Press release

PVC Panel Manufacturing Plant Cost Report 2026: Business Plan, Setup Requirements & ROI Insights

The global construction and interior finishing industry is experiencing dynamic transformation driven by rising construction activities, increasing demand for cost-effective interior solutions, rapid urbanization, and growing preference for moisture-resistant building materials. At the forefront of this evolution stands PVC panel manufacturing-a specialized segment producing versatile, durable panels that combine aesthetic appeal with functional performance for wall cladding, suspended ceilings, partitions, and decorative interior applications. As construction activities accelerate worldwide and modern interior materials gain wider acceptance, establishing a PVC panel manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors seeking to capitalize on the expanding market for innovative, cost-effective alternatives to traditional building materials.IMARC Group's report, "PVC Panel Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The PVC panel manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/pvc-panel-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global PVC panel market demonstrates robust growth trajectory, valued at USD 3.90 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 6.90 Billion by 2034, exhibiting a robust CAGR of 6.50% from 2026-2034. This sustained expansion is driven by rising construction activities, increasing demand for cost-effective interior solutions, rapid urbanization, and growing preference for moisture-resistant solutions.

PVC panels are sturdy, inflexible panels constructed with a mixture of polyvinyl chloride, together with stabilizers, plasticizers, fillers, and additives. The common applications for these panels are wall cladding, suspended ceilings, partitions, and decorative internal areas. The benefits of PVC panels include resistance to water, termites, and fires, long life span, and ease of installation. They come in different textures like wood grain, marble-like, matte, and shiny surfaces, thus appealing to the modern eye. The lightweight, low-maintenance, and affordability of PVC panels make them the option of choice over traditional materials like wood, plywood, and gypsum boards. Besides, their recyclability is a factor that makes them a prime candidate in the areas of residential housing, commercial buildings, medical and retail sectors, and industrial plants.

PVC panels are gaining preference in the construction and interior finishing markets, driven by globalization and urbanization. Modern interior materials have been quickly adopted due to rising urbanization, increasing disposable incomes, and growing commercial infrastructure. For instance, in Uttar Pradesh, India, real estate investments reached INR 69,000 crore in 2025, up 53% compared with the prior year, signaling stronger developer confidence and higher spending on commercial and mixed-use projects. This expansion continues to boost demand for PVC panels, supported by faster construction cycles, cost efficiency, and modern interior requirements. The moisture, termites, and corrosion resistance of PVC panels are among the factors that make them the most sought-after choice in high-humidity regions. The growth in affordable housing projects and commercial renovations further increases market demand. Besides, the cost-effectiveness and speedy construction that come with using prefabricated PVC panels are also factors that contribute to their increased use.

Plant Capacity and Production Scale

The proposed PVC panel manufacturing facility is designed with an annual production capacity ranging between 20,000-40,000 MT, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments across residential construction, commercial real estate, interior design industry, industrial infrastructure, and institutional buildings-ensuring steady demand and consistent revenue streams across multiple end-use applications driven by continuous construction and renovation activities.

Financial Viability and Profitability Analysis

The PVC panel manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 10-15%

These healthy margins are supported by stable demand across residential, commercial, industrial, and institutional construction sectors, value-added manufacturing capabilities through diverse textures and finishes, and the critical advantage of PVC panels as cost-effective alternatives to traditional materials like wood, plywood, and gypsum boards. The project demonstrates strong return on investment (ROI) potential with comprehensive financial analysis covering income projections, expenditure projections, break-even points, net present value (NPV), and internal rate of return. Break-even periods typically range from 2-4 years, depending on production capacity, raw material costs, market demand, and operational efficiency. Favorable pricing and steady sales can help achieve earlier returns, making it an attractive proposition for both new entrants and established industrial players.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a PVC panel manufacturing plant is primarily driven by:

• Raw Materials: 70-80% of total OpEx

• Utilities: 10-15% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with PVC resin accounting for approximately 70-80% of total operating expenses. Additional core materials include calcium carbonate fillers, stabilizers, and printing/coating materials. Other essential additives include plasticizers, lubricants, UV stabilizers, colorants, and fire retardants for durability and finish. In the first year of operations, operating costs are projected to be significant, covering raw materials, utilities, depreciation, taxes, packing, transportation, and repairs and maintenance. By the fifth year, total operational cost is expected to increase substantially due to inflation, market fluctuations, and potential rises in key material costs. Long-term contracts with reliable suppliers help mitigate price volatility and ensure consistent material supply.

Capital Investment Requirements

Setting up a PVC panel manufacturing plant requires substantial capital investment across several critical categories. The total capital investment depends on plant capacity, technology, and location, covering land acquisition, site preparation, and necessary infrastructure.

Land and Site Development: Selection of an optimal location with strategic proximity to raw material sources and target markets is essential to minimize distribution costs. The location must offer easy access to key raw materials such as PVC resin, calcium carbonate fillers, stabilizers, and printing/coating materials. The site must have robust infrastructure, including reliable transportation networks, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must be ensured. The cost of land and site development, including charges for land registration, boundary development, and other related expenses, forms a substantial part of the overall investment, ensuring a solid foundation for safe and efficient plant operations.

Machinery and Equipment: Machinery costs account for the largest portion of the total capital expenditure. High-quality, corrosion-resistant machinery tailored for PVC panel production must be selected. Essential equipment includes:

• Twin screw extruders for compounding and extrusion

• Mixers for raw material blending and homogenization

• Molding dies for panel shaping and calibration

• Cooling systems for temperature control

• Cutting machines for precise panel sizing

• Surface laminators for texture and finish application

• Inspection equipment for quality control

Additional equipment includes mixing systems, cooling conveyors, molds and calibration units, stacking systems, and curing and drying equipment for efficient production. All machinery must comply with industry standards for safety, efficiency, and reliability. The scale of production and automation level will determine the total cost of machinery.

Civil Works: Building construction and factory layout optimization designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities. The layout should be optimized with separate areas for raw material storage, production, quality control, and finished goods storage. Space for future expansion should be incorporated to accommodate business growth.

Other Capital Costs: Costs associated with land acquisition, construction, and utilities including electricity, water, and steam must be considered in the financial plan. Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=8736&method=2175

Major Applications and Market Segments

PVC panel manufacturing outputs serve extensive applications across diverse construction and interior finishing sectors:

Residential Construction Sector: The use of PVC panels leads to creation of interior spaces that are not only attractive but also cost-effective, durable, and require less maintenance for housing projects.

Commercial and Office Spaces: The panels facilitate speedy installations and ensure that the same design is followed in different office spaces, shops, hotels, and corporate interiors.

Healthcare and Institutional Buildings: The surfaces of PVC panels prevent any absorption of moisture and are also easy to clean, thus making them suitable for use in hospitals, labs, and schools.

Industrial Interiors: The panels are installed in power plants, storage areas, and other industrial sites where there is a lot of exposure to corrosive environments due to their resistance to corrosion and long life span.

The manufacturing process involves raw material compounding, mixing and homogenization, extrusion molding, surface finishing and lamination, cooling and cutting, quality inspection, and packaging. Applications span wall panels, ceiling panels, decorative cladding, modular partitions, and moisture-resistant interior surfaces. End-use industries include residential construction, commercial real estate, interior design industry, industrial infrastructure, and institutional buildings, all contributing to sustained market demand.

Why Invest in PVC Panel Manufacturing?

Several compelling factors make PVC panel manufacturing an attractive investment opportunity:

Rising Construction and Renovation Activities: The continual demand for PVC panels is largely due to rapid urban development and renovation of interiors that are trending. Strong real estate investment growth, such as the 53% increase in Uttar Pradesh demonstrating market momentum, supports sustained demand.

Durability and Low Maintenance: PVC panels can last a long time without maintenance, thus they are suitable for both residential and commercial use. Their resistance to water, termites, and fires provides critical advantages.

Cost-Effective Alternative Materials: When compared with wood and gypsum boards, PVC panels have moisture resistance and, at the same time, have competitive pricing, making them economically attractive.

Design Versatility: Manufacturers can always offer a wide range of textures, colors, and finishes to fit in with ever-changing interior design trends. Available textures include wood grain, marble-like, matte, and shiny surfaces appealing to modern aesthetics.

Scalable Manufacturing Operations: The capacity of the production facility can be increased efficiently due to the use of extrusion methods along with proper management of inventory, allowing operational flexibility.

Sustainability Advantages: The recyclability of PVC panels makes them a prime candidate for environmentally conscious construction projects across residential, commercial, medical, retail, and industrial sectors.

Manufacturing Process Excellence

The PVC panel manufacturing process is a multi-step operation involving several unit operations, material handling, and quality checks. The main stages include:

• Raw material preparation of PVC resin and additives

• Mixing and compounding to create uniform blends

• Extrusion or calendering for panel formation

• Cooling for dimensional stability

• Shaping and cutting to specifications

• Lamination or surface treatment for aesthetic finishes

• Curing and drying for final properties

• Quality control for performance verification

• Cutting to final size for customer requirements

• Packaging for distribution and storage

The complete process flow encompasses mass balance and raw material requirements, rigorous quality assurance criteria, and technical tests throughout production. Safety protocols must be implemented throughout the manufacturing process, with advanced monitoring systems installed to detect leaks or deviations. Effluent treatment systems are necessary to minimize environmental impact and ensure compliance with emission standards. A comprehensive quality control system should be established using analytical instruments to monitor product concentration, purity, and stability. Documentation for traceability and regulatory compliance must be maintained.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8736&flag=C

Industry Leadership

The global PVC panel industry is led by established manufacturers with extensive production capabilities and diverse application portfolios. Key industry players include:

• MAA Group

• Azek

• Citadel

• ABC

• Allied

These companies serve diverse end-use sectors including residential, commercial, industrial, and institutional segments, demonstrating the broad market applicability of PVC panels across global construction markets.

Recent Industry Developments

January 2026: The 13th Vinyl India Summit & Exhibition 2026 in Mumbai, India, took place as a key industry platform uniting PVC resin producers, converters, construction material partners, and regulators. The event focused on technology exchange, sustainability discussions, and collaboration across PVC applications, including PVC panel solutions, pipes, profiles, and emerging material innovations.

November 2025: TimberTech's Harvest+ Collection from the Advanced PVC Decking line earned recognition as a winner in Good Housekeeping's 2026 Home Reno Awards, highlighting PVC panel decking aesthetics, durability, and sustainability. The line delivers moisture and fade protection, slip resistance, Cool Touch technology, fire resistance, 50-year warranties, and up to 65% recycled content.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PVC Panel Manufacturing Plant Cost Report 2026: Business Plan, Setup Requirements & ROI Insights here

News-ID: 4377432 • Views: …

More Releases from IMARC Group

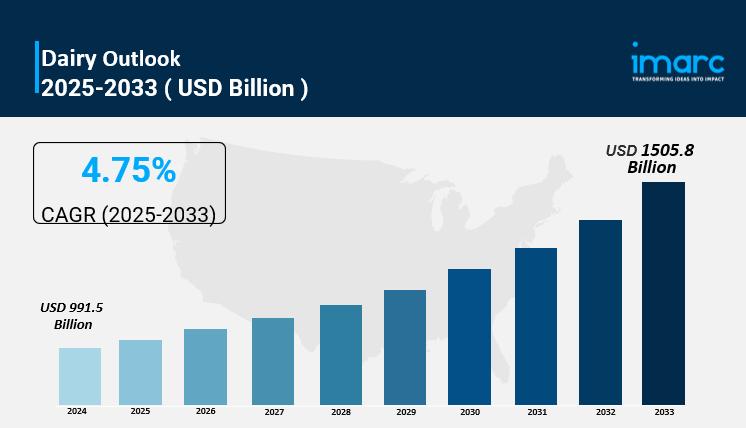

Dairy Market Size, Share, Industry Trends, Growth Factors and Forecast 2025-2033

IMARC Group, a leading market research company, has recently released a report titled "Dairy Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033."The study provides a detailed analysis of the industry, including the Dairy market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Dairy Market Overview

The global dairy market size…

Plastic Pyrolysis Production Plant DPR 2026: Unit Setup, Cost and Requirements

The global plastic pyrolysis manufacturing industry is witnessing robust growth driven by the escalating plastic waste crisis and increasing demand for sustainable waste-to-energy solutions. At the heart of this expansion lies a critical waste valorization technology plastic pyrolysis. As industrial regions transition toward circular economy practices and advanced waste management systems, establishing a plastic pyrolysis manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and environmental technology investors seeking…

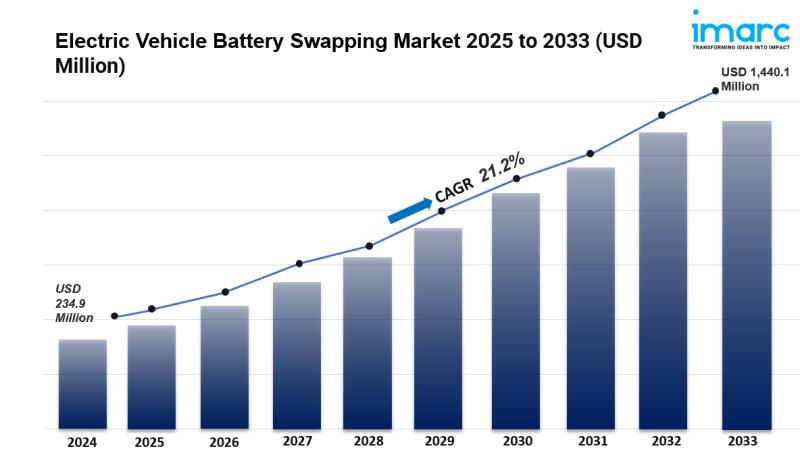

Electric Vehicle Battery Swapping Market is Expected to Grow USD 1,440.12 Millio …

Electric Vehicle Battery Swapping Market Overview:

The global electric vehicle battery swapping market was valued at USD 234.92 Million in 2024 and is projected to reach USD 1,440.12 Million by 2033, exhibiting a CAGR of 21.20% during the 2025-2033 forecast period. Growing demand for sustainable transportation, expanding electric vehicle adoption, and heightened need for time-efficient charging solutions are driving this growth. The electric vehicle battery swapping market size is expanding rapidly…

Battery Recycling Plant Setup 2026: Complete DPR with Process Flow, Machinery & …

The global battery recycling industry is witnessing extraordinary growth driven by the rapidly expanding electric vehicle market and increasing demand for sustainable resource recovery solutions. At the heart of this expansion lies a critical circular economy imperative battery recycling. As industries and consumers transition toward responsible end-of-life battery management and critical mineral recovery, establishing a battery recycling plant presents a strategically compelling business opportunity for entrepreneurs and environmental investors seeking…

More Releases for PVC

PVC Coated Fabrics Market Accelerates at 5.3% CAGR as Transportation, Infrastruc …

The PVC coated fabrics market reached USD million in 2022 and is projected to witness lucrative growth by reaching up to USD million by 2031. The market is growing at a CAGR of 5.3% from 2024 to 2031.

Market growth is fueled by surging demand for durable, waterproof materials in transportation, marine, and construction sectors, alongside rising infrastructure projects and automotive upholstery needs. Key drivers include advancements in eco-friendly PVC formulations…

PVC Foam Profiles Market Outlook 2034: Global Valuation to Reach USD 4.8 Billion …

The global PVC foam profiles market was valued at US$ 2.9 Bn in 2023. As industries continue to adopt lightweight, moisture-resistant, and dimensionally stable materials, PVC foam profiles are witnessing growing integration into construction, automotive, marine, and furniture manufacturing applications. According to current projections, the market is set to expand at a CAGR of 4.2% from 2024 to 2034, ultimately reaching US$ 4.8 Bn by 2034. This sustained growth reflects…

The Growing PVC Window Market

New York, US, - [01-December- 2025] - The PVC window market is experiencing significant growth, driven by increasing demand for energy-efficient and sustainable building materials. As consumers and builders alike prioritize durability, cost-effectiveness, and environmental impact, PVC (polyvinyl chloride) windows have emerged as a preferred choice in residential and commercial construction. This press release provides an overview of the current state of the PVC window market, key trends, and future…

New PVC External Lubricant Improves Performance

Shandong HTX New Material Co., Ltd. is a newly established company that has already made a significant impact in the industry. Since its inception in March 2021, the company has been focused on producing high-quality PVC External Lubricant [https://www.htxchem.com/lubricant-manufacture-price-product/] and other related products. HTX is a comprehensive enterprise that not only specializes in PVC processing aids but also involves itself in research and development, production, and sales.

The product range offered…

PVC Pipes Market to See Major Growth by 2026 | Bow Plastics, Royal PVC, Tulsi Ex …

Latest released the research study on Global PVC Pipes Market, offers a detailed overview of the factors influencing the global business scope. PVC Pipes Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the PVC Pipes

The study covers emerging player’s data, including: competitive…

Global Polyvinyl Chloride (PVC) Market 2017 -

Worldwide Polyvinyl Chloride (PVC) 2017 Research Report presents a professional and complete analysis of Global Polyvinyl Chloride (PVC) Market on the current situation.

In the first part, the report provides a general overview of the Polyvinyl Chloride (PVC) industry 2017 including definitions, classifications, Polyvinyl Chloride (PVC) market analysis, a wide range of applications and Polyvinyl Chloride (PVC) industry chain structure. The 2017's report on Polyvinyl Chloride (PVC) industry offers the global…