Press release

2036 Strategic Analysis of the Cast Polymer Market: Portfolio Priorities, Adoption Trends & Future Demand Outlook

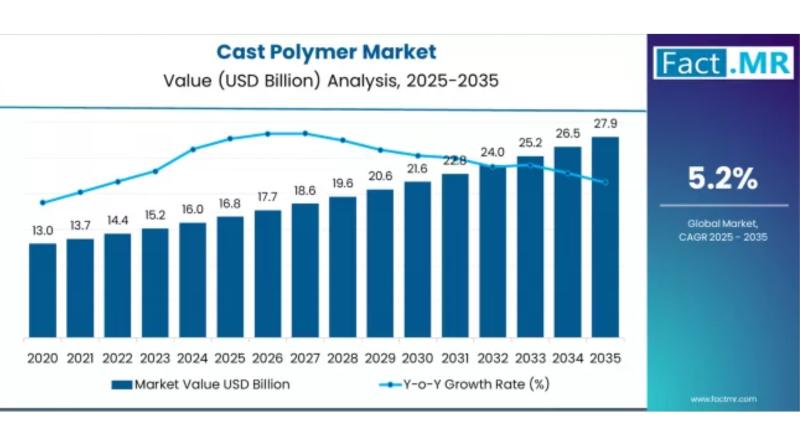

The global cast polymer market is set for steady and sustained expansion, driven by rising demand for cost-effective, durable, and design-flexible surface materials across residential, commercial, and institutional construction sectors. According to recent industry analysis, the market is projected to grow from USD 16.8 billion in 2025 to approximately USD 27.9 billion by 2035, reflecting an absolute increase of USD 11.1 billion over the forecast period.This growth represents a total market expansion of 66.1%, with the industry expected to register a compound annual growth rate (CAGR) of 5.2% between 2025 and 2035.

Cast polymer materials-including solid surface, cultured marble, cultured granite, and engineered stone-continue to gain preference for applications requiring durability, moisture resistance, and aesthetic versatility.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=9352

Key Market Drivers

Rising Demand for Aesthetic and Durable Interior Surfaces

Cast polymer products are widely used in countertops, vanities, sinks, bathtubs, shower surrounds, and wall panels due to their seamless appearance, customizable designs, and long service life. Increasing residential renovations and commercial construction projects are accelerating demand for visually appealing yet low-maintenance surface solutions.

Growth in Construction and Infrastructure Development

Urbanization, rising housing demand, and infrastructure modernization-particularly in emerging economies-are driving the adoption of cast polymer materials. Their cost efficiency compared to natural stone and superior performance in high-moisture environments make them ideal for residential, hospitality, healthcare, and institutional facilities.

Preference for Sustainable and Low-Maintenance Materials

Cast polymer surfaces offer enhanced durability, repairability, and extended lifecycle performance, reducing replacement frequency. Manufacturers are increasingly incorporating recycled content and low-VOC resins, aligning products with sustainability goals and green building certifications.

Browse Full Report: https://www.factmr.com/report/cast-polymer-market

Regional Growth Highlights

North America: Market Leadership Supported by Renovation Demand

North America remains a dominant market, supported by strong residential remodeling activity, widespread adoption in hospitality and healthcare settings, and a mature construction industry. The U.S. continues to lead in solid surface and cultured marble installations.

Europe: Sustainability and Design Innovation Drive Adoption

European markets benefit from strong demand for engineered stone and solid surface materials in premium residential and commercial interiors. Sustainability regulations and emphasis on modern architectural aesthetics are further accelerating market growth.

Asia-Pacific: Fastest-Growing Regional Market

Rapid urbanization, expanding middle-class populations, and large-scale infrastructure investments in China, India, Southeast Asia, and Australia are fueling strong demand for cast polymer products. Increasing awareness of engineered surfaces is boosting adoption across residential and commercial segments.

Middle East & Africa: Infrastructure and Hospitality Expansion

Rising investments in hotels, commercial buildings, and luxury residential developments are driving demand for cast polymer surfaces, particularly in the GCC region.

Market Segmentation Insights

By Product Type

Solid Surface Materials - Widely used for countertops and wall panels due to seamless appearance and repairability

Cultured Marble - Dominant in bathroom fixtures and vanities

Cultured Granite - Preferred for premium residential and commercial applications

Engineered Stone - Growing adoption in high-end countertops and flooring

By Application

Residential Construction - Kitchens, bathrooms, and renovation projects

Commercial Spaces - Offices, retail outlets, hotels, and malls

Healthcare Facilities - Hospitals and clinics requiring hygienic, seamless surfaces

Institutional Buildings - Educational facilities and public infrastructure

Market Challenges

Despite favorable growth prospects, the cast polymer market faces several challenges:

Volatility in Raw Material Prices: Resin and mineral filler cost fluctuations impact margins

Competition from Natural Stone and Ceramics: High-end consumers may prefer traditional materials

Installation Skill Requirements: Improper fabrication or installation can affect performance

Environmental Concerns: Resin-based materials face scrutiny regarding recyclability

Competitive Landscape

The global cast polymer market is moderately competitive, with players focusing on product innovation, sustainability initiatives, and geographic expansion. Manufacturers are investing in advanced molding technologies, customized finishes, and eco-friendly formulations to strengthen market positioning.

Prominent Companies Include:

DuPont

Wilsonart

LG Hausys

Cosentino

Caesarstone

Swan Corporation

Hanwha L&C

Strategic partnerships with construction firms, distributors, and interior designers continue to shape competitive dynamics.

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/9352

Future Outlook: Innovation, Sustainability, and Design Flexibility

Over the next decade, the cast polymer market is expected to benefit from continuous advancements in material technology, growing emphasis on sustainable construction, and increasing preference for customizable interior solutions. As architects, designers, and developers seek materials that balance performance, aesthetics, and cost efficiency, cast polymer surfaces will remain a critical component of modern construction and interior design.

Manufacturers that prioritize sustainable sourcing, innovative product design, and efficient distribution networks are poised to capture significant market share as the industry moves toward long-term growth.

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@factmr.com

Check out More Related Studies Published by Fact.MR Research:

Cast Elastomer Market - https://www.factmr.com/report/cast-elastomers-market

Polymers Market - https://www.factmr.com/report/polymers-market

Cold Cast Elastomers Market - https://www.factmr.com/report/2918/cold-cast-elastomers-market

Polymer Blends & Alloys Market - https://www.factmr.com/report/polymer-blends-and-alloys-market

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 2036 Strategic Analysis of the Cast Polymer Market: Portfolio Priorities, Adoption Trends & Future Demand Outlook here

News-ID: 4324365 • Views: …

More Releases from Fact.MR

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

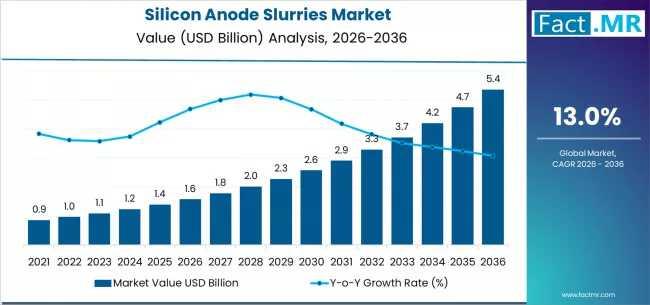

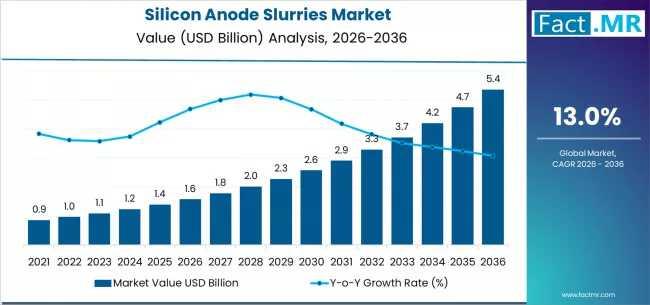

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

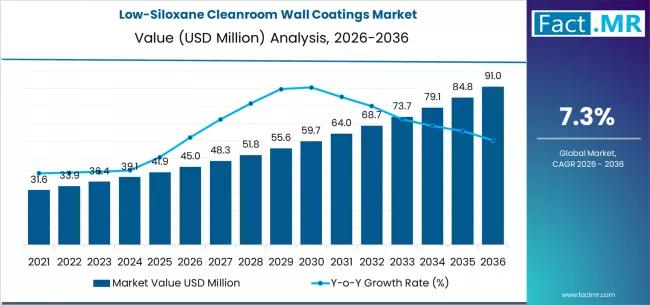

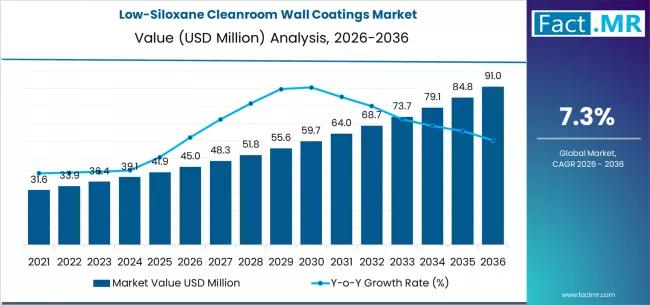

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for Cast

Cast Iron & Cast Iron Castings Market Is Going to Boom |• Erdos Group • Neen …

Worldwide Market Reports has released a new in-depth research study on the "Cast Iron & Cast Iron Castings Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities,…

Cast Iron vs Cast Steel: Which Manifold Enhances Performance?

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mp/image/b70503509e2c4604aa87f3862c47fe21.webp

Manifolds play a crucial role in engine performance. These components channel exhaust gases away from the engine, impacting efficiency and power output. A cast iron exhaust manifold [https://www.werkwell.com/exhaust-manifold/] offers durability and heat retention, making it a popular choice. However, advancements in material technology have introduced alternatives like cast steel [https://www.iron-foundry.com/cast-iron-exhaust-manifold-vs-cast-steel-manifolds.html], which provide enhanced strength and corrosion resistance.

Importance in Engine Performance

Impact on Efficiency

Manifolds significantly influence engine efficiency. Properly designed manifolds…

Cast Elastomer Market is Driven by Growing Demand for Cast Elastomers in the Aut …

A cast elastomer is a type of elastomeric material that is cast or molded into the desired shape. It is a versatile material that can be used for a variety of applications, including seals, gaskets, and vibration-damping materials. The cast elastomer has good mechanical properties and can withstand a wide range of temperatures and chemicals. It is also resistant to abrasion and tearing.

Get a Sample Report- https://www.globalinsightservices.com/request-sample/GIS20867

Key Trends

There are a…

Cast Resin Current Transformers Market Report 2018: Segmentation by Type (Indoor …

Global Cast Resin Current Transformers market research report provides company profile for CHINT, Stemar Electrical Products, Gemini Instratech Ltd., Elba d.o.o., Kaldera Company, ABB, Siemens, Schneider Electric, Toshiba, Fuji Electric and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the…

CONNOR FOX CAST IN SHOUTING SECRETS

Los Angeles, CA (April 28, 2010)- Award-winning actor Connor Fox, has officially signed on to play the role of Brody in the Korinna Sehringer film “Shouting Secrets” which started shooting in Arizona on April 26th. Fox will join Twilight Saga actors Gil Birmingham and Chaske Spencer as well actress, Q'orianka Kilcher (“The New World”), in this film about a successful young writer in Los Angeles who is called back…

Hexis launches carbon cast film

Hexis has launched a new cast vinyl with a carbon fibre look destined for wrapping applications. The company is promoting the new line with a dedicated mini-site: ilovehx.com.

Part of the HX30000 Series, the “Carbon Cast” is a multi-layered 135µm cast vinyl film with a carbon fibre embossed pattern. It carries the proven solvent-based adhesive and a structured PE liner with Hex’Press technology that allows convenient air egress during application. With…