Press release

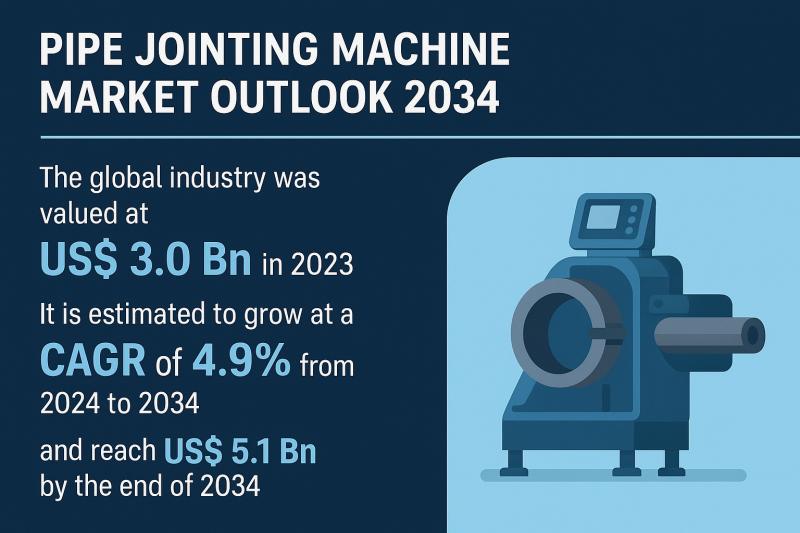

Pipe Jointing Machine Market Set to Reach USD 5.1 Billion by 2034, Driven by Water Infrastructure Upgrades and Oil & Gas Investments | TMR

The global Pipe Jointing Machine Market is poised for steady growth as governments, municipal bodies, and industrial sectors worldwide increasingly prioritize efficient pipeline systems, water conservation, and reliable energy transportation. According to recent market analysis, the industry-valued at US$ 3.0 billion in 2023-is projected to reach US$ 5.1 billion by 2034, expanding at a CAGR of 4.9% between 2024 and 2034.Access key findings and insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86105

This positive outlook is supported by strong demand for advanced pipe jointing technologies, particularly for HDPE, PVC, and metal pipelines used in water supply, oil & gas, chemicals, and infrastructure development.

Market Overview

Pipe jointing machines are crucial equipment used to connect or fuse pipes safely, efficiently, and permanently. These machines support critical infrastructure by ensuring leak-free, durable connections across a variety of materials including HDPE, PP, PVC, and metal pipelines.

Key Applications Include:

Water Distribution & Irrigation

Oil & Gas Transportation

Sewage & Drainage Systems

Chemicals & Petrochemicals

Power Plants & Industrial Utilities

Municipal Infrastructure Projects

Growing awareness regarding the efficiency and long-term savings associated with pipeline systems has spurred demand for sophisticated pipe jointing technologies.

Key Market Growth Drivers

1. Rising Water Leakage Concerns Worldwide

Global water scarcity and climate change have intensified concerns regarding leakage in water distribution networks. Many countries face significant drinking water losses due to old, poorly maintained pipelines.

In 2023, Severn Trent (UK) announced a £1 billion infrastructure investment to reduce water leakage and sewage outflows.

Thames Water recorded one of the highest leakage rates-630 million liters/day-indicating the urgent need for pipeline upgrades.

Significant drought impacts in South Sudan, Madagascar, Pakistan, Somalia, Sudan, Chad, and regions in Central America have forced governments to accelerate water infrastructure rehabilitation.

These challenges have increased the adoption of leak-resistant pipes and advanced pipe fusion machines.

2. Surge in Oil & Gas Infrastructure Investments

Rising global energy demand has pushed governments to expand and modernize oil & gas networks.

Turkmenistan-Afghanistan-Pakistan-India (TAPI) Gas Pipeline Project saw new progress with joint implementation agreements in 2023.

Taqa Arabia (Egypt) created a joint venture with a Saudi entity to build and maintain new gas pipelines.

These developments require high-quality fusion and welding equipment for pipeline installation, boosting the pipe jointing machine market.

3. Technological Advancements in Pipe Fusion Equipment

Leading manufacturers are incorporating:

Intelligent operator interfaces

Automatic temperature control systems

Digital pressure monitoring

Real-time data logging

Noise-free hydraulic mechanisms

Hydraulic automatic HDPE fusion machines capable of handling 90mm to 1000mm pipes are witnessing significant adoption due to their reliability and low maintenance requirements.

4. Growing Industrial and Municipal Infrastructure Development

Widespread urbanization in Asia Pacific, Africa, and Latin America has resulted in:

New wastewater treatment facilities

Sewerage network expansion

Renewable energy pipeline additions

Smart city pipeline construction

These projects demand reliable pipe joining solutions that ensure long-term system integrity.

Explore our report to uncover in-depth insights -

https://www.transparencymarketresearch.com/pipe-jointing-machine-market.html

Analysis of Key Players & Strategies

Global leaders in the pipe jointing machine market include:

Berlia Electricals Pvt. Ltd.

Victaulic Company

GF Piping Systems

McElroy Manufacturing

Uponor Oyj

Georg Fischer Ltd.

Gamson India Private Limited

agru Kunststofftechnik GmbH

ISCO Industries

Key Strategic Approaches

1. Product Innovation

Companies are developing more efficient welding machines with:

Advanced heating systems

Digital monitoring capabilities

Enhanced safety features

Faster cooling and setup time

GF Piping Systems' infrared welding machines and McElroy's automatic fusion systems are strong examples.

2. Prefabrication & Modular Implementation

Victaulic's prefabricated skids-introduced in 2024-showcase the industry's shift towards modular construction, reducing on-site installation time and improving safety.

3. Expanded Global Footprint

Players are expanding distribution channels across the Middle East, Asia Pacific, and Africa, where water supply and oil & gas projects are increasing rapidly.

4. Focus on Sustainable & Low-Maintenance Solutions

Manufacturers are prioritizing environmentally friendly, energy-efficient machines that produce:

Lower emissions

Minimal operational noise

Reduced maintenance costs

Longer service life

Market Challenges & Opportunities

Challenges

High initial investment costs for fully automatic welding machines.

Shortage of skilled operators, especially in developing regions.

Strict regulatory compliance for pipeline safety and installation standards.

Supply chain disruptions affecting steel, electronic components, and machine parts.

Opportunities

Rapid urbanization in India, China, and African nations requiring new pipeline networks.

Water infrastructure modernization driven by leakage control mandates.

Growing transition to HDPE pipelines due to their durability and corrosion resistance.

Smart pipeline technologies enabling connected welding equipment with real-time diagnostics.

Expansion of LNG, hydrogen, and alternative fuel pipelines, opening new market avenues.

Recent Developments

May 2024 - GF Piping Systems showcased new welding systems, valves, pressure management tools, and repair solutions at IFAT Munich 2024.

February 2024 - Victaulic Company presented its advanced pipeline flow control systems at the Big 5 Construct Saudi exhibition.

Many players have invested heavily in digitalization, automation, and hydraulic improvements.

Investment Landscape and ROI Outlook

Investment in the pipe jointing machine market is considered medium-risk with high long-term returns due to:

Strong Demand Drivers

Ongoing global investments in water infrastructure

Expansion of oil & gas networks

Growing chemical and agricultural pipeline projects

Growing Shift to High-Performance HDPE Pipes

HDPE and PE pipes are increasingly replacing metal pipelines due to corrosion resistance and lower lifetime costs-boosting demand for advanced fusion machines.

ROI Outlook

ROI for manufacturers: Positive due to rising investments in automation technologies.

ROI for buyers (contractors/utilities): High, because durable pipe joints reduce maintenance and leakage costs over decades.

Regional Opportunity Hotspots

North America: Mature but high-value oil & gas pipeline sector.

Asia Pacific: Fastest-growing due to smart city projects and agricultural pipeline expansions.

Middle East: Rapid investments in desalination, oil & gas, and district cooling pipelines.

Market Segmentation

By Type

Manual

Semi-automatic

Fully Automatic

By Jointing Range

Up to 100 mm

100 mm to 200 mm

200 mm to 300 mm

300 mm to 400 mm

Above 400 mm

By Power

Up to 3.5 kW

3.5 kW to 4.5 kW

4.5 kW to 5.5 kW

Above 5.5 kW

By Weight

Up to 60 Kg

60 Kg to 100 Kg

100 Kg to 150 Kg

150 Kg to 200 Kg

Above 200 Kg

By Distribution Channel

Direct Sales

Indirect Sales

Regional Outlook

North America - Leading Region

North America dominated the market in 2023, driven by:

Large-scale oil & gas pipeline expansions

High adoption of HDPE fusion technologies

Presence of major industry players

The U.S. recorded 36.35 Tcf of dry natural gas production in 2022, a record high, reinforcing demand for pipeline infrastructure.

Europe

Strong adoption due to:

Water leakage management strategies

Strict environmental regulations

Replacement of aging pipelines in the U.K., Germany, France, and Italy

Asia Pacific

Fastest-growing region due to:

Massive investments in water supply networks

Agricultural infrastructure upgrades

Rising urbanization in China, India, and ASEAN countries

Middle East & Africa

Significant opportunities driven by:

Oil & gas infrastructure expansion

District cooling systems

Water desalination pipelines

South America

Steady growth supported by:

Municipal water infrastructure upgrades

Agricultural irrigation projects

Why Buy This Report?

Comprehensive analysis of market size, trends, and forecasts up to 2034

Detailed segmentation across type, jointing range, power, weight, and distribution channels

Regional breakdown across 25+ countries

Competitive landscape with profiling of top global players

Evaluation of growth drivers, challenges, and future opportunities

Investment and ROI insights for strategic decision-making

Up-to-date analysis on key market developments and technological innovations

This report serves as an essential resource for manufacturers, distributors, EPC contractors, water utilities, and oil & gas companies planning to invest in pipeline installation machinery.

Buy this Premium Research Report for exclusive, in-depth insights -

https://www.transparencymarketresearch.com/checkout.php?rep_id=86105

FAQs

1. What is the current size of the Pipe Jointing Machine Market?

The market was valued at US$ 3.0 billion in 2023 and is projected to reach US$ 5.1 billion by 2034.

2. Which region holds the largest market share?

North America is the leading region due to significant oil & gas pipeline activity and high adoption of advanced welding systems.

3. What are the main growth drivers?

Key drivers include water leakage reduction initiatives, oil & gas infrastructure investments, and technological advancements in pipe fusion systems.

4. Which segment is expected to grow the fastest?

The fully automatic pipe jointing machine segment, driven by its precision, efficiency, and ease of use.

5. Who are the major players in the market?

Major companies include Victaulic Company, GF Piping Systems, McElroy Manufacturing, Georg Fischer Ltd., and agru Kunststofftechnik GmbH, among others.

Explore Latest Research Reports by Transparency Market Research:

Wine Processing Equipment Market - https://www.transparencymarketresearch.com/wine-processing-equipment-market.html

Laser Marking Machine Market - https://www.transparencymarketresearch.com/laser-marking-machine-market.html

HVAC Filters Market - https://www.transparencymarketresearch.com/hvac-filters-market.html

Welded Pipe Market - https://www.transparencymarketresearch.com/welded-pipe-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pipe Jointing Machine Market Set to Reach USD 5.1 Billion by 2034, Driven by Water Infrastructure Upgrades and Oil & Gas Investments | TMR here

News-ID: 4307947 • Views: …

More Releases from Transparency Market Research

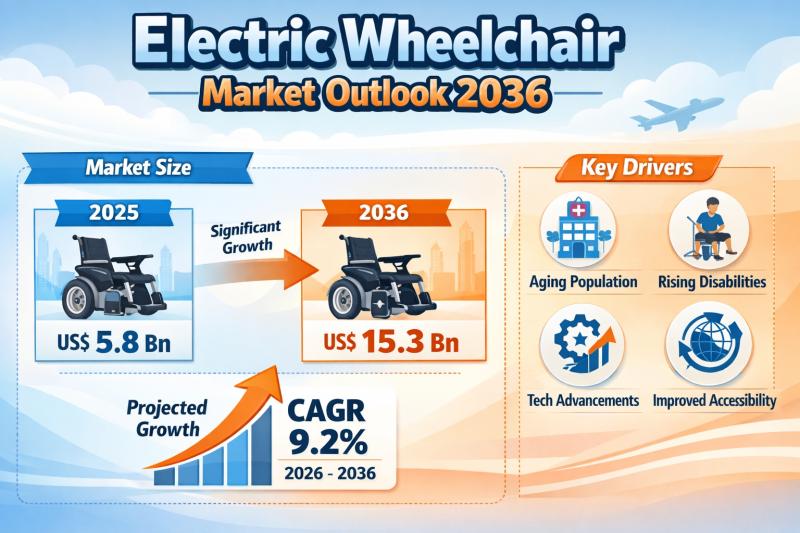

Electric Wheelchair Market Expanding at 9.2% CAGR Through 2036 - By Control Type …

The global electric wheelchair market continues to demonstrate strong and sustained growth, fueled by demographic transitions, technological innovation, and expanding healthcare access worldwide. Valued at US$ 5.8 billion in 2025, the market is projected to reach US$ 15.3 billion by 2036, expanding at a compound annual growth rate (CAGR) of 9.2% from 2026 to 2036.

Discover essential conclusions and data from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=4198

This robust trajectory reflects rising…

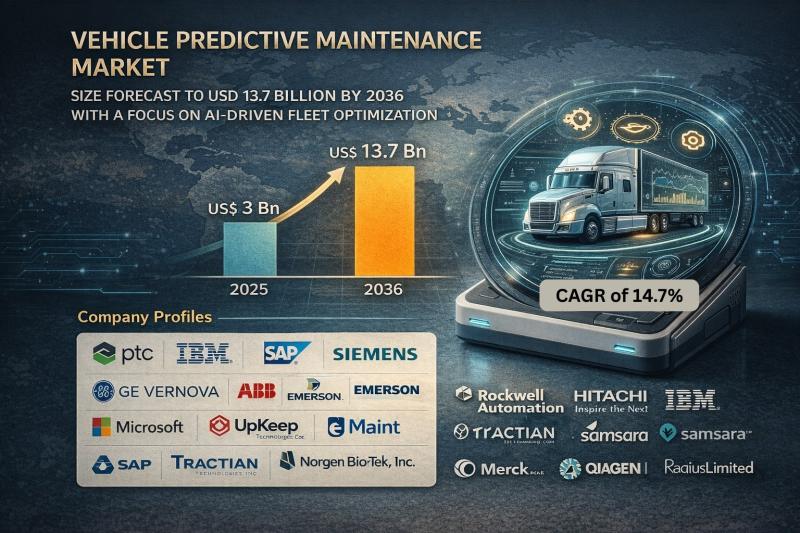

Vehicle Predictive Maintenance Market Size Forecast to USD 13.7 Billion by 2036 …

Vehicle Predictive Maintenance Market Outlook 2036

The global vehicle predictive maintenance market was valued at USD 3 Billion in 2025 and is projected to reach USD 13.7 Billion by 2036, expanding at a robust CAGR of 14.7% from 2026 to 2036. Market growth is driven by increasing adoption of connected vehicles, rising fleet digitalization, advancements in AI-driven analytics, and growing emphasis on minimizing vehicle downtime and maintenance costs.

👉 Get your sample…

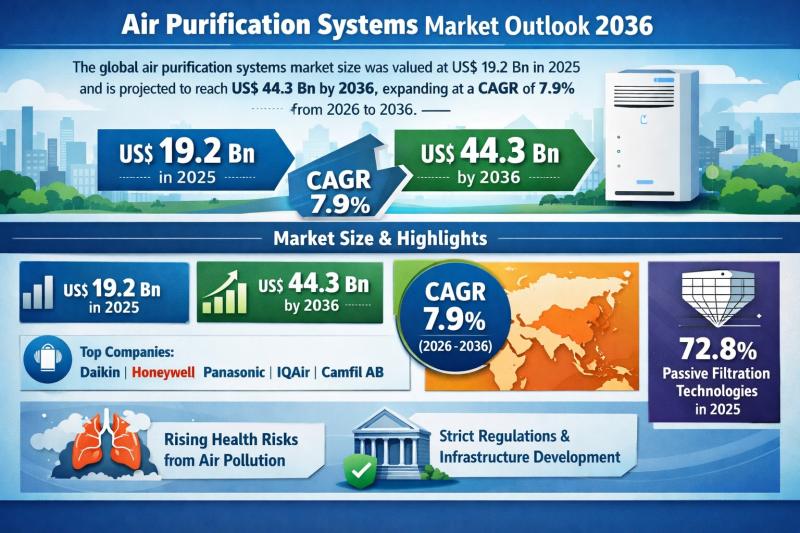

Global Air Purification Systems Market to Reach USD 44.3 Billion by 2036 at 7.9% …

The global Air Purification Systems Market was valued at US$ 19.2 Bn in 2025 and is projected to expand to US$ 44.3 Bn by 2036, registering a compound annual growth rate (CAGR) of 7.9% from 2026 to 2036. The market's upward trajectory reflects the structural shift in indoor air quality (IAQ) management, moving from discretionary consumer spending to mission-critical infrastructure investment.

With historical data available from 2021 to 2024, the industry…

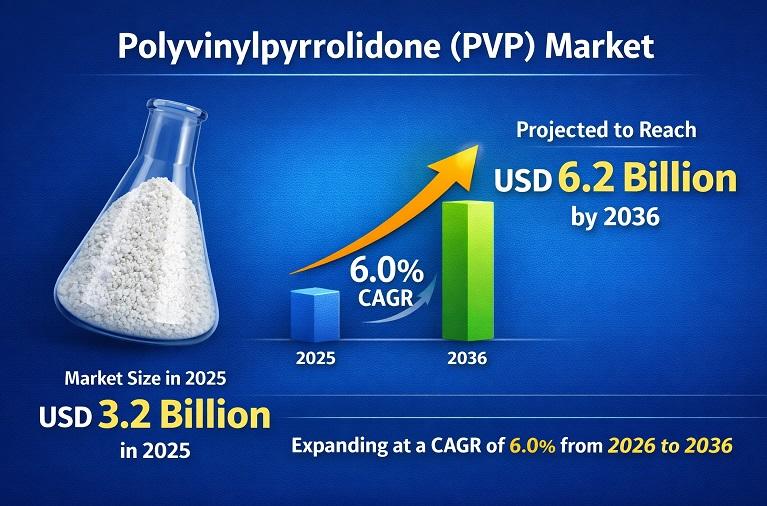

Polyvinylpyrrolidone (PVP) Market to Reach USD 6.2 Billion by 2036 Driven by Pha …

The Polyvinylpyrrolidone (PVP) Market was valued at around US$ 3.2 billion in 2025 and is projected to reach approximately US$ 6.2 billion by 2036, expanding at a steady CAGR of about 6.0% during the forecast period. This growth is primarily driven by rising demand from the pharmaceutical industry, where PVP is widely used as a tablet binder, solubilizer, and stabilizer, along with increasing consumption in cosmetics and personal care products…

More Releases for Pipe

How to choose Seamless Pipe vs Welded Pipe vs Spiral Welded Pipe

Seamless pipe, welded pipe, and spiral welded pipe are the three most common types. They may appear similar in appearance, but the differences are profound in essence, with the core distinction indeed stemming from manufacturing processes.

Comparison Table

FEATURE DIMENSION

SEAMLESS STEEL PIPE

LONGITUDINALLY WELDED PIPE

SPIRAL WELDED PIPE

Manufacturing Process

Solid billet piercing and rolling, no weld seam.

Steel plate/sheet is curved and welded along a longitudinal straight seam.

Steel strip is coiled at a spiral angle, forming…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…