Press release

COSCOM takes over the CNC digitization of the HOMAG Group - from Germany to Shanghai

At the Schopfloch site in the northern Black Forest, around 1,500 employees are responsible for a wide range of products ( (C) In Schopfloch in the northern Black Forest, 1,500 employees manufacture machines for sizing and edge processing)

Four German production sites of the HOMAG Group - including Schopfloch and Herzebrock-Clarholz - as well as the Chinese headquarters in Shanghai will soon have one thing in common: The CNC machines used for the production of drilling, dowel insertion and edge banding machines as well as for panel cutting, among other things, will be networked and managed across the board. The contract for this large-scale digitization project was awarded to COSCOM Computer GmbH.

The project was initially triggered by the replacement of the previous tool and NC program management system, which was operated differently at the various sites and was no longer technologically up-to-date.

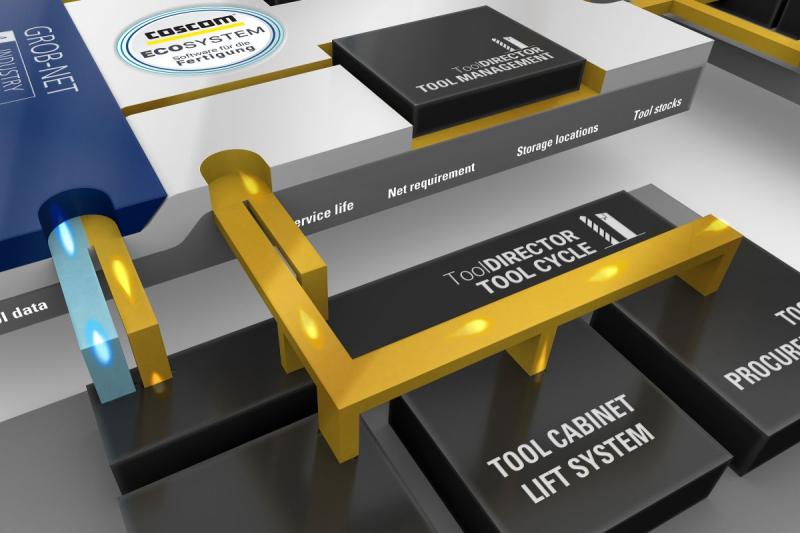

The minimum requirement of the HOMAG Group was the transfer of existing tool and production data to the COSCOM Eco-System - a modular application system based on a central data platform. In this system, ToolDIRECTOR VM (Virtual Machining) supports tool management - from the creation of the digital twin and production simulations to stock management and communication with ERP/PPS systems. FactoryDIRECTOR VM collects all relevant production data from the various systems, links files in the file system and stores information in the central database.

"The customer's minimum requirements were clearly exceeded by our technical implementation skills. We analyzed potential improvements and identified the most effective project steps in order to implement a uniform solution for five locations. The project also had to be implemented without any delays in production," says Henning Felber, Process Consultant at COSCOM, looking back.

David V?gele, project manager at the HOMAG site in Schopfloch, has positive feedback: "COSCOM has also succeeded in generating significantly greater transparency in the management of our tools and in the production processes. The data can be used across all systems - with a central data source in the COSCOM Eco-System that can be updated at any time."

Further information about COSCOM can be found at www.coscom.de.

LEAD Industrie-Marketing GmbH

Hauptstra?e 46

83684 Tegernsee

Germany

http://www.lead-industrie-marketing.de

Herr Andr? Ge?ner

+49 8022 91 53 188

+49 8022 91 53 189

info@lead-industrie-marketing.de

About COSCOM Computer GmbH:

COSCOM - Software, consulting and projects - for digitization in machining production

COSCOM is a leading software system house that standardizes, networks and optimizes production data in the machining industry. The connection between the ERP system and production is a top priority. Projects in tool management, tool and data management, CAD/CAM and machine simulation as well as Infopoint / DNC networking are realized around the CNC machine. Competence in consulting and target-oriented project management are the basis for joint success - one contact, one responsibility, one successful project!

The networking of COSCOM software products creates different, interface-free process solutions for the networking of all participants on the store floor. The main benefits for the user are a more efficient machining process with better product quality, greater adherence to deadlines and lower production costs. COSCOM offers everything from a single source - from software development, process consulting, sales and project management with implementation through to training/coaching, service and support.

COSCOM has been active on the market since 1978 and is therefore one of the most experienced providers in the field of production automation and digitization in machining. Around 6,000 COSCOM solutions and around 25,000 machines and systems are currently networked with COSCOM systems throughout Europe. COSCOM as a partner means investment security, future security and innovation security for the customer.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release COSCOM takes over the CNC digitization of the HOMAG Group - from Germany to Shanghai here

News-ID: 4248640 • Views: …

More Releases from COSCOM Computer GmbH

COSCOM and Kiel University of Applied Sciences start a partnership

From the winter semester 2025/26, Kiel University of Applied Sciences will be offering new practical exercises for students in cooperation with COSCOM Computer GmbH. Prof. Dr. Henning Strau?, Managing Director of the Institute of Production Engineering and CIM Technology Transfer and Head of the Smart Factory and Shopfloor IT working group, will actively apply the software modules of the COSCOM ECO system in teaching and research cases.

Embedded in the shopfloor…

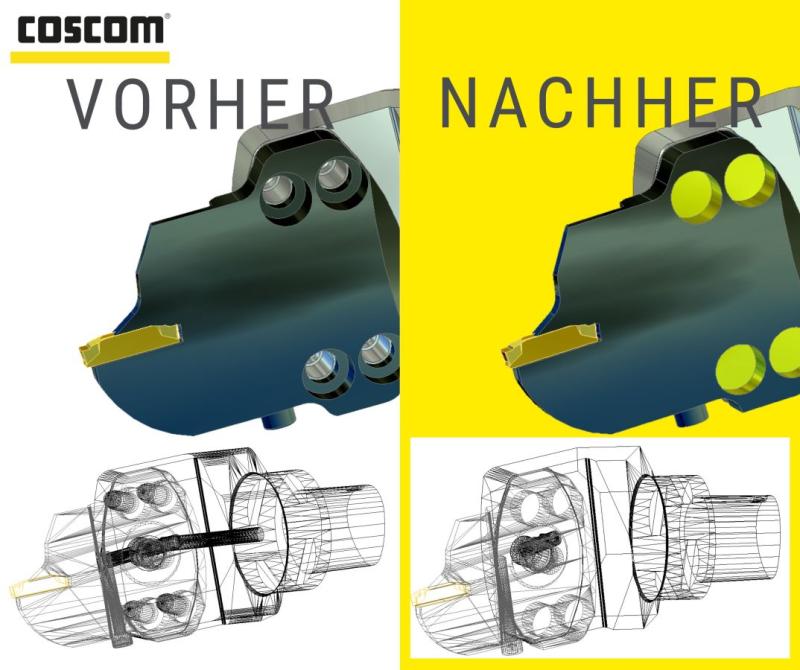

EMO 2025: COSCOM presents new module for optimizing CAD tool data

EMO 2025 will open its doors in Hanover from September 22 to 26, 2025. COSCOM, provider of digitalization solutions in machining technology, will be represented at two locations: in Hall 6, Stand A24 (joint stand "AI + Digitalization") and at the stand of innovation partner Spatial Corp, the subsidiary of Dassault Systemes, in Hall 6, C37.

Since 1978, COSCOM Computer GmbH has been a leading software system house for successful products…

Raising the data treasure: COSCOM ECO-System platform takes legacy data to a new …

Many manufacturing companies have a wealth of data that has been built up over the years - particularly in the area of tool management. In practice, however, the potential of this legacy data often remains untapped because it lies dormant in isolated solutions, is inconsistent or is difficult to access. With its ECO platform, COSCOM, the digitalization specialist for the store floor, offers a powerful solution for consolidating and processing…

Leading position of tool management in digitized machining with COSCOM

Tool data management, previously often referred to simply as a "tool database", has long since evolved from a pure management tool for tool master data to a strategic enabler of digital CNC manufacturing. In traditional solutions, the focus was usually on providing data for CAD/CAM systems, simulations or simple warehouse management. However, the challenges of digitalization and automation in the production environment are more complex today - and the requirements…