Press release

UK Non-Destructive Testing Industry Transformation Report 2036: Innovation Trends, Sustainability Drivers & Competitive Positioning

The United Kingdom's non-destructive testing (NDT) market is on a steady growth trajectory as industry owners and regulators emphasize safety, asset integrity, and predictive maintenance across energy, rail, aerospace, oil & gas, and manufacturing sectors. NDT services and equipment - including ultrasonic testing, phased array ultrasonic testing (PAUT), radiography, eddy current, magnetic particle, and visual inspection - are critical for detecting defects without damaging components, extending asset life, and preventing catastrophic failures. As investment in infrastructure, offshore wind, and energy transition projects accelerates, demand for advanced and digital NDT solutions is increasing.Quick Stats (2025-2035)

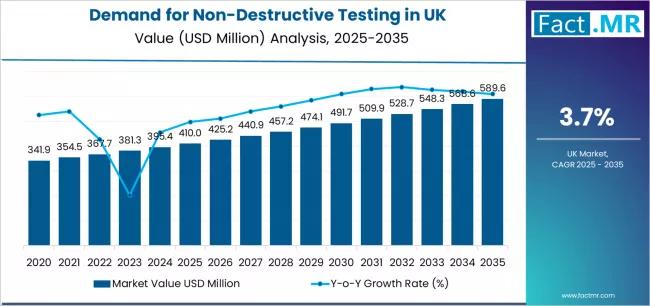

Market Value 2025: USD 410.0 million

Forecast Market Value 2035: USD 589.6 million

Absolute Growth (2025-2035): USD 179.6 million

Forecast CAGR (2025-2035): ~3.7%

Leading Modality (2025): Ultrasonic / PAUT (~34.2% share)

Leading Service Type (2025): Inspection & field services (~56.8% share)

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12331

Market Drivers

1. Infrastructure, Energy & Industrial Investment

Large public and private investments in infrastructure repairs, bridge and tunnel maintenance, and rail upgrades increase demand for regular NDT inspections.

Expansion of offshore wind farms, decommissioning and repurposing of oil & gas assets, and lifecycle management of power generation plants drive recurring inspection cycles.

2. Regulatory & Safety Compliance

Stringent safety regulations and mandatory periodic inspection regimes for pressure vessels, pipelines, aircraft, and rail equipment compel operators to employ certified NDT methods.

Liability and insurance frameworks reward documented NDT programs that reduce catastrophic failure risk.

3. Asset Integrity & Predictive Maintenance Focus

Shift from time-based maintenance to condition-based and predictive strategies elevates the importance of frequent, high-resolution NDT data.

Integration of NDT outputs with digital twins and asset-management systems improves decision making and lowers total lifecycle cost.

4. Technological Advancement & Digitalization

Adoption of advanced PAUT, phased-array radiography alternatives, automated eddy current arrays, drone-based visual inspection, and AI-assisted flaw detection is increasing operational efficiency.

Portable, faster, and more sensitive equipment expands the scope of field inspections and reduces downtime.

Market Structure & Segments

By Modality

Ultrasonic / PAUT: Largest share due to versatility for thickness, flaw detection and weld inspection.

Radiographic Testing (X-ray / Gamma): Used for critical weld and structural inspections-growing where high resolution is required.

Eddy Current & Turbine Blade Inspection: Key for aerospace and power-generation rotating equipment.

Magnetic Particle & Dye Penetrant: Common for surface Krack detection in manufacturing and maintenance.

Visual & VT/Drone Inspection: Rising as a low-cost, rapid triage tool for large or inaccessible assets.

By Offering

Field Inspection Services: The biggest revenue contributor-mobilized teams, on-site diagnostics, certification, and reporting.

Laboratory & Specialized Testing: High-value lab work for complex materials, metallurgical analysis, and failure investigation.

Equipment Sales & Rental: Growing for portable instruments and automated inspection rigs.

Software & Analytics: SaaS and analytics for inspection data, reporting, and digital twin integration are emerging revenue streams.

By End-Use Industry

Energy (including offshore wind and hydrocarbons): Major consumer for pipeline, turbine, and platform inspections.

Aerospace & Defense: High technical thresholds and certification needs; strong for precision NDT.

Rail & Transportation: Ongoing track, wheelset, and bridge inspections support steady demand.

Manufacturing & Fabrication: Quality assurance and acceptance testing for welded assemblies and components.

Regional Dynamics (within UK)

England: Concentrates the largest demand due to dense industrial and transport infrastructure and major ports.

Scotland: Strong activity around offshore wind and oil & gas decommissioning work.

Wales & Northern Ireland: Niche but stable demand linked to steel, manufacturing, and regional infrastructure projects.

Challenges & Constraints

Skilled-Labor Shortage: Certified NDT technicians and inspectors are in limited supply; training and certification cycles slow scaling.

Capital Intensity for Advanced Equipment: High upfront costs for phased-array systems and automated rigs can constrain smaller service providers.

Regulatory Complexity & Certification Burdens: Different industry standards and accreditation pathways require continuous investment in compliance.

Data Management & Interoperability: Integrating inspection data into asset management systems and digital twins remains a technical hurdle.

Opportunities & Strategic Directions

Upskilling & Remote Inspection Models: Invest in training, augmented-reality support for remote operators, and supervised drone inspection to expand service reach.

Automation & Robotics: Robotic crawlers, crawlers with integrated PAUT arrays, and pipeline-inspection robots reduce cost and improve repeatability.

Analytics & Predictive Services: Offer inspection-plus analytics bundles that convert raw NDT data into actionable asset-health scores.

Sector Tailoring: Develop specialized packages for offshore wind, nuclear lifecycle inspections, and rail corridor monitoring to win long-term contracts.

Rental & Managed Fleet Models: Provide equipment-as-a-service or managed inspection fleets to lower customer capital needs and lock in recurring revenue.

Outlook

The UK NDT market is set for measured growth through 2035, expanding from roughly USD 410.0 million in 2025 to about USD 589.6 million by 2035, at an approximate 3.7% CAGR. Growth will be underpinned by infrastructure investment, energy-sector inspection cycles (including renewables and decommissioning), tighter safety regimes, and the steady uptake of digital, automated inspection technologies.

Providers that couple technical capability (advanced modalities) with digital analytics, skilled technicians, and managed-service models will capture the most valuable contracts as asset owners prioritize reliability, uptime, and demonstrable lifecycle cost savings.

Browse Full Report: https://www.factmr.com/report/united-kingdom-non-destructive-testing-market

Purchase Full Report for Detailed Insights

For access to full forecasts, regional break-outs, product- and application-level analysis, company share details, and emerging trend assessments, you can purchase the complete report: https://www.factmr.com/checkout/12331

Have specific requirements or need assistance on report pricing or have a limited budget? Please contact sales@factmr.com

Related Reports:

Demand and Trend Analysis of Air Purifiers in South Asia & Oceania: https://www.factmr.com/report/demand-and-trend-analysis-of-air-purifier-in-south-asia-and-oceania

Demand and Trend Analysis of Air Purifiers in East Asia: https://www.factmr.com/report/demand-and-trend-analysis-of-air-purifier-in-east-asia

Demand and Trend Analysis of Air Purifiers in North America: https://www.factmr.com/report/demand-and-trend-analysis-of-air-purifier-in-north-america

Demand for Intermodal Freight Transportation in USA: https://www.factmr.com/report/united-states-intermodal-freight-transportation-market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

About Fact.MR:

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release UK Non-Destructive Testing Industry Transformation Report 2036: Innovation Trends, Sustainability Drivers & Competitive Positioning here

News-ID: 4323049 • Views: …

More Releases from Fact.MR

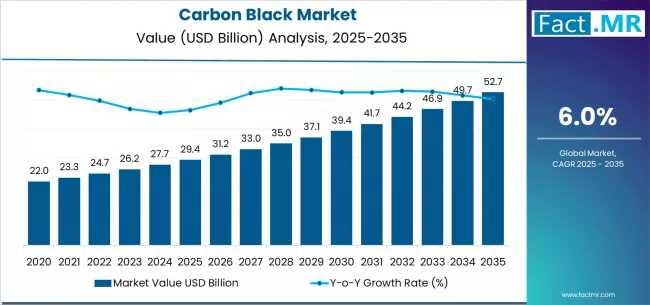

Carbon Black Market Forecast 2026-2036: Market to Reach USD 52.7 Billion by 2036 …

The global carbon black market is valued at USD 29.4 billion in 2025 and is projected to reach USD 52.7 billion by 2035. This robust expansion represents a total growth of 79.1%, progressing at a compound annual growth rate (CAGR) of 6.0% over the ten-year forecast period. As automotive manufacturing scales and tire production capacities rise, the market is expected to grow by approximately 1.8X, driven by the essential role…

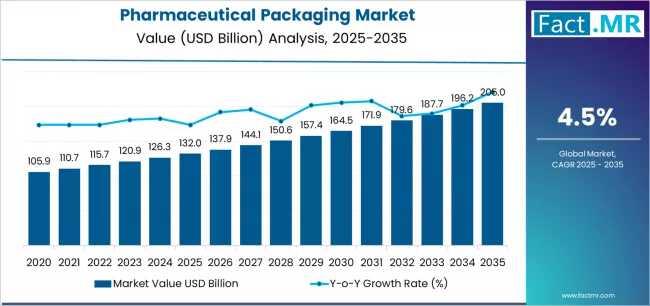

Pharmaceutical Packaging Market Forecast 2026-2036: Market to Reach USD 206.0 Bi …

The global pharmaceutical packaging market is valued at USD 132.0 billion in 2026 and is projected to reach USD 206.0 billion by 2036, expanding at a steady CAGR of 4.5%. This growth reflects a fundamental shift toward advanced sterile packaging, driven by the rapid rise of biologics and the necessity for global regulatory harmonization.

Get Access of Report Sample: https://www.factmr.com/connectus/sample?flag=S&rep_id=4573

pharmaceutical packaging market Quickstat

Market Size 2026: USD 132.0 billion

Market Size…

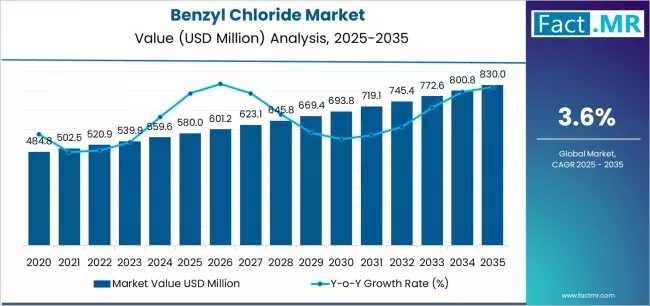

benzyl chloride Market Forecast 2026-2036: Market to Reach USD 830.0 Million by …

The global benzyl chloride market is projected to expand from a valuation of USD 580.0 million in 2025 to approximately USD 830.0 million by 2035. This growth represents an absolute increase of USD 250.0 million, with the market forecast to grow at a compound annual growth rate (CAGR) of 3.6% over the ten-year period. As a critical chemical intermediate, benzyl chloride is seeing heightened utilization in pharmaceutical manufacturing and the…

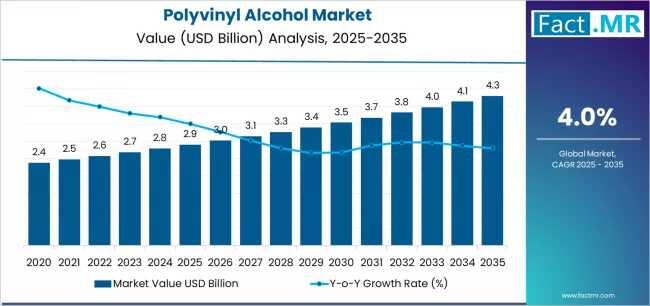

Polyvinyl Alcohol Market Forecast 2026-2036: Market to Reach USD 4,300.0 Million …

The global Polyvinyl Alcohol Market is valued at USD 2,900.0 million in 2025 and is projected to reach USD 4,300.0 million by 2035. This steady expansion represents a CAGR of 4.0% over the ten-year assessment period, marking an absolute increase of USD 1,400.0 million. The market's growth is primarily underpinned by an escalating global demand for water-soluble packaging solutions and advanced film-forming technologies across industrial, textile, and food sectors.

Get Access…

More Releases for NDT

Seamless Digital RT Workflow with DRIVE NDT and D-Tect X from DÜRR NDT

For an optimal digital workflow in radiographic testing (RT), the X-ray inspection software D-Tect X can be integrated with the NDT management software DRIVE NDT. The closely meshed interaction between DRIVE NDT and D-Tect X means that a large part of the process takes place automatically. This not only saves time, but the automatic exchange of data also minimizes the possibility of human error. As all the steps and processes…

Rapid CUI Inspection with the DRA 3543 NDT Flat Panel Detector from DÜRR NDT

NDE Solutions Pty Ltd, located in Adelaide, South Australia with a team of over 60 employees provides non-destructive testing and inspection solutions to the oil and gas, defence, power, and mining industries.

NDE Solutions has been using the DÜRR NDT DRA 3543 digital flat panel since 2021 in combination with Iridium-192 radiation sources to perform Corrosion-Under-Insulation (CUI) radiography for confirming pipe wall loss in oil and gas plants and refineries. The…

DRIVE NDT enables DEKRA to increase its efficiency with digital NDT workflow man …

DEKRA has approximately 48,000 employees and ranks as one of the foremost testing companies worldwide. A pioneering team is introducing the innovative DRIVE NDT to organize non-destructive testing and its peripheral processes at the BAYERNOIL site in Neustadt.

Digital processes are firmly embedded in all industrial fields these days. The resulting advantages are clearly seen by all companies and industries and their potential is also increasingly recognized for non-destructive testing. Benjamin…

Corrosion-Under-Insulation Inspection Made Easy with the CR 35 NDT from DÜRR ND …

Stork Technical Services, located in Kwinana, Western Australia with a team of over 30 employees provides asset integrity and fabric maintenance services to the oil and gas, chemical, power and mining industries.

Stork Technical Services has been using the CR 35 NDT Computed Radiography scanner since 2019 and uses it with Iridium-192 in combination with high-sensitivity white imaging plates to perform Corrosion-Under-Insulation (CUI) radiography and digital gap shots which are…

Applus+ Entrusts DRIVE NDT with Digitization of NDT Workflow

Applus+ Germany is one of the largest providers of non-destructive testing (NDT) services in Germany and with more than 20,000 employees in over 70 countries is one of the largest companies in the industry worldwide.

In order to cement its leading position over the longer term, Applus+ is investing in future technologies. One of the key challenges of the future is the digitalization of all NDT processes. "A key promise is…

HD-CR 35 NDT from DÜRR NDT Increases Efficiency of Oil & Gas RT Inspection Task …

ENOD S.R.L is an NDT service company based in Buenos Aires, serving the energy sector in Argentina since August 1980.

ENOD is one of the largest service providers in Argentina, offering a wide range of inspection methods to fit their customers' needs. They have largely invested in the latest technologies to be one of the pioneers in their local market. A few years ago, they stepped into digital radiography to replace…