September 2025, Maharashtra, in collaboration with ADB, announced a bamboo project worth INR 4,000 crore to increase the production of bamboo and enhance the bamboo-based industries. The project supports the conversion of bamboo into pellets, torrefied fuels, and biofuels for electricity, ethanol, and biomass energy, thus guaranteeing markets for the products, accelerating farmers' incomes, and bringing about sustainable rural and industrial development for the next seven years.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Bamboo Pellets Manufacturing Plant (DPR) Report 2026: Unit Setup, CapEx/OpEx & Profit Margin here

News-ID: 4377476 • Views: …

More Releases from IMARC Group

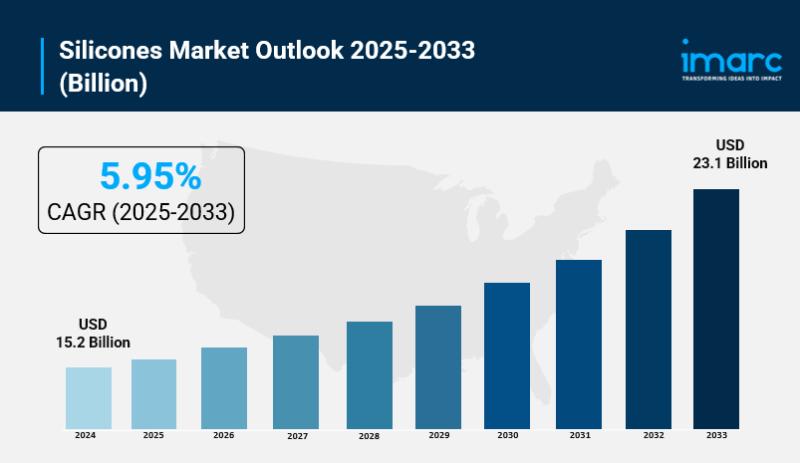

Silicones Market is Expected to Grow USD 23.1 Billion by 2033 | At CAGR 4.8%

IMARC Group, a leading market research company, has recently released a report titled "Silicones Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033." The study provides a detailed analysis of the industry, including the Silicones market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Silicones Market Overview

The global silicones market…

South Korea Tourism Market Size, Industry Analysis, Growth Drivers & Future Dema …

IMARC Group has recently released a new research study titled "South Korea Tourism Market Report by Tourism Type (Medical, Sports, Cultural, Culinary, Wellness, Educational, and Others), Tourist Type (Domestic, International), Travel Type (Solo, Group), Booking Channel (OTA Platform, Direct Booking), Age Group (Below 30 Years, 30 to 41 Years, 42 to 49 Years, 50 Years and Above), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth…

Lithium-Ion Battery Plant DPR 2026: Industry Trends, CapEx/OpEx and Market Growt …

The global lithium-ion battery manufacturing industry is experiencing transformational growth driven by the explosive expansion of electric vehicles and surging demand for energy storage solutions. At the heart of this energy revolution lies a critical enabling technology lithium-ion batteries. As transportation and energy sectors transition toward electrification and renewable integration, establishing a lithium-ion battery manufacturing plant presents an extraordinarily compelling business opportunity for entrepreneurs and industrial investors seeking to capitalize…

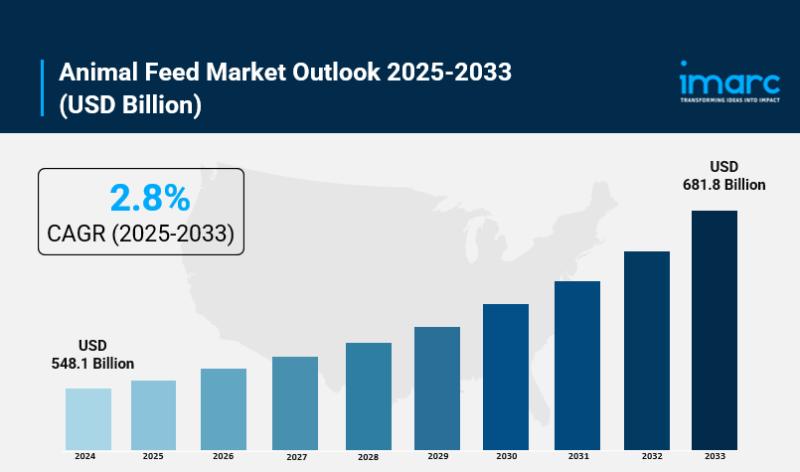

Animal Feed Market is Anticipated to Rise USD 681.8 Billion by 2033 | At CAGR 2. …

IMARC Group, a leading market research company, has recently released a report titled " Animal Feed Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033."The study provides a detailed analysis of the industry, including the Animal Feed Market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Animal Feed…

More Releases for Bamboo

Bamboo Roofing Sheets Market Is Going to Boom | Bamboo Living, EcoPlanet Bamboo

Worldwide Market Reports has added a new research study on "Bamboo Roofing Sheets Market" is projected to experience substantial growth in the coming years. This report provides a comprehensive analysis of the market landscape using an integrated approach that includes research methodology, market size evaluation, data compilation, and insights gathered from multiple credible sources.

The study covers critical market elements such as market dynamics, drivers, restraints, challenges, threats, growth opportunities, development…

Bamboos Market Is Going to Boom | Green Bamboo, Tien Phu Bamboo, and Kaizen Bamb …

The latest study by Coherent Market Insights, titled "Bamboos Market Size, Share & Trends Forecast 2025-2032," offers an in-depth analysis of the global and regional dynamics shaping this rapidly evolving industry. This comprehensive report highlights the competitive landscape, key market segments, value chain analysis, and emerging technological and regulatory trends expected between 2025 and 2032. The report provides actionable insights for business leaders, policymakers, investors, and new market entrants seeking…

Bamboo Wine Market SWOT Analysis by Key Players- Anhui Bamboo Wine, Tianjin Bamb …

The latest study released on the Global Bamboo Wine Market by HTF MI evaluates market size, trend, and forecast to 2031. The Bamboo Wine market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Key Players in…

Bamboo Construction Products Market Is Booming So Rapidly | Major Giants Bamboo …

HTF Market Intelligence just released the Global Bamboo Construction Products Industry Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major companies in Bamboo Construction Products Industry Market…

Bamboo Toothbrush Market Will Hit Big Revenues In Future | Bamboo India, Brush w …

The latest research on "Global Bamboo Toothbrush Report 2022" offered by HTF MI provides a comprehensive investigation into the geographical landscape, industry size along with the revenue estimation of the business. Additionally, the report also highlights the challenges impeding market growth and expansion strategies employed by leading companies in the "Market".

Get Free Sample PDF including full TOC, Tables and Figures and Available customizations) in Global Bamboo Toothbrush: https://www.htfmarketreport.com/sample-report/3895394-global-bamboo-toothbrush-market-7

Proceeding further, the…

Global Bamboo Toothbrush Market Report 2021-2028 Players are Bamboo Brush Co., B …

The Bamboo Toothbrush Market research report has been prepared with the systematic gathering and valuation of market information for Data Bridge Market Research industry which is presented in a form that explains various facts and figures to the business. The Bamboo Toothbrush Industry data presented in the credible report helps to recognize different market opportunities present internationally. This report provides exact information about market trends, industrial changes, and consumer behaviour…