Press release

Start a Vegetable Dehydration Manufacturing Plant: Investment Cost, Drying Technology & Revenue Potential

Vegetable dehydration is a food processing method that removes moisture from fresh vegetables to extend shelf life while retaining nutritional value, flavor, and color. Dehydrated vegetables are widely used in ready-to-eat meals, soups, snacks, seasonings, instant noodles, military rations, and foodservice applications. This process significantly reduces storage, transportation, and wastage costs, making dehydrated vegetables a critical component of modern food supply chains.With increasing demand for convenience foods, rising awareness of food preservation, and expansion of food processing industries, the global vegetable dehydration market continues to grow steadily. Export demand, long shelf life, and minimal refrigeration requirements further strengthen the commercial viability of vegetable dehydration manufacturing plants.

Setting up a vegetable dehydration manufacturing plant involves sourcing fresh vegetables such as onions, garlic, carrots, potatoes, tomatoes, peas, and leafy greens. Investment is required in washing, slicing, blanching, drying, grading, and packaging equipment. Efficient plant layout, strict hygiene standards, skilled manpower, and compliance with food safety regulations are essential for successful operations.

Request for a Sample Report:

https://www.imarcgroup.com/vegetable-dehydration-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Vegetable Dehydration Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for establishing a vegetable dehydration unit. The report covers a comprehensive industry overview along with micro-level insights into processing methods, raw material requirements, utility consumption, infrastructure planning, machinery selection, manpower requirements, quality control, and regulatory compliance.

This comprehensive business plan outlines every critical step involved in setting up a successful vegetable dehydration manufacturing plant-from raw material sourcing and seasonal planning to operational efficiency and financial feasibility. It provides valuable insights into plant setup costs, machinery investment, operating expenses, utility needs, storage, packaging, and logistics planning.

Vegetable Dehydration Industry Outlook 2026:

The vegetable dehydration industry is expected to witness steady growth, driven by increasing consumption of processed foods, rising export demand, and growing preference for shelf-stable ingredients. Advancements in drying technologies such as air drying, freeze drying, and vacuum drying are improving product quality and energy efficiency. Emerging markets offer strong growth potential due to expanding food processing sectors and agricultural output.

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=19446&flag=C

Key Insights for Vegetable Dehydration Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Raw Vegetable Procurement and Sorting

• Washing and Cleaning

• Peeling and Cutting / Slicing

• Blanching (if required)

• Dehydration (Air Drying / Tray Drying / Freeze Drying)

• Cooling and Grading

• Quality Inspection

• Packaging and Storage

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout and Processing Line Design

• Machinery Requirements and Costs

• Raw Material (Vegetables) Requirements and Costs

• Utility Requirements and Costs

• Packaging Material Requirements and Costs

• Cold Storage and Warehouse Requirements

• Transportation and Logistics Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investment Requirements

• Operating and Maintenance Costs

• Expenditure Projections

• Revenue Forecasts

• Taxation and Depreciation

• Profit and Cash Flow Projections

• Financial Feasibility Analysis

Profitability Analysis:

• Total Revenue

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Vegetable Dehydration Manufacturing Plant:

• Raw Materials: Fresh vegetables (onion, garlic, carrot, potato, tomato, peas, etc.).

• Machinery & Equipment: Washers, slicers, blanchers, dryers, graders, and packaging machines.

• Infrastructure & Utilities: Processing building, electricity, water supply, steam or fuel for dryers, and waste management systems.

• Labor & Staffing: Food technologists, machine operators, quality control staff, maintenance workers, and administrative personnel.

• Technology & Automation: Automated slicing and drying systems, temperature and humidity control units.

• Quality Control & Testing: Moisture analysis, microbial testing, and food safety compliance.

• Packaging & Branding: Pouches, bulk packaging, labeling, and marketing expenses.

• Environmental Compliance: Wastewater treatment, organic waste disposal, and regulatory approvals.

• Working Capital: Seasonal raw material procurement, inventory holding, and daily operating expenses.

• Administrative & Overhead Costs: Licensing, certifications, utilities, and office operations.

Buy Now:

https://www.imarcgroup.com/checkout?id=19446&method=2175

Economic Trends Influencing Vegetable Dehydration Plant Setup Costs 2026:

• Seasonal variability in vegetable prices

• Rising energy and fuel costs for drying processes

• Growing demand for export-quality dehydrated products

• Increased investment in energy-efficient drying technologies

• Food safety and quality compliance costs

• Skilled labor availability

• Transportation and logistics cost fluctuations

• Inflation and financing cost pressures

• Demand from ready-to-eat and instant food segments

• Sustainability and waste reduction initiatives

Challenges and Considerations for Investors in Vegetable Dehydration Projects:

• Seasonal dependence on raw material availability

• High energy consumption in dehydration processes

• Maintaining consistent product quality and color

• Compliance with food safety and export regulations

• Efficient moisture control and storage management

• Price sensitivity in bulk markets

• Skilled manpower requirements

• Waste management of peels and trimmings

• Competition from established exporters

• Working capital management during off-season periods

Conclusion:

Investing in a vegetable dehydration manufacturing plant offers a stable and export-oriented opportunity supported by growing demand for shelf-stable food ingredients and convenience products. While the industry faces challenges related to energy costs, seasonal raw materials, and quality compliance, efficient processing, technology adoption, and strong supply-chain planning can ensure long-term profitability. With rising global food demand and focus on reducing post-harvest losses, vegetable dehydration remains a highly attractive sector for investors and entrepreneurs.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Start a Vegetable Dehydration Manufacturing Plant: Investment Cost, Drying Technology & Revenue Potential here

News-ID: 4370927 • Views: …

More Releases from IMARC Group

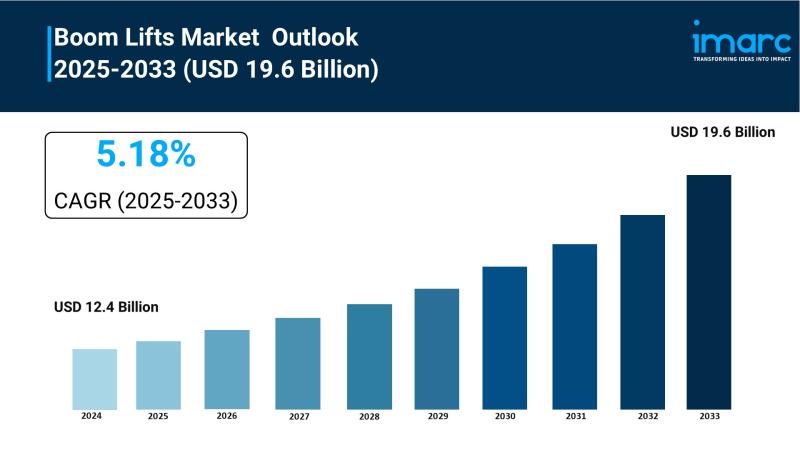

Boom Lifts Market Size to Surpass USD 19.6 Billion by 2033, at a CAGR of 5.18%

Market Overview:

According to IMARC Group's latest research publication, "Boom Lifts Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global boom lifts market size reached USD 12.4 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 19.6 Billion by 2033, exhibiting a growth rate (CAGR) of 5.18% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and…

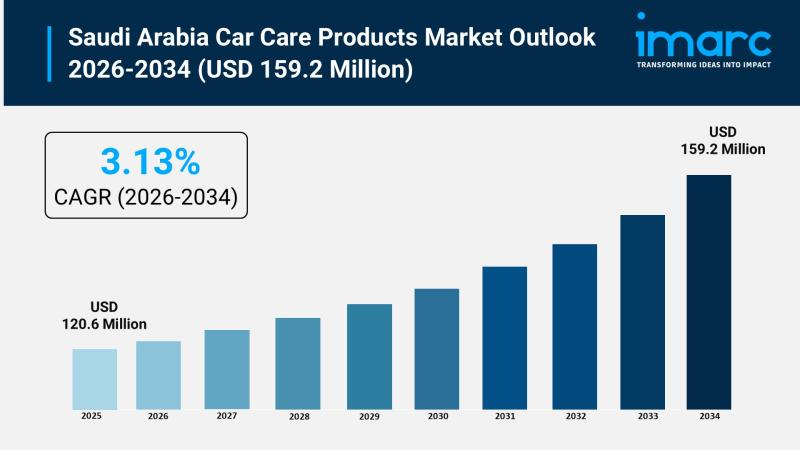

Saudi Arabia Car Care Products Market Size to Worth USD 159.2 Million by 2034 | …

Saudi Arabia Car Care Products Market Overview

Market Size in 2025: USD 120.6 Million

Market Size in 2034: USD 159.2 Million

Market Growth Rate 2026-2034: 3.13%

According to IMARC Group's latest research publication, "Saudi Arabia Car Care Products Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia car care products market size reached USD 120.6 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 159.2 Million…

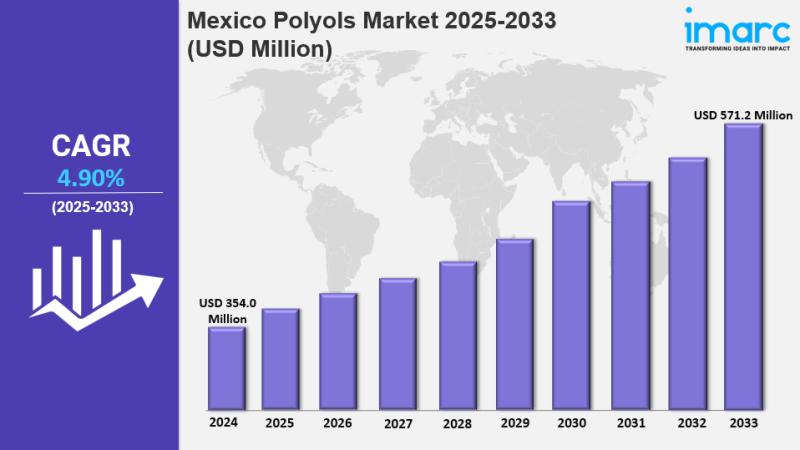

Mexico Polyols Market Size, Share, Trends and Forecast by Type, Application, Ind …

IMARC Group has recently released a new research study titled "Mexico Polyols Market Size, Share, Trends and Forecast by Type, Application, Industry, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico polyols market size reached USD 354.0 Million in 2024. It is expected to grow at a CAGR of 4.90% during…

Planning an Ammonia Production Plant? Setup Cost, Process Technology & Profit Ou …

Ammonia is a vital industrial chemical widely used in the production of fertilizers, explosives, pharmaceuticals, plastics, synthetic fibers, refrigerants, and numerous other chemical products. It is primarily produced by synthesizing nitrogen and hydrogen through the Haber-Bosch process, making it one of the most important building blocks of the global chemical and agricultural industries. Due to its critical role in food security and industrial development, ammonia production remains strategically significant worldwide.

With…

More Releases for Vegetable

Vegetable Juices Market Size Analysis by Application, Type, and Region: Forecast …

USA, New Jersey- According to Market Research Intellect, the global Vegetable Juices market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The Vegetable Juices Market is experiencing significant growth, driven by increasing consumer awareness about health, nutrition, and natural food products. As more individuals shift toward…

Canned Vegetable Market Report 2024 - Canned Vegetable Market Growth And Share

"The Business Research Company recently released a comprehensive report on the Global Canned Vegetable Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The canned vegetable market size…

Fruit - Vegetable Processing Market

Fruit - Vegetable Processing Market report gives detailed explanation of the estimations about the existing state of the market, market size and market share, revenue generated from the product sale, and necessary changes required in the future products are given in an appropriate way. A swiftly transforming market place increases the value of market research report and hence Fruit - Vegetable Processing Market report has been created in a way…

Processed Vegetable Market Size, Share | Processed Vegetable Industry Future Gro …

Global Processed Vegetable Market Report provides a detailed industry overview along with the analysis of Cost Structure, Supply Chain, Development Techniques, Retailers Analysis, Financial Support, business Strategies, Marketing Channels. Global Processed Vegetable Market research report provides a point-by-pointIn-Depth analysis of global market size, regional and country-level market size, segmentation market growth, market share, competitive Landscape, sales analysis, the impact of domestic and global market players, value chain optimization, trade regulations,…

Global Textured Vegetable Protein Market

According to a new market research report published by Global Market Estimates, the Global Textured Vegetable Protein Market is expected to grow at a CAGR of 6.40% during the forecast period. The increasing adoption of meat alternatives among consumers, along with the growing demand for protein-rich food is some of the major factors influencing the growth of the textured vegetable protein market.

Browse 148 Market Data Tables and 90 Figures spread…

Frozen Fruits & Vegetable Processing Unit

Fruits and Vegetables Processing sector is one of the largest and most dynamic sectors of the food industry. Processed Fruits & Vegetables covers various categories, like sun-dried, Machine dried, frozen, dehydrated and frozen, pickled with natural substances, pickled with chemicals, etc. Amongst which the popularity of frozen fruits and vegetables in daily diets is steadily increasing, driven by shifting food preferences throughout the world.

The global frozen fruits and vegetable market…