Press release

Biodegradable Plastic Granules Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Project Cost

The global biodegradable plastic granules manufacturing industry is witnessing robust growth driven by the rapidly expanding sustainable packaging, agricultural film, and eco-friendly consumer goods sectors and increasing demand for environmentally responsible alternatives to conventional petroleum-based plastics. At the heart of this expansion lies a critical product category-biodegradable plastic granules. As industries worldwide transition toward circular economy principles and governments enforce stringent regulations against single-use plastics, establishing a biodegradable plastic granules manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and sustainable materials investors seeking to capitalize on this growing and essential market.Market Overview and Growth Potential

The global biodegradable plastics market is experiencing strong growth, with Europe accounting for the largest market share of 42.7% of the total market. According to industrial reports, the production capacity of global bioplastics is anticipated to increase significantly, rising from roughly 2.47 million tonnes in 2024 to an estimated 5.73 million tonnes by 2029, as reported by European Bioplastics. This sustained expansion is driven by stringent regulations on single-use plastics, rising environmental concerns, increasing adoption of sustainable packaging, and growing demand from food service and agricultural sectors.

Biodegradable plastic granules are a polymer material designed to break down into harmless end-products such as water, carbon dioxide, and biomass under specific environmental conditions. Most granules are produced from renewable or bio-based feedstock including corn starch, potato starch blends, polylactic acid (PLA), and polyhydroxyalkanoates (PHA). Besides their biodegradable nature, they offer similar resistance, flexibility, and processability compared to conventional plastics with a considerably lower environmental impact. Biodegradable plastic granules are designed to be compatible with standard plastic processing equipment.

The biodegradable plastic granules market is witnessing robust demand due to increasing regulatory restrictions on petroleum-based plastics and rising global awareness of plastic pollution. The packaging industry is a major contributor due to the growing shift toward compostable and eco-friendly materials. According to IBEF, the biodegradable plastic market in India is expected to grow to USD 223 million in 2030, as India escalates efforts under the single-use plastic ban. Agricultural demand is also rising, particularly for biodegradable mulch films that eliminate post-harvest plastic waste, while consumer preference for sustainable products is encouraging manufacturers to adopt biodegradable polymers across multiple applications.

Plant Capacity and Production Scale

The proposed biodegradable plastic granules manufacturing facility is designed with an annual production capacity ranging between 20,000-50,000 MT per Year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from compostable packaging films and agricultural mulch films to disposable cutlery, non-woven fabrics, and medical implants-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Request for a Sample Report: https://www.imarcgroup.com/biodegradable-plastic-granules-manufacturing-plant-project-report/requestsample

Financial Viability and Profitability Analysis

The biodegradable plastic granules manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 30-40%

Net Profit Margins: 12-18%

These margins are supported by stable demand across packaging, agriculture, consumer goods, and medical sectors, value-added sustainable materials positioning, and the critical nature of biodegradable plastic granules in replacing conventional petroleum-based plastics. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established polymer manufacturers looking to diversify their product portfolio in the sustainable materials segment.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a biodegradable plastic granules manufacturing plant is primarily driven by:

Raw Materials: 50-60% of total OpEx

Utilities: 20-30% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with corn starch/sugarcane (for PLA production), bacterial strains/nutrients (for PHA production), and bio-based additives being the primary input materials. Establishing long-term contracts with reliable bio-feedstock suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that bio-based feedstock procurement represents the most significant cost factor in biodegradable plastic granules manufacturing.

Capital Investment Requirements

Setting up a biodegradable plastic granules manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to corn starch/sugarcane suppliers (for PLA), bacterial strain/nutrient suppliers (for PHA), and bio-based additive sources. Proximity to target packaging, agriculture, and consumer goods markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Industrial mixers and compounders for blending bio-based polymers with additives, plasticizers, and performance modifiers to achieve target properties

• Twin-screw extruders for melting, mixing, and homogenizing biodegradable polymer compounds under controlled temperature and pressure conditions

• Pelletizing and cutting systems for forming molten polymer into uniform granules with consistent size and shape specifications

• Cooling baths and water systems for rapidly solidifying extruded polymer strands before pelletization and cutting operations

• Drying units for removing residual moisture from pelletized granules to ensure proper storage stability and processing performance

• Quality control sieves and screening equipment for separating off-spec granules and ensuring uniform particle size distribution

• Automated packaging machines for weighing, bagging, and palletizing finished biodegradable plastic granules for distribution

• Environmental control and effluent treatment systems for managing process emissions and ensuring regulatory compliance

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize environmental impact throughout the production process. The layout should be optimized with separate areas for raw material storage and pre-processing, polymerization and compounding zone, extrusion section, pelletizing unit, cooling and drying area, quality control laboratory, finished goods warehouse, utility block, effluent treatment area, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, environmental and biodegradability certification costs, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=13665&flag=C

Major Applications and Market Segments

Biodegradable plastic granule products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Packaging: Used extensively for producing biodegradable films, compostable containers, and flexible packaging products that decompose naturally, reducing landfill waste and supporting circular economy initiatives in food packaging and retail applications.

Agriculture: Applied in manufacturing biodegradable mulch films, seed trays, and plant pots that eliminate post-harvest plastic waste and improve soil health by decomposing naturally without requiring removal or disposal.

Consumer Goods: Utilized for producing disposable cutlery, tableware, and household items that offer convenient single-use functionality while ensuring environmental responsibility through natural biodegradation after disposal.

Medical and Hygiene: Used in manufacturing compostable medical disposables, sanitary products, and pharmaceutical packaging where biodegradability and safety compliance are critical for responsible healthcare waste management.

Why Invest in Biodegradable Plastic Granules Manufacturing?

Several compelling factors make biodegradable plastic granules manufacturing an attractive investment opportunity:

Essential Sustainability Material: Biodegradable plastic granules are a core input for compostable packaging, agricultural films, consumer goods, and single-use alternatives, making them critical materials in the global transition away from conventional plastics toward sustainable circular economy solutions.

Moderate but Defensible Entry Barriers: While capital requirements are lower than petrochemical polymers, consistent formulation control, resin compounding expertise, compliance with biodegradability standards (PLA, PBAT, starch blends), and certification norms (EN 13432, ASTM D6400) create entry barriers favoring technically capable and quality-focused manufacturers.

Megatrend Alignment: Global megatrends such as sustainability mandates, plastic waste reduction, eco-conscious consumer behavior, and corporate ESG commitments are driving strong growth in biodegradable plastics, with packaging, agriculture, and food-service segments expanding at high single- to double-digit rates worldwide.

Policy and Regulatory Push: Government bans on single-use plastics, extended producer responsibility (EPR) frameworks, compostability regulations, and incentives for green materials directly accelerate demand for biodegradable plastic granules across developed and emerging economies.

Localization and Supply Chain Security: Brand owners, converters, and FMCG companies increasingly prefer local and reliable suppliers to reduce import dependence, manage price volatility of bio-resins, ensure regulatory compliance, and maintain uninterrupted supply-creating strong opportunities for regional manufacturers with efficient sourcing and scalable operations.

Import Substitution Opportunities: Emerging economies such as India, China, and Southeast Asian nations are expanding local biodegradable plastics manufacturing to reduce dependence on imported bio-polymers, creating significant market opportunities for domestic producers.

Corporate Sustainability Commitments: Major global brands and retailers are committing to sustainable packaging targets, driving long-term demand for biodegradable plastic granules as companies transition from conventional plastics to certified compostable alternatives.

Manufacturing Process Excellence

The biodegradable plastic granules manufacturing process involves several precision-controlled stages:

• Raw Material Preparation: Bio-based feedstocks such as corn starch, sugarcane, or bacterial cultures are sourced, verified for quality, and prepared for polymerization or fermentation processes

• Polymerization: Monomers derived from bio-feedstocks undergo controlled polymerization reactions to form biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA)

• Compounding and Pelletizing: Polymerized bio-resins are mixed with additives, plasticizers, and performance modifiers in compounders, then extruded and pelletized into uniform biodegradable plastic granules

• Cooling: Extruded polymer strands pass through water cooling baths to solidify the material before pelletization and ensure dimensional stability

• Drying: Pelletized granules are dried using hot air or vacuum drying systems to remove residual moisture and achieve optimal storage and processing characteristics

• Quality Control: Finished granules undergo comprehensive testing for biodegradability, mechanical properties, thermal stability, and compliance with international standards (EN 13432, ASTM D6400)

• Packaging: Quality-verified biodegradable plastic granules are automatically weighed, bagged, and palletized for distribution to converters, molders, and end-use manufacturers

Industry Leadership

The global biodegradable plastic granules industry is led by established biopolymer manufacturers with extensive production capabilities and diverse application portfolios. Key industry players include:

• NatureWorks LLC

• BASF SE

• Novamont S.p.A.

• TotalEnergies Corbion

• Danimer Scientific

• FKuR Kunststoff GmbH

These companies serve diverse end-use sectors including packaging, agriculture, consumer goods, textiles, and biomedical applications, demonstrating the broad market applicability of biodegradable plastic granule products.

Buy Now:

https://www.imarcgroup.com/checkout?id=13665&method=2175

Recent Industry Developments

November 2024: Toray Industries, Inc. announced that it had signed a memorandum of understanding with major Thai petrochemicals manufacturer PTT Global Chemical Public Company Limited (GC) to develop mass production technology for adipic acid produced from non-edible biomass, supporting the expansion of sustainable bio-based polymer feedstocks.

September 2024: Danimer Scientific, Inc. and Ningbo Homelink Eco-iTech Co. Ltd. announced the commercial introduction of biopolymers for home compostable extrusion coatings created with Nodax, Danimer's trademark polyhydroxyalkanoate (PHA). Homelink's cups utilizing Nodax PHA-based biopolymer coating will provide consumers with a fully repulpable, industrially and home compostable substitute for conventional paper cups.

Conclusion

The biodegradable plastic granules manufacturing sector presents a strategically positioned investment opportunity at the intersection of sustainable materials innovation, environmental responsibility, and circular economy advancement. With favorable profit margins ranging from 30-40% gross profit and 12-18% net profit, strong market drivers including stringent single-use plastic regulations, rising corporate sustainability commitments, expanding eco-conscious consumer demand, and supportive government policies promoting bio-based materials, establishing a biodegradable plastic granules manufacturing plant offers significant potential for long-term business success and sustainable returns. The combination of essential sustainable packaging applications, critical role in reducing plastic pollution, expanding agricultural and medical applications, and import substitution opportunities in emerging economies creates an attractive value proposition for serious sustainable materials investors committed to quality manufacturing and environmental excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. IMARC Group provides a comprehensive suite of market entry and expansion services, including market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Biodegradable Plastic Granules Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Project Cost here

News-ID: 4377273 • Views: …

More Releases from IMARC Group

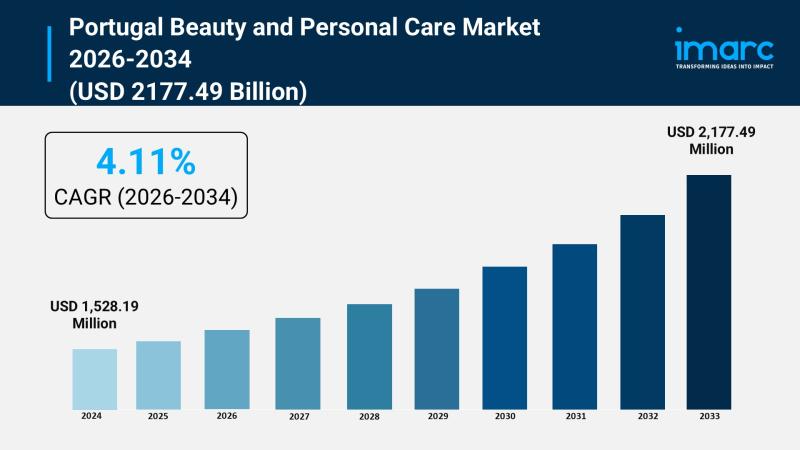

Portugal Beauty and Personal Care Market Growth Outlook Supported by Wellness-Dr …

Market Overview

The Portugal beauty and personal care market size reached USD 1,528.19 Million in 2025 and is expected to grow to USD 2,177.49 Million by 2034. The market is forecasted to grow at a CAGR of 4.01% during the period 2026-2034. Growth is driven by consumer trends toward skincare, fragrances, and color cosmetics emphasizing ingredient transparency, natural formulations, and sustainability. Omnichannel retailing enhances access to new product launches while premiumization…

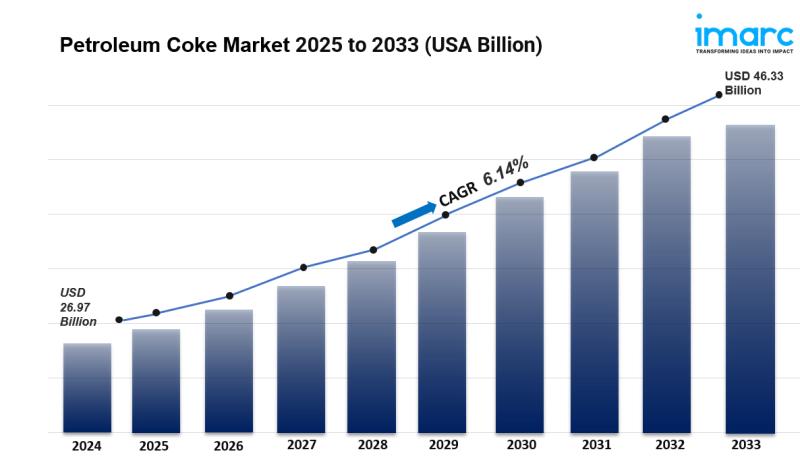

Petroleum Coke Market Size to Surpass USD 48.4 Billion by 2033 | Rising at a CAG …

Petroleum Coke Market Overview:

The global Petroleum Coke Market was valued at USD 26.97 Billion in 2024 and is forecast to reach USD 46.33 Billion by 2033, growing at a CAGR of 6.14% during 2025-2033. This growth is driven by increasing demand from the aluminum industry, expanding power generation sectors, rising use as a cost-effective fuel alternative across various industries, and growing consumption in cement and steel manufacturing.

The global Petroleum Coke…

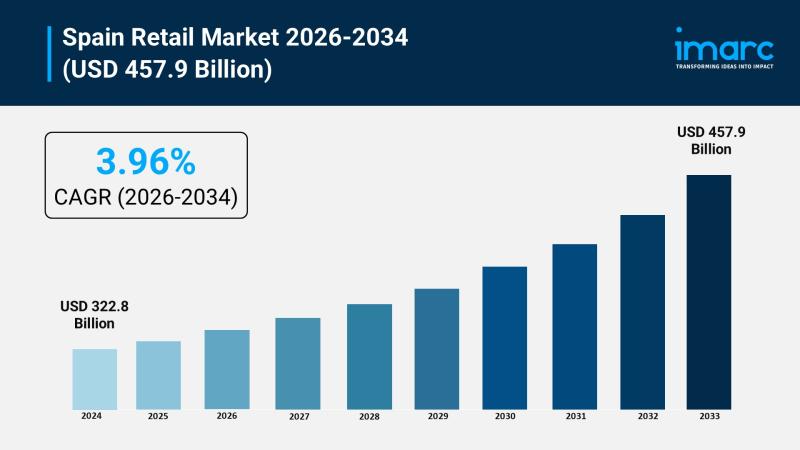

Spain Retail Market Size, Growth Trends, and Forecast 2026-2034

Market Overview

The Spain retail market size reached USD 322.8 Billion in 2025. It is expected to grow to USD 457.9 Billion by 2034, exhibiting a CAGR of 3.96% during the forecast period from 2026 to 2034. Key growth factors include rising disposable incomes, expansion of e-commerce, increased consumer focus on sustainability and personalized shopping, technological advances, and a booming tourism sector.

Study Assumption Years

• Base Year: 2025

• Historical Year/Period: 2020-2025

• Forecast Year/Period: 2026-2034

Spain…

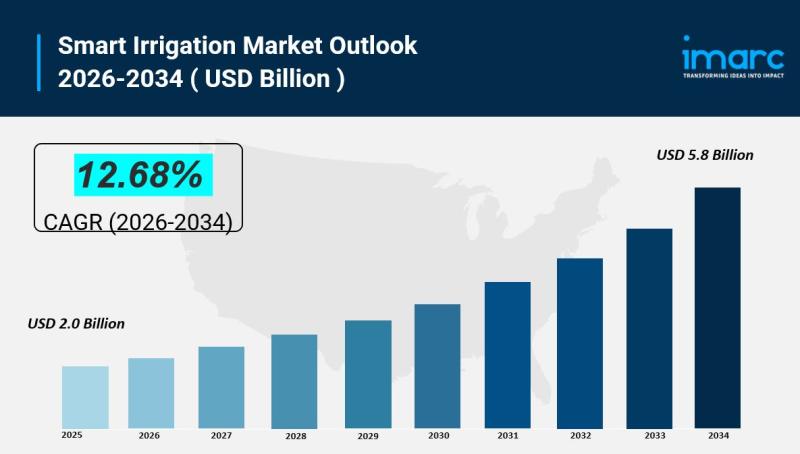

Smart Irrigation Market is Expected to Grow USD 5.8 Billion by 2034 | At CAGR 12 …

Smart Irrigation Market Overview:

The global Smart Irrigation Market was valued at USD 2.0 Billion in 2025 and is forecast to reach USD 5.8 Billion by 2034, growing at a CAGR of 12.68% during 2026-2034. This growth is driven by increasing awareness of water conservation, advancements in sensor technology and data analytics, government initiatives promoting sustainable agriculture, and surging demand for cost-effective water-saving technologies.

The smart irrigation market size is expanding rapidly…

More Releases for Biodegradable

Biodegradable Films Market Beyond Plastic: Biodegradable Films Market Drives Eco …

Biodegradable Films Market to reach over USD 1,766.36 Mn by the year 2031 - Exclusive Report by InsightAce Analytic

"Biodegradable Films Market" in terms of revenue was estimated to be worth $1,091.28 Mn in 2023 and is poised to reach $1,766.36 Mn by 2031, growing at a CAGR of 6.41% from 2023 to 2031 according to a new report by InsightAce Analytic.

Get Free Sample Report @ https://www.insightaceanalytic.com/request-sample/1618

Latest Drivers Restraint…

Biodegradable Cup Market Set for More Growth : Biodegradable Food Service, AmerC …

Advance Market Analytics published a new research publication on "Biodegradable Cup Market Insights, to 2027" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Biodegradable Cup market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of…

Biodegradable Mg-Alloy Implant market: Technological Advancements in 2022 | Biod …

"The global Biodegradable Mg-Alloy Implant Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Biodegradable Mg-Alloy Implant Market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and opportunities of…

Global Biodegradable plastic Market

Biodegradable plastic is made using raw materials or petrochemicals and can be decomposed by living organisms such as bacteria. Biodegradable plastic takes less time to break down as it is made up of eco-friendly material and requires less energy for production. The global Biodegradable Plastic Market is facing challenges due to the COVID-19 pandemic as the manufacturing facilities and supply chain of many organizations is at a halt. The increasing…

Global Biodegradable Films Market Report

The global biodegradable films market is projected to grow at a CAGR of 6.1 percent in the forecast years, according to a recent research report gathered by the Global Market Estimates.

Browse 167 Market Data Tables and 97 Figures spread through 188 Pages and in-depth TOC on "Biodegradable Films Market - Forecast to 2026"

https://www.globalmarketestimates.com/market-report/global-biodegradable-films-market-2518

By Type (PLA, Biodegradable Polyester, PHA, Starch Blends, Others), By Application (Food Packaging, Agriculture & Horticulture,…

Biodegradable Polymers Market 2019-2025 Worldwide Key Players : Aquapak Polymers …

Adroit Market Research published a study on the “Global Biodegradable Polymers Market Size 2017 By Production (Starch-based, Polylactic acid (PLA), Polyhydroxyalkanoates (PHA), Synthetic), By Application (Packaging, Loose fill, Bags and sacks, Fibre, Others), By Region and Forecast 2018 to 2025”. The global biodegradable Polymers market size is estimated based on the ongoing trend of bioplastic and consumption patterns of the bioPolymerss across the globe. The report also provides the various…