Press release

Electric Car Manufacturing Plant Feasibility (DPR) 2026: CapEx/OpEx with Profitability Forecast

The global electric car manufacturing industry is witnessing robust growth driven by the rapidly expanding clean energy transition and increasing demand for sustainable transportation solutions. At the heart of this expansion lies a revolutionary mobility product: the electric car. As automotive markets transition toward zero-emission vehicles and advanced electric powertrains, establishing an electric car manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and automotive investors seeking to capitalize on this growing and transformative market.Market Overview and Growth Potential

The global electric car market demonstrates strong growth trajectory, valued at USD 205.62 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 749.21 Billion by 2034, exhibiting a robust CAGR of 15.5% from 2026-2034. This sustained expansion is driven by rapidly expanding environmental regulations, increasing fuel cost concerns, rising adoption of clean energy infrastructure, and expanding consumer preference for sustainable mobility across developed and developing economies.

Electric cars are battery-powered vehicles that use electric motors instead of internal combustion engines for propulsion. They appear as sophisticated transportation systems with zero tailpipe emissions and advanced technology integration. Electric cars contain lithium-ion battery packs, electric motors, power electronics, regenerative braking systems, and intelligent control software, making them efficient zero-emission vehicles used for personal transportation, commercial fleets, and ride-sharing services. Due to their energy efficiency and environmental benefits, they help reduce carbon emissions and dependence on fossil fuels while providing instant torque and smooth acceleration. Their low operating costs, quiet operation, and compatibility with renewable energy charging make them a preferred option in sustainable urban mobility and long-distance travel.

The electric car market is witnessing robust demand due to the rising need for clean transportation solutions that support climate goals and air quality improvement. Automotive markets increasingly transitioning toward electric propulsion particularly in Europe, China, North America, and progressive Asian economies are driving large-scale adoption. According to the International Energy Agency (IEA), electric vehicle sales reached record levels with governments worldwide setting aggressive targets for phasing out internal combustion engines. Government-led electrification programs, charging infrastructure development subsidies, and emission reduction mandates further strengthen market prospects.

Request for a Sample Report: https://www.imarcgroup.com/electric-car-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed electric car manufacturing facility is designed with an annual production capacity ranging between 50,000-250,000 units per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments from compact urban vehicles and mid-size sedans to SUVs, commercial vans, and premium luxury electric vehicles-ensuring steady demand and consistent revenue streams across multiple consumer categories.

Financial Viability and Profitability Analysis

The electric car manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 15-25%

Net Profit Margins: 5-12%

These margins are supported by stable demand across automotive segments, premium technology positioning, and the critical nature of electric cars in transportation decarbonization. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established automotive manufacturers looking to diversify their product portfolio in the electric mobility sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for an electric car manufacturing plant is primarily driven by:

Raw Materials and Components: 80-85% of total OpEx

Utilities: 5-8% of OpEx

Other Expenses: Including labor, R&D, warranty, transportation, maintenance, depreciation, and taxes

Raw materials and components constitute the largest portion of operating costs, with battery packs, electric motors, power electronics, and structural components being the primary input materials. Establishing long-term contracts with reliable battery cell suppliers and component manufacturers helps mitigate price volatility and ensures consistent supply, which is critical given that lithium-ion battery price fluctuations represent the most significant cost factor in electric car manufacturing.

Capital Investment Requirements

Setting up an electric car manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development

Selection of an optimal location with strategic proximity to battery suppliers and automotive component ecosystems. Proximity to target markets and ports will help minimize logistics costs. The site must have robust infrastructure, including reliable high-voltage power supply, transportation networks, and environmental management systems. Compliance with local zoning laws, automotive safety regulations, and environmental standards must also be ensured.

Machinery and Equipment

The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Body stamping presses for chassis and structural components

• Robotic welding systems for body assembly and joining

• Battery pack assembly lines with automated cell integration

• Electric motor assembly equipment with precision winding machines

• Power electronics manufacturing and testing systems

• Paint shops with advanced coating and curing systems

• Final assembly lines with ergonomic workstations

• Quality inspection systems including 3D scanning and testing

• Dynamometer testing facilities for performance validation

• Charging system integration and testing equipment

• Advanced driver assistance system (ADAS) calibration centers

• Environmental test chambers for durability validation

• Software programming and over-the-air update infrastructure

Civil Works

Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize production complexities throughout the manufacturing process. The layout should be optimized with separate areas for stamping plant, body shop, paint shop, battery assembly area, motor assembly zone, final assembly line, quality control center, finished vehicle storage, charging infrastructure, utility block, waste management facility, and administrative headquarters.

Other Capital Costs

Pre-operative expenses, machinery installation costs, regulatory compliance certifications (crash testing, emission standards, safety approvals), initial working capital requirements, research and development facilities, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Electric car products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Personal Transportation

Primary use as emission-free private vehicles for daily commuting and family transportation, particularly valuable in urban environments with congestion charges and low-emission zones where environmental benefits are prioritized.

Commercial Fleets

Specialized applications in corporate fleets, delivery services, and ride-hailing operations where lower operating costs and environmental credentials provide competitive advantages.

Public Transportation

Government and municipal applications in taxi services, shuttle operations, and last-mile connectivity solutions where zero-emission mandates drive adoption.

Premium and Luxury Segment

High-performance electric vehicles offering advanced technology, long range, and luxury features catering to affluent consumers seeking sustainable prestige transportation.

Utility and Commercial Vehicles

Specialized applications in electric vans, light trucks, and commercial vehicles for urban delivery, service operations, and business transportation.

End-use categories include individual consumers, corporate fleets, ride-sharing platforms, government agencies, and commercial operators, all of which contribute to sustained market demand.

Buy now: https://www.imarcgroup.com/checkout?id=22375&method=2175

Why Invest in Electric Car Manufacturing?

Several compelling factors make electric car manufacturing an attractive investment opportunity:

Essential Mobility Transition

Electric cars serve as critical technology enabling the global shift toward sustainable transportation, making them indispensable for achieving climate goals and reducing urban air pollution.

Rising Environmental Regulations

Automotive markets increasingly implementing stringent emission standards and internal combustion engine phase-out timelines-particularly in Europe, China, California, and other progressive regions-are driving accelerated electric vehicle adoption.

Total Cost of Ownership Advantage

The product's lower operating costs through reduced fuel expenses and minimal maintenance, combined with government incentives, offers significant financial advantages and positions electric cars favorably against conventional vehicles.

Charging Infrastructure Expansion

The rapid deployment of public charging networks and home charging solutions is eliminating range anxiety and positioning electric cars as practical alternatives for mainstream consumers globally.

Government Support

Government-led electrification programs, purchase subsidies, tax incentives, charging infrastructure development, and regulatory mandates further strengthen market prospects and support industry growth.

Technology Leadership Opportunities

Electric car manufacturing enables participation in cutting-edge automotive technologies including autonomous driving, connected services, battery innovation, and software-defined vehicles.

Energy Security Alignment

The transportation electrification agenda and reduced dependence on imported petroleum are expected to enhance long-term growth opportunities for domestically manufactured electric vehicles.

Manufacturing Process Excellence

The electric car manufacturing process involves several precision-controlled stages:

• Design and Engineering: Vehicle architecture development, battery integration design, and software system specification

• Stamping: Metal sheets are pressed into body panels and structural components using high-tonnage presses

• Body Assembly: Robotic welding systems join stamped parts into vehicle body structure with precision

• Paint Application: Multi-layer coating process providing corrosion protection and aesthetic finish

• Battery Pack Assembly: Lithium-ion cells are integrated into battery modules and complete pack assemblies

• Motor Assembly: Electric motors are wound, assembled, and tested for performance specifications

• Final Assembly: Battery pack, motor, power electronics, interior, and exterior components are integrated

• Quality Testing: Comprehensive inspection including electrical systems, safety features, and performance validation

• Software Programming: Vehicle control software, infotainment systems, and connectivity features are installed and calibrated

Industry Leadership

The global electric car industry is led by established automotive manufacturers and innovative new entrants with extensive production capabilities and diverse vehicle portfolios. Key industry players include:

• Tesla, Inc.

• BYD Company

• Volkswagen Group

• General Motors

• Hyundai Motor Group

• Nissan-Renault Alliance

• BMW Group

• Mercedes-Benz Group

• NIO Inc.

• Li Auto

These companies serve diverse consumer segments across affordable mass-market vehicles, premium luxury models, commercial applications, and performance variants, demonstrating the broad market applicability of electric car products.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=22375&flag=C

Recent Industry Developments

October 2024: Tesla announced expansion of its Gigafactory network with new facilities planned in Mexico and Indonesia, investing over USD 5 billion to support production capacity of 2 million vehicles annually by 2026, incorporating next-generation manufacturing technologies and reduced production costs.

August 2024: BYD launched its advanced Blade Battery 2.0 technology offering 15% higher energy density and faster charging capabilities, enabling electric vehicles with 600+ km range and 10-80% charging in under 20 minutes, setting new industry benchmarks for performance.

Conclusion

The electric car manufacturing sector presents a strategically positioned investment opportunity at the intersection of sustainable transportation, advanced technology, and global climate action. With favorable profit margins ranging from 15-25% gross profit and 5-12% net profit, strong market drivers including rising emission regulations, growing consumer environmental awareness, expanding charging infrastructure, and supportive government policies promoting electric mobility and clean energy transition, establishing an electric car manufacturing plant offers significant potential for long-term business success and sustainable returns. The combination of environmental necessity, technological advancement, total cost ownership benefits, and regulatory support in major automotive markets creates an attractive value proposition for serious automotive investors committed to quality manufacturing, innovation excellence, and operational scale.

About IMARC Group

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electric Car Manufacturing Plant Feasibility (DPR) 2026: CapEx/OpEx with Profitability Forecast here

News-ID: 4374750 • Views: …

More Releases from IMARC Group

Silica Sand Processing Plant Cost DPR & Unit Setup - 2026: Capex, Opex and ROI E …

Silica sand, a granular material predominantly composed of silicon dioxide (SiO2), stands as one of the most critical industrial raw materials across global manufacturing and infrastructure sectors. Originating from weathered quartz-rich rocks, processed silica sand is characterized by high chemical purity, controlled grain size distribution, a high melting point, and excellent hardness - properties that make it indispensable in applications ranging from glass manufacturing and foundry casting to construction materials…

Neem Oil Processing Plant Project (DPR) 2026: Setup, Market Trends & Profitabili …

The global neem oil processing industry is witnessing robust growth driven by the rapidly expanding organic agriculture sector and increasing demand for natural pest control and wellness products. At the heart of this expansion lies a critical natural extract: neem oil. As agricultural regions transition toward sustainable farming practices and eco-friendly pest management methods, establishing a neem oil processing plant presents a strategically compelling business opportunity for entrepreneurs and agro-based…

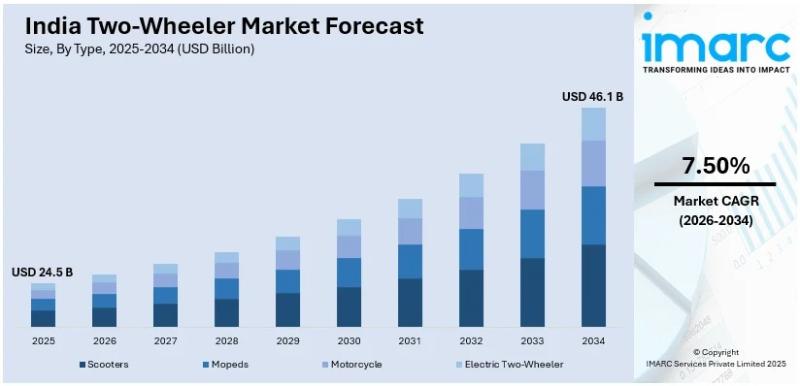

India Two-Wheeler Market to Hit USD 46.1 Billion by 2034: Driven by Premiumizati …

Source: IMARC Group | Category: Automotive

Report Introduction

According to IMARC Group's latest report titled "India Two-Wheeler Market Size, Share, Trends and Forecast by Type, Technology, Transmission, Engine Capacity, Fuel Type, End User, Distribution Channel, and Region, 2026-2034", this study offers a granular analysis of the industry's shift towards connected technologies and premiumization. The report covers critical market dynamics, including the impact of flexible ownership models like subscription services, the…

Chocolate Manufacturing Plant Setup Cost Analysis (DPR) 2026: Complete Investmen …

The global chocolate manufacturing industry is witnessing robust growth driven by the rapidly expanding confectionery sector and increasing demand for premium and specialty chocolate products. At the heart of this expansion lies a beloved consumer product: chocolate. As consumer preferences transition toward artisanal varieties, organic ingredients, and innovative flavor combinations, establishing a chocolate manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and food industry investors seeking to capitalize…

More Releases for Electric

Electrical Isolators Market 2023: Mitsubishi Electric, Orient Electric, Schneide …

The Electrical Isolators Market size (volume and value) and industry chain structure published by The Insight Partners through its high quality database which is a valuable source of guidance and direction for companies and individual interested in the industry.

An electrical isolator is a material in which electric current does not flow freely. The atoms of the insulator have tightly bound electrons which cannot readily move. Other materials, semiconductors and conductors…

Electric Motors for Electric Vehicle Market by Manufacturers: Hitachi Automotive …

Electric Motors for Electric Vehicle Market research report analyzes and studies the Electric Motors for Electric Vehicle Market's production, value, financial status, and capacity. It also provides information about market share and development plans during the projected period. Moreover, the Electric Motors for Electric Vehicle Market research report provides data about key manufacturers and focuses on the market competition landscape by analyzing the market by application, product type, and region.

Click…

Thermal Overload Relay Market 2021 Precise Outlook - ABB, Schneider Electric, Ea …

Global Thermal Overload Relay Market Size, Status and Forecast 2021

The Global Thermal Overload Relay Market report offers in-depth information and comprehensive analysis of the market. It provides a complete overview of the market with detailed insights on key aspects including the current market situation, potential size, volume, and dynamics of the market. This research report makes a thorough assessment of the COVID-19 pandemic and its impact on the current market…

Global Electric Motors for Electric Vehicles Market 2025 | MAHLE GmbH, Protean E …

Researchmoz added Most up-to-date research on "Global Electric Motors for Electric Vehicles Market Insights, Forecast to 2025" to its huge collection of research reports.

This report presents the worldwide Electric Motors for Electric Vehicles market size (value, production and consumption), splits the breakdown (data status 2013-2018 and forecast to 2025), by manufacturers, region, type and application.

This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities…

Yokogawa Electric, General Electric Profiled in Smart Factory Solutions Market 2 …

Global Smart Factory Solutions Market which focuses on effective strategies of the business framework. It highlights the recent market trends stringent energy regulations and growing pressure to conform to energy efficiency. The research methods and tools used to analyze the studies are both primary and secondary research.

This market research report on analyzes the growth prospects for the key vendors operating in this market space including Siemens, ABB, Honeywell International, Yokogawa…

Global Quartz Heat Lamps Market 2017 : Indu Electric Gerber, Schneider Electric, …

The Market Research Store report offers majority of the latest and newest industry data that covers the overall market situation along with future prospects for Quartz Heat Lamps market around the globe. The research study includes significant data and also forecasts of the global market which makes the research report a helpful resource for marketing people, analysts, industry executives, consultants, sales and product managers, and other people who are in…