Press release

FDM 3D Printing Material Market to Reach USD 1,872 Million by 2031 Top 20 Company Globally

This research focuses on fused deposition modeling (FDM) 3D-printing materials commonly sold as filaments and granules used in desktop and industrial FDM/FFF printers and on the commercial dynamics that govern their manufacture, supply chains and downstream demand. The report treats FDM materials as an industrial commodity that sits at the intersection of polymer chemistry, extrusion manufacturing and the hardware innovations of the printer makers. FDM materials range from commodity PLA and ABS to engineering thermoplastics (PETG, Nylon/PA, PC, PEEK) and composite blends (carbon- or glass-filled grades), and the industry is shaped by feedstock resin prices, compounding/additive know-how, extrusion line thruput, quality control and traceability (color, diameter, tolerance). Because material formulation drives part performance (mechanical, thermal, chemical resistance) and printer settings, material manufacturers work closely with printer OEMs and third-party ecosystem players (slicers, feeders, tool changers) to enable predictable production at scale.The 2024 global market size for FDM 3D-printing materials is USD 1,284 million with a projected compound annual growth rate of 5.5% through 2031, reaching market size USD 1,872 million by 2031. With an average selling price of USD 30,745 per metric ton, implies to roughly 41,762 tons of FDM material sold globally in 2024. Factory gross margin at 42.9%, factory gross profit per ton near USD 12,298 and a COGS per ton of approximately USD 18,447. A COGS breakdown is raw polymer feedstock, compounding/additives, energy & utilities, factory overhead & maintenance, direct labor, packaging & spooling, quality control & testing, logistics, regulatory/compliance, waste/rework. A single line full machine capacity production is around 1,300 ton per line per year. The downstream segment includes end-users and distribution channels: end-users cover consumer/hobbyists (for prototyping and DIY projects), educational institutions (for teaching and research), and industrial sectors (automotive, aerospace, medical, and consumer electronics for tooling, functional parts, and product iteration).

Latest Trends and Technological Developments

Tool-changer and multi-material innovations continue to be high-visibility drivers because they expand FDM use cases: Toms Hardware covered the surge of tool-changing FDM machines and Prusas re-entry into multi-tool systems on September 2025, noting multiple recent product announcements that expand multi-material printing capability. This trend increases demand for well-specified and compatible filament grades. Creality announced the K2 Pro CoreXY FDM printer on August 2025, emphasizing heated-chamber capability and compatibility with PPA-CF and other engineering filaments a hardware move that broadens marketable filament types and higher-margin engineering polymers. In late-September 2025, 3DPrint.com summarized developments in pellet-fed and large-format systems (e.g., new pellet/FGF lines and multi-material/upcycling announcements) on September 2025, which signal industry momentum toward higher throughput, lower per-kg material cost and more recycled feedstocks for FDM production. These technology pushes (multi-material heads, pellet extrusion, heated chambers) change material formulation and quality requirements, raising the bar for compounding and lot-control from filament suppliers.

Aerospace component manufacturer Collins Aerospace regularly purchases high-performance, flame-retardant ULTEM 9085 filament from Stratasys Direct Manufacturing for approximately $450 - $600 per kilogram to produce certified air ducting and cabin components. Similarly, automotive giant Ford Motor Company sources large volumes of carbon-fiber reinforced nylon (Onyx) from Markforged for $190 per kilogram to create robust jigs, fixtures, and custom tooling for their assembly lines. In the medical device sector, Johnson & Johnson procures sterile, biocompatible MED610 resin (for PolyJet, but illustrating the high-cost, specialized material niche) from Stratasys for over $3,000 per kilogram for surgical guides and prototypes.

The product, Stratasys ASA thermoplastic, is used by Siemens Mobility for the manufacturing of end-use, exterior train panel prototypes. These large-format parts are 3D printed and installed on full-scale train carriages for aerodynamic testing and fit-and-finish validation at their German facilities. The use of ASA, which costs approximately $110 per kilogram, allows Siemens to avoid the high cost and long lead times of traditional tooling for these massive components, saving an estimated $200,000 and 12 weeks of development time per train model.

Asia is a critical centre for both upstream polymer production and downstream FDM adoption. Large chemical firms in Asia supply base resins and specialty modifiers; concurrent growth in local OEM printers (from consumer to industrial) has nurtured regional filament brands and contract compounding/extrusion businesses. China remains the largest single manufacturing hub for commodity filament extrusion as well as for low-cost desktop printers, while Japan and South Korea host specialized engineering-grade compounders. Market intelligence shows varied CAGR and segmentation across Asian markets, with stronger industrial adoption in advanced manufacturing clusters and a vigorous hobby/education sector in urban coastal centers. The continents value chain advantages proximity to resin suppliers, skilled mechanical OEM clusters, and established logistics networks help compress lead times but also intensify competition on price. Recent regional analyses and market trackers confirm Asian leadership in volume and a growing shift toward higher-performance and recycled filament blends.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5406118

FDM 3D Printing Material by Type:

Thermoplastics

Composites

Metal-Filled Filaments

High-Performance Polymers

FDM 3D Printing Material by Product Category:

Standard Strength

High Strength

Flexible

FDM 3D Printing Material by Market Segment:

Matte Finish

Glossy Finish

FDM 3D Printing Material by Features:

High Temperature Resistance

Eco Friendly

Heat Resistant

Easy to Print

Others

FDM 3D Printing Material by Shape:

Solid Filaments

Pelletized Materials

Composite Reinforced Strands

Flexible Filament Coils

Others

FDM 3D Printing Material by Application:

Aerospace

Automotive

Consumer Goods

Medical Devices

Education and Research

Global Top 20 Key Companies in the FDM 3D Printing Material Market

BASF

Stratasys

Ultimaker

MakerBot

Formlabs

Polymaker

Proto-Pasta

eSUN

Markforged

ColorFabb

Airwolf

Magigoo

Infinite Material Solution

Bamboo Lab

IGUS

NinjaFlex

EOS GmbH

AON3D

FELIXprinters

Zortrax

Regional Insights

Within ASEAN, adoption rates are uneven: Singapore and Malaysia show faster industrial uptake for end-use parts and healthcare/biomedical pilots; Thailand and Vietnam exhibit growing integration into regional manufacturing networks; Indonesia presents rapidly expanding maker communities, education adoption and a nascent industrial user base. Indonesias local filament market and small-to-medium filament producers are growing, supported by rising desktop printer penetration and increased interest from OEMs in local materials sourcing. Regional market reports place Southeast Asias industrial 3D-printing activity as a high-growth area, with industrial and large-format projects (construction, tooling, automotive subcomponents) pulling in more engineering filaments and pellet-fed production. These ASEAN dynamics point to a two-track market: steady volume growth for commodity filaments (PLA, PETG, ABS) driven by education/hobby, and faster percentage growth for engineering and recycled grades used by industry pilots and localized manufacturing hubs.

Material producers face several persistent challenges. Feedstock resin price volatility and tariffs/transport cost shocks can compress margins because resins typically account for the majority of COGS. Quality consistency filament diameter tolerance, moisture content, and additive dispersion is essential but costly to guarantee at scale; customers will pay premiums for traceability and certified batches, but only up to a point. Regulatory and sustainability pressures are increasing: buyers ask for recycled or biodegradable grades, driving R&D and sometimes higher production costs. Competition from low-cost manufacturers squeezes prices, while new hardware capabilities (e.g., higher temperature printers, tool changers, pellet extruders) demand more advanced formulations raising barrier to entry for simple commodity producers.

Producers should prioritize three concurrent strategies: consolidate quality & traceability (certified batches, tighter QC to win OEM partnerships); expand into higher-margin engineering/composite blends and recycled-content grades (to capture industrial demand), and optimize capacity via modular extrusion lines. Regional partnerships with printer OEMs in Asia/ASEAN will shorten validation cycles for new materials. Pricing power is strongest where materials are co-developed with OEMs for validated industrial use; in contrast, commodity PLA/PETG competition will continue to be price-sensitive. Investors and strategic buyers should therefore look for companies with proven QC processes, existing OEM relationships, and flexible production footprints.

Product Models

Fused Deposition Modeling (FDM) 3D printing is one of the most widely used additive manufacturing technologies, known for its accessibility, material versatility, and cost efficiency.

Thermoplastics are the most common materials used in FDM 3D printing, known for their easy processing, recyclability, and wide range of mechanical properties. Typical thermoplastics include PLA, ABS, PETG, and TPU. Notable products include:

PLA+ - eSUN: Enhanced polylactic acid filament with improved toughness and surface finish, ideal for general-purpose prototyping.

ABS-M30 - Stratasys: Industrial-grade ABS with higher strength and thermal resistance, suitable for functional prototypes.

Ultrafuse PLA - BASF Forward AM: A premium PLA filament designed for consistent layer adhesion and surface quality.

Tough PLA - Ultimaker: Engineered to offer durability and higher impact strength while maintaining PLAs printability.

3D850 PLA - NatureWorks: Biopolymer-based filament optimized for faster printing speeds and minimal warping.

Composite filaments are thermoplastics reinforced with fibers such as carbon, glass, or wood to enhance mechanical strength, stiffness, and aesthetic properties. Examples include:

CarbonX Carbon Fiber PLA - 3DXTech: PLA infused with chopped carbon fibers for increased rigidity and dimensional stability.

Onyx - Markforged: Nylon-based composite with micro-carbon reinforcement for high strength-to-weight ratio parts.

ColorFabb XT-CF20 - ColorFabb: Co-polyester with 20% carbon fiber content for improved stiffness and heat resistance.

Proto-pasta Carbon Fiber PLA - Proto-pasta: Provides lightweight, strong parts with a matte finish and minimal warp.

NylonX - MatterHackers: Nylon reinforced with carbon fibers for superior durability and toughness.

Metal-filled filaments are thermoplastics blended with fine metal powders such as bronze, copper, or stainless steel to mimic the weight, appearance, and luster of real metals while remaining printable on standard FDM printers. Notable products include:

BronzeFill - ColorFabb: PLA infused with bronze powder for metallic look and heavy weight.

Stainless Steel PLA - Proto-pasta: PLA base blended with fine steel powder for magnetic and metallic aesthetics.

Ultrafuse 316L - BASF: Metal-polymer composite filament designed for debinding and sintering into solid stainless steel.

Metal Composite PLA - The Virtual Foundry: Metal-loaded filament allowing post-processing into near-pure metal parts.

Copper Metal PLA - Polymaker: Combines PLA with copper powder for conductivity and metallic aesthetics.

High-performance polymers are advanced engineering thermoplastics designed for extreme environments requiring high strength, heat resistance, and chemical stability, often used in aerospace, automotive, and medical sectors. Notable products include:

Ultem 9085 - SABIC: PEI-based filament with exceptional flame, smoke, and toxicity ratings for aerospace use.

PEEK - Victrex: High-performance polymer with outstanding mechanical and thermal resistance up to 250°C.

PEKK-A - Arkema: Semi-crystalline polymer offering strength, chemical resistance, and low flammability.

Antero 840CN03 - Stratasys: PEKK-based ESD-safe material suitable for aerospace and electronic applications.

PPSU - Solvay: High-temperature amorphous polymer with excellent chemical and hydrolysis resistance.

FDM materials are maturing from a largely hobbyist and prototyping product into a more segmented industrial market where performance, traceability and compatibility with next-generation FDM hardware matter. With a 2024 base of USD 1,284 million and the unit volumes implied by the USD 30,745/ton price point, the market is substantial and geographically concentrated in Asia for volume, while higher-value growth pockets appear across ASEANs industrial adopters. Manufacturers and investors who prioritize validated engineering grades, strong QC, and scalable extrusion capacity positioned near OEM clusters will be best placed to convert the modest overall CAGR into higher profit growth.

Investor Analysis

This report highlights several investor-relevant signals. What to watch: product mix, margins per ton, and capacity utilization. How investors can act: prioritize investments in firms that demonstrate OEM co-development, secure resin supply agreements (hedging or vertical integration), and show evidence of premium pricing for certified, high-performance or recycled grades. Why this matters: the filament markets combination of predictable per-ton economics, rising hardware capability (tool changers, heated chambers, pellet lines) and geographic concentration in Asia/ASEAN creates a runway for margin expansion if manufacturers can move up the value chain; conversely, commodity price competition and resin volatility are real downside risks so capital allocation should favor firms with quality differentiation and flexible capacity.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5406118

5 Reasons to Buy This Report

It consolidates a market snapshot anchored to a 2024 base size of USD 1,284M and reconciles unit volumes using the industry price you supplied.

It explains manufacturer economics (COGS breakdown, per-ton gross profit and margin benchmarking) so buyers understand factory-level profitability.

It offers focused Asia & ASEAN regional insight critical because volume and OEM influence are concentrated there.

It summarizes recent technology and product-level developments (tool changers, pellet printing, heated-chamber printers) with dated news references to inform timing and R&D bets.

It lists strategic priorities and investor actions practical guidance for deal sourcing, due diligence and portfolio construction.

5 Key Questions Answered

What is the 2024 market size and the implied volume at the given per-ton price?

How do typical producer COGS break down by input and what is a factory-level gross profit per ton under practical margins?

Which Asia and ASEAN markets show the strongest near-term demand and why is Indonesia specifically relevant?

What recent hardware and material technology developments will change filament demand profiles?

Which companies dominate the filament/material landscape and how do chemical majors and specialty brands differ strategically?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global FDM 3D Printing Material Market Research Report 2025

https://www.qyresearch.com/reports/4432851/fdm-3d-printing-material

Global FDM 3D Printing Material Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/4446775/fdm-3d-printing-material

Global FDM 3D Printing Material Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5065125/fdm-3d-printing-material

FDM 3D Printing Material - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5406118/fdm-3d-printing-material

Global 3D Printed Materials Market Research Report 2025

https://www.qyresearch.com/reports/4159770/3d-printed-materials

Global ESD 3D Printing Material Market Research Report 2025

https://www.qyresearch.com/reports/4431329/esd-3d-printing-material

Global 3D Printing Raw Material Market Research Report 2025

https://www.qyresearch.com/reports/4042017/3d-printing-raw-material

Global 3D Printing PMMA Material Market Research Report 2025

https://www.qyresearch.com/reports/4433618/3d-printing-pmma-material

Global 3D Printing PLA Materials Market Research Report 2025

https://www.qyresearch.com/reports/4433617/3d-printing-pla-materials

Global Nylon 3D Printing Material Market Research Report 2025

https://www.qyresearch.com/reports/3798306/nylon-3d-printing-material

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release FDM 3D Printing Material Market to Reach USD 1,872 Million by 2031 Top 20 Company Globally here

News-ID: 4262352 • Views: …

More Releases from QY Research

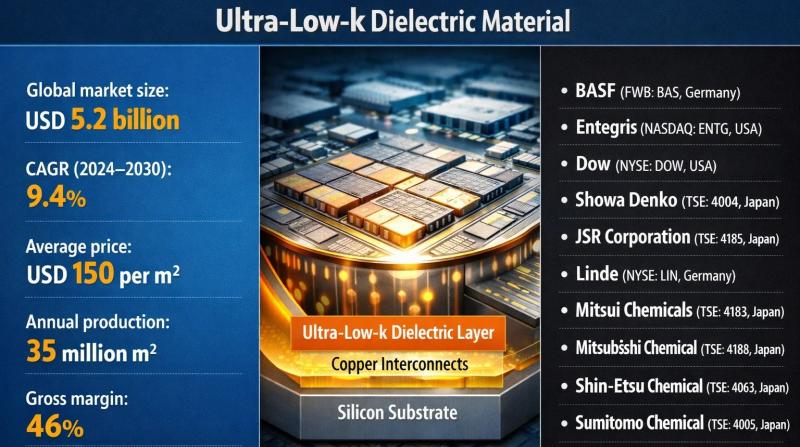

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for FDM

Flight Data Monitoring Market Report 2018: Segmentation by Solution Type (On Boa …

Global Flight Data Monitoring market research report provides company profile for Curtiss Wright (US), Teledyne Controls LLC (US), Safran Electronics & Defense (US), Guardian Mobility (US), Flight Data Services Ltd. (US), Scaled Analytics Inc. (US) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth…

Enjoy flawless downloads with FDM!

FDM team has released Free Download Manager 5.1 for Mac!

Free Download Manager is developed to increase downloads speed up to 10 times which is possible due to multi-thread acceleration system. FDM provides users with a great number of features and modern user interface. It's compatible with all latest versions of Mac OS. In combination with the extension, the software is an all-in-one tool that gives its users freedom of…

FDM Honours First FDM MSc Programme Graduate

The UK’s leading IT graduate employer, FDM Group, has honoured its first graduate from the FDM MSc Programme at the Brighton Dome.

The graduation ceremony, held on 28th July, saw FDM Trainer Kevin Wright accept his Master’s in Applied Computer Science from University of Brighton. FDM fully-funded the course, which he studied via distance learning alongside his day job with the company.

Developed in partnership with University of Brighton,…

FDM Group continues to champion women worldwide

Top Ten IT Employer for Women, FDM Group, has today revealed a further increase to its growing female workforce. The IT services provider, whose wider industry has a mere 17% average of females in the sector, has risen above the statistic announcing that 24% of its global workforce are women.

Of this achievement, FDM’s Chief Operating Officer, Sheila Flavell, said, “I am delighted that we have reached such a landmark…

FDM Group supports Movember for another year

International IT services provider, FDM Group, is once again taking part in the biggest charity drive for men in the country, Movember.

During November each year, Movember is responsible for the sprouting of moustaches on thousands of men’s faces in the UK and around the world. The aim of which is to raise vital funds and awareness for men’s health, specifically prostate cancer and testicular cancer. Last year, over £75 million…

FDM Group Granted Supplier Excellence Award

International IT services provider, FDM Group, has been granted a Supplier Excellence Award at the 2011 LeasePlan UK Supplier Conference this year.

FDM has been servicing LeasePlan for over two years and has built a close working relationship around LeasePlan's Testing environments. This award recognises FDM's flexible test delivery on a significant new LeasePlan end client offering called SalaryPlan - a Salary Sacrifice Company Car scheme for clients employees.

FDM…