Press release

Behind the Pipes: Market Forces, Margins, and Regional Shifts in Cryogenic Infrastructure

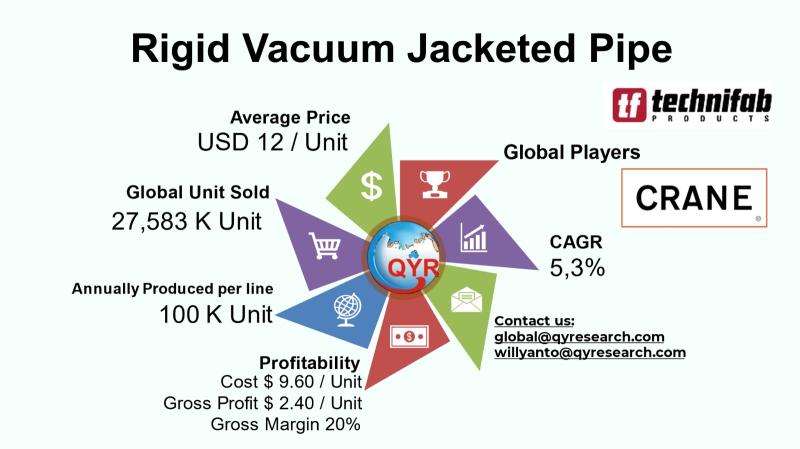

The rigid vacuum jacketed pipe industry serves as a foundational element in efficient cryogenic and thermal fluid transportation across industrial applications including LNG distribution, semiconductor fabrication, chemical processing, and healthcare cryogenics. These pipes utilize a double-walled structure with an evacuated space between inner and outer pipes, minimizing heat transfer and maintaining ultra-low temperature fluid stability. The growing demand for energy-efficient and high-performance insulation systems globally is a major driver behind the adoption of rigid vacuum jacketed pipe systems.In 2024, the global rigid vacuum jacketed pipe market was valued at USD 331 million with a growing compound annual growth rate of 5.3% through 2031, reaching market size USD 473 million by 2031. With an average selling price of USD 12 per unit, the total 27,583 K units sold in 2024. The factory gross margin at 20% implies to a factory gross profit is at USD 2,40 per unit and cost of goods sold at USD 9.60 per unit. The COGS breakdown is raw materials, vacuum jackets, insulation layers, fabrication labor, testing, quality assurance and distribution. A single line full machine capacity production is around 1,000 K units. Downstream demand is concentrated in food & beverages, semiconductor, biopharmaceutical, industrial manufacturing aerospace and other fields.

Latest Trends and Technological Developments

Industry technology trends in 2025 show increased focus on digital monitoring and advanced multi-layer insulation technologies to improve thermal performance and reduce boil-off loss in cryogenic services. For instance, advancements in material science and embedded sensors for real-time condition monitoring have gained traction to ensure operational reliability under extreme conditions. Reports indicate a push for IoT-enabled vacuum pipe systems that allow remote diagnostics and predictive maintenance, enhancing uptime and service life in industrial environments. The industry is also witnessing heightened integration of automated manufacturing processes that reduce human error and improve consistency in vacuum sealing and insulation application, enhancing overall system performance and safety. These developments reflect broader industrial trends of energy efficiency, sustainability, and digital transformation shaping manufacturing and end-use performance in the rigid vacuum jacketed pipe market.

ExxonMobil Corporation purchases Rigid Vacuum Jacketed Pipe from Chart Industries, Inc. for its LNG terminal expansion project in Texas, USA. The order consists of 500 linear meters of 4-inch stainless steel vacuum jacketed piping, designed for cryogenic ethylene transfer at -104°C, at a total contract value of USD 320,000, equating to approximately USD 640 per linear meter.

The Rigid Vacuum Jacketed Pipe is installed in Air Products helium liquefaction facility in Wyoming, USA. The piping system, supplied by Vacuum Barrier Corporation, is used to transfer liquid helium at -269°C from the main liquefier to storage tanks with near-zero boil-off. The installed system spans 300 meters, with a project cost of USD 210,000, or USD 700 per linear meter, ensuring thermal efficiency and operational safety in ultra-low temperature processes.

Asia stands out as a fast-growing region for rigid vacuum jacketed pipe adoption, driven by rapid industrialization, expanding energy infrastructure, and increased semiconductor production capacity. China, Japan, South Korea, and India represent important hubs of demand where LNG terminal build-outs, chemical manufacturing, and large-scale industrial gas supply chains depend on reliable cryogenic piping. Governments across these countries are channeling investments into energy distribution networks and advanced manufacturing clusters, stimulating global suppliers to expand their regional footprint and service networks. China in particular has seen increased focus on energy efficiency and industrial optimization, fostering a competitive landscape for both domestic and international rigid vacuum jacketed pipe manufacturers seeking market share.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5544472

Rigid Vacuum Jacketed Pipe by Type:

Carbon Steel

Stainless Steel

Nickel Alloy

Others

Rigid Vacuum Jacketed Pipe by Product Category:

Large Diameter

Small Diameter

Rigid Vacuum Jacketed Pipe by Market Segment:

Static Vacuum Jacketed Pipe

Dynamic Vacuum Jacketed Pipe

Rigid Vacuum Jacketed Pipe by Features:

High Thermal Insulation

Ultra Low Heat Leak Performance

Factory Evacuated and Sealed Vacuum Jacket

Low Maintenance

Others

Rigid Vacuum Jacketed Pipe by Shape:

Straight Rigid Pipe Sections

Elbow and Bend Pipe Assemblies

Tee and Branch Pipe Configurations

Others

Rigid Vacuum Jacketed Pipe by Application:

Energy Industry

Medical and Health

Industrial Manufacturing

Scientific Research Experiment

Others

Global Top 20 Key Companies in the Rigid Vacuum Jacketed Pipe Market

Technifab (US)

Crane (US)

CSM-Cryogenic (Malaysia)

REGO Europe GmbH (Germany)

Chart Industries (US)

Concept Group (US)

BUTTING CryoTech (Germany)

Vacuum Barrier Corporation (US)

CryoWorks (US)

Cryospain (Spain)

JMR Europe (UK)

Ability Engineering Technology (US)

Cryofab (US)

Cryocomp (US)

CONCOA (US)

PHPK Technologies (US)

Chengdu Holy Cryogenic Equipment (China)

Acme Cryogenics (US)

Cryotherm (US)

Cryeng Group (Australia)

Regional Insights

Southeast Asia, with Indonesia as a key emerging market, is poised for accelerated uptake of rigid vacuum jacketed pipes as the region upgrades its LNG import terminals and gas distribution infrastructure. Indonesias expanding downstream energy production and petrochemical sectors are creating tangible demand for cryogenic piping solutions, supported by government initiatives to improve energy access and industrial capacity. Markets in Malaysia, Vietnam, Thailand, and the Philippines are also evolving, with LNG bunkering projects and industrial gas installations driving demand for vacuum insulated piping systems. Southeast Asian adoption rates are increasing as regional energy and process industries seek to align with global performance standards, emphasizing system reliability and insulation efficiency.

Despite growth prospects, the industry faces several challenges. Material price volatility, especially for high-grade stainless steel and specialized alloys, impacts overall COGS and pricing strategies. Regulatory compliance for pressure-retaining equipment in cryogenic applications adds complexity and cost to product development and certification, particularly in markets with strict safety standards. Supply chain disruptions and logistics constraints can delay project execution, prompting manufacturers to refine inventory planning and supplier diversification to maintain market responsiveness.

Successful players in the rigid vacuum jacketed pipe market are investing in research and development, focusing on advanced materials, enhanced vacuum stability, and integrated digital diagnostics. Strategic collaboration with end-use sectors like LNG infrastructure developers and semiconductor fabs enhances customer alignment and long-term contract opportunities. Localization of production and technical support in key growth regions like Asia and Southeast Asia is increasingly important as customers seek responsive service and shorter delivery lead times. Partnerships with engineering, procurement, and construction (EPC) firms support project-based sales and integration into complex industrial facilities.

Product Models

Rigid Vacuum Jacketed Pipe (RVJP) is a double-walled piping system designed for the efficient, low-loss transfer of cryogenic liquids and gases. A vacuum space between the inner and outer pipes acts as a thermal barrier, dramatically reducing heat transfer and minimizing product boil-off compared to traditional insulation methods.

Carbon Steel is a durable and cost-effective for less corrosive environments. Notable products include:

Crane CS-VJP CS Line Crane ChemPharma: Rigid carbon steel core vacuum jacketed pipe for industrial gas distribution; Mid Segment (~$7,500 to $12,000/m).

CSM-CS Cryo Line CSM Cryogenic: Engineered carbon steel insulated pipe for bulk cryogenic tank withdrawal; Mid Segment (~$6,000 to $10,000/m).

Cryeng VJP Carbon HD Series Cryeng Group: Large-bore carbon steel vacuum jacketed pipes with full field support for major plant installs. Price: ~$3,500 to $7,000/meter; Customers: Petrochemicals, industrial gas networks.

Stainless Steel excellent low-temperature performance and corrosion resistance. Notable products include:

CSM-SS CryoLine CSM Cryogenic: Corrosion-resistant stainless RVJP for low-temp fluids; Mid Segment (~$9,000 to $18,000/m).

Cryospain SS Cryo Pipe Cryospain: Stainless piping solutions tailored for LNG and industrial gases; Mid Segment (~$10,000 to $16,000/m).

Python® VIP Ultra HP Chart Industries: Top-tier stainless steel VIP for extreme conditions. Price Range: $4,000 to $7,500/meter; Customers: Petrochemical, aerospace.

CRANE VJP Stainless S-Series CRANE Cryogenics: High-precision vacuum jacketed stainless system. Price Range: $3,800 to $7,000/meter; Customers: LNG, hydrogen transfer lines.

StainGuard VIP Elite Butting CryoTech: Engineered for critical corrosion resistance. Price Range: $3,600 to $6,800/meter; Customers: Chemical processing.

Nickel Alloy used in ultra-low temperature and highly corrosive service where enhanced strength and toughness are required. Notable products include:

JMR-Ni Alloy Series JMR Europe: Nickel-based alloy RVJP for ultra-low temp applications High Segment.

Inconel VIP Custom Ultra Chart Industries (customized): Engineered vacuum jacketed pipe using Inconel inner pipe for extreme corrosion/hydrogen service with carbon steel or alloy jacket. Price: ~$10,000 to $18,000/meter; Customers: Aerospace & specialty chemical.

Crane CRYOFLO® Nickel Alloy VIP Crane ChemPharma & Energy (custom): Nickel alloy vacuum jacketed piping for specialty media such as liquid hydrogen or corrosive cryogens. Price: ~$9,000 to $14,000/meter; Customers: Defense and advanced materials.

Alloy 625 VIP Standard Cryofab (customised): Standard vacuum jacketed pipe with Inconel 625 inner pipe and optimized insulation. Price: ~$6,000 to $10,000/meter; Customers: Mid-size chemical processors.

Nickel Alloy VIP Midline Taylor-Wharton (engineered option): Mid-tier nickel alloy vacuum insulated pipe for cryogenic fluid lines requiring better corrosion resistance. Price: ~$5,500 to $9,000/meter; Customers: Specialty gas distributors

The rigid vacuum jacketed pipe market is entering a phase of measured growth driven by expanding industrial, energy, and semiconductor applications worldwide. The push for energy efficiency and improved thermal insulation in cryogenic fluid transport systems underpins demand across regions, with Asia and Southeast Asia emerging as pivotal growth arenas. Global industry performance through 2031 will hinge on technological innovation, strategic market positioning, and supply chain resilience.

Investor Analysis

For investors, this market report offers crucial insights into growth dynamics, regional opportunities, pricing benchmarks, and competitive structures that can guide investment decisions. Understanding market size, CAGR projections, unit economics, and downstream demand trends equips investors to evaluate potential returns, assess competitive risks, and identify high-impact market segments. The emphasis on Asia and Southeast Asia highlights geographies where structural industrial shifts are creating demand, making these markets attractive targets for capital allocation and strategic partnerships. Investors can leverage information on cost structures and gross margins to forecast profitability scenarios and inform valuations of industry players or potential acquisitions.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5544472

5 Reasons to Buy This Report

Comprehensive analysis of global and regional rigid vacuum jacketed pipe market dynamics.

Detailed insights into unit economics, production capacity, and downstream industry demand.

Strategic evaluation of market trends and technological developments shaping industry direction.

Focused regional intelligence for Asia and ASEAN, including Indonesia.

Competitive landscape profiling of the top industry players.

5 Key Questions Answered

What is the current size and future growth trajectory of the global rigid vacuum jacketed pipe market?

How do unit economics and pricing structures impact profitability across regions?

What are the key regional demand drivers in Asia and Southeast Asia?

Which technological innovations are influencing market competitiveness?

Who are the leading companies and how are they positioned within the global market?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Rigid Vacuum Jacketed Pipe Market Research Report 2026

https://www.qyresearch.com/reports/5544472/rigid-vacuum-jacketed-pipe

Rigid Vacuum Jacketed Pipe- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032

https://www.qyresearch.com/reports/5544463/rigid-vacuum-jacketed-pipe

Global Rigid Vacuum Jacketed Pipe Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/4705958/rigid-vacuum-jacketed-pipe

Global Rigid Vacuum Jacketed Pipe Market Insights, Forecast to 2031

https://www.qyresearch.com/reports/4705957/rigid-vacuum-jacketed-pipe

Global Vacuum Jacketed Pipe (VIP) System Market Research Report 2026

https://www.qyresearch.com/reports/5520546/vacuum-jacketed-pipe--vip--system

Global Vacuum Jacketed Pipe and Bayonets Market Research Report 2025

https://www.qyresearch.com/reports/3967898/vacuum-jacketed-pipe-and-bayonets

Global Vacuum Jacketed Pipe for Semiconductor Market Research Report 2025

https://www.qyresearch.com/reports/4416736/vacuum-jacketed-pipe-for-semiconductor

Global Vacuum Jacketed Pipe for Cryogenic Liquids Market Research Report 2025

https://www.qyresearch.com/reports/4528199/vacuum-jacketed-pipe-for-cryogenic-liquids

Global Rigid Vacuum Insulated Pipes Market Research Report 2025

https://www.qyresearch.com/reports/4601743/rigid-vacuum-insulated-pipes

Global Jacketed Pipe Market Research Report 2025

https://www.qyresearch.com/reports/3627464/jacketed-pipe

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Behind the Pipes: Market Forces, Margins, and Regional Shifts in Cryogenic Infrastructure here

News-ID: 4326821 • Views: …

More Releases from QY Research

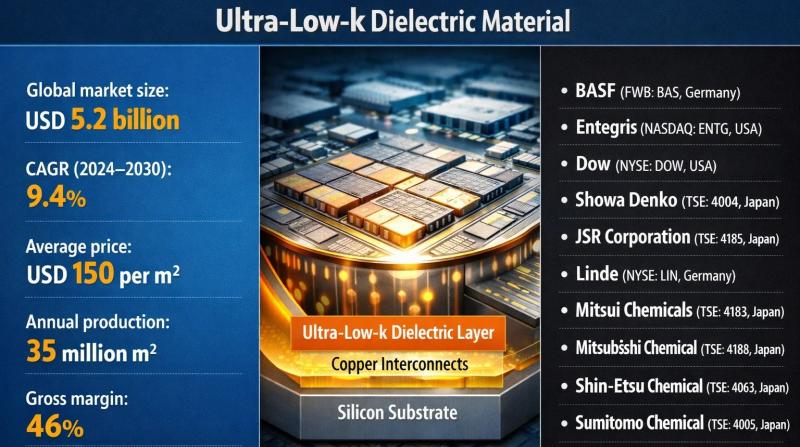

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for Pipe

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…

Stainless Steel Pipe and Industrial Stainless Steel Pipe

Stainless steel pipe is divided into two series: decorative stainless steel pipe(stainless steel pipe) and industrial stainless steel pipe.

Decorative stainless steel pipe(stainless steel pipe(SS)): usually outside the wall will be bright tube, hence the name of thinking, stainless steel pipe(SS) is used for decorative purposes. Stainless steel pipe(SS) mainly used to decorate, such as railings, staircase handrails, windows, etc., the wall thickness is very thin. As with the industrial stainless…