Press release

Detergent Powder Manufacturing Plant Setup Report 2026: Machinery Cost, and ROI Analysis

The global detergent powder industry is experiencing significant growth driven by the increasing demand for efficient cleaning solutions in both household and industrial sectors. As rising disposable income combines with growing consumer awareness regarding hygiene and cleanliness, and consumers increasingly demand eco-friendly, concentrated, and multi-purpose detergent solutions, establishing a detergent powder manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and consumer goods investors seeking to capitalize on this essential and rapidly expanding market.IMARC Group's report, "Detergent Powder Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The detergent powder manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/detergent-powder-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global detergent powder market demonstrates strong growth trajectory, valued at USD 132.14 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 204.99 Billion by 2034, exhibiting a solid CAGR of 5.0% from 2026-2034. This sustained expansion is driven by increasing demand for efficient cleaning solutions, rising disposable income, growing hygiene awareness, and expanding industrial-scale cleaning requirements across hospitality, healthcare, and textile sectors.

Detergent powder is a cleaning agent designed primarily for laundry applications, composed of various chemical ingredients that help remove dirt, stains, and odors from fabrics. It typically contains surfactants, which lower the surface tension between water and dirt, allowing the detergent to lift away impurities. Other key components include builders like sodium carbonate, enzymes for breaking down organic stains, optical brighteners to enhance fabric whiteness, and fillers to give the powder structure. Detergent powders are effective in both handwashing and machine-washing, offering a convenient, cost-effective, and long-lasting cleaning solution.

The high frequency of laundry activity drives strong demand for detergent products, fueling growth in the detergent powder market as consumers seek reliable and efficient cleaning solutions for their everyday needs. For instance, on average, American families do 8-10 loads of laundry weekly, with US consumers washing over 660 million loads per week, equating to about 35 billion loads annually and 100 million tons of clothes. This means that, every second of the day, 1,000 wash loads are started in the US. The shift towards eco-friendly and concentrated products is also a significant driver, as consumers become more conscious of environmental impact.

Plant Capacity and Production Scale

The proposed detergent powder manufacturing facility is designed with an annual production capacity of 50,000 MT, enabling economies of scale while maintaining operational flexibility. This capacity allows manufacturers to cater to diverse market segments-from household laundry and industrial laundry (hotels, hospitals, textile manufacturers) to commercial cleaning services and automotive applications-ensuring steady demand and consistent revenue streams across multiple end-use sectors.

Financial Viability and Profitability Analysis

The detergent powder manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 20-30%

• Net Profit Margins: 8-15%

These margins are supported by stable demand across household and industrial sectors, cost-effectiveness compared to liquid detergents, longer shelf life and convenient storage, and value-added applications spanning laundry, stain removal, and odor control. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established consumer goods manufacturers looking to expand their cleaning products portfolio.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a detergent powder manufacturing plant is primarily driven by:

• Raw Materials: 70-80% of total OpEx

• Utilities: 5-10% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with Linear Alkyl Benzene (LAB), Sodium Tripolyphosphate (STPP), sodium sulphate, and perfumes being the primary input materials. Establishing long-term contracts with reliable surfactant and builder suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical for maintaining production continuity and product quality.

Capital Investment Requirements

Setting up a detergent powder manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic access to Linear Alkyl Benzene (LAB), Sodium Tripolyphosphate (STPP), sodium sulphate, and perfumes. Proximity to target consumer markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Mixing and blending equipment (ribbon blenders or ploughshare mixers) for combining surfactants, builders, fillers, and additives

• Spray dryers or drum dryers for converting slurry into powder form

• Cooling and sieving systems for ensuring uniform granule size and temperature control

• Packaging lines (automatic or semi-automatic) for filling moisture-proof packaging

• Grinding mills (cage mills) for particle size reduction

• Dust collection systems for maintaining air quality and environmental compliance

• Storage silos for raw materials and finished products

• Control panels and conveyor systems for automated material handling

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should accommodate raw material storage, mixing, drying, cooling, sieving, packaging, quality control, and finished goods storage.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=7436&method=2175

Major Applications and Market Segments

Detergent powder products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Household Laundry: Detergent powders are predominantly used in household laundry, offering a cost-effective solution for cleaning clothes. The increasing demand for convenient and efficient cleaning solutions in residential households is a significant driver for this segment.

Industrial Laundry: Industries such as hotels, hospitals, and textile manufacturers require specialized detergent powders for heavy-duty cleaning. Detergents in this sector need to handle larger loads and tougher stains effectively.

Commercial Cleaning Services: Detergent powders are also used by professional cleaning services to clean commercial spaces, including offices, malls, and factories. These powders are often formulated for large-scale and quick cleaning purposes.

Automotive Industry: In the automotive sector, detergent powders are used for cleaning vehicle parts, especially in manufacturing facilities, ensuring the removal of grease, oil, and other contaminants.

End-use industries include household laundry, industrial laundry (hotels, hospitals, textile manufacturers), commercial cleaning services, and automotive applications, all of which contribute to sustained market demand.

Why Invest in Detergent Powder Manufacturing?

Several compelling factors make detergent powder manufacturing an attractive investment opportunity:

Increased Demand for Hygiene: The growing awareness of hygiene and cleanliness, especially after the COVID-19 pandemic, has significantly driven the demand for cleaning products, including detergent powders, creating sustained market momentum.

Cost-Effective Production: Detergent powders offer a more affordable option for both manufacturers and consumers compared to liquid detergents. Cost-effectiveness, combined with the ease of handling and storing, gives detergent powders a competitive advantage in the market.

Eco-Friendly Innovations: The demand for eco-friendly detergent powders, such as those made with biodegradable ingredients, is rising. Manufacturers are increasingly focusing on producing environmentally safe products that cater to environmentally conscious consumers.

Technological Advancements in Formula Development: Advances in chemical formulations have allowed manufacturers to create detergent powders that are more concentrated, efficient, and tailored to various fabrics and stains. These innovations contribute to the growing popularity of detergent powders.

Longer Shelf Life and Storage Convenience: Detergent powders continue to dominate the market due to their cost-efficiency, longer shelf life, and convenience in storage and transport compared to liquid alternatives.

Growing Industrial Demand: The growing need for industrial-scale cleaning in sectors like hospitality, healthcare, and textiles further boosts demand for specialized heavy-duty detergent formulations.

High Laundry Frequency: With billions of laundry loads conducted annually worldwide, the fundamental necessity of regular fabric cleaning creates a stable, recession-resistant market foundation.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7436&flag=C

Manufacturing Process Excellence

The detergent powder manufacturing process involves several precision-controlled stages:

• Raw Materials Measured and Blended: Surfactants, builders, fillers, and additives are precisely measured and thoroughly mixed

• Slurry Mixture Heated: The blended mixture is heated to form a homogeneous paste

• Spray Drying: The slurry is converted into powder form through spray drying or drum drying processes

• Additives Mixed: Enzymes, optical brighteners, fragrances, and other performance-enhancing additives are incorporated

• Powder Screened: The product is sieved to ensure uniform granule size and quality consistency

• Product Packed: Finished powder is filled into moisture-proof packaging for preservation and distribution

• Quality Checks: Comprehensive quality control performed before final dispatch

• Storage and Distribution: Products are stored appropriately and distributed to retail and industrial customers

Industry Leadership

The global detergent powder industry is led by established multinational companies with extensive production capabilities and diverse application portfolios. Key industry players include:

• Procter & Gamble Co.

• Unilever

• Henkel AG & Co. KGaA

• The Clorox Company

• Colgate-Palmolive Company

• Reckitt Benckiser Group plc

• Lion Corporation

• Kao Corporation

These companies serve diverse end-use sectors including household laundry, industrial laundry, commercial cleaning services, and automotive applications, demonstrating the broad market applicability of detergent powder products.

Recent Industry Developments

November 2025: Dm-drogerie markt introduced new eco-friendly laundry detergents under its Denkmit brand. The first two variants, color and all-purpose laundry detergents are available in over 2,150 dm stores across Germany. In collaboration with production partners LanzaTech and the Mibelle Group, dm-drogerie markt developed an environmentally sustainable manufacturing process for these detergents. This move towards eco-conscious products is tapping into the growing consumer demand and driving the market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Detergent Powder Manufacturing Plant Setup Report 2026: Machinery Cost, and ROI Analysis here

News-ID: 4374895 • Views: …

More Releases from IMARC Group

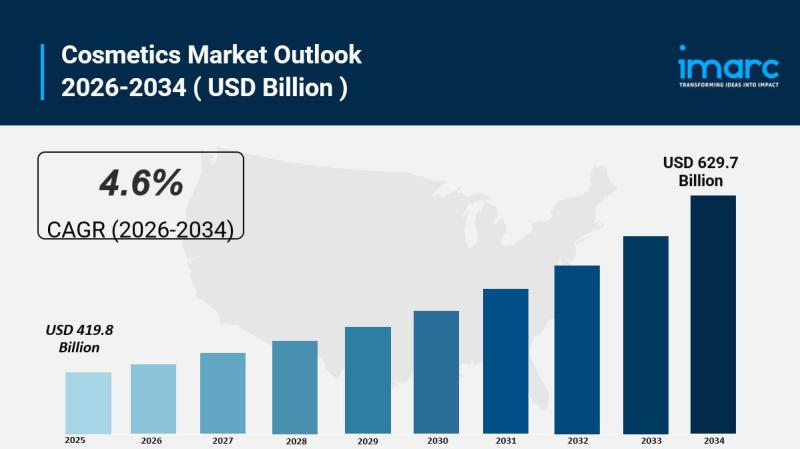

Cosmetics Market is Projected to Grow USD 629.7 Billion by 2034 | At CAGR 4.6%

IMARC Group, a leading market research company, has recently released a report titled "Cosmetics Market Size, Share, Trends and Forecast by Product Type, Category, Gender, Distribution Channel, and Region, 2026-2034" The study provides a detailed analysis of the industry, including the cosmetics market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Cosmetics Market Overview

The global Cosmetics Market…

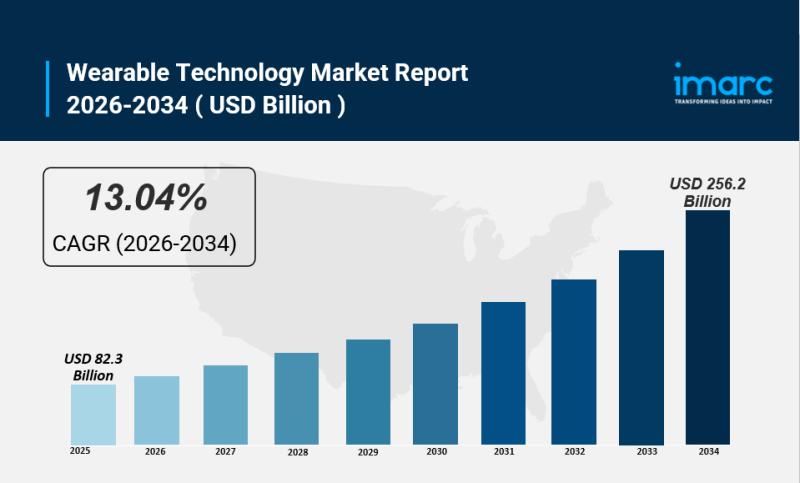

Wearable Technology Market is Expected to Grow USD 256.2 Billion by 2034 | At CA …

Wearable Technology Market Overview

The global wearable technology market size was valued at USD 82.3 Billion in 2025 and is projected to reach USD 256.2 Billion by 2034, exhibiting a CAGR of 13.04% during the forecast period from 2026 to 2034. This growth is driven by rising consumer demand for health tracking, advancements in sensor technology, expanding healthcare applications, and increasing integration with Internet of Things (IoT) ecosystems. North America currently…

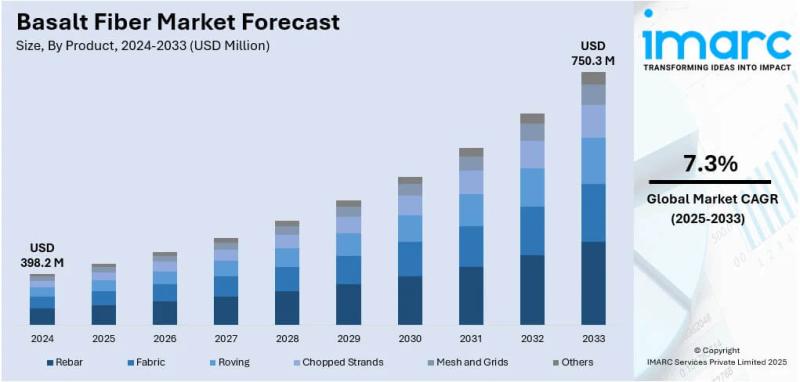

Basalt Fiber Market Size, Share, Industry Trends, Growth Factors and Forecast to …

Report Highlights:

How Big Is the global basalt fiber market?

The global basalt fiber market size reached USD 398.2 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 750.3 Million by 2033, exhibiting a growth rate (CAGR) of 7.3% during 2025-2033.

Increasing Demand from Construction and Infrastructure Sectors

The growth of the global basalt fiber market is substantial and the main reason behind this is the need for construction and…

Home Energy Management Systems Market Size, Share And Growth Report 2033

Home Energy Management Systems Market Overview

The global Home Energy Management Systems Market was valued at USD 3.5 Billion in 2024 and is projected to reach USD 13.7 Billion by 2033. The market is expected to grow at a CAGR of 15.55% during the forecast period 2025-2033. North America leads the market driven by technological adoption, strong support for smart home technologies, and a focus on energy efficiency, with product innovations…

More Releases for Detergent

Key Influencer in the Detergent Chemicals Market 2025: Textile Industry Surge Pr …

What combination of drivers is leading to accelerated growth in the detergent chemicals market?

The detergent chemicals market's growth is predicted to be driven by the expansion of the textile industry. The textile industry encompasses all activities, from researching and designing to producing and distributing textiles, fabrics, and clothing. Textile detergents, which are designed to scour, remove sizing materials and grease from textiles, and clean fabrics, are integral to the industry.…

Laundry Detergent Market Expected to Rise Progressively Owing to the Increasing …

The global laundry detergent market is expected to witness significant growth by 2028, owing to the increasing household expenditure for laundry detergent. The Asia-Pacific region is expected to have massive growth opportunities.

As per the report published by Research Dive, the global laundry detergent market is anticipated to generate a revenue of $103,286.00 million and grow at a healthy CAGR of 6.70% over the analysis timeframe from 2021 to…

Miracle laundry detergent sheets review 2022: Is miracle detergent sheets the be …

Miracle laundry detergent sheets review: Clothes are among the fundamental human needs, there are needs to cover up our body. There has been an incessant need to make sure the clothing materials are kept in a neat and clean

condition. In other words there is a need to wash them when dirty.

I hope you've heard about the one of the world's best selling detergents. "Miracle Laundry Detergent Sheet" if you haven't…

Global Detergent Chemical Market Report

According to a new market research report published by Global Market Estimates, the Global Detergent Chemical Market is expected to grow at a CAGR of 8.65% during the forecast period. The demand for detergent chemicals is projected due to a rise in public awareness regarding cleaning amid the COVID-19 outbreak.

Browse 145 Market Data Tables and 117 Figures spread through 180 Pages and in-depth TOC on " …

Detergent Market Size, Share & Forecast 2026

Detergent market overview: 2026

The global Detergent market is valued at US$ xx million in 2020 and is expected to reach US$ xx million by the end of 2026, growing at a CAGR of xx% during 2021-2026.

This report focuses on Detergent volume and value at the global level, regional level and company level. From a global perspective, this report represents overall Detergent market size by analysing historical data and future prospects.…

Market Research on Dishwasher Detergent Market 2018 and Analysis to 2028(Segment …

Dishwasher Detergent Market-Introduction

Dishwasher is an artificial intelligence device which upon setting, automatically washes utensils. With the increasing use of dishwashers at households, the market for dishwasher detergents is expanding at a fast pace.

Owing to its effective cleaning of utensils and its ease of use, dishwasher detergents have already found a place in the detergents market. Chemically, dishwasher detergents forms lather and washes away the dirt, oil, grease etc. Also increase…