Press release

Start a Vegetable Dehydration Processing Plant: Business Model, Setup Guide, and Returns

IMARC Group's report, "Vegetable Dehydration Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a complete roadmap for establishing a vegetable dehydration processing plant. The report provides in-depth insights into production processes, capital investments, operating expenses, profitability projections, and financial analysis, empowering entrepreneurs, investors, and industry stakeholders to make informed decisions in the fast-growing food processing and preservation markets.In 2025, the demand for vegetable dehydration processing plants is rising steadily worldwide, driven by rapid adoption of preserved food products across retail, food service, ready-to-eat meals, snack manufacturing, spice blending, and export markets. This project report provides a comprehensive overview of cost analysis, required machinery, raw material availability, and plant setup guidelines for investors across India, the UAE, the US, Africa, and Europe.

Request for Sample Report: https://www.imarcgroup.com/vegetable-dehydration-manufacturing-plant-project-report/requestsample

What is Vegetable Dehydration?

A vegetable dehydration processing plant is an advanced food preservation facility that removes moisture from fresh vegetables through controlled drying methods to extend shelf life and retain nutritional value. It enables the production of lightweight, shelf-stable vegetable products by reducing water content through thermal processing, air circulation, or freeze-drying techniques. Dehydrated vegetables are widely used in instant soups, seasonings, ready-to-eat meals, camping food, food service operations, and retail packaged products. Their ability to reduce storage costs, minimize food waste, facilitate transportation, and provide year-round availability makes them essential in modern food supply chains.

Is Vegetable Dehydration Processing Profitable?

Yes, setting up a vegetable dehydration processing plant can be highly profitable due to rising global demand for preserved and convenient food products. Industries are rapidly shifting toward shelf-stable ingredients, nutritious snacking options, and sustainable food preservation, creating sustained demand for dehydrated vegetables. The sector offers strong margins, scalability, and long-term growth potential. Increasing consumer preference for healthy foods, export opportunities, government support for food processing infrastructure, and the growing organic food market further enhance profitability prospects.

How Much Does It Cost to Set Up a Vegetable Dehydration Processing Plant?

Establishing a vegetable dehydration processing plant involves costs related to land, construction, advanced dehydration equipment, washing and sorting systems, drying chambers, raw material procurement, utilities, labor, and quality testing facilities. Expenses also include installation, temperature control systems, packaging machinery, cold storage units, food safety compliance, and regulatory approvals. Total investment varies depending on production capacity, automation level, technology type (hot air drying, freeze drying, vacuum drying, solar drying, etc.), and geographic location.

Market Trends and Drivers of Vegetable Dehydration

The vegetable dehydration market is experiencing strong global growth due to:

• Rising demand for convenient, ready-to-cook food products

• Increasing consumer preference for healthy, preservative-free snacks

• Growing export opportunities for dehydrated vegetables

• Expansion of food service and quick-service restaurant sectors

• Rising awareness about reducing post-harvest food waste

• Growing demand for organic and natural food ingredients

• Advancements in dehydration technology and energy efficiency

• Government initiatives promoting food processing and value addition

These trends are driving significant future demand and making vegetable dehydration processing an attractive investment opportunity.

Buy Full Report Now: https://www.imarcgroup.com/checkout?id=19446&method=2142

Key Insights Covered in the Vegetable Dehydration Processing Plant Report

Market Coverage:

• Global trends in food preservation and dehydrated vegetable markets

• Market segmentation by product type, application, distribution channel, and end-use industry

• Regional analysis of demand and processing ecosystems

• Price analysis of raw vegetables, packaging materials, and energy costs

• Impact of food safety regulations and quality standards

• Market forecasts and future growth potential

Key Aspects Required for Setting Up a Vegetable Dehydration Processing Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved (washing, peeling, slicing, blanching, dehydration, cooling, packaging)

• Bill of Materials and Raw Material Requirements

• Quality Assurance and Testing Standards

• Technical and Food Safety Tests

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material and Vegetable Requirements

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs (water, electricity, fuel)

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments: Land, building, machinery, dehydration systems, packaging lines

• Operating Costs: Raw vegetables, utilities, labor, maintenance, quality control

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections: ROI, NPV, break-even analysis

• Financial Feasibility and Risk Assessment

Customization Options Available:

• Plant Location: Based on vegetable growing regions, logistics, regulations, and market access

• Plant Capacity: Tailored to production scale (small, medium, or large-scale operations)

• Machinery: Automatic, semi-automatic, or manual processing systems

• List of Machinery Providers: Global and domestic equipment suppliers specializing in food processing

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=19446&flag=C

About Us

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants worldwide.

Our expertise includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and Factory Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Procurement and Supply Chain Research

• Branding, Marketing, and Sales Strategy

Contact Us

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Start a Vegetable Dehydration Processing Plant: Business Model, Setup Guide, and Returns here

News-ID: 4316854 • Views: …

More Releases from IMARC Group

Indonesia Battery Market to Surge to USD 4.4 Billion by 2034 at 11.72% CAGR - Re …

A Comprehensive Introduction to the Indonesia Battery Market Report

According to IMARC Group's report titled "Indonesia Battery Market Size, Share, Trends and Forecast by Technology, Application, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Get Instant Access to the Free Sample (Corporate Email Required): https://www.imarcgroup.com/indonesia-battery-market/requestsample

Indonesia Battery Market Overview

The Indonesia battery market size was valued at USD 1.6 Billion in 2025.…

Thailand Cheese Market to Reach USD 31.0 Billion by 2033 | 11.80% CAGR | Get Fre …

Thailand Cheese Market Report Introduction

According to IMARC Group's report titled "Thailand Cheese Market Size, Share, Trends and Forecast by Source, Type, Product, Format, Distribution Channel, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email): https://www.imarcgroup.com/thailand-cheese-market/requestsample (Note: We are currently updating our reports to the 2026-2034 period. Click the link above to…

India Two-Wheeler Loan Market to Reach USD 14.55 Billion by 2033 | 6.43% CAGR | …

India Two-wheeler Loan Market Report Introduction

According to IMARC Group's report titled "India Two-Wheeler Loan Market Size, Share, Trends and Forecast by Type, Provider Type, Percentage Amount Sanctioned, Tenure, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email): https://www.imarcgroup.com/india-two-wheeler-loan-market/requestsample

Note : We are in the process of updating our reports to cover…

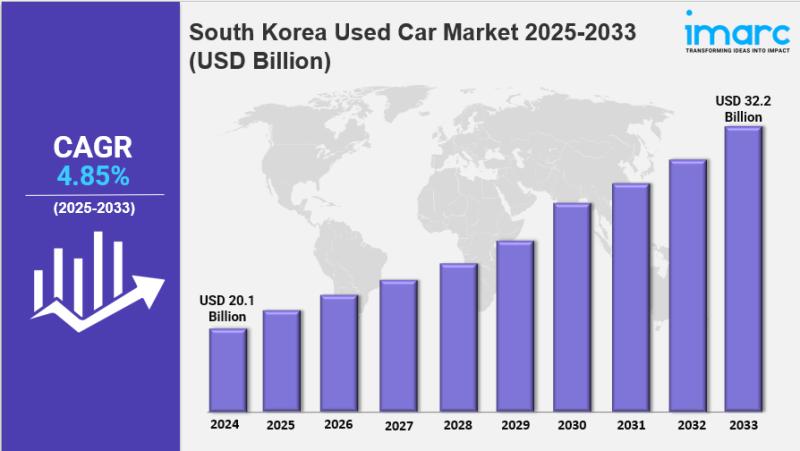

South Korea Used Car Market Size, Share, Industry Overview, Trends and Forecast …

IMARC Group has recently released a new research study titled "South Korea Used Car Market Report by Vehicle Type (Hatchback, Sedan, Sports Utility Vehicle, and Others), Vendor Type (Organized, Unorganized), Fuel Type (Gasoline, Diesel, and Others), Sales Channel (Online, Offline), and Region 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

South Korea Used Car Market…

More Releases for Vegetable

Vegetable Juices Market Size Analysis by Application, Type, and Region: Forecast …

USA, New Jersey- According to Market Research Intellect, the global Vegetable Juices market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The Vegetable Juices Market is experiencing significant growth, driven by increasing consumer awareness about health, nutrition, and natural food products. As more individuals shift toward…

Canned Vegetable Market Report 2024 - Canned Vegetable Market Growth And Share

"The Business Research Company recently released a comprehensive report on the Global Canned Vegetable Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The canned vegetable market size…

Fruit - Vegetable Processing Market

Fruit - Vegetable Processing Market report gives detailed explanation of the estimations about the existing state of the market, market size and market share, revenue generated from the product sale, and necessary changes required in the future products are given in an appropriate way. A swiftly transforming market place increases the value of market research report and hence Fruit - Vegetable Processing Market report has been created in a way…

Processed Vegetable Market Size, Share | Processed Vegetable Industry Future Gro …

Global Processed Vegetable Market Report provides a detailed industry overview along with the analysis of Cost Structure, Supply Chain, Development Techniques, Retailers Analysis, Financial Support, business Strategies, Marketing Channels. Global Processed Vegetable Market research report provides a point-by-pointIn-Depth analysis of global market size, regional and country-level market size, segmentation market growth, market share, competitive Landscape, sales analysis, the impact of domestic and global market players, value chain optimization, trade regulations,…

Global Textured Vegetable Protein Market

According to a new market research report published by Global Market Estimates, the Global Textured Vegetable Protein Market is expected to grow at a CAGR of 6.40% during the forecast period. The increasing adoption of meat alternatives among consumers, along with the growing demand for protein-rich food is some of the major factors influencing the growth of the textured vegetable protein market.

Browse 148 Market Data Tables and 90 Figures spread…

Frozen Fruits & Vegetable Processing Unit

Fruits and Vegetables Processing sector is one of the largest and most dynamic sectors of the food industry. Processed Fruits & Vegetables covers various categories, like sun-dried, Machine dried, frozen, dehydrated and frozen, pickled with natural substances, pickled with chemicals, etc. Amongst which the popularity of frozen fruits and vegetables in daily diets is steadily increasing, driven by shifting food preferences throughout the world.

The global frozen fruits and vegetable market…