Press release

Spot Welding Robots Market, Revolutionizing Precision and Productivity in Modern Manufacturing

The Spot Welding Robots Market is witnessing accelerated growth as industries worldwide embrace automation to improve production efficiency, consistency, and safety. Spot welding robots have become an integral part of modern manufacturing, especially within high-volume industries such as automotive, metal fabrication, and electronics. These robots are used to join two or more metal surfaces by applying pressure and heat from an electric current at precise spots, ensuring superior weld strength and uniformity. Over the past decade, increasing labor costs, the shortage of skilled welders, and the global drive toward Industry 4.0 automation have positioned robotic welding systems as essential assets for manufacturing competitiveness.Get a Sample PDF Brochure of the Report: https://www.persistencemarketresearch.com/samples/24562

The rapid adoption of automation across industries, coupled with advancements in sensor technology, machine vision, and artificial intelligence, is expected to further enhance robot precision, reliability, and adaptability. The automotive and transportation sector continues to lead market adoption, accounting for the largest share due to its extensive use of spot welding robots in vehicle body assembly lines. Geographically, the Asia-Pacific region remains the largest and fastest-growing market, supported by robust automotive production, industrial expansion, and rising labor costs that encourage automation investments across China, Japan, South Korea, and India.

Key Highlights from the Report

• Automotive manufacturing continues to dominate the demand for spot welding robots globally.

• Asia-Pacific holds the largest market share and remains the fastest-growing region.

• Technological innovations such as AI, machine vision, and collaborative welding systems are reshaping industry dynamics.

• High initial investment costs remain a challenge for small and medium-sized enterprises.

• Future growth opportunities lie in flexible robotic welding systems and SME-focused automation solutions.

Market Segmentation

The Spot Welding Robots Market is segmented based on robot type, payload capacity, end-user industry, and geography. Each segment plays a distinct role in shaping the industry's evolution and reflects the diversity of applications across different sectors.

By Robot Type

The market is primarily divided into articulated robots, SCARA robots, Cartesian robots, and collaborative robots (cobots). Articulated robots dominate the market due to their flexibility, precision, and ability to perform complex welding tasks in confined spaces. These multi-jointed robots are widely used in the automotive industry for assembling body-in-white components. Collaborative robots, on the other hand, are gaining traction among small and mid-sized manufacturers. They are designed to safely operate alongside human workers, offering flexibility for mixed production lines and quick reprogramming for different welding tasks. The rise of cobots represents a significant shift toward safer, more adaptive, and cost-efficient robotic welding solutions.

By Payload Capacity

Spot welding robots can also be categorized by their payload capacity-typically segmented into light-duty (up to 50 kg), medium-duty (50-150 kg), and heavy-duty (above 150 kg) systems. Medium-duty robots dominate the market, as they are ideal for handling typical automotive body panels and medium-gauge metal components. Heavy-duty robots are used in industrial and construction equipment manufacturing, where thicker materials and larger assemblies require higher strength and reach. Light-duty robots are expanding in demand within consumer electronics and appliance manufacturing sectors where smaller welds and precision assembly are needed.

By End-User Industry

The automotive and transportation sector accounts for the largest market share, driven by extensive applications in car body assembly, chassis manufacturing, and component fabrication. The use of spot welding robots enables automakers to achieve superior weld consistency, reduce defects, and increase production speed, all of which are critical for competitiveness in a cost-sensitive market. Beyond automotive, electronics manufacturing, metal fabrication, aerospace, and construction industries are also emerging as significant users. In electronics and battery manufacturing, robots are used for precision joining of thin metal sheets and components in electric vehicle (EV) battery packs-an area expected to see exponential growth in the coming years.

By Geography

Geographically, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Among these, Asia-Pacific stands out as the largest market, thanks to rapid industrialization, a vast manufacturing base, and strong government initiatives promoting smart factories and robotics adoption. North America follows closely, with steady adoption in the automotive and aerospace industries, while Europe continues to innovate in robotic integration and sustainable manufacturing practices.

Read More In Detail: https://www.persistencemarketresearch.com/market-research/spot-welding-robots-market.asp

Regional Insights

The Asia-Pacific region leads the global spot welding robots market, holding nearly half of the total market share. The region's dominance is fueled by the presence of major automotive manufacturers, expanding industrial bases, and increasing government support for automation. China remains at the forefront, accounting for the majority of robot installations globally, driven by its aggressive push toward industrial modernization and smart manufacturing. Japan and South Korea are also key contributors, leveraging advanced robotics expertise and integrating AI-driven automation in automotive and electronics manufacturing.

In North America, the market is mature but continues to grow steadily, supported by high labor costs, the shortage of skilled welders, and strong investments in industrial automation. The United States leads the region, particularly in automotive manufacturing, aerospace, and heavy machinery sectors. The trend toward reshoring manufacturing and the integration of flexible robotic systems are expected to further boost demand in the coming years.

Europe maintains a strong foothold due to its established automotive industry and increasing emphasis on energy-efficient, high-quality production. Germany, the UK, France, and Italy are key markets where robotic welding is widely implemented in vehicle assembly, metal fabrication, and industrial machinery manufacturing. The region's focus on sustainability and smart factory integration is expected to accelerate future growth.

Meanwhile, Latin America and the Middle East & Africa are gradually adopting spot welding robots, primarily driven by foreign investment in manufacturing and infrastructure development. While adoption is slower due to limited industrial automation infrastructure and higher costs, these regions present long-term growth potential as governments seek to diversify their economies through industrial expansion.

Market Drivers

Several strong drivers are fueling the expansion of the Spot Welding Robots Market. The most prominent is the rising demand for automation across manufacturing sectors. As industries face increasing production complexity, shorter product lifecycles, and the need for higher precision, automation has become a strategic necessity. Spot welding robots deliver consistent weld quality, faster cycle times, and reduced material wastage, enabling manufacturers to achieve operational excellence and cost optimization.

The automotive industry remains the backbone of this demand. Automakers rely heavily on spot welding robots for assembling vehicle body structures-an operation that demands precision, speed, and repeatability. The growing production of electric vehicles (EVs) further drives this trend, as EV manufacturers require advanced robotic welding systems to handle lighter materials, complex geometries, and high-strength alloys.

Another key driver is the rising cost of manual labor and shortage of skilled welders, which has become a global issue. Manufacturers are increasingly turning to automation to bridge the skills gap, reduce dependency on manual processes, and enhance safety by minimizing human exposure to heat, sparks, and fumes. The push toward Industry 4.0 and smart factory integration is also propelling demand for interconnected robotic systems capable of real-time monitoring, predictive maintenance, and adaptive welding based on AI-driven analytics.

Technological advancements are further accelerating market growth. Integration of machine vision, sensors, and AI algorithms allows robots to detect joint misalignments, adjust welding parameters on the fly, and ensure flawless weld quality. These innovations are enabling more flexible, intelligent, and self-optimizing robotic welding systems suitable for diverse production environments.

Market Restraints

Despite its strong growth prospects, the spot welding robots market faces several challenges. The foremost restraint is the high initial investment associated with purchasing and integrating robotic welding systems. The cost of robots, welding guns, end-effectors, software, and control systems, combined with the expense of line redesign and worker training, can be substantial-especially for small and medium-sized enterprises (SMEs). While the long-term benefits of automation are significant, the upfront capital outlay can limit adoption among cost-sensitive manufacturers.

Another challenge lies in the complex integration process. Spot welding robots must be precisely synchronized with conveyor systems, material-handling robots, and quality-inspection equipment. Achieving seamless integration often requires specialized expertise, extensive calibration, and advanced software capabilities. For manufacturers with legacy production lines, the transition can involve considerable downtime and engineering effort.

The market also faces a shortage of skilled robotics professionals capable of programming, maintaining, and troubleshooting advanced robotic systems. In addition, there are safety and regulatory considerations that require compliance with industrial standards for human-robot collaboration. Lastly, the potential fear of job displacement due to automation remains a social and organizational barrier in certain regions, slowing down adoption despite the clear productivity benefits.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/24562

Market Opportunities

The future of the Spot Welding Robots Market holds tremendous opportunities. One of the most promising avenues lies in the expansion of robotic welding systems among SMEs. As technology becomes more modular, user-friendly, and affordable, small and medium manufacturers can now integrate robotic spot welding solutions without major overhauls. Compact and collaborative robots, which require less floor space and minimal safety barriers, are opening new markets in small-scale metal fabrication and component assembly.

Another opportunity is the integration of artificial intelligence, machine learning, and vision-based technologies. These advancements enable robots to self-adjust welding parameters, identify defects in real-time, and optimize performance based on data analytics. Such intelligent systems will redefine productivity standards by reducing rates and minimizing manual supervision.

Additionally, the electric vehicle (EV) revolution presents a vast new application domain. Spot welding robots are essential in the manufacturing of EV battery packs, frames, and lightweight structures, where precision and repeatability are critical. As global EV production accelerates, so will the demand for robotic spot welding systems tailored to new materials such as aluminum and composites.

The trend toward flexible and reconfigurable manufacturing systems also represents a key opportunity. Manufacturers increasingly seek robotic cells that can handle multiple product types and adapt to frequent design changes. The rise of collaborative welding robots that can share workspace with humans and perform smaller-scale spot welds safely and efficiently will further broaden adoption across industries.

Company Insights

Leading players operating in the Spot Welding Robots Market include:

• ABB Ltd.

• FANUC Corporation

• Yaskawa Electric Corporation

• KUKA AG

• Comau S.p.A.

• Daihen Corporation

• Nachi-Fujikoshi Corp.

• Kawasaki Heavy Industries Ltd.

• Panasonic Corporation

• Midea Group

These companies dominate the global market through their extensive product portfolios, technological innovation, and global service networks. They are actively investing in the development of smarter, more energy-efficient robots equipped with advanced sensors, machine vision, and AI-based control systems to cater to evolving industry demands.

Recent Developments:

In 2025, ABB announced a strategic spin-off of its robotics division to focus more on autonomous manufacturing and next-generation automation technologies, enhancing operational independence and innovation speed.

In the same year, KUKA introduced a new generation of spot welding robots designed with lightweight carbon-fiber arms and integrated sensors for improved precision and reduced energy consumption, signaling the industry's shift toward sustainability and efficiency.

Related Reports:

https://www.persistencemarketresearch.com/market-research/combine-harvester-market.asp

https://www.persistencemarketresearch.com/market-research/fall-protection-equipment-market.asp

https://www.persistencemarketresearch.com/market-research/container-handling-equipment-market.asp

https://www.persistencemarketresearch.com/market-research/noise-barrier-system-market.asp

https://www.persistencemarketresearch.com/market-research/shiplifts-transfer-systems-market.asp

https://www.persistencemarketresearch.com/market-research/electric-overhead-travelling-crane-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Spot Welding Robots Market, Revolutionizing Precision and Productivity in Modern Manufacturing here

News-ID: 4246120 • Views: …

More Releases from Persistence Market Research

Residential Lighting Fixtures Market Set for Robust Growth Through 2032

The global residential lighting fixtures market is poised for strong expansion over the coming decade, underpinned by shifting consumer preferences toward energy efficient, smart, and design centric lighting solutions. According to a comprehensive market analysis by Persistence Market Research, the market was valued at US$ 20.4 billion in 2025 and is projected to reach US$ 32.2 billion by 2032, growing at a CAGR of 5.9 % from 2025 to 2032.

➤…

Active Modified Atmospheric Packaging Market to Reach US$ 37.9 Billion by 2033 - …

The active modified atmospheric packaging market is gaining strong traction as food manufacturers retailers and logistics providers focus on extending product shelf life while maintaining freshness quality and safety. Active modified atmospheric packaging integrates gas flushing scavengers and moisture regulators to actively control the internal atmosphere of a package thereby slowing microbial growth oxidation and spoilage. Unlike passive packaging this advanced technology continuously interacts with the packaged product creating an…

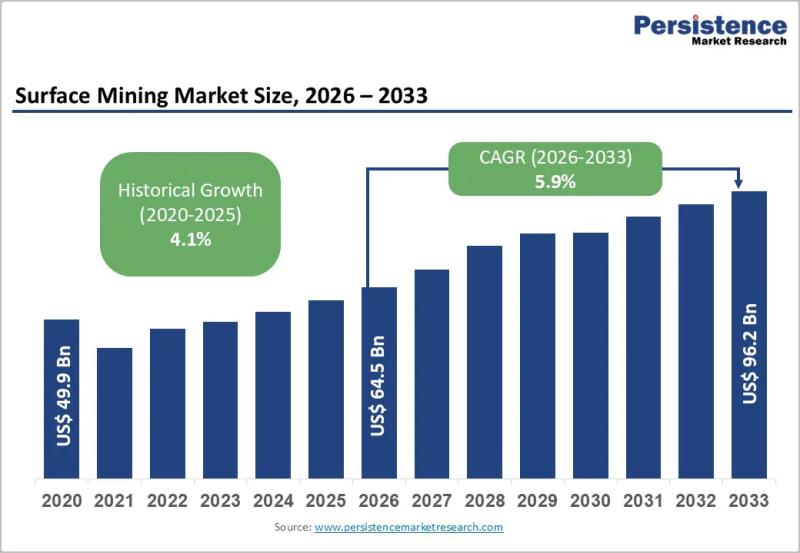

Surface Mining Market Size to Reach US$ 96.2 Billion by 2033 - Persistence Marke …

The surface mining market plays a critical role in the global extraction industry, enabling efficient recovery of minerals, metals, and fossil fuels located near the earth's surface. Surface mining techniques such as open pit mining, strip mining, mountaintop removal, and quarrying are widely used for coal, iron ore, copper, bauxite, and other industrial minerals. Compared to underground mining, surface mining offers higher production rates, lower operational risks, and improved cost…

Algae Ink Market to Reach US$576.6 Million by 2033 - Persistence Market Research

The algae ink market is emerging as a transformative segment within the broader sustainable inks and bio based pigments industry. Algae ink is derived from renewable algae biomass and offers a low carbon alternative to petroleum based inks and synthetic colorants. As environmental concerns intensify and industries face stricter regulations on volatile organic compounds and hazardous chemicals, algae based ink solutions are gaining traction across packaging, textile, publishing, and commercial…

More Releases for Spot

Spot Cooler Market Size, Share and Forecast By Key Players-Spot Coolers, Movinco …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global Spot Cooler market is anticipated to grow at a compound annual growth rate (CAGR) of 7.55% between 2024 and 2031. The market is expected to grow to USD 65.6 Billion by 2024. The valuation is expected to reach USD 109.19 Billion by 2031.

Strong demand from a variety of industries, including commercial, industrial, and residential applications, is propelling…

Blind Spot Detection (BSD) System: Empowering Drivers with Unparalleled Blind Sp …

According to a new report published by Allied Market Research, titled, "Blind Spot Detection (BSD) System Market," The blind spot detection (bsd) system market was valued at $3.9 billion in 2021, and is estimated to reach $13.7 billion by 2031, growing at a CAGR of 13.7% from 2022 to 2031.

𝗥𝗲𝗾𝘂𝗲𝘀𝘁 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐚𝐭: https://www.alliedmarketresearch.com/request-sample/9473

Automotive manufacturers in the region have focused on reducing road fatalities by adopting various safety ensuring programs…

Smart Parking Spot Lock Market is Booming Worldwide | Thats My Spot, Designated …

HTF MI recently Announced Global Smart Parking Spot Lock study with 100+ market data Tables and Figures spread through Pages and easy to understand detailed TOC on "Smart Parking Spot Lock. Global Smart Parking Spot Lock research allows you to get different methods for maximizing your profit. The research study provides estimates for Global Smart Parking Spot Lock Forecast till 2025*. Some of the Leading key Company’s Covered for this…

Remote Control Parking Spot Lock Market Size 2017 Thats My Spot, Designated Park …

Remote Control Parking Spot Lock Market Research Report

A market study ” Global Remote Control Parking Spot Lock Market ” examines the performance of the Remote Control Parking Spot Lock market Size 2017. It encloses an in-depth Research of the Remote Control Parking Spot Lock market state and the competitive landscape globally. This report analyzes the potential of Remote Control Parking Spot Lock market in the present and the future…

Cocoa beans hitting the spot

The USA-based company Seguine Cacao Cocoa & Chocolate Advisors carries out extensive research into studying and assessing cocoa beans and their flavors.

Cocoa beans are his life:

When it comes to evaluating the quality and flavor of cocoa beans and chocolate, Ed Seguine is the leading specialist in the field. Ed Seguine

is the chairman of various international organizations of countries that produce and import cocoa and sits on several committees.…

Brazil is Investment Hot Spot

One of the world’s hottest destinations for investment, Brazil is also creating record numbers of jobs. Government figures point to 2.52 million jobs in 2010 with 3 million expected this year.

Brazil’s investment potential recently led the Daily Mail Investment Extra to describe it as “a hot spot for those seeking big returns”. Brazil is currently the world’s eighth largest economy and one of the fastest growing. Thanks to massive sums…