Press release

Cardboard Boxes Manufacturing Plant (DPR) 2026: Machinery Requirement, Setup Cost and Profit Margin

The global cardboard boxes industry is experiencing steady growth driven by the expanding e-commerce sector, increasing demand for sustainable packaging solutions, and growing retail packaging requirements across diverse industries. As businesses shift away from plastic packaging toward recyclable and biodegradable alternatives, and online retail platforms demand efficient and eco-friendly packaging for worldwide shipment, establishing a cardboard boxes manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and packaging investors seeking to capitalize on this essential and rapidly expanding market.IMARC Group's report, "Cardboard Boxes Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The cardboard boxes manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/cardboard-boxes-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The cardboard boxes market is driven by growth in e-commerce, retail packaging, and the increasing need for sustainable packaging solutions. According to industrial reports, APAC accounts for over 44% of the market share. The market demonstrates sustained expansion driven by the expanding e-commerce industry, increasing demand for sustainable packaging solutions, rising consumption of packaged food and beverages, and growing adoption across electronics, retail, and logistics sectors.

Cardboard boxes are made from paperboard, typically consisting of one or more layers of paper. These boxes are highly versatile and widely used for packaging, storage, and shipping in various industries. The manufacturing process involves the corrugation of paper sheets to create a strong, lightweight, and durable packaging material that is both cost-effective and eco-friendly. Cardboard boxes come in various forms, including corrugated, rigid, and folding, and are essential for the transportation of goods, particularly in sectors such as food and beverage, electronics, and retail.

The global cardboard box market is witnessing steady growth, primarily driven by the expanding e-commerce industry and the increasing demand for sustainable packaging solutions. According to the International Trade Administration, the value of Indian e-commerce was USD 46.2 billion in 2020 and is expected to grow at 18.29 percent to USD 136.47 billion by 2026. Sustainability initiatives are pushing businesses to move away from plastic packaging, further fueling the growth of cardboard box manufacturing.

Plant Capacity and Production Scale

The proposed cardboard boxes manufacturing facility is designed with an annual production capacity ranging between 5,000-20,000 MT, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from e-commerce, retail, and food and beverage to electronics and logistics-ensuring steady demand and consistent revenue streams across multiple end-use sectors.

Financial Viability and Profitability Analysis

The cardboard boxes manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 8-15%

These margins are supported by stable demand across packaging, logistics, retail, and e-commerce sectors, recyclability and eco-friendly positioning, cost-effectiveness of paperboard materials, and value-added applications spanning consumer goods, food products, and electronics packaging. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established packaging manufacturers looking to expand their sustainable packaging portfolio.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a cardboard boxes manufacturing plant is primarily driven by:

• Raw Materials: 65-75% of total OpEx

• Utilities: 5-10% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with kraft paper, liner, and adhesive (starch) being the primary input materials. Establishing long-term contracts with reliable kraft paper and liner suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical for maintaining production continuity and meeting customer delivery schedules.

Capital Investment Requirements

Setting up a cardboard boxes manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic access to kraft paper, liner, and adhesive (starch) suppliers. Proximity to target e-commerce and retail markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Pulpers for breaking down paper materials into pulp form

• Sheet formers for creating uniform paper sheets from pulp

• Corrugators for creating fluted corrugated medium between liner sheets

• Laminators for bonding multiple layers together

• Die-cutters for precision cutting of box shapes and designs

• Flexographic printers for high-quality printing on cardboard surfaces

• Folding machines for creating box creases and fold lines

• Gluers for applying adhesive and assembling box components

• Bundling systems for packaging finished products for shipment

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should accommodate raw material storage, pulping, sheet forming, corrugating, laminating, die-cutting, printing, folding, gluing, quality control, and finished goods storage.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=11895&method=2175

Major Applications and Market Segments

Cardboard boxes find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Packaging & Logistics: Used for shipping cartons, protective packaging, and transit-ready boxes, supporting safe and efficient product transportation across supply chains.

Retail & E-commerce: Essential for display-ready boxes, branded packaging, and subscription boxes, providing attractive and functional packaging solutions for consumer products.

Food & Beverage: Corrugated boxes for storage, transport, and secondary packaging of food products, ensuring product protection and maintaining hygiene standards.

Industrial & Manufacturing: Heavy-duty cartons, pallet boxes, and bulk packaging solutions for industrial components, machinery parts, and manufacturing materials.

End-use industries include e-commerce, retail, food and beverage, electronics, and logistics, all of which contribute to sustained market demand.

Why Invest in Cardboard Boxes Manufacturing?

Several compelling factors make cardboard boxes manufacturing an attractive investment opportunity:

Growing Demand from E-commerce: The increasing popularity of e-commerce and the expansion of online retail platforms are major drivers for the growth of the cardboard box market. E-commerce requires efficient, safe, and eco-friendly packaging for products shipped worldwide.

Sustainability Trends: As consumer demand shifts toward eco-conscious products, cardboard boxes-being recyclable and biodegradable-have become a preferred alternative to plastic packaging. The emphasis on sustainability by businesses and governments is contributing to the growth of the cardboard packaging market.

Rising Demand in the Food and Beverage Industry: The rising consumption of packaged food and beverages, along with the growing need for hygiene and safety, is propelling the demand for durable and safe packaging solutions like cardboard boxes.

Moderate Entry Barriers: While the cardboard box manufacturing industry requires capital investment for machinery and plant setup, the entry barriers are relatively moderate compared to high-tech industries, allowing for new entrants with a strong focus on quality and operational efficiency.

Cost-Effective and Versatile Material: Cardboard is increasingly being adopted in a variety of sectors due to its cost-effectiveness and environmental benefits, making it a preferred choice for packaging across industries.

Strong Regional Growth: With APAC accounting for over 44% of market share, emerging markets present significant opportunities for expansion and capacity development.

Diverse Application Portfolio: The versatility of cardboard boxes across packaging, logistics, retail, food, and industrial sectors creates multiple revenue streams and reduces market concentration risk.

Manufacturing Process Excellence

The cardboard boxes manufacturing process involves several precision-controlled stages:

• Corrugating: Paper sheets are corrugated to create the fluted medium that provides structural strength

• Cutting: Corrugated sheets are precisely cut to required dimensions using die-cutters

• Folding: Cut sheets are scored and folded to create box shapes and structures

• Gluing: Starch-based adhesive is applied to bond box flaps and components

• Printing: Flexographic printing applies branding, product information, and decorative designs

• Quality Control: Finished boxes undergo inspection for structural integrity, print quality, and dimensional accuracy

• Bundling and Storage: Approved boxes are bundled, packaged, and stored for distribution

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=11895&flag=C

Industry Leadership

The global cardboard boxes industry is led by established multinational companies with extensive production capabilities and diverse application portfolios. Key industry players include:

• Smurfit Kappa Group

• International Paper

• WestRock Company

• Georgia-Pacific LLC

• Mondi Group

These companies serve diverse end-use sectors including e-commerce, retail, food and beverage, electronics, and logistics, demonstrating the broad market applicability of cardboard boxes.

Recent Industry Developments

April 2025: Amcor plc announced the successful completion of its all-stock combination with Berry Global. Through this combination, Amcor enhances its position as a global leader in consumer and healthcare packaging solutions with the unique material science and innovation capabilities required to revolutionize product development and meet customers' and consumers' sustainability aspirations.

January 2025: International Paper announced the completion of its acquisition of DS Smith plc. The combined company creates a global leader in sustainable packaging solutions.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cardboard Boxes Manufacturing Plant (DPR) 2026: Machinery Requirement, Setup Cost and Profit Margin here

News-ID: 4374985 • Views: …

More Releases from IMARC Group

UK Ice Cream Market Size, Share, Trends, Forecast, Growth, Outlook, Report 2025- …

Market Overview

The UK Ice Cream Market was valued at USD 1.8 Billion in 2024 and is projected to grow to USD 3.0 Billion by 2033, registering a CAGR of 5.2% during the forecast period of 2025-2033. Growth is driven by consumer preference for artisanal flavors, health-conscious choices like low-sugar and dairy-free options, advancing packaging innovations, and expanding online sales. These factors collectively stimulate market expansion particularly during peak seasons.

Study Assumption…

Prepaid Electricity Metering Market Size, Trends, Key Players, Growth and Foreca …

Market Overview

The global prepaid electricity metering market was valued at USD 6.6 Billion in 2024 and is projected to reach USD 11.6 Billion by 2033, growing at a CAGR of 6.4% during the forecast period of 2025-2033. The market growth is driven by factors such as increasing focus on energy conservation and efficient power utilization, rising demand for energy security globally, growing need to reduce financial losses from electricity theft…

Detergent Powder Manufacturing Plant Setup Report 2026: Machinery Cost, and ROI …

The global detergent powder industry is experiencing significant growth driven by the increasing demand for efficient cleaning solutions in both household and industrial sectors. As rising disposable income combines with growing consumer awareness regarding hygiene and cleanliness, and consumers increasingly demand eco-friendly, concentrated, and multi-purpose detergent solutions, establishing a detergent powder manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and consumer goods investors seeking to capitalize on this…

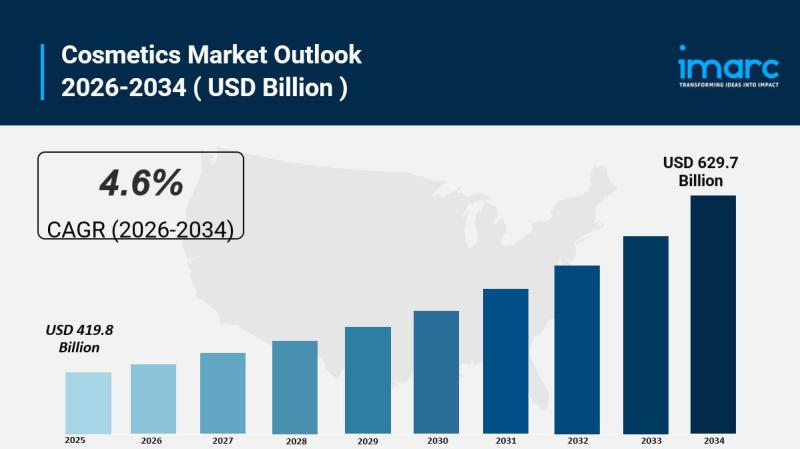

Cosmetics Market is Projected to Grow USD 629.7 Billion by 2034 | At CAGR 4.6%

IMARC Group, a leading market research company, has recently released a report titled "Cosmetics Market Size, Share, Trends and Forecast by Product Type, Category, Gender, Distribution Channel, and Region, 2026-2034" The study provides a detailed analysis of the industry, including the cosmetics market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Cosmetics Market Overview

The global Cosmetics Market…

More Releases for Cardboard

Nupack Packaging: Providing Quality EFTPOS Rolls, Cardboard Envelopes, and Rigid …

Nupack Packaging is now offering high-quality EFTPOS rolls, cardboard envelopes, and rigid cardboard envelopes for businesses in Melbourne, Australia. The company is committed to providing durable, reliable, and cost-effective packaging solutions to meet the diverse needs of businesses in various industries.

Melbourne, Australia - Nupack Packaging [https://nupack.com.au/], a leading packaging supplier in Melbourne, is pleased to announce the availability of premium EFTPOS rolls [https://nupack.com.au/collections/eftpos-rolls], cardboard envelopes [https://nupack.com.au/collections/cardboard-envelopes], and rigid cardboard envelopes…

How to produce heavy duty cardboard carton boxes?

1 What does a heavy-duty cardboard carton box mean?

Heavy-duty carton box refer to cartons made of a specially made high-strength, moisture-resistant corrugated cardboard box. General cartons are made of 3 to 5-ply cardboard, which is composed of relatively low-weight face paper, core paper (i.e., middle corrugated paperboard), and lining paper. Heavy-duty carton boxes are generally more than 5 layers, and the face paper, core paper, and middle partition paper are…

Holographic Cardboard Market

Holographic cardboard, also sometimes called holographic cardstock, is regular cardboard with a special surface that creates a rainbow-like effect, shimmering and changing colors when viewed from different angles. In the realm of packaging and presentation, holographic cardboard emerges as a luminary, captivating consumers with its mesmerizing display of colors and reflections.

The global holographic cardboard market is experiencing a surge driven by several compelling factors that have contributed to its widespread…

Corrugated Cardboard Market Set for Explosive Growth| Bobst, Cardboard Box, Grap …

Advance Market Analytics published a new research publication on "Corrugated Cardboard Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Corrugated Cardboard market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of…

Virtual Reality Cardboard Market Is Dazzling Worldwide | Major Giants DODOCase, …

The latest report released on Global Virtual Reality Cardboard Market analyses areas where there is still room for improvement. Irrespective of industry, organization size, or geographic location, the Virtual Reality Cardboard Market study suggests that advanced technologies are playing a bigger role than ever before. The market Study is segmented by key a region that is accelerating the marketization. The assessment provides trend, growth factors, and estimates for Global Virtual…

Cardboard Drums Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Cardboard Drums Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Cardboard Drums players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Cardboard Drums with respect to individual growth…