Press release

Plastic Pyrolysis Production Plant DPR 2026: Unit Setup, Cost and Requirements

The global plastic pyrolysis manufacturing industry is witnessing robust growth driven by the escalating plastic waste crisis and increasing demand for sustainable waste-to-energy solutions. At the heart of this expansion lies a critical waste valorization technology plastic pyrolysis. As industrial regions transition toward circular economy practices and advanced waste management systems, establishing a plastic pyrolysis manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and environmental technology investors seeking to capitalize on this growing and essential market.Market Overview and Growth Potential

The global plastic pyrolysis market demonstrates strong growth trajectory, valued at USD 771.22 Million in 2025. According to comprehensive market analysis, the market is projected to reach USD 11,61.34 Million by 2034, exhibiting a robust CAGR of 5.6% from 2026-2034. This sustained expansion is driven by rapidly escalating plastic waste volumes, stringent environmental regulations banning single-use plastics, rising crude oil prices enhancing alternative fuel economics, and expanding waste-to-energy infrastructure across developed and developing economies.

Plastic pyrolysis is a thermochemical decomposition process where plastic waste is heated in an oxygen-free environment at temperatures ranging from 350°C to 500°C. This process breaks down long-chain polymer molecules into shorter hydrocarbon chains, producing three primary outputs: pyrolysis oil (plastic crude oil), carbon black, and combustible gases. The pyrolysis oil can be refined into diesel, gasoline, or industrial fuel oil. Carbon black serves as a valuable additive in rubber manufacturing, pigments, and construction materials. Its efficient waste conversion, multiple revenue streams, and environmental benefits make it a preferred option in circular economy implementation and sustainable waste management.

The plastic pyrolysis market is witnessing robust demand due to the rising need for sustainable waste management solutions that address plastic pollution challenges. Industrial regions increasingly transitioning toward waste valorization-particularly in municipal waste management, industrial plastic waste treatment, and agricultural plastic recycling-are driving large-scale adoption. Government-led Extended Producer Responsibility (EPR) frameworks, subsidies for waste-to-energy projects, and circular economy initiatives further strengthen market prospects.

Request for a Sample Report: https://www.imarcgroup.com/plastic-pyrolysis-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed plastic pyrolysis manufacturing facility is designed with an annual production capacity ranging between 10,000-20,000 MT , enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from industrial fuel oil and carbon black to combustible gas applications-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Financial Viability and Profitability Analysis

The plastic pyrolysis manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 30-40%

• Net Profit Margins: 12-18%

These margins are supported by minimal or negative feedstock costs (plastic waste with tipping fees), value-added energy product positioning, and the critical nature of plastic pyrolysis in circular economy applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established waste management companies looking to diversify their product portfolio in the waste-to-energy sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a plastic pyrolysis manufacturing plant is primarily driven by:

• Raw Materials: 40-50% of OpEx

• Utilities: 20-25% of OpEx

Other Expenses: Including labor, maintenance, transportation, depreciation, and taxes

Feedstock procurement constitutes a significant but often advantageous cost component, with plastic waste frequently available at minimal cost or with tipping fees from waste generators. Establishing long-term contracts with municipalities, waste aggregators, and industrial facilities helps ensure consistent feedstock supply, which is critical given that feedstock quality and consistency represent the most significant operational factors in plastic pyrolysis manufacturing.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=19440&flag=C

Capital Investment Requirements

Setting up a plastic pyrolysis manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to plastic waste sources and industrial fuel markets. Proximity to target industrial customers will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Pre-processing equipment including shredders, crushers, and sorting systems for feedstock preparation

• Pyrolysis reactor with high-temperature resistance and precise temperature control (350-500°C)

• Heating systems with automated temperature regulation and energy recovery capability

• Condensation systems for converting pyrolysis vapors into liquid oil products

• Gas handling systems for combustible gas capture, cleaning, and recirculation

• Carbon black collection and processing systems for solid residue recovery

• Quality control laboratory equipment for fuel properties and carbon black testing

• Pollution control systems including scrubbers, filters, and emission monitoring equipment

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for feedstock storage, pre-processing zone, pyrolysis reactor section, condensation unit, carbon black collection area, quality control laboratory, finished goods warehouse, utility block, pollution control area, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=19440&method=2175

Major Applications and Market Segments

Plastic pyrolysis products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Industrial Fuel Oil: Primary use as alternative fuel for boilers, furnaces, and industrial heating systems in manufacturing facilities, cement kilns, and steel plants, replacing conventional heavy fuel oil with cost-effective alternatives.

Petroleum Refineries: Specialized applications as feedstock for petroleum refineries where pyrolysis oil undergoes distillation and upgrading to produce diesel and gasoline blending components.

Carbon Black Manufacturing: Utilized as reinforcing filler in tire production, rubber products, pigments for printing inks, paints and coatings, and construction material additives.

Energy Generation: Applications in power generation facilities and on-site electricity production through combustible gas utilization in gas engines or turbines.

Chemical Synthesis: Specialized industrial applications in chemical manufacturing where pyrolysis oil serves as raw material for petrochemical processes after appropriate treatment.

End-use industries include cement, steel, power generation, chemical manufacturing, rubber production, construction, and fuel distribution, all of which contribute to sustained market demand.

Why Invest in Plastic Pyrolysis Manufacturing?

Several compelling factors make plastic pyrolysis manufacturing an attractive investment opportunity:

Essential Waste Valorization Technology: Plastic pyrolysis serves as a critical waste-to-energy solution supporting circular economy principles, sustainable waste management, and environmental protection, making it indispensable for modern waste management operations focused on landfill diversion and resource recovery.

Rising Circular Economy Adoption: Industrial regions increasingly transitioning toward waste valorization-particularly in municipal waste management, industrial plastic recycling, and agricultural plastic treatment-are driving large-scale adoption of pyrolysis technologies.

Multiple Revenue Streams: The technology's ability to produce pyrolysis oil, carbon black, and combustible gas from single feedstock, combined with potential tipping fee revenues, offers significant economic advantages and positions it favorably against conventional waste disposal methods.

Plastic Waste Crisis Solutions: The technology's effectiveness in converting non-recyclable plastic waste into valuable products positions it as a preferred solution in regions facing plastic pollution challenges, especially across Asia, Europe, and North America.

Government Support: Government-led Extended Producer Responsibility frameworks, subsidies for waste-to-energy projects, and circular economy initiatives further strengthen market prospects and support industry growth.

Import Substitution Opportunities: Emerging economies such as India, China, Brazil, and Southeast Asian nations are expanding local pyrolysis capacity as part of their strategy to reduce dependence on imported fuels and address domestic plastic waste challenges.

Environmental Impact Alignment: The carbon footprint reduction agenda and increasing corporate sustainability commitments are expected to enhance long-term growth opportunities for waste-to-energy technologies.

Manufacturing Process Excellence

The plastic pyrolysis manufacturing process involves several precision-controlled stages:

• Feedstock Reception and Storage: Plastic waste is received, inspected, and stored in designated areas with inventory management

• Pre-processing: Plastic waste undergoes shredding, magnetic separation, and screening to remove contaminants and achieve optimal particle size

• Thermal Decomposition: Pre-processed plastic is fed into the pyrolysis reactor and heated to 350-500°C in oxygen-free atmosphere to break down polymer chains

• Vapor Condensation: Pyrolysis vapors are directed through multi-stage condensation systems to produce liquid oil products

• Gas Collection: Non-condensable gases are collected, cleaned, and recirculated to fuel the reactor heating system

• Carbon Black Recovery: Solid residue is discharged, cooled, and processed to achieve consistent particle size distribution

• Product Storage and Dispatch: Pyrolysis oil is stored in tanks, carbon black in silos, and products dispatched according to customer specifications

Industry Leadership

The global plastic pyrolysis industry is led by established technology providers with extensive production capabilities and diverse application portfolios. Key industry players include:

• Agilyx

• Plastic Energy

• Brightmark Energy

• Green EnviroTech Holdings

• Klean Industries

These companies serve diverse end-use sectors including cement, steel, power generation, chemical manufacturing, rubber production, and fuel distribution, demonstrating the broad market applicability of plastic pyrolysis products.

Recent Industry Developments

August 2025:

SABIC Plastic Energy Advanced Recycling (SPEAR), the joint recycling venture between Plastic Energy and SABIC, successfully produced its first batch of pyrolysis oil, branded as TACOIL, at its Geleen facility in the Netherlands. The pyrolysis oil is derived from hard-to-recycle post-consumer plastic waste that would otherwise be sent to landfill or incineration, marking a key milestone in advanced chemical recycling operations.

May 2025:

Alterra announced the successful utilization of plastic pyrolysis oil in Australia, representing a major advancement toward circular plastic solutions. As part of a trial, 9.5 tonnes of plastic pyrolysis oil (PPO) produced from end-of-life plastics at Alterra's Ohio facility were processed at Viva Energy's Geelong Refinery, demonstrating the commercial viability of pyrolysis oil in conventional refining infrastructure.

Conclusion

The plastic pyrolysis manufacturing sector presents a strategically positioned investment opportunity at the intersection of waste management, circular economy, and sustainable energy production. With favorable profit margins ranging from 30-40% gross profit and 12-18% net profit, strong market drivers including escalating plastic waste volumes, rising adoption of waste-to-energy solutions, growing demand for alternative fuels, and supportive government policies promoting circular economy and Extended Producer Responsibility, establishing a plastic pyrolysis manufacturing plant offers significant potential for long-term business success and sustainable returns.

The combination of multiple revenue streams, minimal feedstock costs with tipping fee potential, critical role in addressing plastic pollution, expanding waste-to-energy infrastructure, and environmental impact advantages creates an attractive value proposition for serious environmental technology investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Plastic Pyrolysis Production Plant DPR 2026: Unit Setup, Cost and Requirements here

News-ID: 4377434 • Views: …

More Releases from IMARC Group

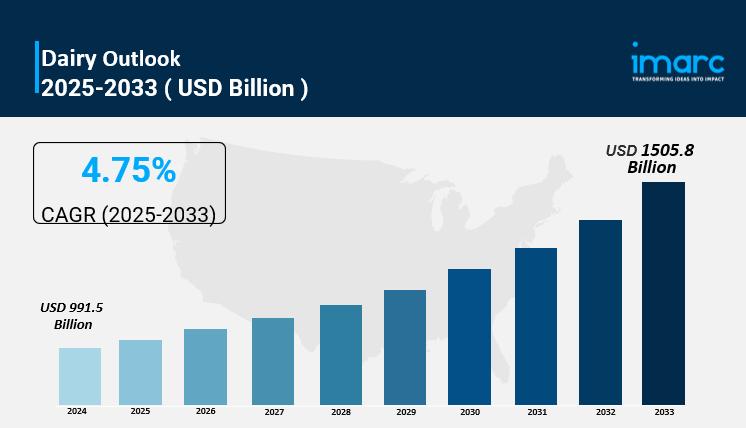

Dairy Market Size, Share, Industry Trends, Growth Factors and Forecast 2025-2033

IMARC Group, a leading market research company, has recently released a report titled "Dairy Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033."The study provides a detailed analysis of the industry, including the Dairy market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Dairy Market Overview

The global dairy market size…

PVC Panel Manufacturing Plant Cost Report 2026: Business Plan, Setup Requirement …

The global construction and interior finishing industry is experiencing dynamic transformation driven by rising construction activities, increasing demand for cost-effective interior solutions, rapid urbanization, and growing preference for moisture-resistant building materials. At the forefront of this evolution stands PVC panel manufacturing-a specialized segment producing versatile, durable panels that combine aesthetic appeal with functional performance for wall cladding, suspended ceilings, partitions, and decorative interior applications. As construction activities accelerate worldwide and…

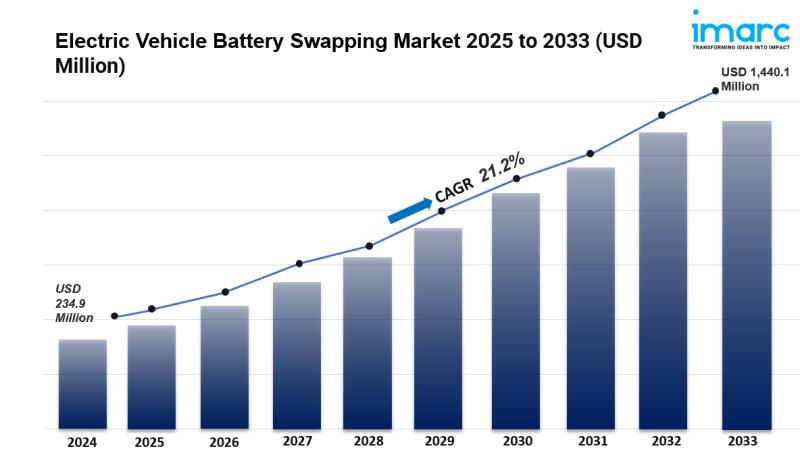

Electric Vehicle Battery Swapping Market is Expected to Grow USD 1,440.12 Millio …

Electric Vehicle Battery Swapping Market Overview:

The global electric vehicle battery swapping market was valued at USD 234.92 Million in 2024 and is projected to reach USD 1,440.12 Million by 2033, exhibiting a CAGR of 21.20% during the 2025-2033 forecast period. Growing demand for sustainable transportation, expanding electric vehicle adoption, and heightened need for time-efficient charging solutions are driving this growth. The electric vehicle battery swapping market size is expanding rapidly…

Battery Recycling Plant Setup 2026: Complete DPR with Process Flow, Machinery & …

The global battery recycling industry is witnessing extraordinary growth driven by the rapidly expanding electric vehicle market and increasing demand for sustainable resource recovery solutions. At the heart of this expansion lies a critical circular economy imperative battery recycling. As industries and consumers transition toward responsible end-of-life battery management and critical mineral recovery, establishing a battery recycling plant presents a strategically compelling business opportunity for entrepreneurs and environmental investors seeking…

More Releases for Plastic

Plastic bottles at events - Better party with plastic

Partying, dancing, camping - festivals attract hundreds of thousands of visitors every year in Germany alone. One challenge: supply and safety. For this reason, drinks in glass bottles are banned at most events due to the risk of injury. Lightweight and unbreakable plastic bottles, on the other hand, are considered a safe and practical alternative. Not only that: they can even be used to make a musical instrument.

Festivals or pageants…

Plastic Pallet With Plastic Crate Use: Efficient Material Handling

When it comes to efficient moving and storage of goods, a combination of plastic pallets [https://www.agriculture-solution.com/plastic-pallet/]and plastic crates is a popular choice. They are widely used in various industries such as manufacturing, retail, agriculture, etc. for storage and transportation of goods. Plastic pallets are designed to provide a stable base for stacking and shipping goods, while plastic crates provide safe and protective containers for stored or transported items. Plastic pallets…

Plastic Granules Market to Witness Massive Growth by Balaji Plastic, Navkar Indu …

The Worldwide Plastic Granules Market has witnessed continuous growth in the past few years and is projected to grow at a good pace during the forecast period of 2023-2029. The exploration provides a 360° view and insights, highlighting major outcomes of Worldwide Plastic Granules industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improve profitability. Additionally, the study helps venture or emerging…

Insights on the Growth of Plastic Granules Market 2018 to 2025 | Profiling Key C …

UpMarketResearch offers a Latest report on “Plastic Granules Market Analysis & Forecast 2018-2025” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 114 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy of This Report@ https://www.upmarketresearch.com/home/requested_sample/49052

Plastic Granules research report delivers a close watch on leading competitors with strategic…

Agriculture Film Market SWOT Analysis of Leading Key Players Shandong Tianhe Pla …

HTF MI recently introduced Global Agriculture Film Market study with in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status to 2023. The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence and some of the key players from the complete study are British Polythene Industries (BPI), Trioplast, Berry Plastics, Armando Alvarez, Polypak, Barbier…

Building Materials Market 218 : Hepworth, National Plastic Industry, Hira Indust …

Building materials in this report covered the PVC pipes and fittings, PPR pipes and fittings, PE pipes and fittings, fabrication, ducts systems for infrastructure, valves and pumps and electrical conduits PVC systems.

At present, Hepworth, National Plastic Industry, Hira Industries, Florance Plastic Industries, Polyfab Plastic Industry, MPI, Union Pipes Industry, ANABEEB, Borouge and ACO Group are the UAE leading suppliers of the building materials, and top ten of them shared about…