Press release

Leading position of tool management in digitized machining with COSCOM

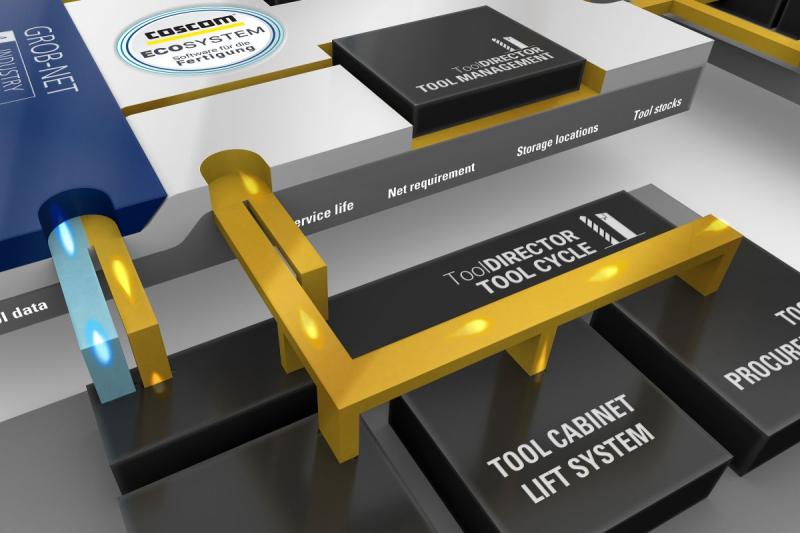

Modern tool data management does more than just master data and inventory management. (© COSCOM Computer GmbH)

In recent years, the COSCOM consulting team has held intensive discussions with numerous manufacturing companies in the DACH region. The conclusion was clear: conventional tool databases are no longer sufficient for modern, digitally driven production. Instead, what is needed is a holistic, integrative process solution that makes data consistently available from the ERP system to the CNC machine and networks all relevant players and systems with one another.

Based on these requirements, COSCOM - an expert in the digitalization of manufacturing for decades - has consistently developed its tool data management software further. The result: a powerful, modular ECO system that combines various software modules into a central data and process management system. Depending on the digitization focus, the system can be individually configured and flexibly expanded - and thus forms the basis for a seamless flow of information on the store floor.

At the heart of the COSCOM ECO system is a central data platform that can not only be equipped with COSCOM's own applications, but can also be seamlessly integrated into existing IT landscapes and third-party systems thanks to the integrated REST API. The applications from COSCOM impress with their sophisticated logic in tool data and production data management and enable relevant information to be linked, further processed and made available in context - for example for simulation, planning, logistics or quality assurance.

CNC automation as a new challenge for tool and tool data provision

Digitally networked tool data management is becoming increasingly important, particularly in the context of the increasing automation of CNC machines. Automation solutions with host computer systems open up new scope - at the same time, the requirements for data availability and process reliability are growing. This is where the COSCOM ECO system provides the digital bridge between automation and physical tool provision. The digital tool list of an NC program defines the specific requirement, automatically checks the machine's current magazine stock and uses this to determine the actual net tool requirement. Missing tools are ordered digitally, the measurement is automated and all actual data is transmitted to the system as a "digital twin". In this way, the entire process is digitally monitored, visualized and documented.

Another added value: all process data, movement profiles and statuses are stored centrally and are available for evaluations, optimizations or AI-based analyses. This makes the ECO system not only an efficiency driver, but also an intelligent learning and control mechanism for production.

The future of production is digital. And starts with intelligent tool data management

Thanks to numerous successfully implemented customer projects, the COSCOM ECO system has established itself as a flexible solution that can be used independently of existing IT structures, tool storage systems or measuring equipment. Thanks to its open architecture and centralized data storage, the system is future-proof, scalable and ready to significantly support the digital transformation in CNC manufacturing.

Further information can be found at www.coscom.de

LEAD Industrie-Marketing GmbH

Hauptstraße 46

83684 Tegernsee

Germany

http://www.lead-industrie-marketing.de

Herr André Geßner

+49 8022 91 53 188

+49 8022 91 53 189

info@lead-industrie-marketing.de

About COSCOM Computer GmbH:

COSCOM - Software, consulting and projects - for digitization in machining production

COSCOM is a leading software system house that standardizes, networks and optimizes production data in the machining industry. The connection between the ERP system and production is a top priority. Projects in tool management, tool and data management, CAD/CAM and machine simulation as well as Infopoint / DNC networking are realized around the CNC machine. Competence in consulting and target-oriented project management are the basis for joint success - one contact, one responsibility, one successful project!

By networking the COSCOM software products, different, interface-free process solutions are created for networking all participants on the store floor. The main benefits for the user are a more efficient machining process with better product quality, greater adherence to deadlines and lower production costs. COSCOM offers everything from a single source - from software development, process consulting, sales and project management with implementation through to training/coaching, service and support.

COSCOM has been active on the market since 1978, making it one of the most experienced providers in the field of production automation and digitization in machining. Around 6,000 COSCOM solutions and around 25,000 machines and systems are currently networked with COSCOM systems throughout Europe. COSCOM as a partner means investment security, future security and innovation security for the customer.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Leading position of tool management in digitized machining with COSCOM here

News-ID: 4003634 • Views: …

More Releases from COSCOM Computer GmbH

COSCOM takes over the CNC digitization of the HOMAG Group - from Germany to Shan …

The HOMAG Group, part of the D?rr Group, is one of the leading suppliers of woodworking machinery and has a global market share of over 30 percent. The product portfolio includes machines, software and services along the process chain for furniture and construction element production. A groundbreaking decision was made in 2024: Five production sites are to be uniformly digitalized - with COSCOM Eco-System.

Four German production sites of the HOMAG…

COSCOM and Kiel University of Applied Sciences start a partnership

From the winter semester 2025/26, Kiel University of Applied Sciences will be offering new practical exercises for students in cooperation with COSCOM Computer GmbH. Prof. Dr. Henning Strau?, Managing Director of the Institute of Production Engineering and CIM Technology Transfer and Head of the Smart Factory and Shopfloor IT working group, will actively apply the software modules of the COSCOM ECO system in teaching and research cases.

Embedded in the shopfloor…

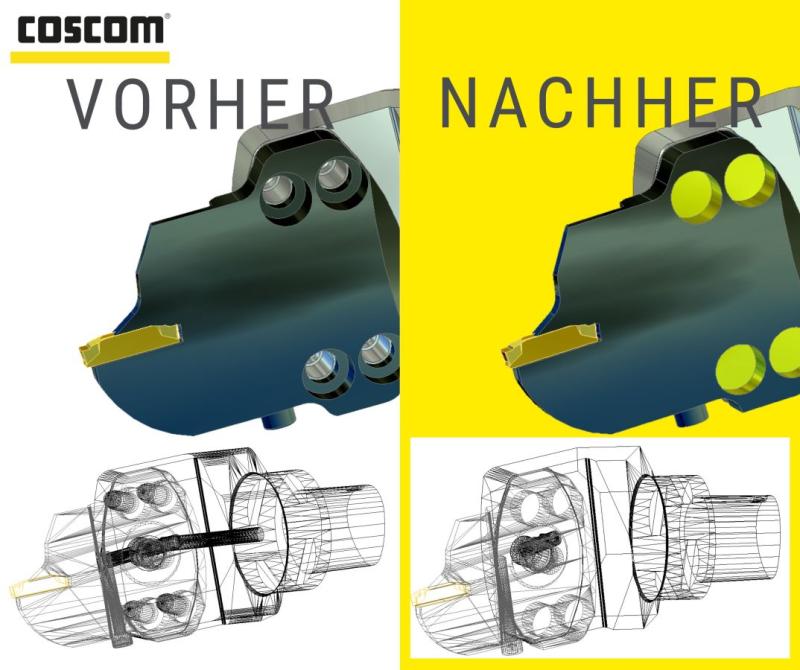

EMO 2025: COSCOM presents new module for optimizing CAD tool data

EMO 2025 will open its doors in Hanover from September 22 to 26, 2025. COSCOM, provider of digitalization solutions in machining technology, will be represented at two locations: in Hall 6, Stand A24 (joint stand "AI + Digitalization") and at the stand of innovation partner Spatial Corp, the subsidiary of Dassault Systemes, in Hall 6, C37.

Since 1978, COSCOM Computer GmbH has been a leading software system house for successful products…

Raising the data treasure: COSCOM ECO-System platform takes legacy data to a new …

Many manufacturing companies have a wealth of data that has been built up over the years - particularly in the area of tool management. In practice, however, the potential of this legacy data often remains untapped because it lies dormant in isolated solutions, is inconsistent or is difficult to access. With its ECO platform, COSCOM, the digitalization specialist for the store floor, offers a powerful solution for consolidating and processing…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…