Press release

European Bimodal HDPE Market Outlook 2025-2035: Key Developments and Future Scope

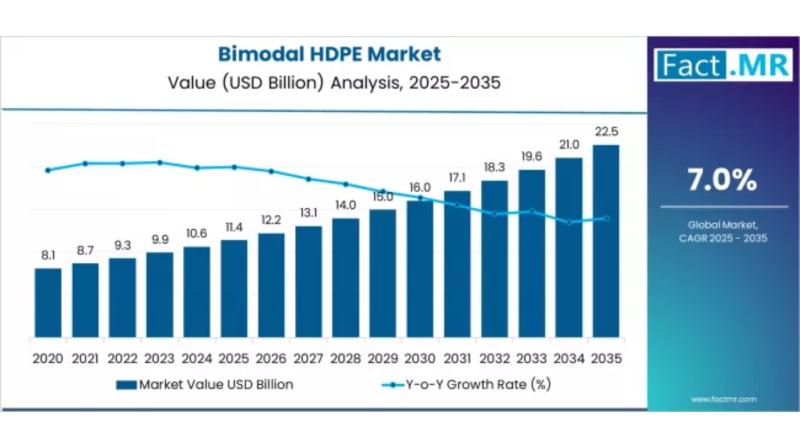

The global bimodal high-density polyethylene market is set for significant expansion, driven by rising demand for high-strength plastics in packaging, infrastructure development, and advanced industrial applications.According to a new analysis by Fact.MR, the market is expected to grow from USD 11.39 billion in 2025 to USD 22.50 billion by 2035, delivering an absolute growth of USD 11.11 billion over the forecast period. This reflects a strong CAGR of 7.0% during 2025-2035.

Bimodal HDPE, known for its superior mechanical strength, high stress resistance, and enhanced processability, continues to gain adoption in pipe systems, blow molding, rigid packaging, and film applications.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12377

Strategic Market Drivers

Rising Use in Pressure Pipes & Infrastructure

The construction and utilities sectors are significantly increasing their adoption of bimodal HDPE for water and gas pipelines due to its:

Exceptional durability

High resistance to slow

Long service life

Urban infrastructure expansion, especially in Asia, the Middle East, and Africa, continues to propel demand.

Growth in Rigid & Flexible Packaging

Bimodal HDPE's enhanced stiffness, toughness, and environmental stress resistance make it ideal for:

Bottles

Containers

Caps & closures

Industrial drums

Films and liners

The global shift toward sustainable, lightweight, and recyclable packaging materials further elevates consumption.

Browse Full Report: https://www.factmr.com/report/bimodal-hdpe-market

High Demand in Industrial Manufacturing

Industrial sectors rely on bimodal HDPE for chemical storage tanks, geomembranes, and industrial components that require superior mechanical performance.

Technological Advancements in Polymer Production

Improved catalyst technologies, advanced polymerization processes, and customization capabilities have enabled manufacturers to develop application-specific bimodal HDPE grades.

Regional Growth Highlights

North America: Strong Consumption in Infrastructure & Packaging

The region leads with high demand for pressure pipes, blow-molded containers, and industrial-grade HDPE products. Investments in water-recycling infrastructure and packaging innovation support market growth.

Europe: Sustainability Mandates Drive Adoption

Strict EU regulations promoting recyclable and lightweight plastics boost the use of bimodal HDPE in:

Packaging

Construction

Industrial manufacturing

Germany, the U.K., France, and Italy are major consumers.

East Asia: World's Largest Production & Consumption Hub

China's rapidly expanding construction industry, along with strong packaging and industrial manufacturing ecosystems across Japan and South Korea, drives large-scale market uptake.

Emerging Markets: Rapid Industrialization & Urban Growth

India, Southeast Asia, Latin America, and Africa are witnessing rising consumption fueled by:

Urban infrastructure development

Expansion of packaged goods

Growth in water management systems

Market Segmentation Insights

By Application

Pipes & Fittings - Largest segment due to infrastructure investments.

Blow Molding - High usage in containers, bottles, industrial tanks.

Film & Sheet - Growing demand in packaging and agriculture.

Injection Molding - Used for caps, crates, and industrial components.

Others - Including geomembranes, wire & cable jackets.

By End Use

Construction & Infrastructure - Fastest-growing segment.

Packaging - High-volume consumption.

Automotive - Lightweight components and fuel tanks.

Industrial & Chemical - Storage and transport solutions.

Agriculture - Irrigation and greenhouse films.

Challenges Impacting Market Growth

Volatile Raw Material Prices

Fluctuating ethylene and crude oil prices impact production costs and pricing stability.

Recycling & Environmental Pressure

Rising scrutiny on plastic waste challenges manufacturers to shift toward:

High-recyclability grades

Circular economy initiatives

Technological Barriers

Advanced production processes require significant capital investment and technical expertise.

Competitive Landscape

The market is moderately consolidated, with leading players focusing on product innovation, improved polymer technologies, and capacity expansions.

Key Companies Profiled

ExxonMobil Chemical

LyondellBasell

SABIC

INEOS Group

Dow Inc.

Borealis AG

Chevron Phillips Chemical

TotalEnergies

PetroChina

Mitsui Chemicals

Companies are investing in:

Advanced catalyst systems

Sustainable and recyclable HDPE grades

Higher-performance bimodal products

Capacity expansion in high-growth economies

Recent Developments

2024: Innovations in high-strength bimodal HDPE grades for next-gen water and gas pipelines.

2023: Global packaging leaders adopt bimodal HDPE for lightweight, durable bottles and industrial drums.

2022: Major chemical producers expand bimodal HDPE production capacities across Asia and the Middle East.

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/12377

Future Outlook: A Decade of High-Performance Polymer Innovation

Over the next decade, the bimodal HDPE market is expected to benefit from:

Expanding infrastructure development

Growth in sustainable packaging

Rising adoption in industrial applications

Advancements in catalyst and polymerization technology

Increasing focus on circular plastics and recyclability

As industries prioritize durable, high-strength, and cost-efficient materials, bimodal HDPE will continue to expand its global footprint through 2035.

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release European Bimodal HDPE Market Outlook 2025-2035: Key Developments and Future Scope here

News-ID: 4310966 • Views: …

More Releases from Fact.MR

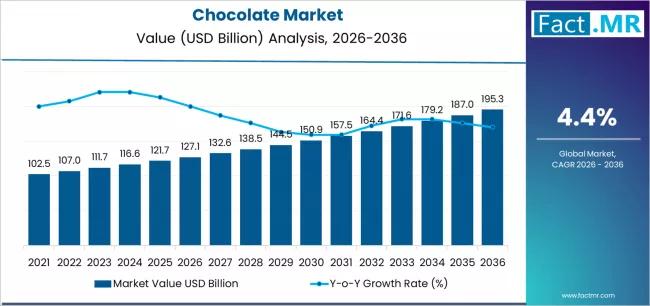

Chocolate Market Trends to 2036: Innovation Impact, Regulations & Revenue Foreca …

The global chocolate market is projected to grow from USD 135.2 billion in 2026 to approximately USD 198.4 billion by 2036. This growth represents an absolute increase of USD 63.2 billion over the forecast period, expanding at a compound annual growth rate (CAGR) of 3.9%. The market is being transformed by a dual trend: the rising demand for affordable indulgence in emerging markets and a significant shift toward premium, "clean-label,"…

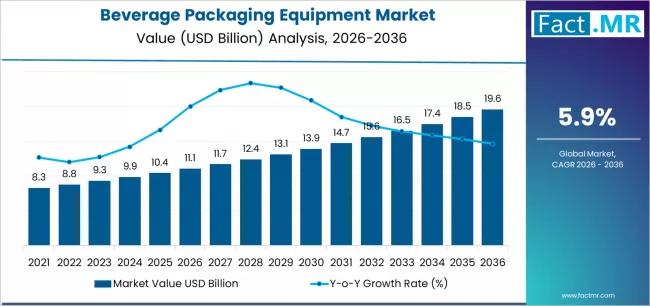

Beverage Packaging Equipment Industry Outlook 2026-2036: R&D Focus, Expansion St …

The global beverage packaging equipment market is projected to grow from USD 6.1 billion in 2026 to approximately USD 9.4 billion by 2036. This expansion represents an absolute increase of USD 3.3 billion over the forecast period, with the market set to expand at a compound annual growth rate (CAGR) of 4.4% between 2026 and 2036.

The market is being driven by the surge in demand for single-serve beverage formats…

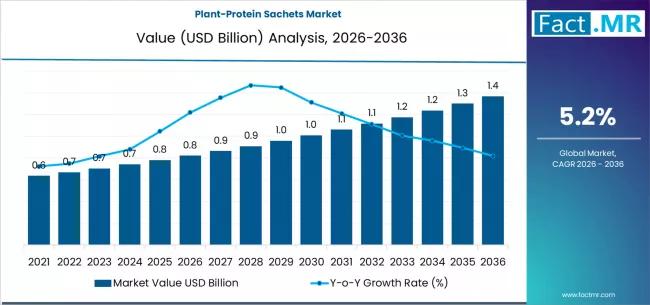

Plant Protein Sachets Market Landscape to 2036: Pricing Analysis, Regional Hotsp …

The global Plant Protein Sachets Market is projected to experience robust growth over the next decade as consumer demand for convenient, protein-rich nutrition, clean label formulations, and sustainable protein sources continues to rise. Industry analysis indicates that the market, valued at approximately USD 1.2 billion in 2025, is expected to exceed USD 2.4 billion by 2035, expanding at a compound annual growth rate (CAGR) of about 7.2% over the forecast…

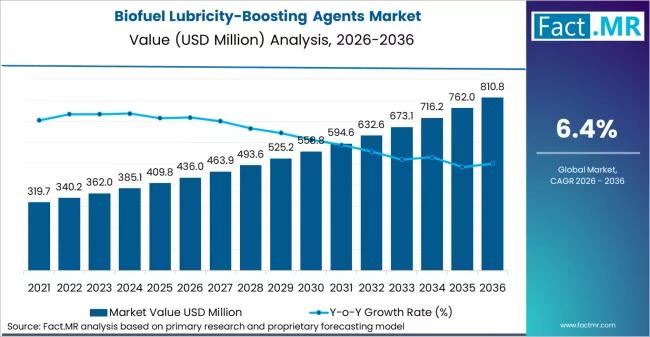

Biofuel Lubricity-Boosting Agents Market Analysis 2036: Technology Shifts, Deman …

The global biofuel lubricity boosting agents market is projected to grow from USD 174.5 million in 2026 to approximately USD 310.2 million by 2036. This growth represents a compound annual growth rate (CAGR) of 5.9% over the ten-year forecast period. The market is primarily driven by the global transition to Ultra-Low Sulfur Diesel (ULSD) and the increasing blending mandates for biodiesel, which require specialized additives to prevent engine wear.

Quick Stats:

Market…

More Releases for HDPE

Beyond Numbers: Understanding PCR HDPE Market Size

In this comprehensive report, analysts conduct an in-depth study of the global PCR HDPE market, delving into key factors such as drivers, challenges, recent trends, opportunities, advancements, and the competitive landscape. Utilizing research techniques like PESTLE and Porter's Five Forces analysis, the researchers provide a clear understanding of both the current and future scenarios within the global PCR HDPE industry. Accurate data on PCR HDPE production, capacity, price, cost, margin,…

Latest Trends In Global Recycled HDPE Market

Recycled HDPE, or High-Density Polyethylene, is a versatile and environmentally friendly material derived from the recycling of plastic products made from HDPE.

HDPE is a type of plastic commonly used for items like milk jugs, detergent bottles, and plastic bags. The recycling process for HDPE involves collecting, cleaning, and melting down these used plastic items to create new products.

Request for Sample@

https://mobilityforesights.com/contact-us/?report=20042

Recycled HDPE is valued for its durability, resistance…

Geomembrane manufacturer, HDPE geomembrane factory, geosynthetics supplier

MTTVS® Geosynthetics company specializes in research ,development,production,promotion and application of geosynthetics.And is the world's leading supplier of geosynthetics. Founded in 2014,located in Shandong China.With ISO9001,ISO14001,ISO45001 international authoritative management system certification of powerful large manufucture.We have more than 10 international advanced equipment production lines and a huge professional engineering and technical team.and has successfully consolideated and developed core markets to maximize value for customers.Through the processing of synthetic raw materials.we develop,manufacture…

hdpe geomembrane liner fabric manufacturer,geotextile manufacturer Company,HDPE …

GD Geosynthetics Company is a comprehensive processing enterprise of composite geosynthetics, geotextiles, geomembranes, geogrids, geounits, three-dimensional composite drainage nets, ecological bags, drainage boards. High-level management, high-level scientific research team, conform to the trend of domestic and international chemical fiber market, constantly innovate and update, cater to the market and meet the needs of consumers. Gained the trust of consumers.

Geosynthetics are widely used in anti-seepage treatment of roads, bridges, reservoirs, tunnels,…

Research Focuses on Global HDPE Geomembrane

HDPE Geomembrane Report by Material, Application, and Geography – Global Forecast to 2021 is a professional and in-depth research report on the world's major regional market conditions, focusing on the main regions (North America, Europe and Asia-Pacific) and the main countries (United States, Germany, united Kingdom, Japan, South Korea and China).

The report firstly introduced the HDPE Geomembrane basics: definitions, classifications, applications and market overview; product specifications; manufacturing processes; cost structures,…

Global HDPE Decking Market Research Report 2017

HDPE Decking Revenue, means the sales value of HDPE Decking This report studies HDPE Decking in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with capacity, production, price, revenue and market share for each manufacturer, covering UPM Kymmene Universal Forest Products Advanced Environmental Recycling Technologies Fiberon Azek Building Products Cardinal Building Products Certainteed Corporation Duralife Decking and Railing…