Press release

Biodiesel Manufacturing Plant DPR 2026: Investment Cost, Market Growth & ROI

The global biodiesel manufacturing industry is witnessing robust growth driven by the rapidly expanding renewable energy sector and increasing demand for sustainable transportation fuels. At the heart of this expansion lies a critical clean fuel solution-biodiesel. As transportation sectors transition toward low-carbon alternatives and controlled emissions reduction methods, establishing a biodiesel manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and renewable energy investors seeking to capitalize on this growing and essential market.Market Overview and Growth Potential

The global biodiesel market demonstrates strong growth trajectory, valued at USD 47.76 Billion in 2025. According to market analysis from multiple research firms, the market is projected to reach USD 65.66 Billion by 2034, exhibiting a robust CAGR of 3.6% from 2026 to 2034. This sustained expansion is driven by rapidly expanding renewable energy adoption, increasing demand for clean transportation fuels, rising government mandates for biodiesel blending, and expanding sustainability requirements across developed and developing economies.

Request for a Sample Report: https://www.imarcgroup.com/biodiesel-manufacturing-plant-project-report/requestsample

Biodiesel is a renewable, biodegradable fuel derived from vegetable oils, animal fats, or recycled cooking oils through a chemical process called transesterification. It appears as a yellowish-brown liquid with diesel-like properties and superior lubricity characteristics. Biodiesel contains fatty acid methyl esters (FAME), making it an efficient petroleum diesel substitute used primarily in transportation, agriculture, marine vessels, and stationary power generation applications. Due to its significantly lower greenhouse gas emissions, it helps reduce carbon footprint and prevents air pollution in urban areas. Its high compatibility with existing diesel engines, biodegradable nature, and renewable feedstock availability make it a preferred option in sustainable transportation and industrial fuel applications.

The biodiesel market is witnessing robust demand due to the rising need for clean fuels that support emissions reduction and energy independence. Transportation sectors increasingly transitioning toward renewable fuel adoption-particularly in fleet vehicles, heavy-duty trucks, and agricultural equipment-are driving large-scale adoption. According to various government initiatives worldwide, biodiesel blending mandates are being progressively increased across major economies, with targets ranging from B5 to B20 and higher. Government-led renewable energy programs, subsidies for biodiesel production, and carbon emission reduction initiatives further strengthen market prospects.

Plant Capacity and Production Scale

The proposed biodiesel manufacturing facility is designed with an annual production capacity ranging between between 50,000 - 100,000 MT, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from transportation and agriculture to marine vessels, industrial power generation, and heating applications-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=14934&flag=C

Financial Viability and Profitability Analysis

The biodiesel manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 15-25%

Net Profit Margins: 5-10%

These margins are supported by stable demand across transportation and industrial sectors, value-added renewable fuel positioning, and the critical nature of biodiesel in decarbonization applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established energy companies looking to diversify their product portfolio in the renewable fuels sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a biodiesel manufacturing plant is primarily driven by:

Raw Materials: 80-85% of total OpEx

Utilities: 5-10% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with vegetable oils (soybean, palm, canola), animal fats, used cooking oil, and methanol being the primary input materials. Establishing long-term contracts with reliable feedstock suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that vegetable oil price fluctuations represent the most significant cost factor in biodiesel manufacturing.

Capital Investment Requirements

Setting up a biodiesel manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to feedstock suppliers (oilseed crushing facilities, rendering plants, used cooking oil collection centers). Proximity to target transportation markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Buy Now: https://www.imarcgroup.com/checkout?id=14934&method=2175

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

- Feedstock pretreatment systems for removing impurities and water from oils and fats

- Transesterification reactors for converting triglycerides to biodiesel through catalyst-assisted reaction

- Methanol recovery systems for recycling unreacted alcohol and reducing operating costs

- Separation equipment for glycerin removal and biodiesel purification

- Washing and drying systems for removing impurities and achieving fuel specifications

- Distillation columns for methanol and water recovery from both biodiesel and glycerin streams

- Storage tanks for feedstock, methanol, biodiesel, and glycerin byproduct

- Quality control laboratory equipment for testing fuel properties and ASTM compliance

- Effluent treatment systems for managing wastewater and ensuring environmental compliance

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for feedstock receiving, pretreatment zone, transesterification reactor area, separation and washing section, drying unit, methanol recovery area, quality control laboratory, finished product storage, glycerin storage, utility block, effluent treatment area, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Biodiesel products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Transportation: Primary use as a renewable diesel fuel in on-road vehicles including fleet vehicles, heavy-duty trucks, buses, and light-duty vehicles, particularly valuable in commercial transportation, public transit, and logistics where emissions reduction is essential.

Agriculture: Specialized applications in agricultural equipment, tractors, harvesters, and irrigation pumps where renewable fuel adoption and on-farm energy independence are critical for sustainable farming operations.

Marine Vessels: Utilized in maritime transportation, fishing vessels, and recreational boats where biodiesel's biodegradable properties provide environmental protection in sensitive aquatic ecosystems.

Industrial Power Generation: Applications in stationary diesel generators, backup power systems, and remote power generation where reliable renewable energy is required.

Heating Applications: Specialized applications in home heating systems, industrial boilers, and furnaces where biodiesel's clean-burning properties provide environmental benefits.

End-use industries include transportation, agriculture, marine, power generation, and heating applications, all of which contribute to sustained market demand.

Why Invest in Biodiesel Manufacturing?

Several compelling factors make biodiesel manufacturing an attractive investment opportunity:

Essential Renewable Fuel Segment: Biodiesel serves as a critical renewable fuel supporting transportation decarbonization, energy independence, and emissions reduction, making it indispensable for modern economies focused on sustainability and climate goals.

Rising Clean Energy Adoption: Transportation and industrial sectors increasingly transitioning toward low-carbon fuels-particularly in fleet vehicles, heavy-duty trucking, and agricultural operations-are driving large-scale adoption of renewable fuels like biodiesel.

Drop-in Fuel Compatibility: The product's ability to be used directly in existing diesel engines without modification, combined with its superior lubricity properties, offers significant operational advantages and positions it favorably against petroleum diesel.

Climate Action Solutions: The product's effectiveness in reducing lifecycle greenhouse gas emissions by 50-80% compared to petroleum diesel positions it as a preferred fuel in climate-conscious regions, especially across North America, Europe, and Asia-Pacific.

Government Support: Government-led renewable energy programs, biodiesel blending mandates, tax incentives, and carbon credit mechanisms further strengthen market prospects and support industry growth.

Domestic Production Opportunities: Emerging economies such as India, Brazil, Indonesia, and developing nations are expanding local manufacturing as part of their strategy to reduce dependence on imported petroleum fuels, creating opportunities for domestic producers.

Energy Security Alignment: The energy independence agenda and increasing demand for domestically-produced renewable fuels are expected to enhance long-term growth opportunities for sustainable fuel production.

Manufacturing Process Excellence

The biodiesel manufacturing process involves several precision-controlled stages:

- Feedstock Pretreatment: Vegetable oils, animal fats, or used cooking oils are filtered and treated to remove impurities, water, and free fatty acids

- Transesterification Reaction: Pretreated feedstock reacts with methanol in the presence of a catalyst (typically sodium or potassium hydroxide) to form biodiesel and glycerin

- Phase Separation: The reaction mixture separates into two layers-biodiesel (top layer) and crude glycerin (bottom layer)

- Biodiesel Washing: Biodiesel is washed with water to remove residual catalyst, methanol, and impurities

- Drying: Washed biodiesel is dried to remove moisture and achieve final fuel specifications

- Methanol Recovery: Excess methanol is recovered from both biodiesel and glycerin streams through distillation for reuse

- Quality Testing: Final product is tested for compliance with ASTM D6751 or EN 14214 standards

- Storage and Distribution: Finished biodiesel is stored in tanks and distributed to customers

Industry Leadership

The global biodiesel industry is led by established energy companies with extensive production capabilities and diverse feedstock portfolios. Key industry players include:

- Neste Corporation

- Renewable Energy Group (REG)

- Archer Daniels Midland (ADM)

- Cargill, Inc.

- Bunge Limited

These companies serve diverse end-use sectors including transportation, agriculture, marine, industrial, and heating applications, demonstrating the broad market applicability of biodiesel products.

Recent Industry Developments

February 2025: BASF announced a mid-double-digit million-euro investment in a new alcoholates plant at its Ludwigshafen, Germany location. These chemicals are crucial for biodiesel manufacturing as well as pharmaceutical and agricultural applications, supporting the growing demand for renewable fuel production infrastructure.

Conclusion

The biodiesel manufacturing sector presents a strategically positioned investment opportunity at the intersection of renewable energy, sustainable transportation, and climate action. With favorable profit margins ranging from 15-25% gross profit and 5-10% net profit, strong market drivers including rising adoption of clean fuels, growing government blending mandates, expanding emissions reduction requirements, and supportive policies promoting renewable energy and carbon reduction, establishing a biodiesel manufacturing plant offers significant potential for long-term business success and sustainable returns. The combination of drop-in fuel compatibility, critical role in transportation decarbonization, expanding renewable energy requirements, and import substitution opportunities in emerging economies creates an attractive value proposition for serious renewable energy investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Biodiesel Manufacturing Plant DPR 2026: Investment Cost, Market Growth & ROI here

News-ID: 4377294 • Views: …

More Releases from IMARC Group

India Hospital Market Overview: Size, Industry Expansion & Growth Potential 2026 …

India Hospital Market Report Introduction:

According to IMARC Group's report titled "India Hospital Market Size, Share, Growth & Forecast 2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

How Big is the India Hospital Industry?

The India hospital market size was valued at USD 193.42 Billion in 2025 and is projected to reach USD 364.55 Billion by 2034, growing at a compound annual growth…

Gelato Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

The global gelato industry is experiencing robust growth driven by rising consumer preference for premium frozen desserts, growth in foodservice outlets such as cafes and ice cream parlors, expansion of retail channels, and increasing awareness of artisanal and high-quality frozen treats. As urbanization accelerates, disposable incomes rise, and consumers shift toward premium frozen dessert options with natural ingredients and innovative flavors, establishing a gelato manufacturing plant presents a strategically compelling…

Biodegradable Plastic Granules Manufacturing Plant DPR & Unit Setup - 2026: Dema …

The global biodegradable plastic granules manufacturing industry is witnessing robust growth driven by the rapidly expanding sustainable packaging, agricultural film, and eco-friendly consumer goods sectors and increasing demand for environmentally responsible alternatives to conventional petroleum-based plastics. At the heart of this expansion lies a critical product category-biodegradable plastic granules. As industries worldwide transition toward circular economy principles and governments enforce stringent regulations against single-use plastics, establishing a biodegradable plastic granules…

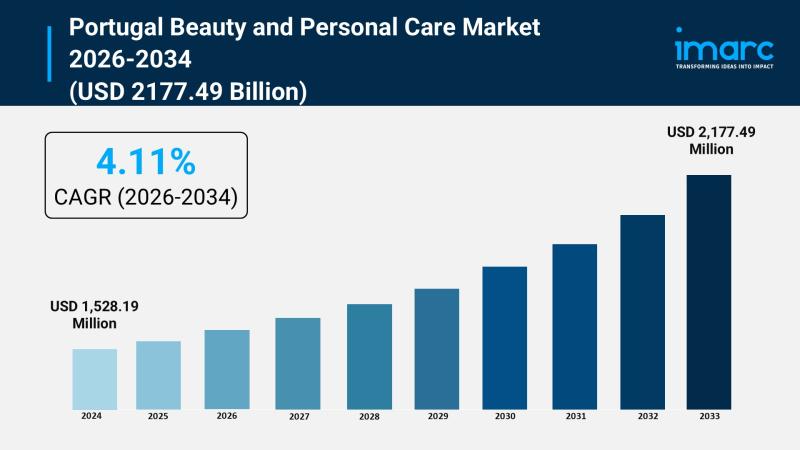

Portugal Beauty and Personal Care Market Growth Outlook Supported by Wellness-Dr …

Market Overview

The Portugal beauty and personal care market size reached USD 1,528.19 Million in 2025 and is expected to grow to USD 2,177.49 Million by 2034. The market is forecasted to grow at a CAGR of 4.01% during the period 2026-2034. Growth is driven by consumer trends toward skincare, fragrances, and color cosmetics emphasizing ingredient transparency, natural formulations, and sustainability. Omnichannel retailing enhances access to new product launches while premiumization…

More Releases for Biodiesel

A Complete Guide to Biodiesel

Biodiesel is a renewable fuel produced from renewable sources such as vegetable oils, animal fats, and recycled cooking oil. It works seamlessly with existing diesel engines and diesel vehicles. It is mainly used as a blend with petroleum diesel fuel in diesel vehicles. Biodiesel is known to increase the cetane number of the fuel and increase fuel lubricity. It is utilized as an alternative biofuel in existing diesel engines without…

Biodiesel Price Trend Analysis

Biodiesel is a renewable fuel produced from various feedstocks, including vegetable oils, animal fats, and recycled cooking oils. It can be blended with petroleum diesel or used as a complete substitute in diesel engines. As a renewable alternative to fossil fuels, biodiesel plays an important role in reducing greenhouse gas emissions and decreasing dependence on crude oil. Because of these environmental benefits, many countries support biodiesel production through renewable energy…

Factors Influencing Global Waste Grease Biodiesel Market through 2023 and Beyond …

Global Waste Grease Biodiesel Market Research Report provides a key analysis of the market status of Waste Grease Biodiesel with the best facts and figures, meaning, definition, SWOT analysis, expert opinions, and the latest developments across the globe. The report also calculates the market size, Sales, Price, Revenue, Gross Margin, Market Share, cost structure, and growth rate. The report considers the revenue generated from the sales of This Report and…

Global Biodiesel Market 2020 Business Strategies – Delta American Fuel, Wester …

The Zion Market Research added a new report “Global Biodiesel Market - By Application (Power Generation, Fuel, And Others); By Production Technology (Trans-Esterification, Pyrolysis, And Others); By Feedstock Type (Animal Fats, Vegetable Oils, And Others); By Blend (B5, B10, B20, And B100); And By Region- Global Industry Perspective, Comprehensive Analysis, and Forecast, 2020 – 2026” in its database, which provides an expert and in-depth analysis of key business trends and…

Biodiesel Processing Unit

While reserves of petroleum are decreasing every passing day, energy consumption is increasing at 6.5% per annum. And for solving this issue many countries are implementing new policies for minimizing the usage of fossil fuels and increase the use of alternative sources like solar power and Biodiesel. Biodiesel is a diesel fuel substitute made from a variety of oils, fats, and greases which can become a cheaper alternative to fossil…

Biodiesel Market Growth and Industry Key Players are Western Dubuque Biodiesel, …

Global Biodiesel Market size is expected to move up at a moderate rate in the next few years. Biodiesel is derived from animal fats, cooking oils, yellow grease, and vegetable oils by a process known as transesterification which converts fats and oils into chemicals. It is a substitute fuel similar to fossil or conventional fuels.

Need for energy independence and increasing environmental concern have driven the demand for biodiesel market…